Application of sludge biochar in adsorption to organic pollutants or ammonia nitrogen in sewage and preparation of sludge biochar

A technology of organic pollutants and biochar, applied in the direction of adsorption of water/sewage treatment, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc., can solve the problems of low practical value, high cost, low ammonia nitrogen removal efficiency, etc. problems, to achieve the effect of increasing added value, excellent adsorption capacity, and rich surface functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

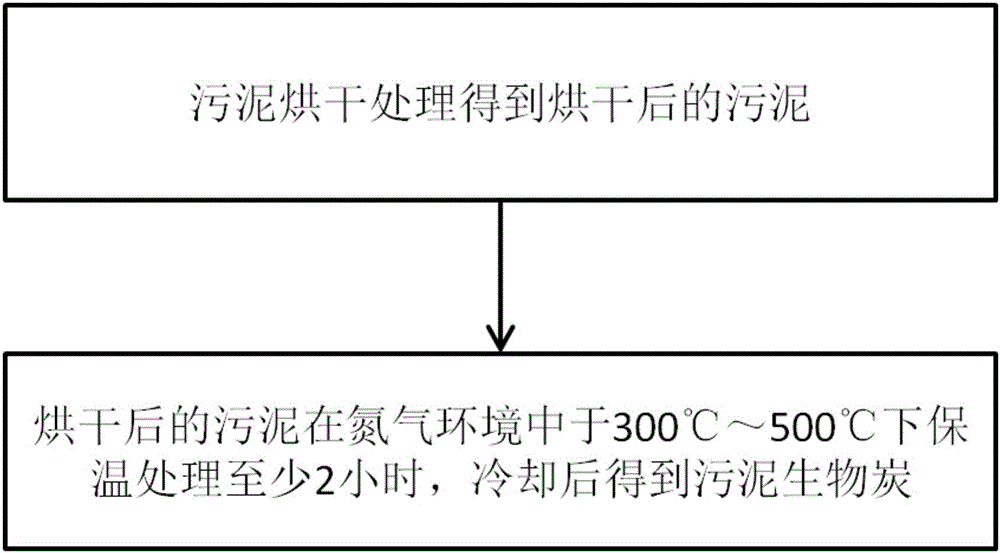

[0025] The preparation steps of sludge biochar among the present invention are as follows:

[0026] (1) drying municipal sludge with a moisture content of about 80% at 105°C for 24 hours;

[0027] (2) Put the dried sludge into the muffle furnace which was pre-evacuated and then filled with nitrogen to atmospheric pressure and kept the muffle furnace closed, and heated to 300°C, 350°C, 400°C, 450°C at a rate of 10°C / min. ℃, 500℃, and keep the temperature for 2 hours, cool naturally to 25℃ and take it out from the furnace. Exhaust gas absorption device;

[0028] (3) Grind the taken out biochar through a 200-mesh sieve (that is, the particle size of the sludge biochar should be finer than 200 mesh), wash it with distilled water three times and dry it at 105°C for later use. The specific surface area of the fired biochar is: 46.98m 2 / g, 54.73m 2 / g, 75.34m 2 / g, 77.42m 2 / g, 80.25m 2 / g (corresponding to the pyrolysis temperatures of 300°C, 350°C, 400°C, 450°C, and 500°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com