Aqueous copolyester hot melt adhesive and preparation method thereof

A copolyester, hot-melt technology, used in adhesives and other directions, can solve the problems of slow crystallization rate of hot-melt polyester, environmental pollution of solvent-based polyester, insufficient initial tack strength, etc. Good initial adhesion strength, good adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0023] The preparation of embodiment 1~7 aqueous copolyester hot-melt type adhesive and conventional adhesive

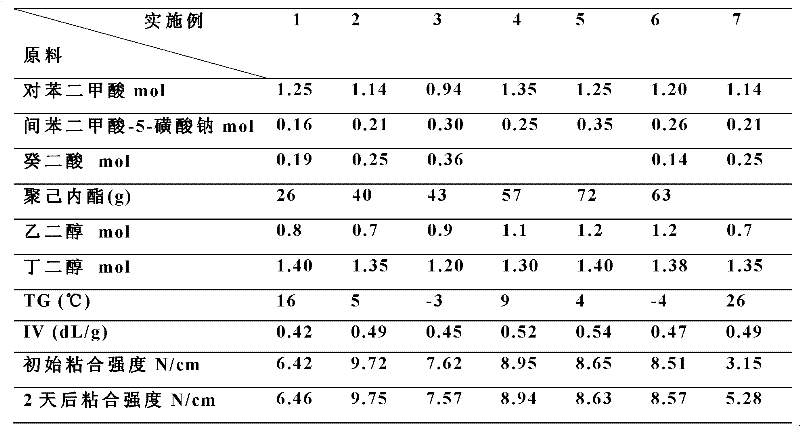

[0024] Table 1 is that embodiment 1~6 is the specific formula that the present invention prepares water-based copolyester hot-melt adhesive, and preparation process is roughly the same, but raw material component has change, and embodiment 7 is a comparative example, wherein does not adopt polyester Polycondensation of caprolactone.

[0025] The formula of the hot-melt adhesive of table 1 embodiment 1~7 and the performance parameter of measurement

[0026]

[0027] Process steps:

Embodiment 1

[0028] Example 1 is prepared in this way: 1.25mol of terephthalic acid, 0.19mol of sebacic acid, 0.16mol of sodium isophthalic acid-5-sulfonate, 0.8mol of ethylene glycol and 1.4mol of butanediol are put into the reaction In the still, and add manganese acetate 0.28g, in the nitrogen atmosphere environment, heat up to 250 ℃ and keep warm to carry out reaction for about 3 hours, when the by-product amount reaches nearly 99% of the theoretical amount, finish the reaction. Cool down to 200°C, add 0.1g of antimony acetate, 0.1g of tetrabutyl titanate, 0.15g of triphenyl phosphate, 0.12g of sodium acetate and 40g of polycaprolactone, continue to raise the temperature and slowly depressurize to 100Pa , the temperature is controlled between 265 ~ 275 ℃, and the polycondensation reaction is carried out. Sampling analysis, when the viscosity of the polymer reaches the expected value, the stirring is stopped, the vacuum is eliminated, and the product is discharged to obtain a water-solu...

Embodiment 8

[0032] Embodiment 8 Preparation of water-based copolyester hot-melt adhesive and conventional adhesive

[0033] Put 1.30mol of dimethyl terephthalate, 0.11mol of sebacic acid, 0.19mol of sodium isophthalic acid-5-sulfonate, 0.85mol of ethylene glycol and 1.5mol of butanediol into the reaction kettle, and add Zinc acetate 0.2g, in nitrogen atmosphere environment, heat up to 210 ℃ and keep it warm for reaction for about 1 hour, then heat up to 230 and react for about 2 hours, when the amount of by-products reaches 99% of the theoretical amount, the reaction ends. Cool down to 200°C, add 0.09g of antimony acetate, 0.12g of tetrabutyl titanate, 0.17g of triphenyl phosphate, 0.15g of sodium acetate and 65g of polycaprolactone, continue to raise the temperature and slowly reduce the pressure to 100Pa , the temperature is controlled between 270 and 275°C for polycondensation reaction. Sampling analysis, when the viscosity of the polymer reaches the expected value, the stirring is st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com