Patents

Literature

60results about How to "High enzyme activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recombinant Bacillus subtilis for producing chondroitinase and application thereof

ActiveCN106148265AHigh enzyme activityGreat application valueBacteriaMicroorganism based processesSignal peptideBioengineerings

The invention discloses recombinant Bacillus subtilis for producing chondroitinase and application thereof and belongs to the technical field of bioengineering. Chondroitinase of common Proteus origin is heterologously expressed in Bacillus subtilis, signal peptide amyX is selected, 3 strong constitutive promoters and strong RBS (ribosome binding site) of pP43NMK vector itself are utilized, histidine tags are added to facilitate subsequent purification, and expressive enzyme activity of chondroitinase in Bacillus subtilis is improved. Certain basis is laid for efficiently producing chondroitinase from food-grade microbes, and the recombinant Bacillus subtilis is suitable for industrial application.

Owner:JIANGNAN UNIV

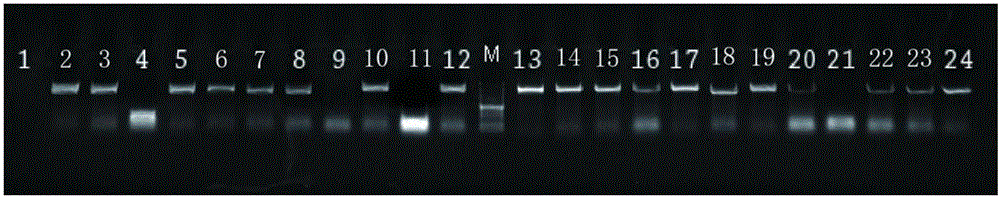

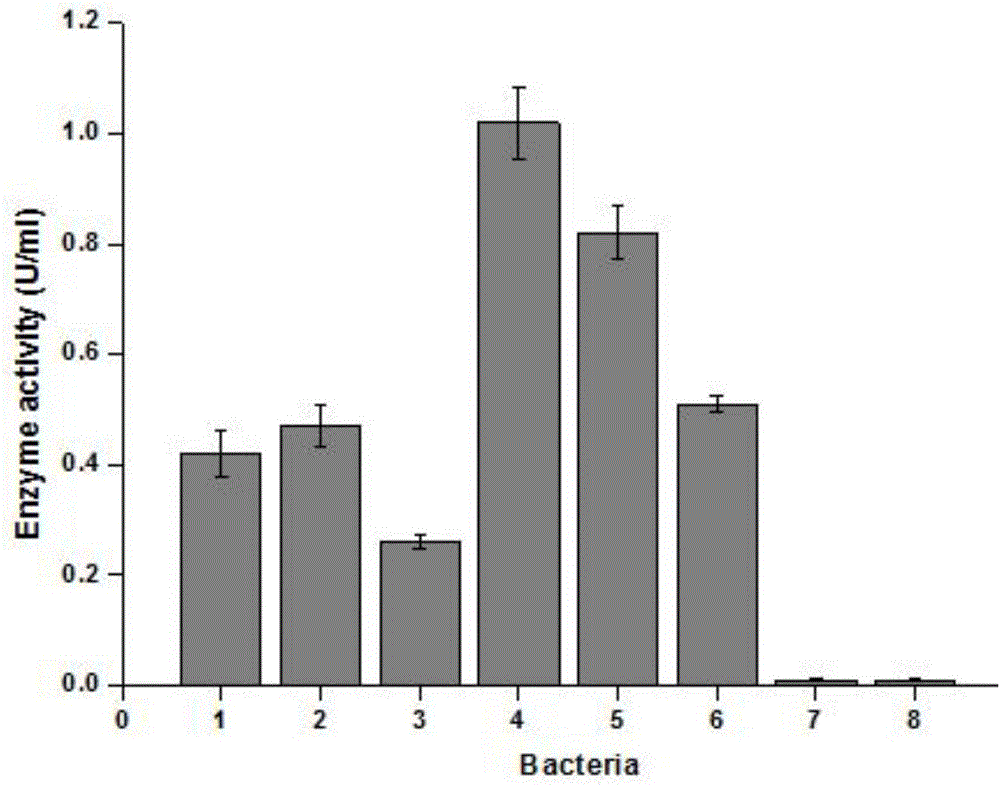

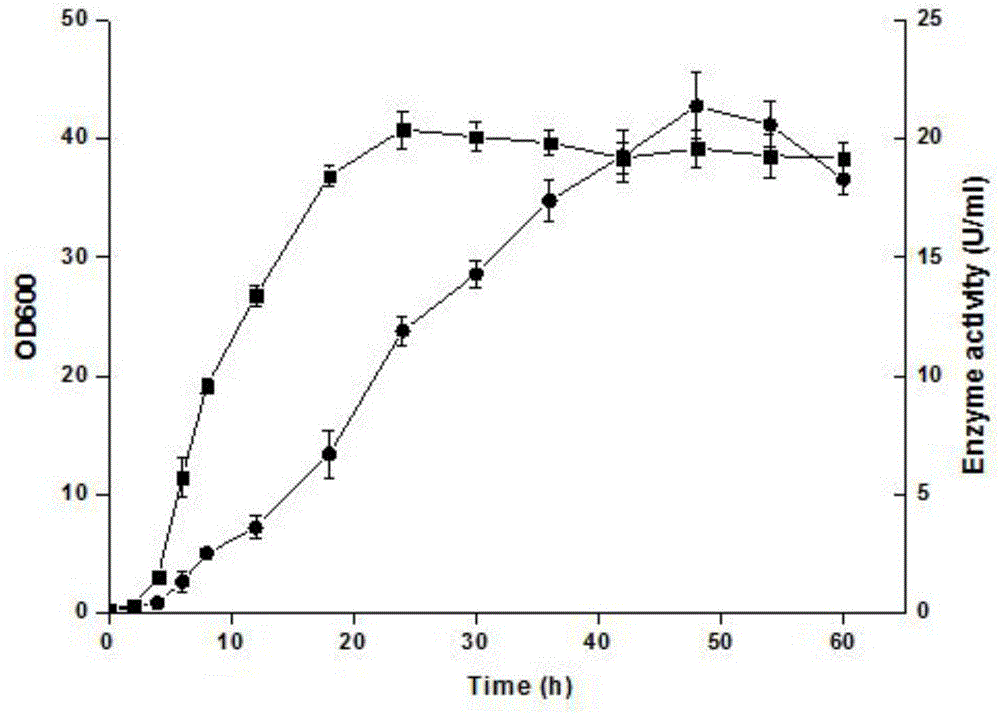

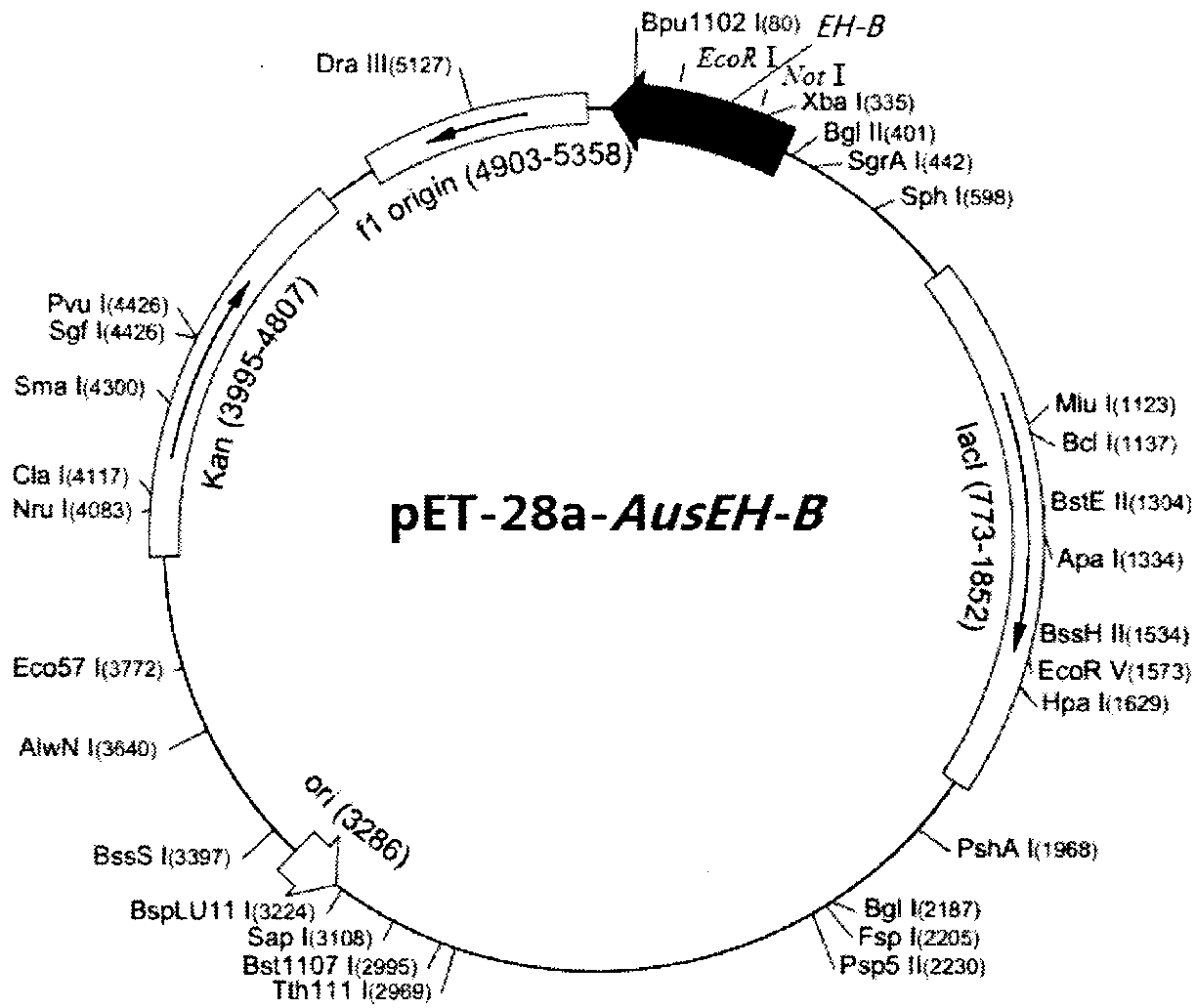

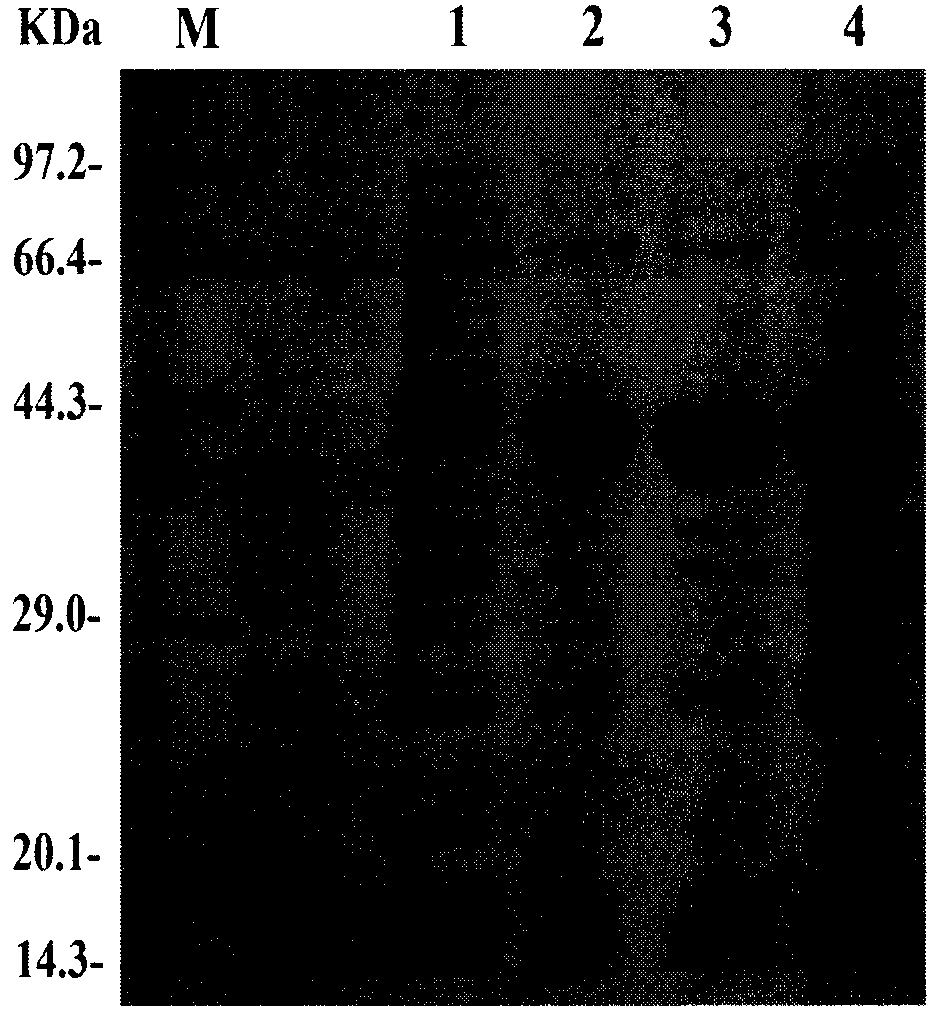

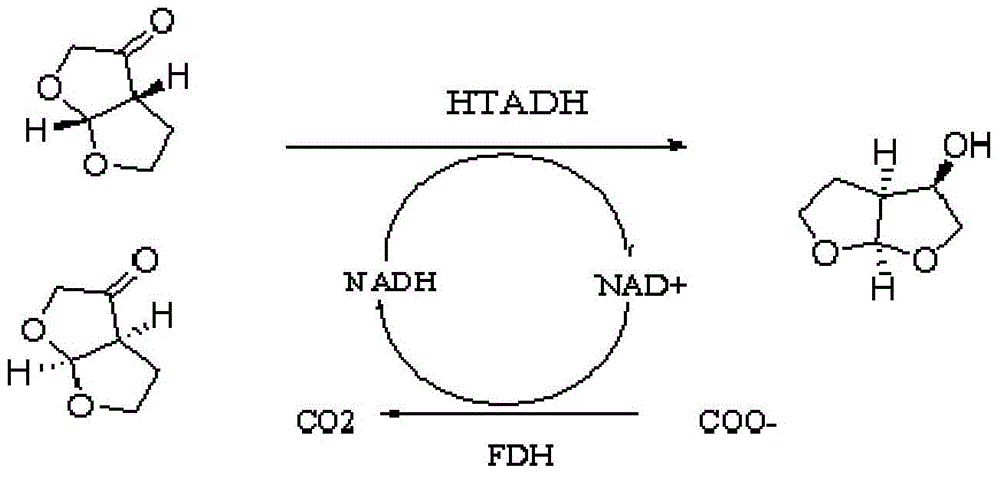

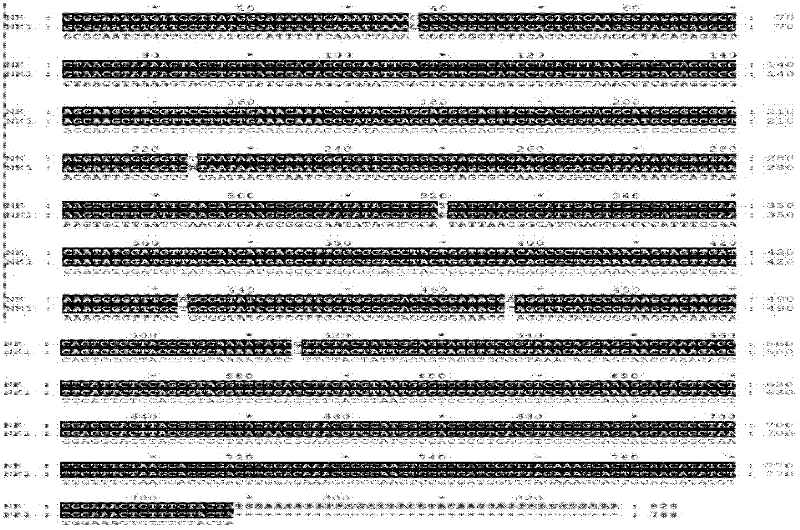

Pronucleus expression of epoxide hydrolase gene (EH-B) and preparation of chiral epichlorohydrin

InactiveCN102994470AHigh enzyme activityHigh enantioselectivityHydrolasesMicroorganism based processesEpoxide hydrolaseAspergillus usamii

The invention provides a clone and a pronucleus expression method of a novel B class epoxide hydrolase gene mature peptide cDNA sequence from Aspergillus usamii E001. The nucleotide sequence of the novel B class epoxide hydrolase gene mature peptide cDNA sequence is SEQ ID NO:1, the corresponding amino acid sequence is SEQ ID NO:2, and the corresponding gene is named Aus EH-B. According to the invention, good stereoselectivity is achieved for (R)-epichlorohydrin through chiral gas chromatography analysis rEH, and a produced (S)-epichlorohydrin antipode excess value achieves 99%. The pronucleus expression method provided by the invention lays the foundation for the industrialized production of epoxide hydrolase and provides the basis for preparing chiral epichlorohydrin by researching an EH enzyme kinetic resolution method for biological catalysis technology industrialization.

Owner:JIANGNAN UNIV

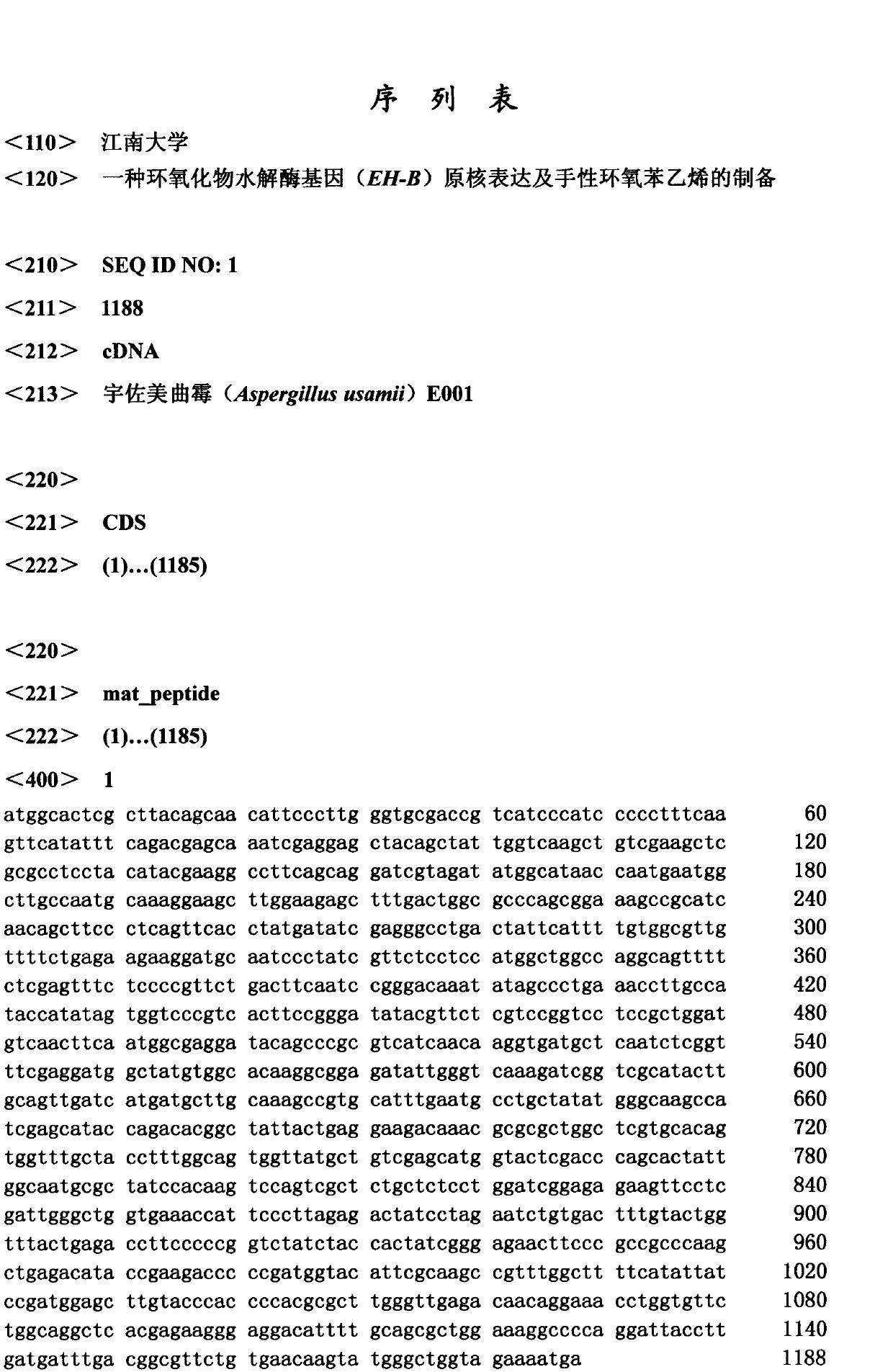

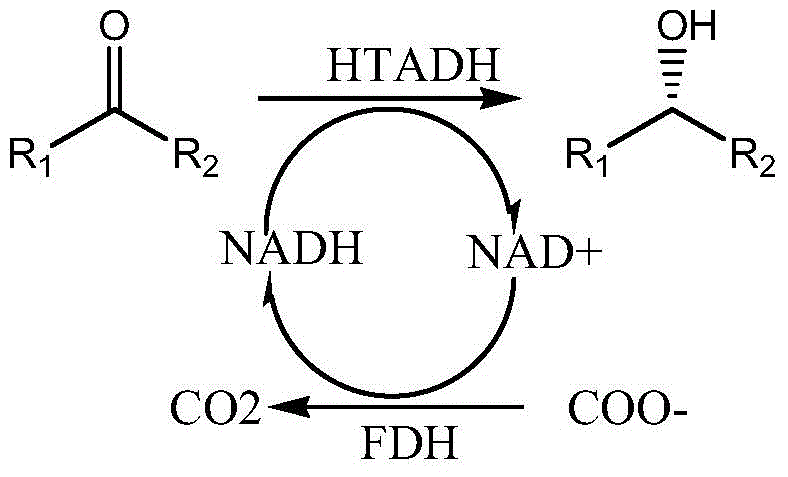

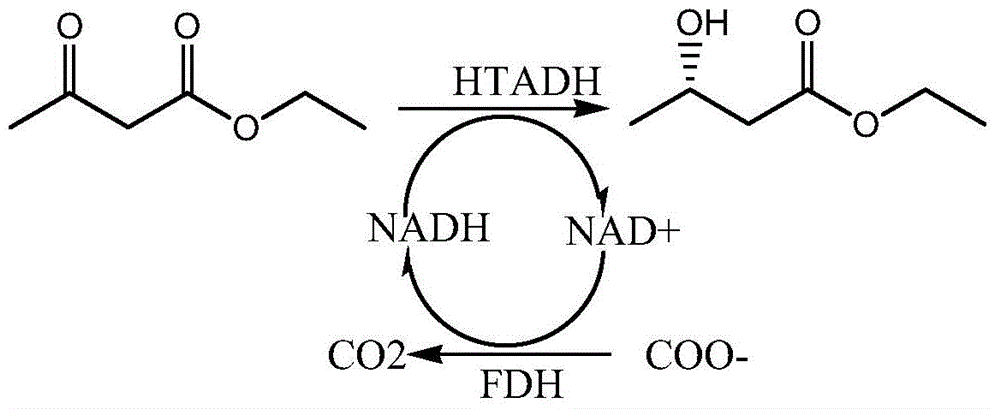

Alcohol dehydrogenase mutant and application thereof

ActiveCN104531628AHigh stereoselectivityHigh enzyme activityBacteriaOxidoreductasesMutantAlcohol dehydrogenase

The invention discloses an alcohol dehydrogenase mutant and application thereof. The amino acid sequence of the alcohol dehydrogenase mutant is an amino acid sequence obtained by mutating an amino acid sequence as shown in SEQ ID NO:9; the mutated amino acid sequence has at least one mutation site selected from the following mutation sites: the 40th position, the 87th position, the 194th position and the 331st position; T on the 40th position is mutated into S, A or C; W on the 87th position is mutated into F, Y or H; V on the 194th position is mutated into I, L or E; R on the 331st position is mutated into A, K or M; or the amino acid sequence of the alcohol dehydrogenase mutant has the mutation sites in the mutated amino acid sequence, and the alcohol dehydrogenase mutant contains more than 90% of amino acid sequences which are homologous with the mutated amino acid sequence. The stereoselectivity and enzyme activity of the alcohol dehydrogenase mutant which is provided with the at least one mutation site or retains the mutation site and contains more than 90% of amino acid sequences which are homologous with the mutated amino acid sequence are greatly improved.

Owner:ASYMCHEM LAB TIANJIN +5

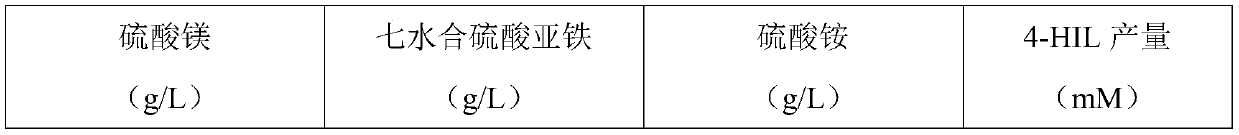

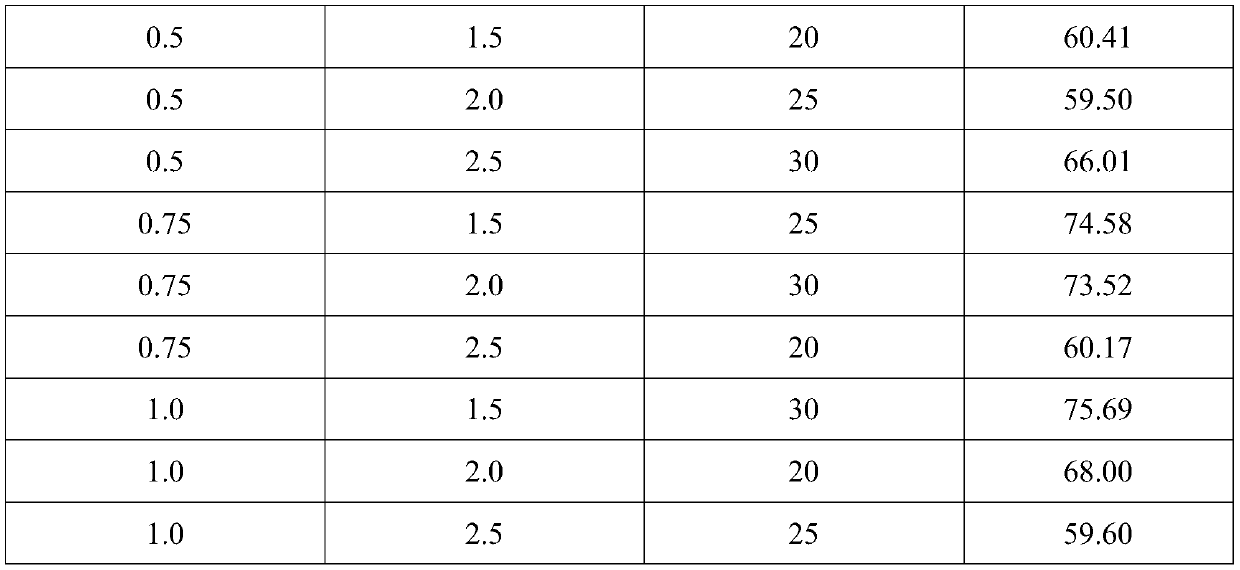

Genetic engineering bacterium for producing 4-hydroxyisoleucine and application thereof

ActiveCN109929790AHigh enzyme activityIncrease enzyme activityBacteriaMicroorganism based processesGenetic engineeringIsoleucine

The invention discloses a genetic engineering bacterium for producing 4-hydroxyisoleucine and application thereof, and belongs to the field of genetic engineering. Two isoleucine dioxygenase encodinggenes Btido and Bwido in different species are co-expressed in an L-isoleucine producing bacterium to enhance the enzymatic activity of isoleucine dioxygenase and promote the L-isoleucine accumulatedby the bacterium to have faster hydroxylation reaction to produce more 4-hydroxyisoleucine. The yield of the 4-HIL is increased to 91.56mM, and the conversion rate of the L-isoleucine to the 4-HIL is86%. By means of fermentation medium optimization, the yield of 4-HIL of the genetic engineering bacterium is increased to 111.11 mM at the shake flask level, and the conversion rate of the L-isoleucine to the 4-HIL reaches 98%. The bacterium proves the feasibility and the advantages of co-expression of double genes, and lays a good foundation for industrial application.

Owner:JIANGNAN UNIV

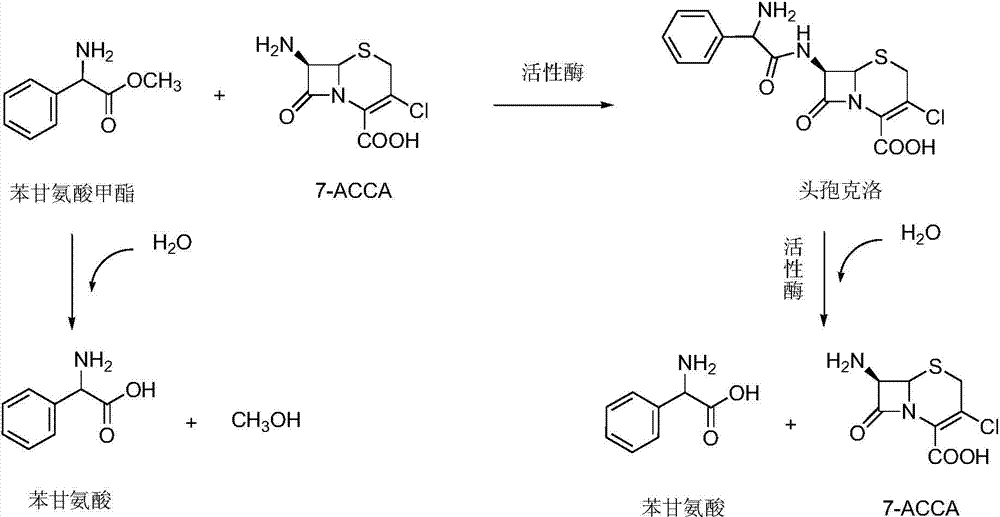

Penicillin G acylation enzyme mutant, and application thereof in synthesis of cephalosporin antibiotics

The invention discloses a penicillin G acylation enzyme mutant, and application thereof in synthesis of cephalosporin antibiotics. An amino acid sequence of the penicillin G acylation enzyme mutant is shown in SEQ ID NO.1; a nucleotide sequence of an encoding gene is shown in SEQ ID NO.2. The invention also provides application of the penicillin G acylation enzyme mutant in synthesis of cefaclor. The invention provides a novel penicillin acylation enzyme mutant. Compared with the wild penicillin acylation enzyme mutant, the penicillin G acylation enzyme mutant has higher activity in synthesis of cephalosporin antibiotics, such as cefprozil, cefaclor or cefadroxil; especially when the penicillin G acylation enzyme mutant is used for catalyzing 7-ACCA and phenylglycine methyl ester to synthesize the cefaclor, the vitality is improved to 29.8U / mg from 1.2U / mg in the past, the synthesis and hydrolysis activity is almost consistent with that of the wild penicillin acylation enzyme mutant, the synthesis and hydrolysis ratio can be up to 1.7, and the yield of the cefaclor can be up to 71.5%.

Owner:ZHEJIANG APELOA TOSPO PHARMA +1

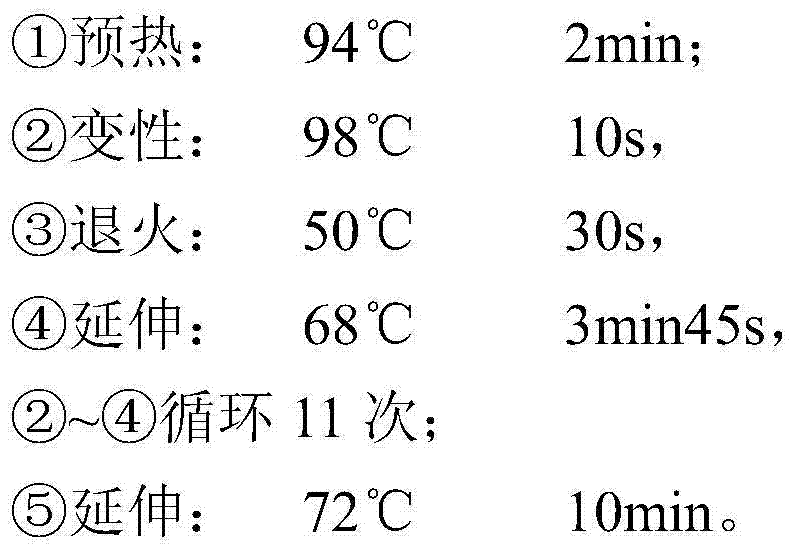

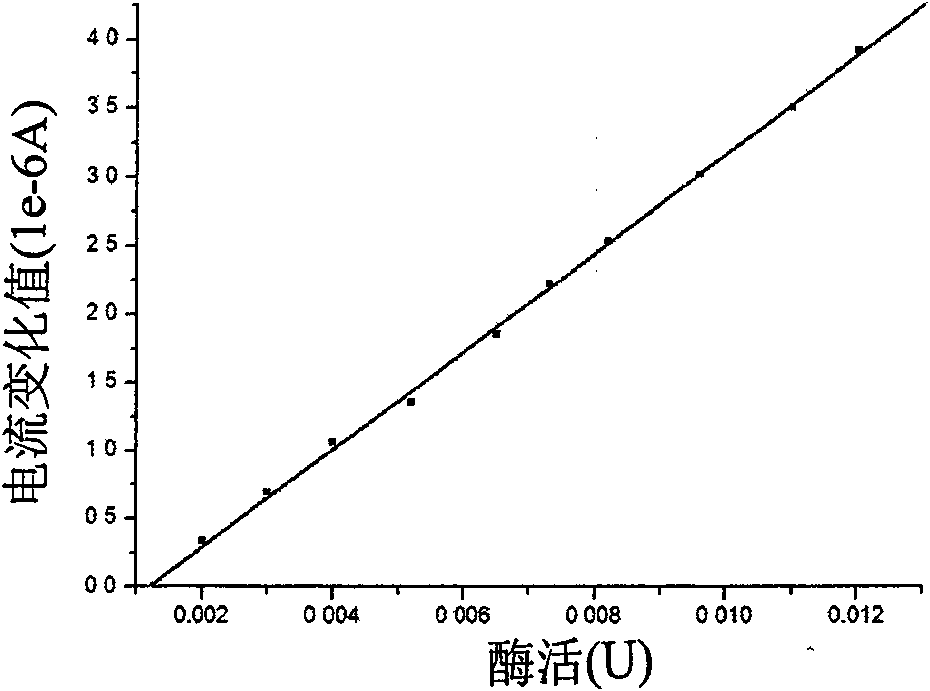

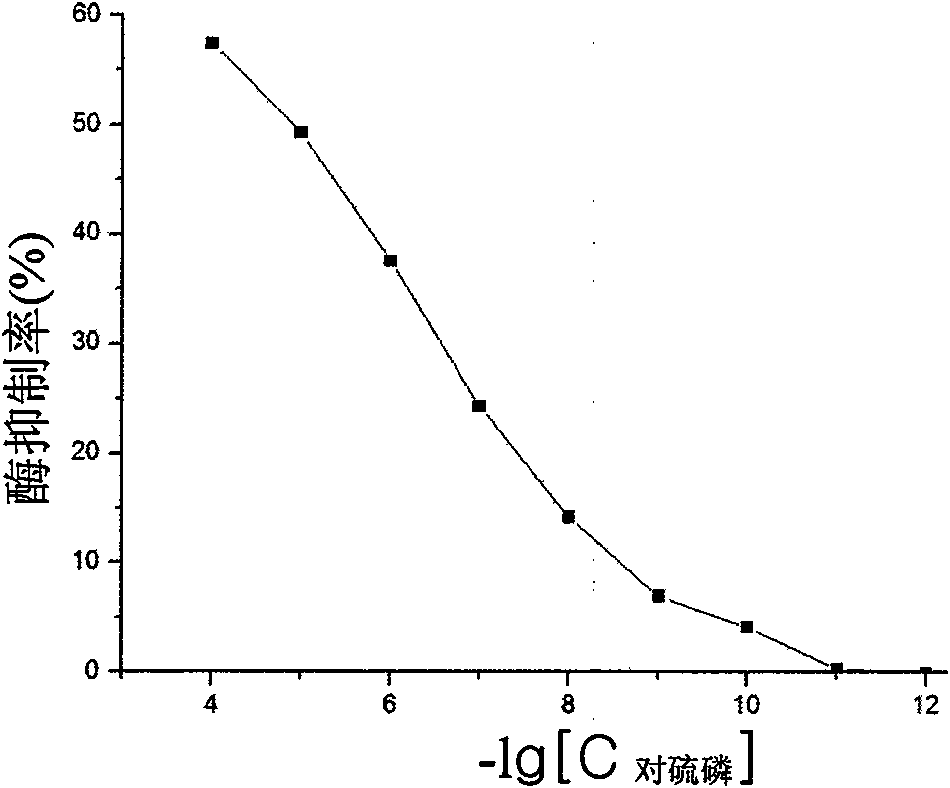

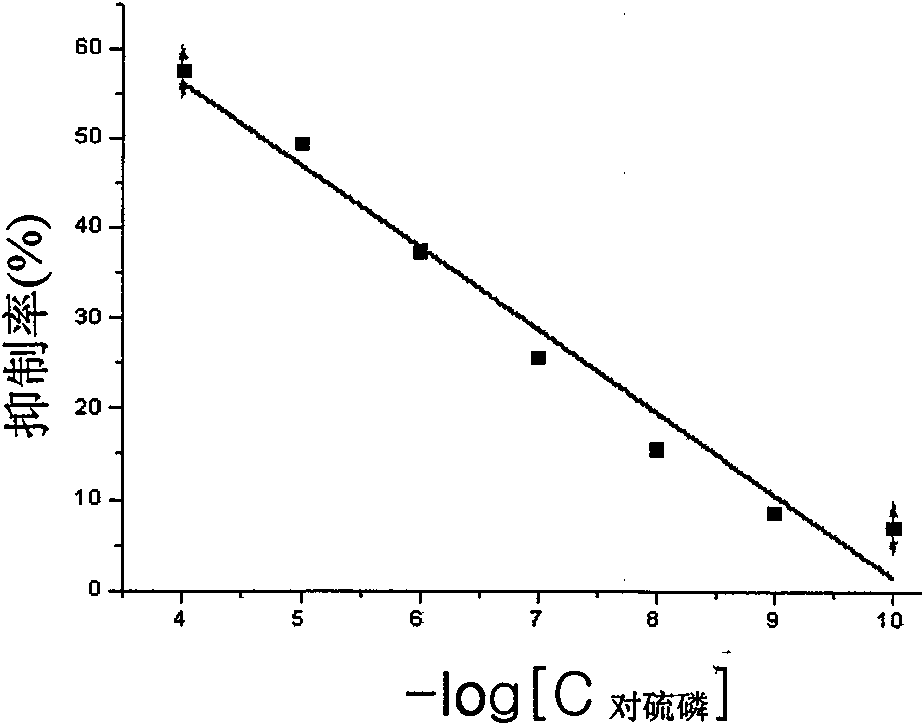

Preparation of immobilization acetylcholinesterase electrochemistry biosensor

InactiveCN101551356AHigh enzyme activityRapid and stable detectionMaterial analysis by electric/magnetic meansCarbon nanotubeAcetylcholine breakdown

The invention relates to a method for preparing an electrochemistry biosensor, in particular an immobilization acetylcholinesterase method and a method for preparing current type biosensor. Specifically, electrodeposition technology is used to deposit a carbon nano tube with negative charge on the surface of glassy carbon electrode; subsequently, layer-by-layer electrostatic self-assembly process is conducted in polydiene propyl dimethyl ammonium chloride solution and carbon nano tube dispersion liquid to obtain a modified electrode with high self-assembly efficiency and stable modified layer. And then, layer-by-layer self-assembly is conducted again in the polydiene propyl dimethyl ammonium chloride solution and PBS of choline esterase to obtain an immobilization acetylcholinesterase current type biosensor with high stability. The method can quickly and stably detect the concentration of parathion in remains of pesticide under normal temperature.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

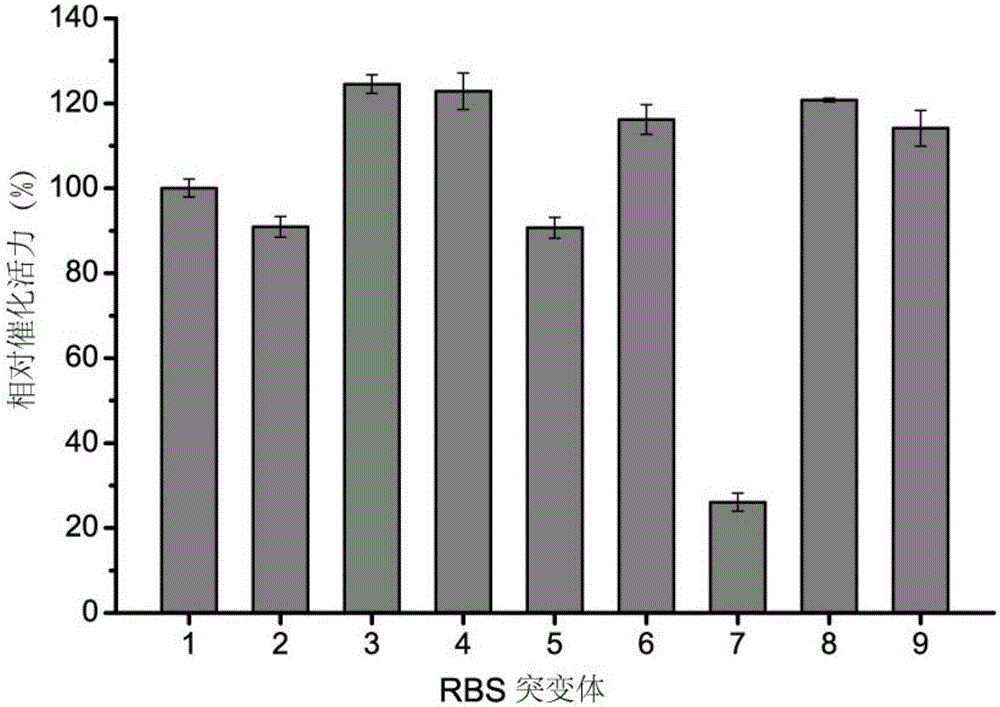

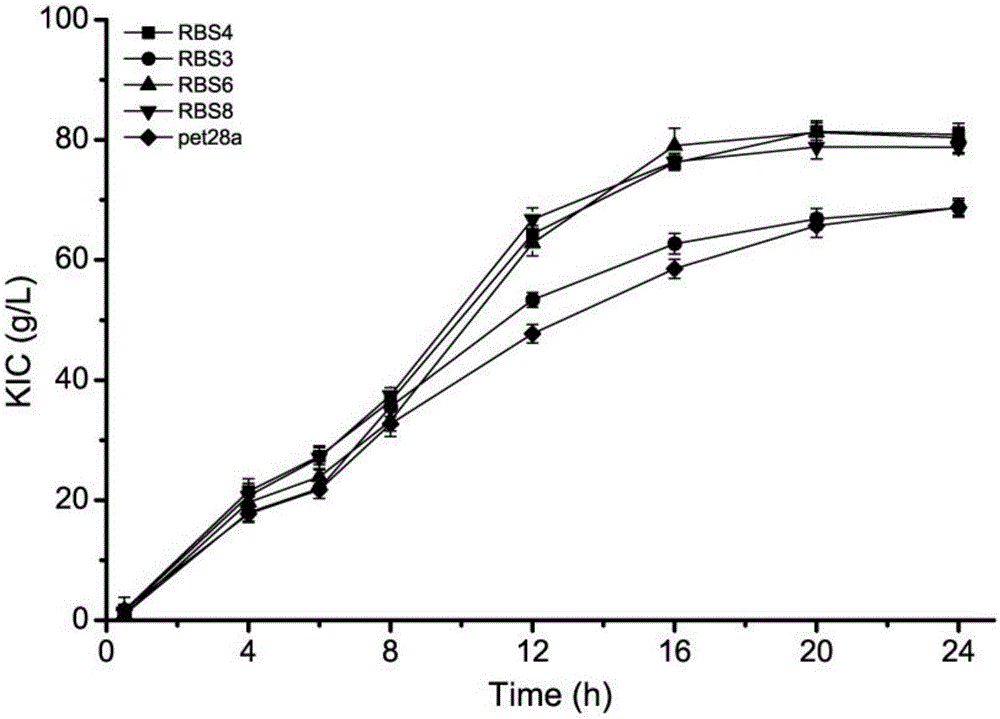

Method for improving alpha-ketoisocaproate yield through RBS optimization

ActiveCN105087457AImprove translation efficiencyHigh enzyme activityBacteriaMicroorganism based processesGenetic engineeringAlpha-ketoisocaproate

The invention discloses a method for improving alpha-ketoisocaproate yield through RBS optimization, and belongs to the field of genetic engineering. By virtue of a genetic engineering bacterium which is subject to RBS optimization, alpha-ketoisocaproate is produced through full-cell catalysis by taking leucine as a substrate. The method disclosed by the invention has the advantages of low production cost, mild production condition, less impurities in a transformation system, simple process step, safe production operation and the like. The alpha-ketoisocaproate produced by the method disclosed by the invention is high in yield, and each liter of transformation liquid contains 81.41g of alpha-ketoisocaproate; and the transformation rate of L-leucine reaches 88.66%.

Owner:JIANGNAN UNIV

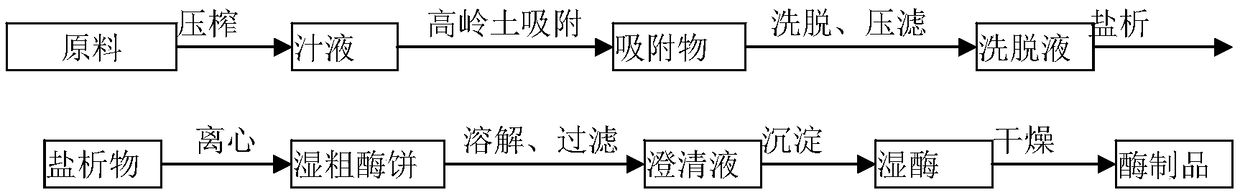

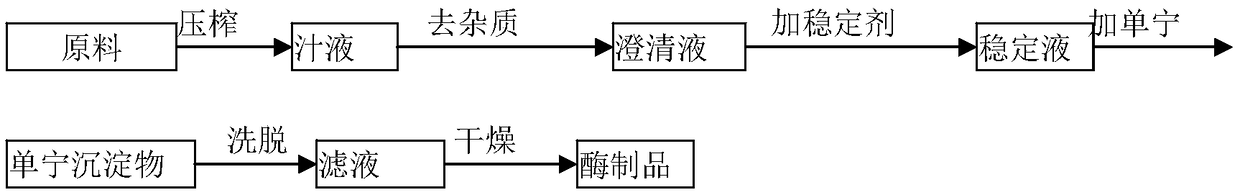

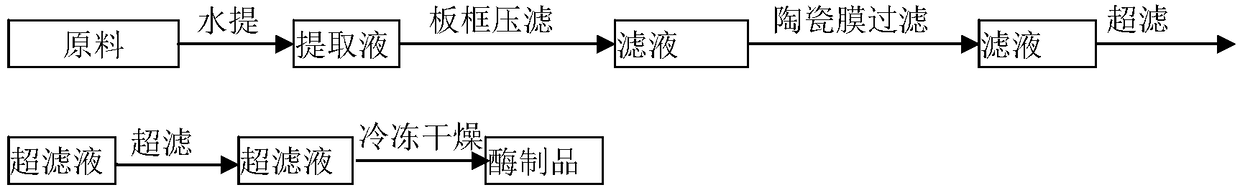

Plant proteinase extraction method and obtained plant proteinase

The invention relates to a plant proteinase extraction method and obtained plant proteinase. The method comprises the following steps: mixing slurry or a crushed material of plants with water in a solid-liquid ratio of 1:(5-20), then carrying out water extraction, and collecting an extracting solution; filtering the obtained extracting solution by virtue of a plate-and-frame filter press and a ceramic membrane sequentially, wherein the pore size of filter cloth of the plate-and-frame filter press is 100-150 meshes, and the pore size of the ceramic membrane is 50-200nm; carrying out primary ultrafiltration treatment on a filtrate by using an ultrafiltration membrane with the molecular weight cutoff of 30-100KDa, collecting the filtrate, carrying out secondary ultrafiltration treatment on the filtrate by using an ultrafiltration membrane with the molecular weight cutoff of 5-15KDa, and collecting trapped fluid; and concentrating the trapped fluid to obtain a concentrated solution, and carrying out freeze drying on the concentrated solution, so that the plant proteinase is obtained. The method provided by the invention has the advantages of simple technology, no pollution to the environment, the feasibility of large-scale industrial production and high proteinase activity and purity. The plant proteinase has the advantages of good activity, high purity and no solvent residue and meets usage requirements of the food, daily chemical and medicine industries.

Owner:XIAN HERB REFINE BIOLOGIC PRODS

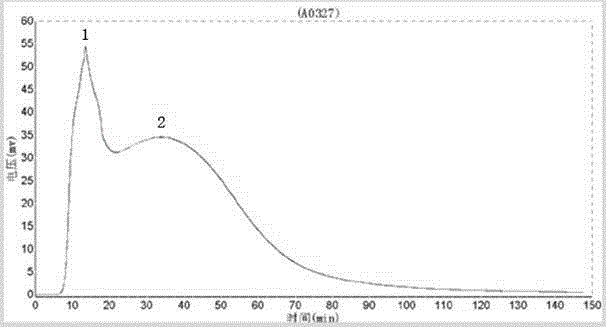

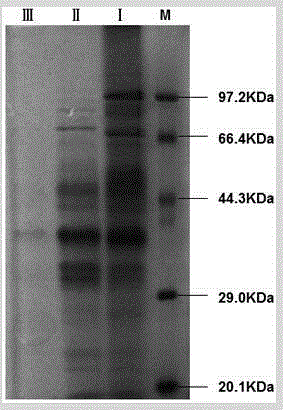

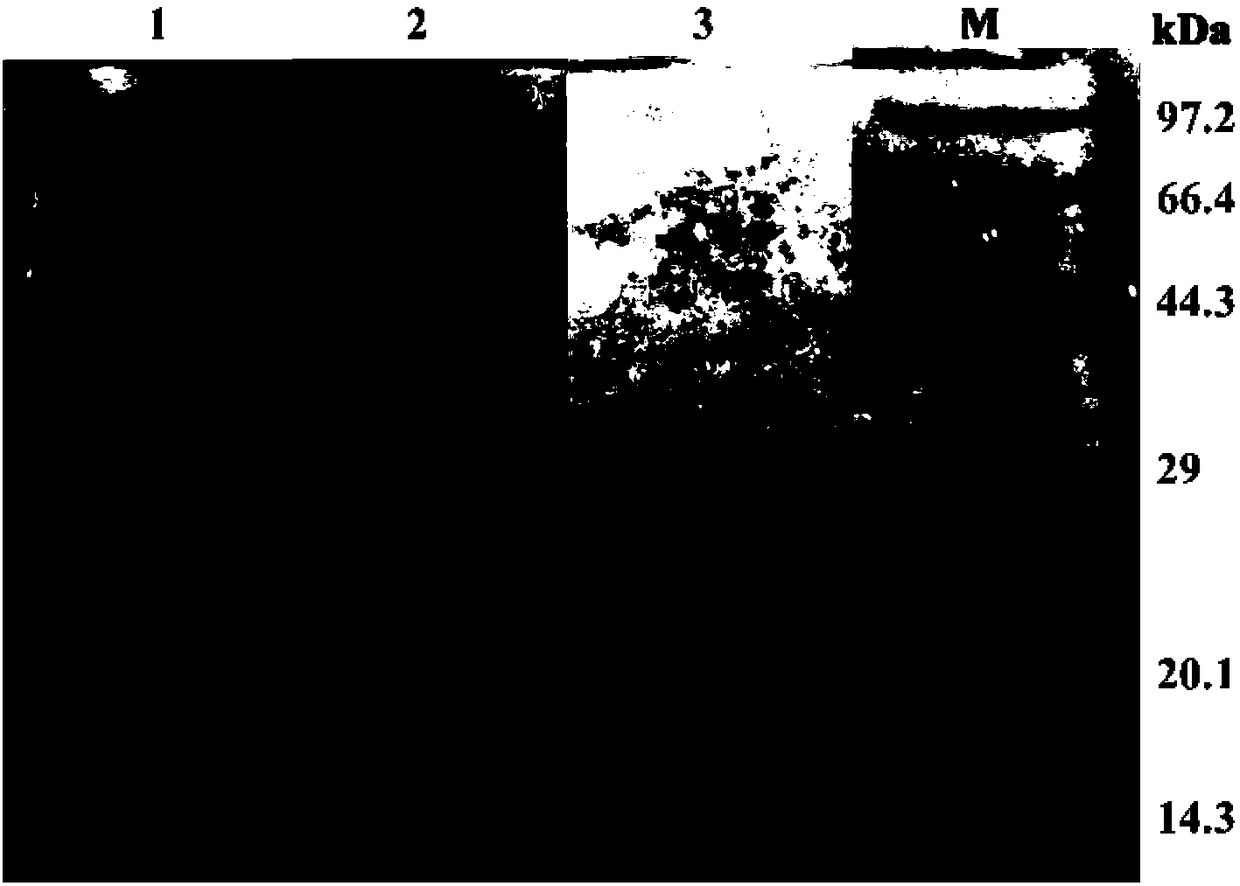

Method for separating and purifying xylanase from waste flammulina velutiper cultivation material

The invention provides a method for separating and purifying xylanase from waste flammulina velutiper cultivation materials. According to the method, digestion conditions of xylanase left in the waste flammulina velutiper cultivation materials are optimized, and methods such as ammonium sulfate precipitation, dialysis, SephadexG-100 sephadex chromatography and DEAEC-52 ion-exchange chromatography are adopted to separate and purify cellulose, and the purity of protein achieves electrophoresis purity by virtue of SDS-PAGE identification. The xylanase is extracted from the waste flammulina velutiper cultivation materials and is effectively separated and purified, the structure and the function of xylanase can be deeply studied, and the scientific reference is provided for production and application of xylanase.

Owner:FUJIAN AGRI & FORESTRY UNIV

Beta-glucanase containing special enzyme for growing pigs and preparation method thereof

ActiveCN103805582AHigh enzyme activityWide pH rangeClimate change adaptationAnimal feeding stuffPhases of clinical researchAlpha-amylase

The invention relates to a beta-glucanase containing special enzyme for growing pigs and a preparation method thereof, belonging to the technical field of feed enzyme preparations. The special enzyme for growing pigs is prepared from the following enzyme preparations in parts by weight: 0.5-2 parts of Chinese herbal medicine powder, 80-100 parts of xylanase, 20-40 parts of protease, 10-20 parts of pectinase, 10-15 parts of cellulase, 15-25 parts of beta-glucanase and 10-15 parts of medium-temperature alpha-amylase, wherein the beta-glucanase is produced from bacillus licheniformis beta-10-25, has the collection number of CCTCC No: M2013538, and is prepared by a preparation method which comprises the following steps: carrying out inclined-face strain activation and culture, so as to obtain a liquid seed; at a fermentation stage, adopting a low-temperature culture medium supplementing and batched inoculating combined method; filtrating, concentrating, fine-filtrating and drying fermentation liquor, thereby obtaining beta-glucanase with good thermal stability. According to the compound enzyme, the conversion ratio of feed can be increased, and the cost of the feed can be reduced.

Owner:HUNAN HONGYING BIOTECHNOLOGY CO LTD

Preparation method of compound enzymes and probiotics for forage by biotransformation of broccoli rhizome and soybean cake

InactiveCN103315131AStrong enzyme production capacityHigh enzyme activityAnimal feeding stuffDrug biotransformationFermented tea

The invention discloses a preparation method of compound enzymes and probiotics for forage by biotransformation of broccoli rhizome and soybean cake, including the steps of fully mixing Pu'er fermented tea, mushroom stick, agrocybe cylindracea stick, first broccoli rhizome, first soybean cake, first wheat bran, first apple slag and first water after pile fermentation and obtaining a starter after habituated culture; and fully mixing the starter, second broccoli rhizome, second soybean cake, second wheat bran, second apple slag and second water and obtaining a compound enzyme and probiotics for forage after fermentation. In the invention, safe floras at food grade with stable microbiology are used for the fermentation of broccoli rhizome and soybean cake in order to prepare compound enzymes and probiotics for forage that has every good performance index, and the biotransformation of broccoli rhizome and soybean cake has low cost and high efficiency. At the same time, in the invention, microbes are easy to grow; the enzyme activity is high; the fermentation is extensive; and no strict aseptic condition is needed, therefore the invention method is suitable for industrial mass production.

Owner:ZHEJIANG UNIV

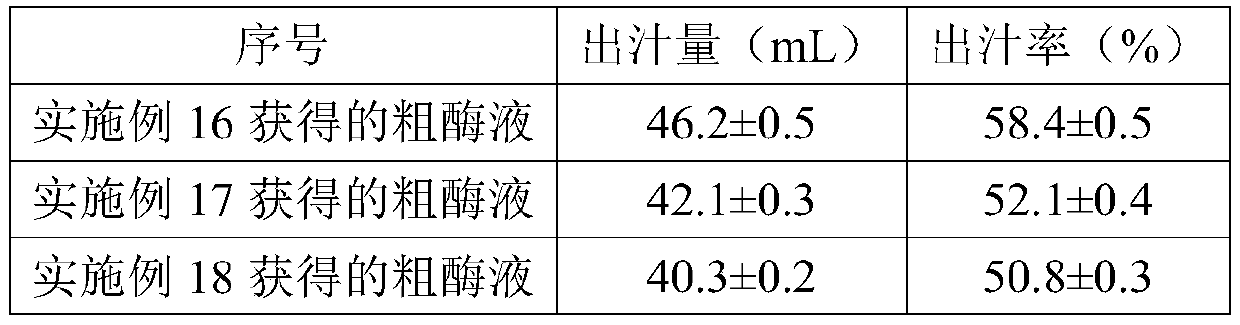

Method for preparing beta-mannanase by using natural Bacillus subtilis

ActiveCN102154247AIncrease the amount of fermented enzymesHigh enzyme activityMicroorganism based processesEnzymesChemistryBeta-Mannanase

The invention provides a method for preparing beta-mannanase by using natural Bacillus subtilis, which comprises: culturing Bacillus subtilis HSO121 by using culture medium containing refined rivier giantarum rhizome powder and a composite nitrogen source, centrifuging the obtained culture liquid to remove thallus cells and thus obtaining coarse beta-mannanase liquid, wherein the mass concentration of refined rivier giantarum rhizome powder in the culture medium is 2.5 to 5.0 percent; and the composite nitrogen source comprises KNO3 at a concentration of 80 to 140mmol / L and peptone at a concentration of 0.1 to 1 weight percent. In the invention, the beta-mannanase is prepared by optimizing the formula of the culture medium and by using the natural Bacillus subtilis HSO121, so the beta-mannanase yield of the fermentation of the Bacillus subtilis HSO121 is improved and a good technical effect is produced.

Owner:DAQING HUALI ENERGY BIOLOGICAL TECH

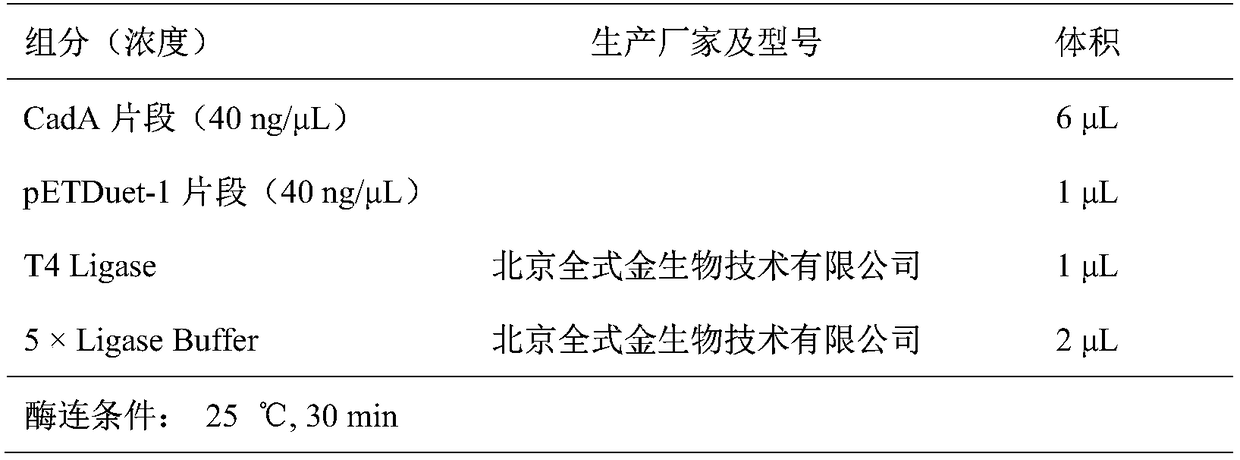

Lysine decarboxylase mutant, encoding gene and expression thereof and application

ActiveCN108795916AHigh enzyme activityEnhanced alkali resistance and catalytic performanceBacteriaMicroorganism based processesMutantLysine decarboxylase

The invention discloses a lysine decarboxylase mutant. The lysine decarboxylase mutant is obtained by carrying out site-directed mutation on lysine decarboxylase with an amino acid sequence shown as SEQ ID No: 2 and is any one of (1) and (2): (1) valine at a 12th site of lysine decarboxylase with the amino acid sequence shown as SEQ ID No: 2 is mutated into cysteine and aspartic acid at a 41st site is mutated into the cysteine to obtain the lysine decarboxylase mutant V12C / D41C; (2) leucine at a 89th site of lysine decarboxylase with the amino acid sequence shown as SEQ ID No: 2 is mutated into the cysteine and leucine at a 442nd site is mutated into the cysteine to obtain the lysine decarboxylase mutant L89C / L442C. According to the lysine decarboxylase mutant provided by the invention, the alkali-resisting and catalytic performance is greatly improved and the lysine decarboxylase mutant is more suitable for industrialized production requirements and meets the requirements of social production.

Owner:NANJING UNIV OF TECH

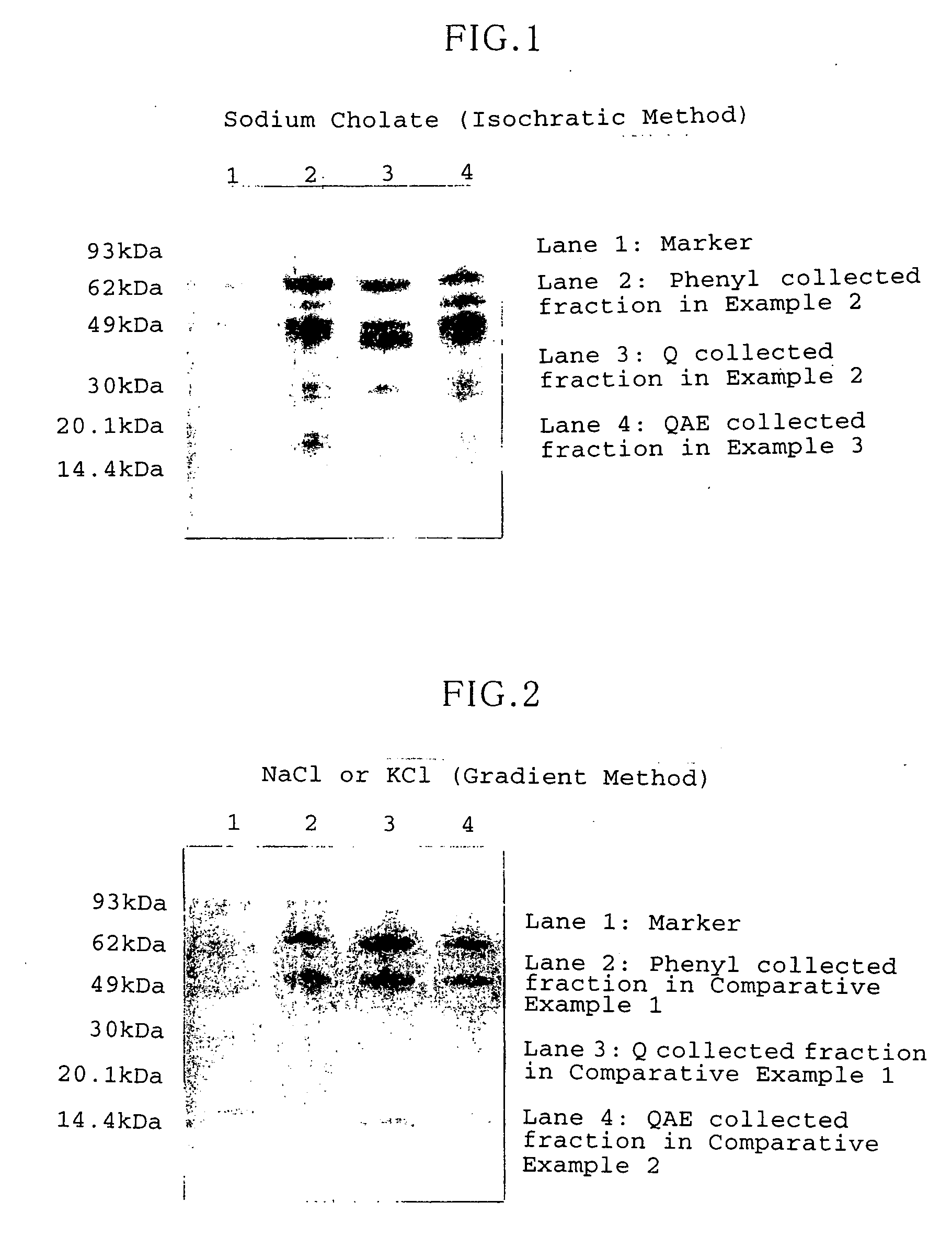

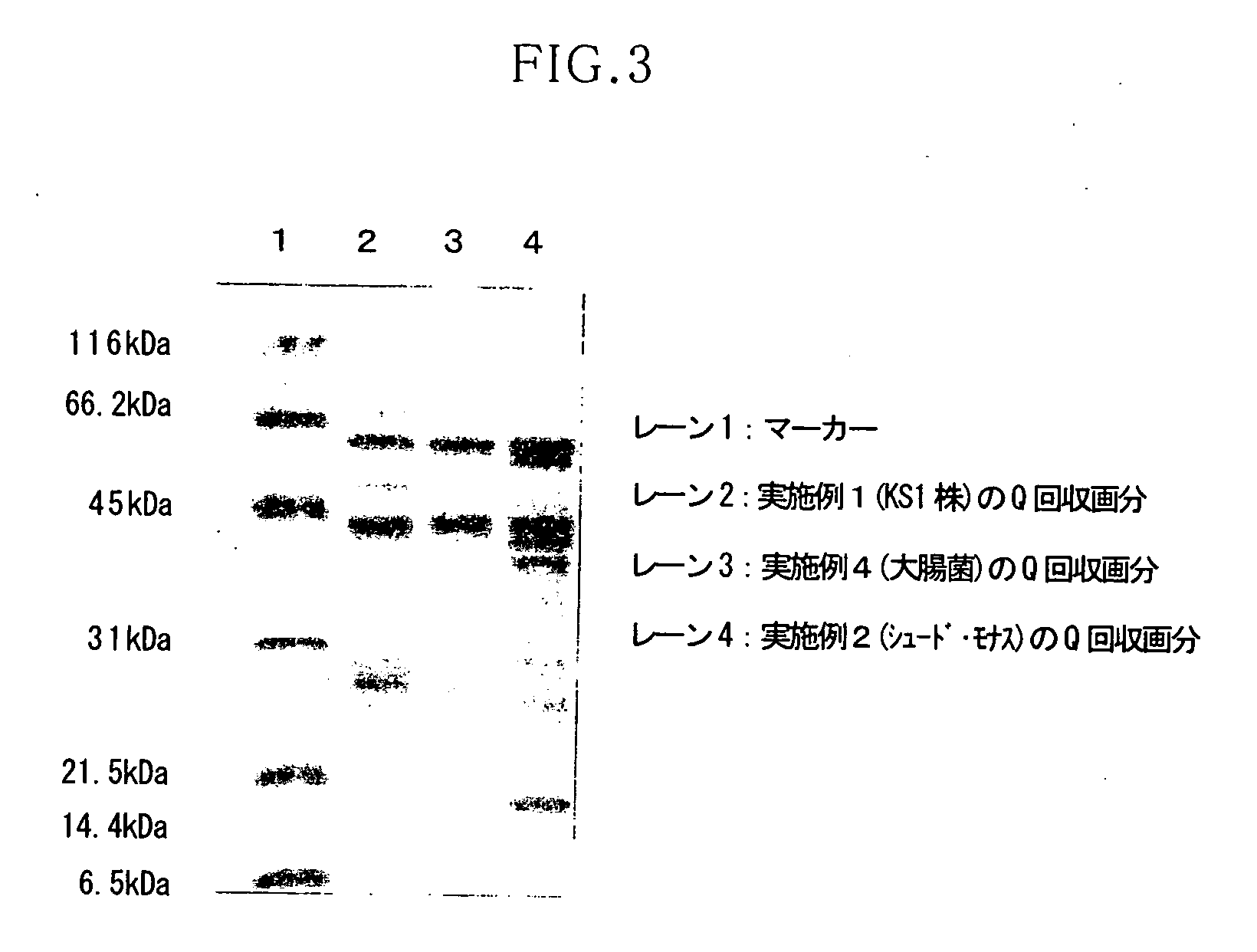

Method for purifying protein and glucose dehydrogenase

InactiveUS20060094098A1High enzyme activityPromote efficient productionPeptide preparation methodsOxidoreductasesProtein targetAnion-exchange chromatography

A method of purifying a target protein from a solution, in which the target protein containing an electron transfer protein is dissolved, with the use of liquid chromatography. The liquid chromatography is performed by introducing the above-described protein solution into a tank filled with a packing agent, thus bonding the target protein to the packing agent, removing impurities, and then eluting the target protein from the packing agent with the use of an eluent containing a hydroxycholanoic acid salt. As an example of the above protein, glucose dehydrogenase containing a protein having an activity of dehydrogenating glucose is cited. The liquid chromatography is performed by combining hydrophobic chromatography with anion exchange chromatography.

Owner:ARKRAY INC

Method for processing internal organs of abalone by autolysis

ActiveCN102511844AHigh enzyme activityInhibition of growth and reproductionFood preparationFlavorBiology

The invention relates to a method for processing internal organs of abalone by autolysis and belongs to the field of fish and shellfish autolysis and hydrolysis. By the adoption of the method, the product amino nitrogen obtained has high content of amino nitrogen, and the production efficiency is raised; in addition, the finished product has weak bitter fishy smell and has a good color. The method comprises the following steps of: (1) chopping and mashing washed internal organs of abalone into a homogenate; (2) processing the abalone internal organ homogenate in the high intensity pulsed electric field; (3) adding a few salt and uniformly stirring; (4) processing the abalone internal organ homogenate by an ultraviolet irradiation method; and (5) carrying out autolysis and hydrolysis on the abalone internal organs by a high temperature method. By the adoption of the method, the content of amino nitrogen is greatly raised within a certain time, unique and rich flavor of the hydrolysate obtained is guaranteed, the problem of low content of amino nitrogen by a traditional autolysis method is solved, and the problem of poor flavor by a fast autolysis method is also solved.

Owner:FUJIAN AGRI & FORESTRY UNIV

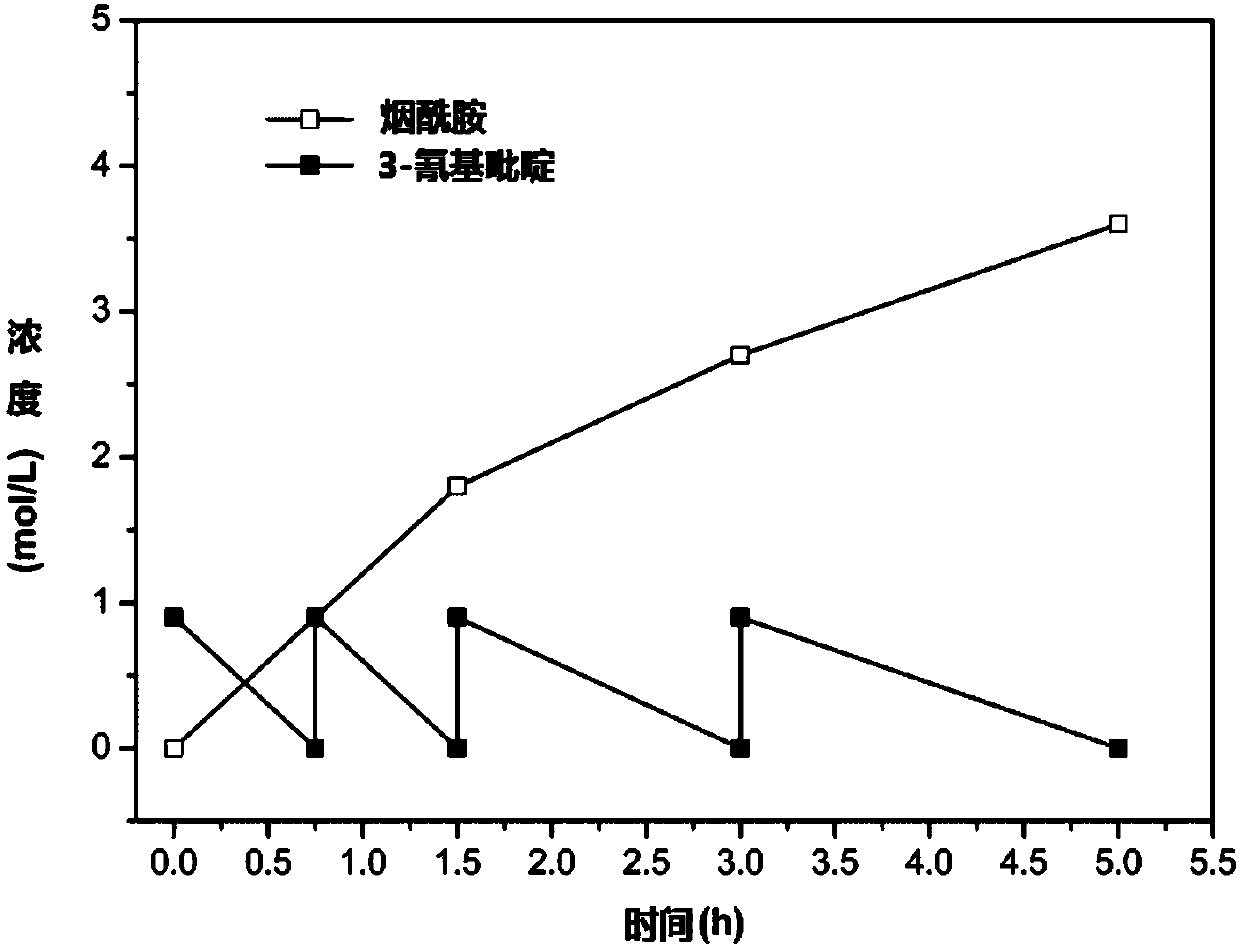

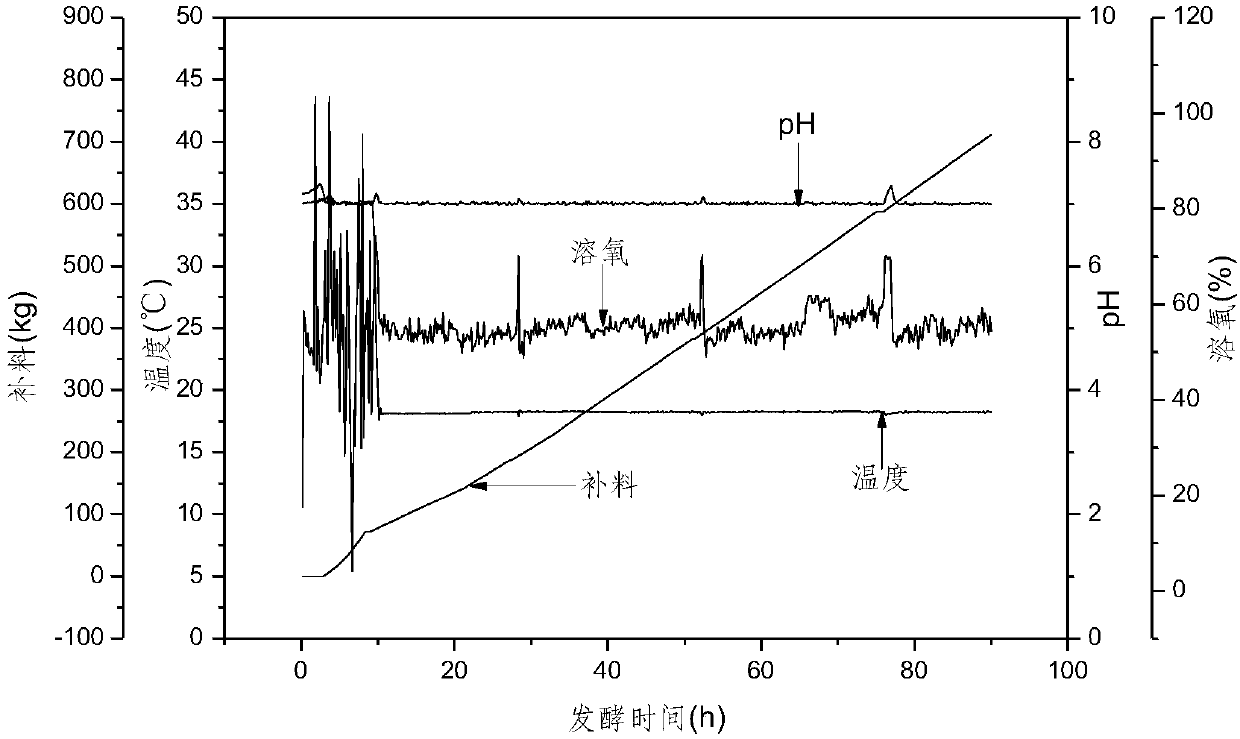

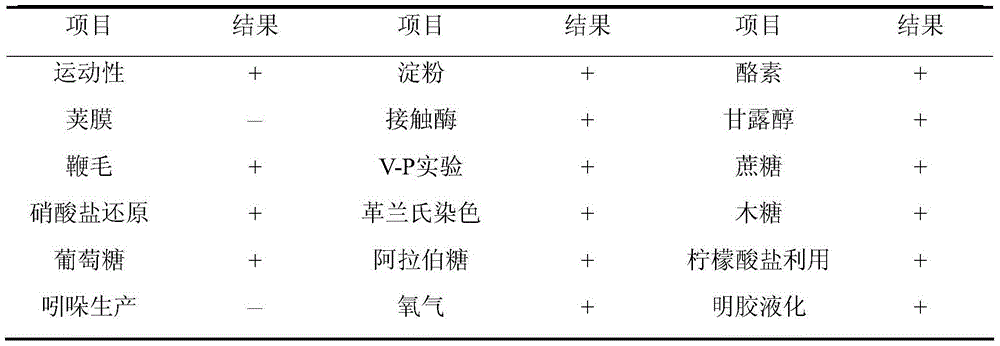

Preparation technology of niacinamide

ActiveCN107916283AHigh enzyme activityImprove product qualityMicroorganism based processesFermentationNiacinamideBase sequence

The invention discloses a preparation technology of niacinamide. The preparation technology comprises the following steps of building of gene engineering bacteria, fermenting culture of engineering bacteria, and performing catalytic reaction, wherein the engineering bacteria comprise escherichia coli host cells and a nitrile hydratase gene of which the base sequence is shown in SEQ ID NO.1 or SEQID NO.2; in the catalyzing process, pure water is used as a reaction medium to prepare a cell suspension liquid; 3-cyanopyridine is added into the cell suspension liquid by batches, and the concentration of the 3-cyanopyridine in the reaction system is controlled to be 90g / L or less, so as to obtain the niacinamide. The preparation technology has the advantages that the gene engineering bacteria containing the recombinant nitrile hydratase with high enzyme activity is used for fermenting culture, the pure water is used as the reaction medium, and the 3-cyanopyridine is added into the cell suspension liquid in a batched base matter adding way, so as to perform the hydration reaction at high efficiency, thereby obtaining the niacinamide product; the conversion rate of the hydration reactionis more than 99.9%, the quality of the obtained product is high, and the impurities and byproducts are not produced.

Owner:ZHEJIANG UNIV

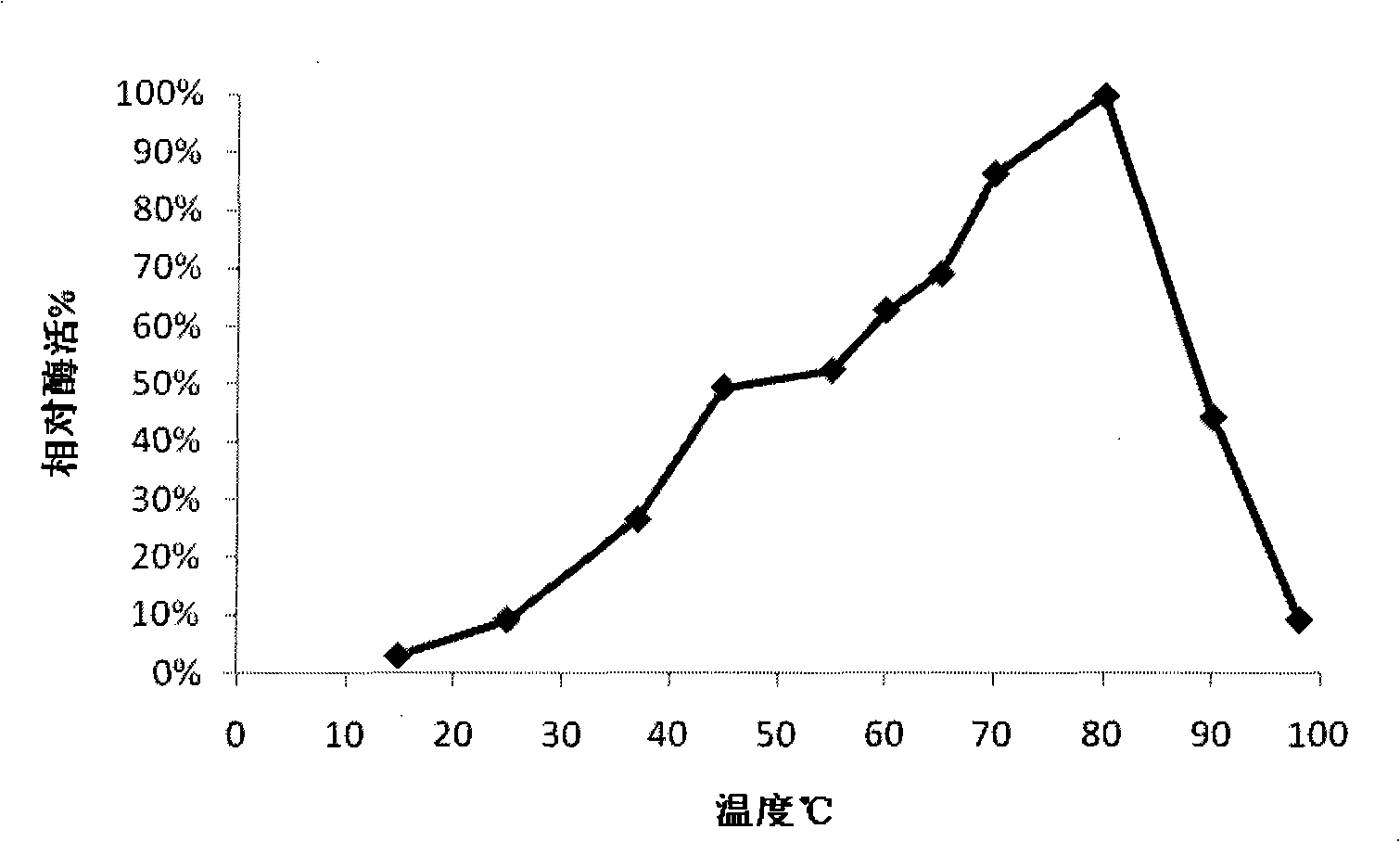

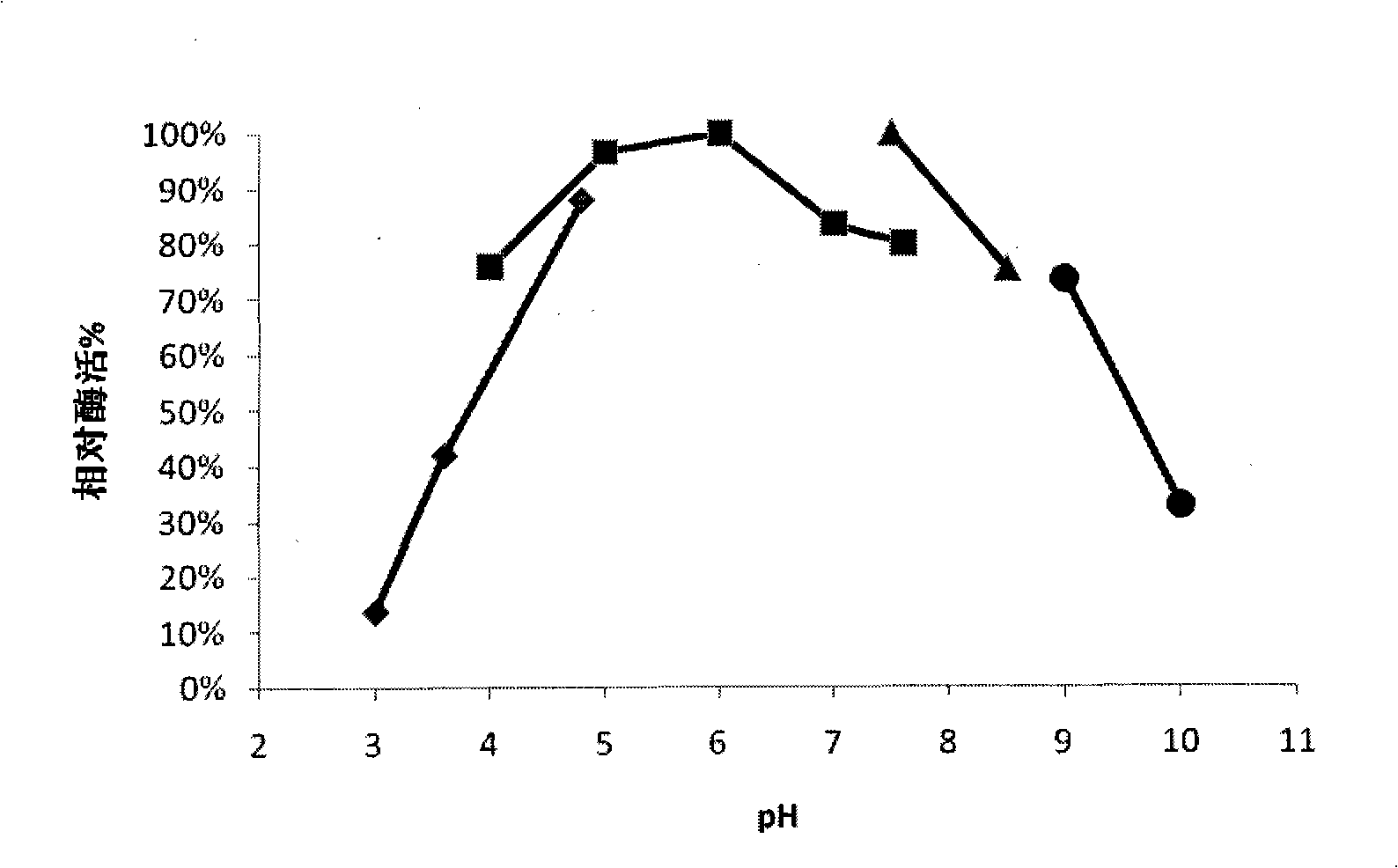

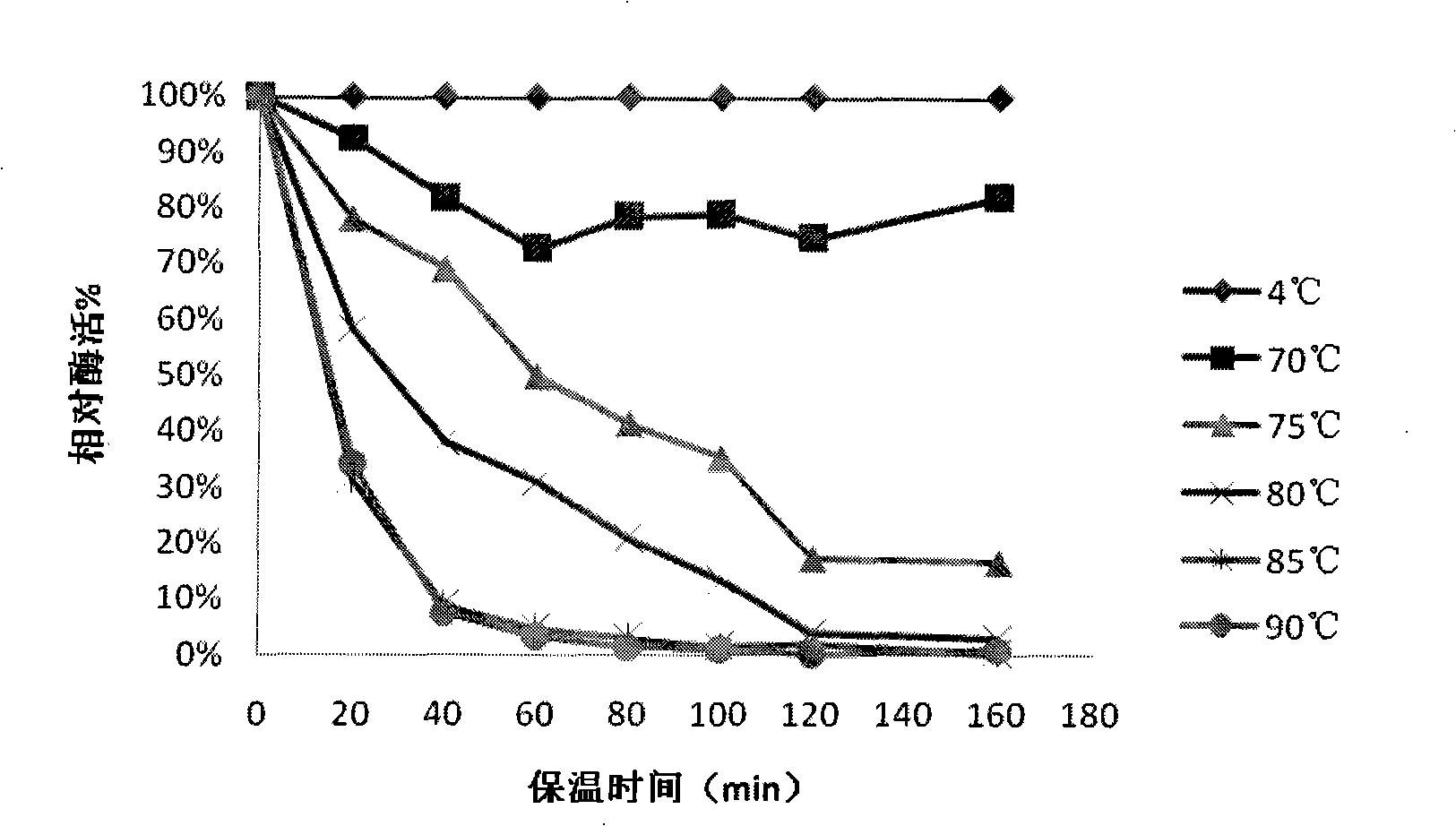

Bacillus subtilis yielding mesothermal alpha-amylase

ActiveCN104450572AHigh enzyme activityWide pH rangeBacteriaMicroorganism based processesChemistryEnzyme

The invention discloses bacillus subtilis yielding mesothermal alpha-amylase. The strain is obtained by compound mutation by virtue of lithium chloride-diethyl sulfate. The bacillus subtilis 304 is specifically Bacillus subtilis 304, wherein the preservation number is CCTCC NO: M 2013600. The optimum action temperature of the mesothermal alpha-amylase yielded by bacillus subtilis is 65 DEG C and the mesothermal alpha-amylase which is preserved at 65 DEG C for 24 hours still has 80% enzyme activity and which is preserved at 70 DEG C for 12 hours still has 50% enzyme activity; the optimum reaction pH value of the enzyme is 5.0 and the mesothermal alpha-amylase which is preserved at pH of 4-6 for 18 hours still has over 80% enzyme activity; the enzyme activity is 7000-8500U / ml. The bacillus subtilis is particularly suitable for industrial demand, wherein the reaction temperature is high and a liquefaction process and a saccharification process exist.

Owner:湖南新鸿鹰生物工程有限公司

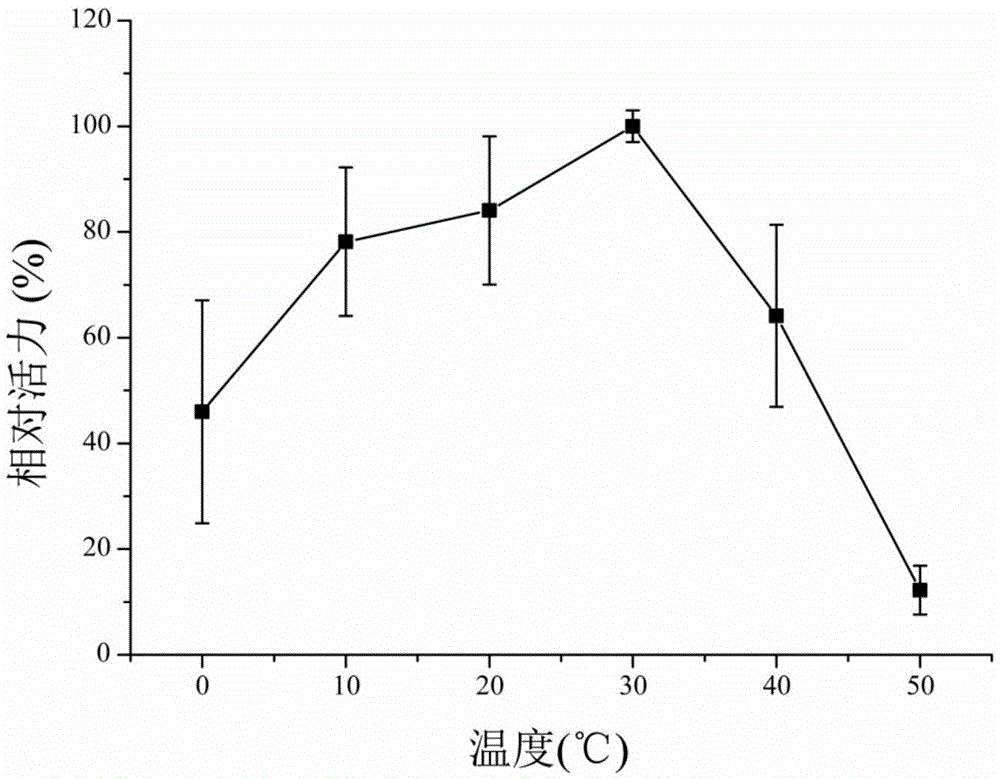

Novel feruloyl esterase, coding gene and application thereof

ActiveCN108342371AHigh enzyme activityPromote wound healingHydrolasesFermentationPhylogenetic profilingOrganic solvent

The invention provides a novel feruloyl esterase gene from soil. The nucleotide sequence and the amino acid sequence of the novel feruloyl esterase gene are respectively shown in SEQ ID NO.1 and SEQ ID NO.2. The esterase gene is heterologously expressed in escherichia coli BL21(DE3), and the molecular weight of purified recombinase (FAEXuan) is 29kDa. The catalytic activity of the FAEXuan for a substrate (ferulic acid methyl ester) is highest, the enzyme activity is 40U / mg, the optimum temperature is 30 DEG C, and the optimum pH is 5.0. After reaction for 4 hours under the pH of 3.0-10.0, theferuloyl esterase can keep the activity still by 75% or more, so that stronger pH stability is shown. The feruloyl esterase FAEXuan has better tolerance to metal ions and organic solvent. The substrate utilization preference and the phylogenetic analysis show that the FAEXuan belongs A-type feruloyl esterase. Due to good enzymatic properties, the FAEXuan has wide application prospect in industrialproduction of the fields of foods, pharmacy and feed and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

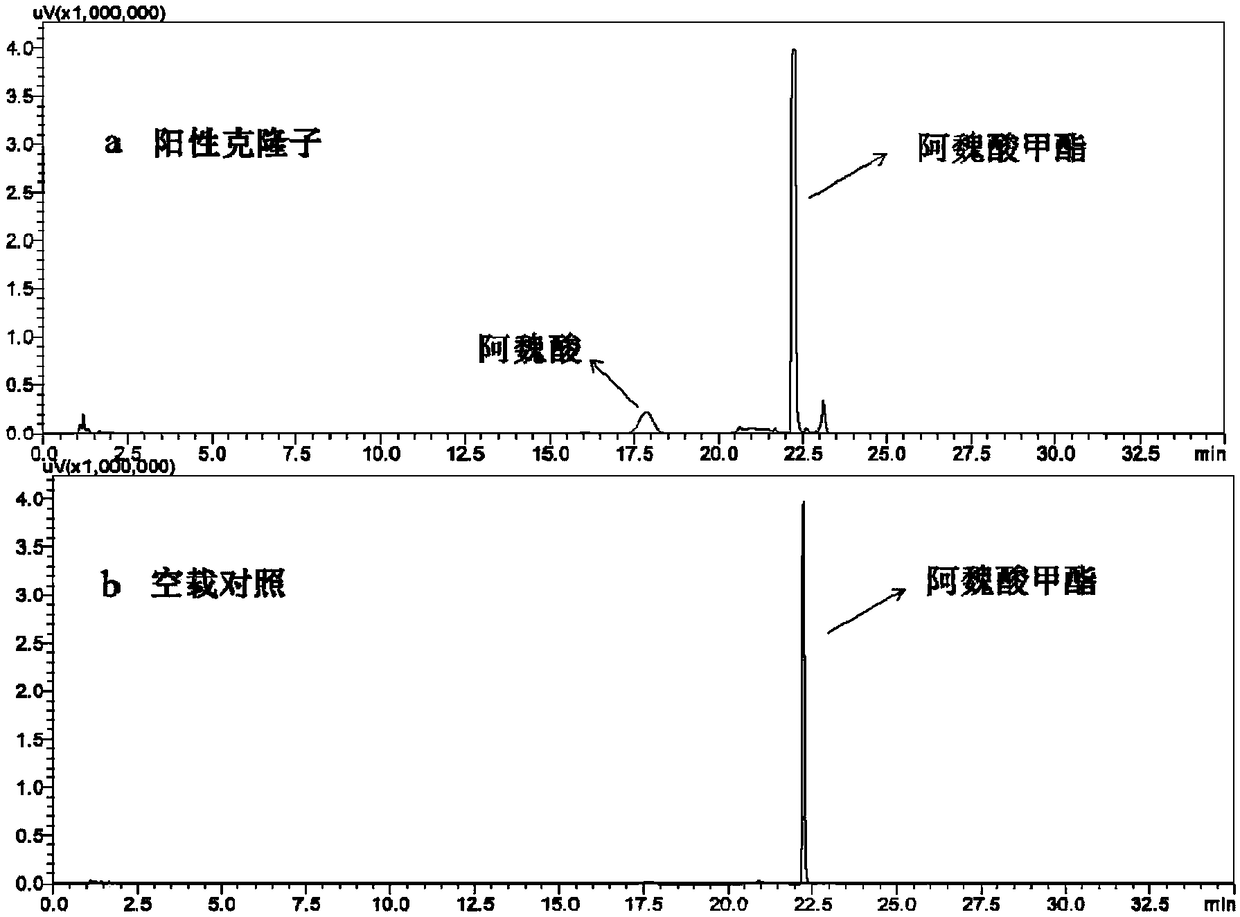

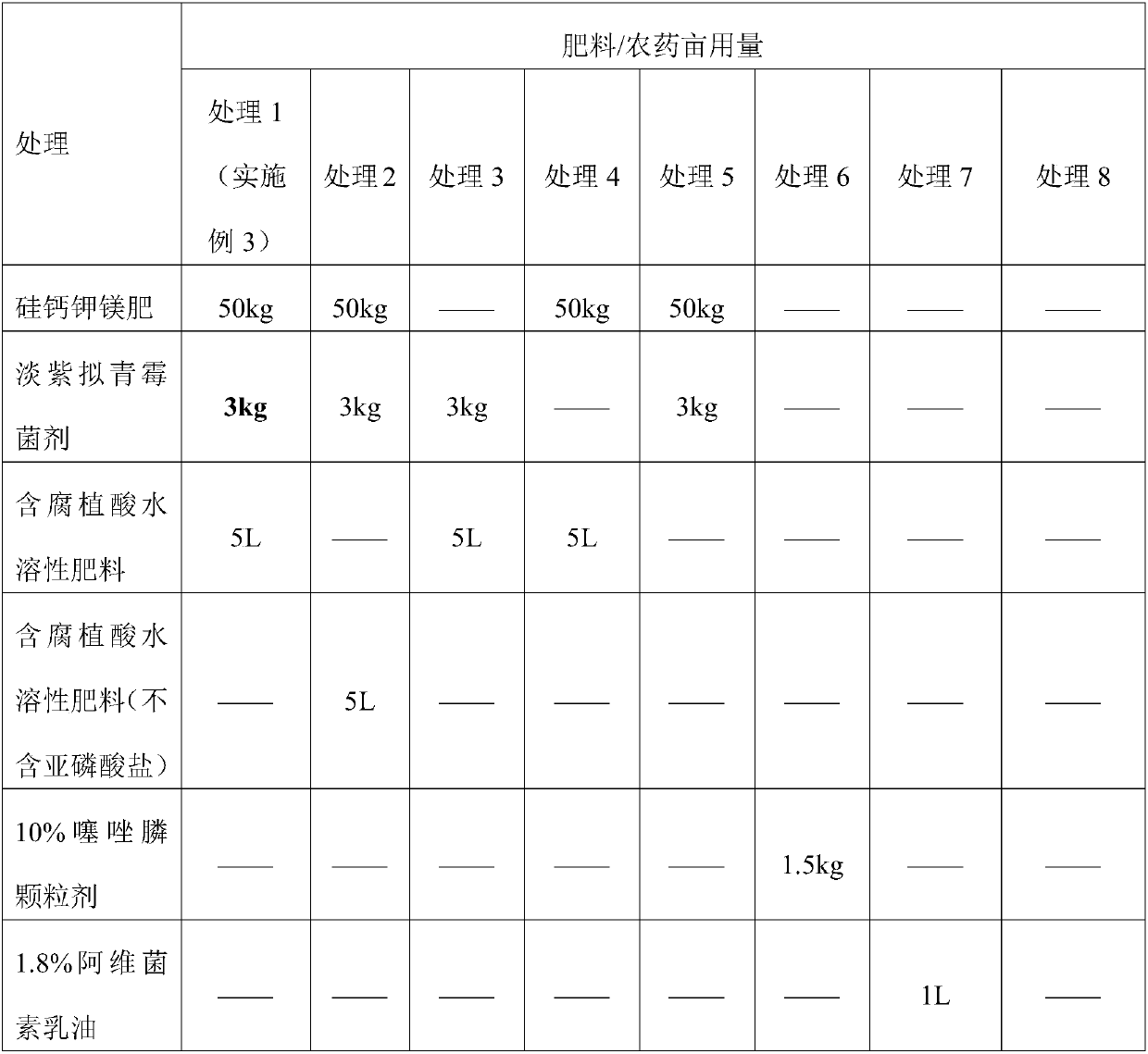

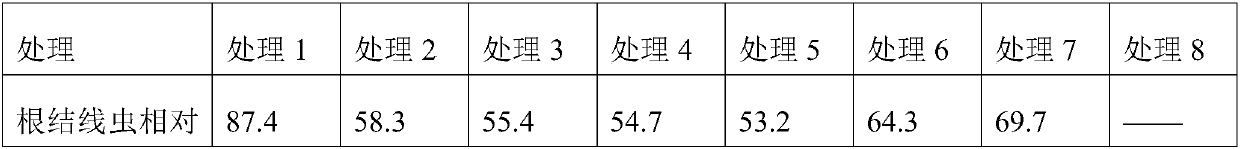

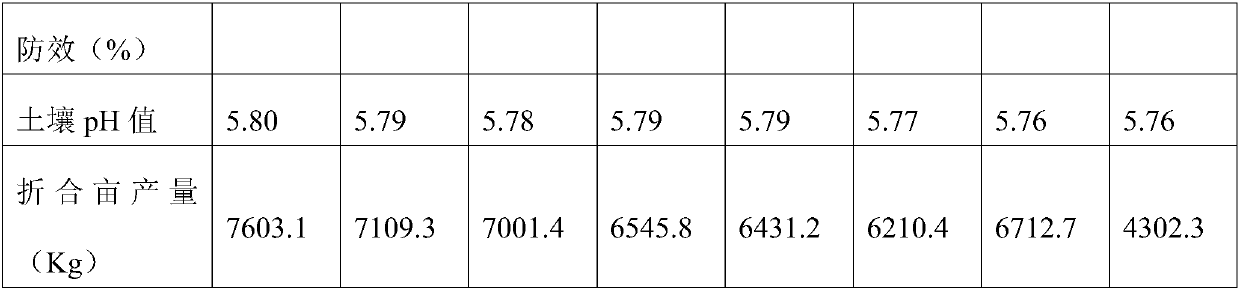

Tomato package fertilizer for prevention and control of root-knot nematode and fertilizing method thereof

InactiveCN107840741AReduce soil acidificationHigh enzyme activityCalcareous fertilisersMagnesium fertilisersHumic acidNutrition

The invention relates to a tomato package fertilizer for prevention and control of root-knot nematode. The tomato package fertilizer includes an alkaline soil conditioner, a paecilomyces lilacinus agent and a humic acid-containing water-soluble fertilizer; the soil conditioner silicon-calcium-potassium-magnesium fertilizer is evenly broadcasted during soil tillage; the paecilomyces lilacinus agentis applied during transplanting; the humic acid-containing water-soluble fertilizer is applied after fixed planting. The package fertilizer is in synergtic mutual promotion, increases the preventioneffect from different views, also improves acidified soil, satisfies the nutrition of the whole growth period of tomato, has no pesticide application, is combined with tomato fertilization and root-knot nematode generation laws, is performed with pure fertilizers, achieves the integrated efficacy of drugs and fertilizers, and is suitable for the whole growth process of the tomato; and in addition,the package fertilizer has the advantages of safety, environmental protection and more prominent continuous application effect, and is of great promotion value in prevention and control of root-knotnematode.

Owner:KINGENTA ECOLOGICAL ENG GRP +2

Thrombolysis protease gene NKS1 and purpose thereof

InactiveCN102337282AHigh enzyme activityHigh activityPeptide/protein ingredientsMicrobiological testing/measurementBacillus nattoThrombolysis

The invention discloses a thrombolysis protease gene NKS1. The gene is used for encoding a protease with an amino acid sequence represented by SEQ ID NO:1 in the sequence list, or a protease with a homology above 70% with the amino acid sequence represented by SEQ ID NO:1. According to the invention, with a DNA re-organization technology, a novel natto kinase NKS1 is obtained. The gene encodes natto kinase with a stronger activity than wild natto kinase genes.

Owner:南京百吉生物科技有限公司

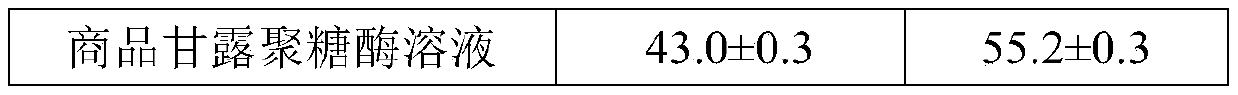

Method for producing mannanase by lactobacillus brevis

ActiveCN110295156AShort preparation cycleHigh enzyme activityFood processingMicroorganism based processesEnzymeChemistry

The invention discloses a method for producing mannanase by lactobacillus brevis and relates to a method for producing mannanase. The method for producing the mannanase by lactobacillus brevis comprises the specific steps: inoculating lactobacillus brevis HDRS8 into a polysaccharide carbon source culture medium for culture to obtain a fermentation liquor; and then centrifuging the fermentation liquor, discarding the precipitate and leaving the supernatant to obtain a crude enzyme solution containing mannanase. The activity of the mannanase in the obtained crude enzyme solution containing the mannanase and obtained by the method is 45-65 U / mL, the preparation period of the method is short, and the enzyme activity of the mannanase is high.

Owner:HEILONGJIANG UNIV

Aspartase mutant, recombinant expression vector containing aspartase mutant, recombinant bacterium and application thereof

ActiveCN110791494AHigh enzyme activityImprove abilitiesCarbon-nitrogen lyasesBacteriaGenetic engineeringMutant

The invention provides an aspartase mutant, a recombinant expression vector containing the aspartase mutant, recombinant bacteria containing the aspartase mutant and an application thereof, which belong to the technical field of gene engineering. The amino acid sequence of the aspartase mutant is shown as SEQ ID NO: 1. According to the aspartase mutant disclosed by the invention, glutamic acid atthe 427th site is mutated into glutamine on the basis of aspartase (an amino acid sequence is shown as SEQ ID NO: 3). The 427th amino acid residue of aspartase is mutated into glutamine, the polar environment near an active site is changed, and ammonia supply during a substrate reaction is facilitated, so that the enzyme activity is improved, the beta-amino acid synthesis capacity of the aspartaseis enhanced, and an actual effective strategy is provided for industrial production of the aspartase.

Owner:JIANGNAN UNIV

A method for extracting malt limit dextrinase

The invention discloses a method for extracting malt limit dextrinase. The method includes: 1) crushing the dried barley malt with a pulverizer; 2) passing the crushed malt powder through a 40-80 mesh sieve to obtain pretreated malt powder; 3) adding 15-25mmol / LL - 0.1mol / L acetic acid-sodium acetate buffer solution with a pH value of 5.0~6.0 of cysteine hydrochloride, adjust the solid-liquid ratio to 1:4~1:6g / mL, and place it at a speed of 80~120r / mL min in a water bath constant temperature oscillator, separated and extracted at a temperature of 35 to 45°C for 12 to 20 hours, and centrifuged in a centrifuge with a rotation speed of 3000 to 5000r / min for 10 to 15 minutes to obtain malt limit dextrinase. The limit dextrinase is preliminarily separated by this method, the process is simple, the target enzyme can be dissolved to the greatest extent, the extraction effect is good and the cost is low.

Owner:SOUTH CHINA UNIV OF TECH

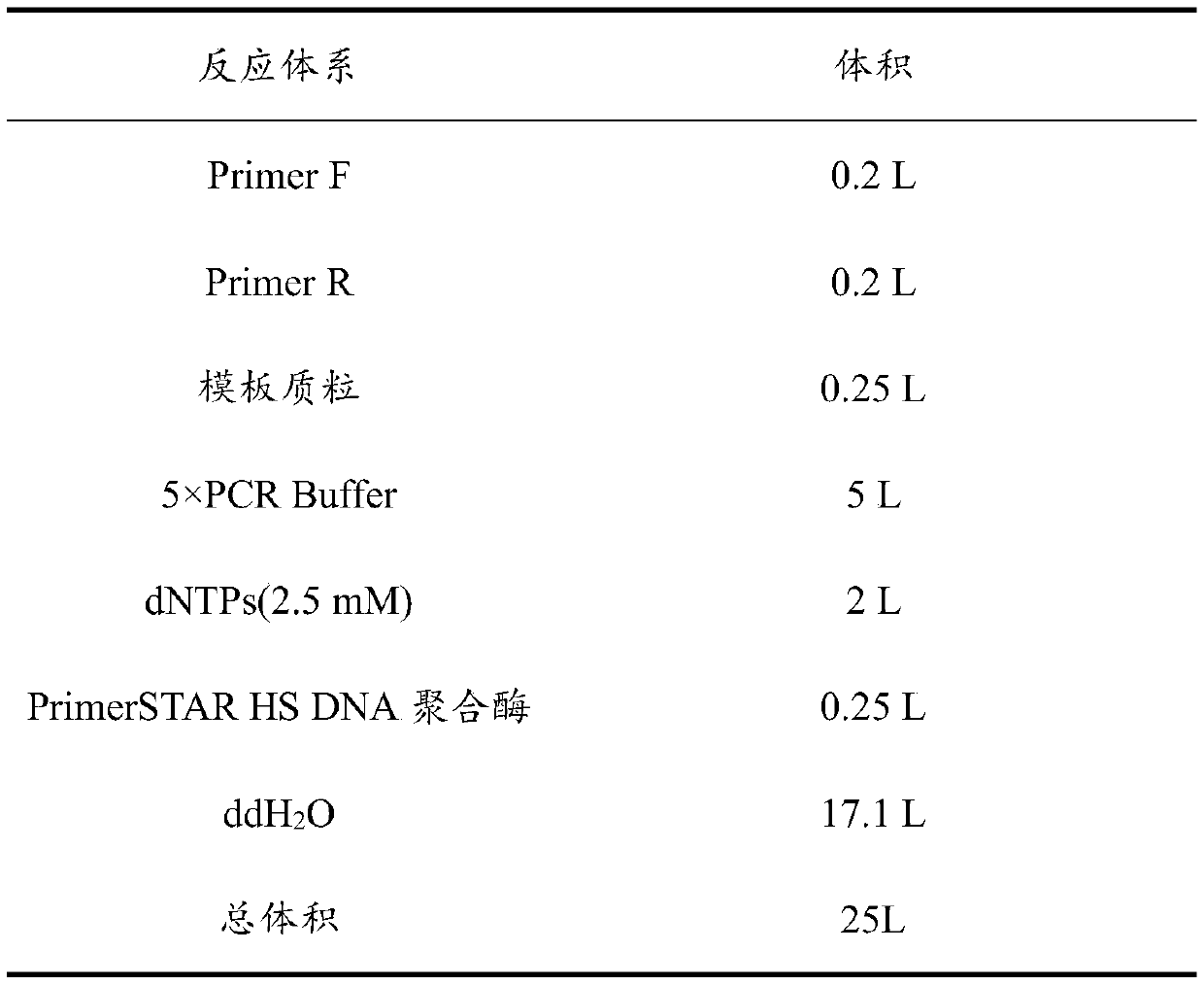

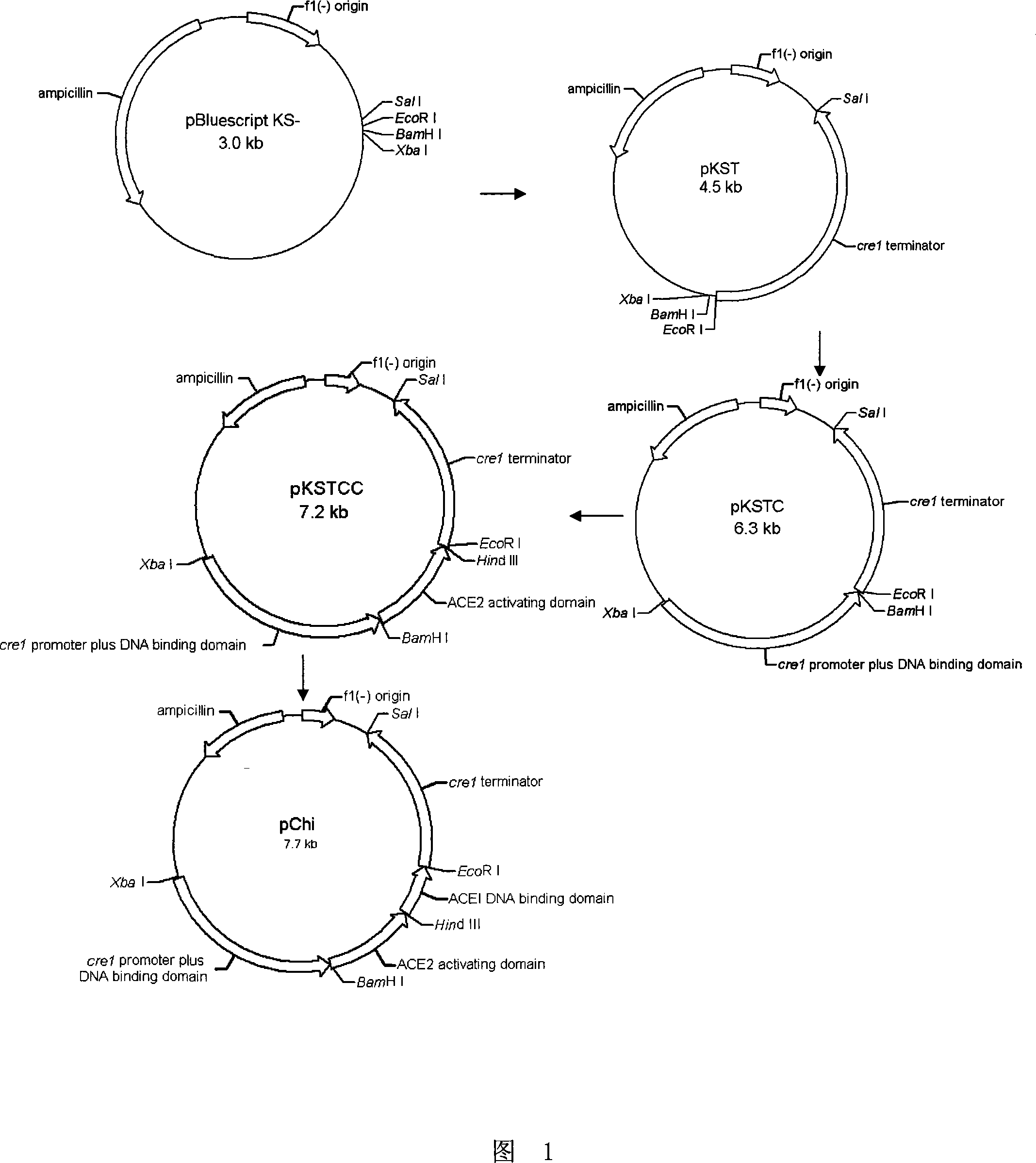

Transcription activating factor as well as coding gene and application thereof

InactiveCN101182352AImprove expression levelHigh enzyme activityDepsipeptidesFermentationXylanaseCellulase

The invention discloses a transcription activator, its coding gene and application. The transcription activator can increase the expression level of cellulase and xylanase, and is a protein of (a) or (b): (a) a protein consisting of the amino acid residue sequence of sequence 1 in the sequence listing; (b) Substitution and / or deletion and / or addition of one or several amino acid residues to the amino acid residue sequence of Sequence 1 in the Sequence Listing and having the function of a transcriptional activator that can increase the expression level of cellulase and xylanase is composed of (a) Derivatized protein. The transcription activator and its coding gene of the present invention can increase the expression level of cellulase and xylanase gene.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

Method for producing heat-resistant superoxide dismutase (SOD) through Marinamoeba thermophila

InactiveCN104818256AHigh enzyme activityGood heat resistanceMicroorganism based processesOxidoreductasesChemistryBioengineerings

The invention relates to a method for producing heat-resistant superoxide dismutase (SOD) by using Marinamoeba thermophila, and belongs to the technical field of bioengineering. According to the present invention, Marinamoeba thermophila is utilized to produce SOD under a liquid-state fermentation condition, and is an extracellular enzyme, wherein the heat-resistant SOD yield can be up to 2000 U / ml; and the method has good industrial application prospects.

Owner:JIANGNAN UNIV

Organic material decomposing agent and preparation method thereof

PendingCN111621446AHigh bacterial countHigh enzyme activityBio-organic fraction processingFungiClostridialesEcosystem

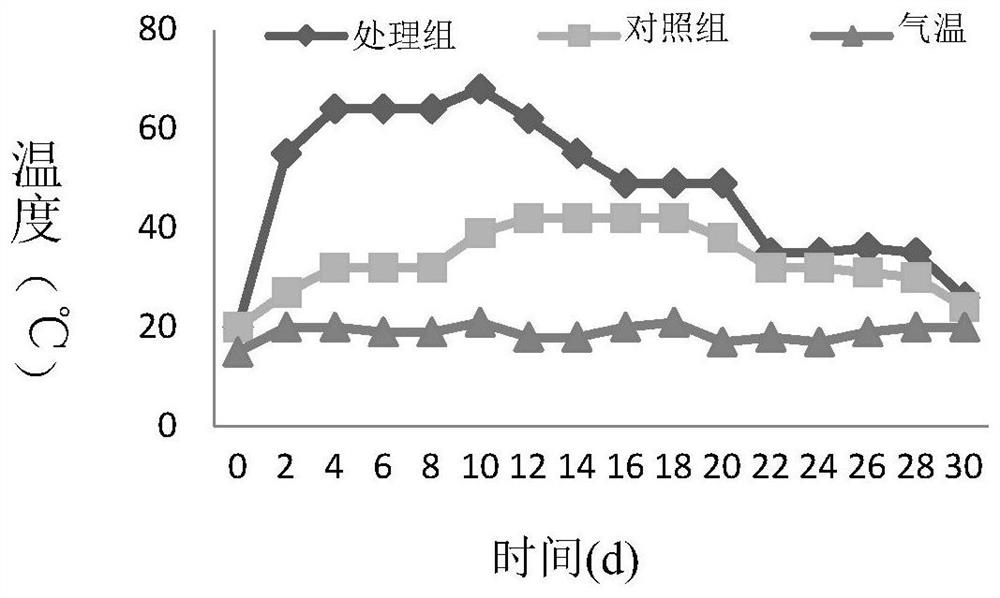

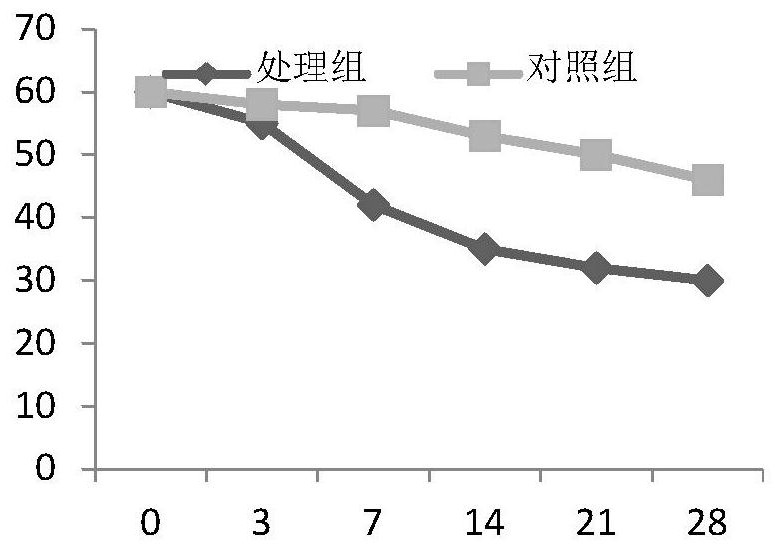

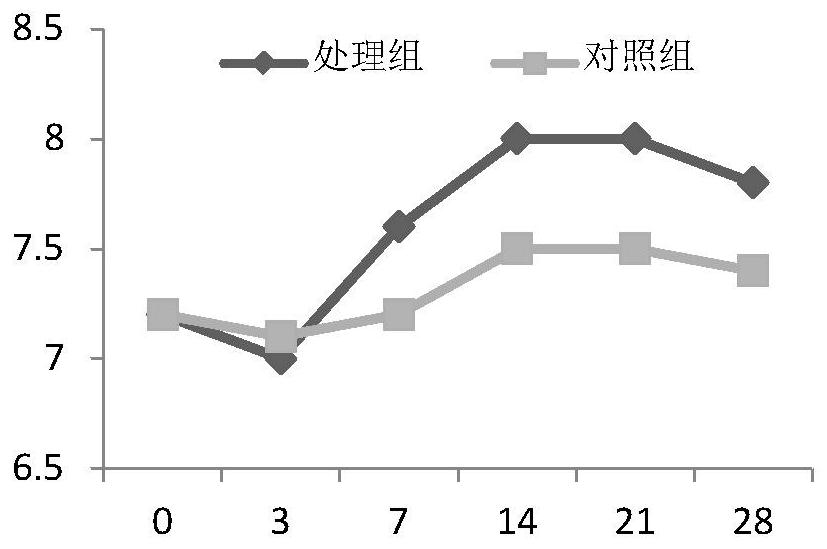

The invention provides a preparation method and an application of an organic material decomposing agent. According to the organic material decomposing agent, a microbial composite strain composed of various functional microorganisms is mainly taken as a strain, and is subjected to liquid-solid multi-stage comprehensive fermentation, and comprehensively applied and transformed into the organic material decomposing agent, wherein the weight ratio of a clostridium butyricum strain, a saccharomyces cerevisiae strain, a lactobacillus plantarum strain and a bacillus subtilis strain is (10-15): (20-25): (10-20): (35-40); and product production simulates the process of compost heating-high temperature-cooling. When the organic material decomposing agent acts on livestock and poultry manure compost, the fermentation temperature rises rapidly, the highest temperature of compost is 76.5 DEG C, the high temperature period lasts for 12-16 days, the use is highly compatible with the microbial evolution process of natural compost, and functional bacteria reproduce rapidly to be dominant and play a role; and due to in-situ fermentation, a large number of proteases, cellulases and amylases are produced in the fermentation process to form a stable and efficient micro-ecosystem, which has a large number of bacteria and high enzyme activity, and functional bacteria and enzyme substances act together to rapidly achieve harmless treatment of livestock and poultry manure.

Owner:天津市圣世莱科技有限公司

Low-molecular-weight chondroitin sulfate and preparation method thereof

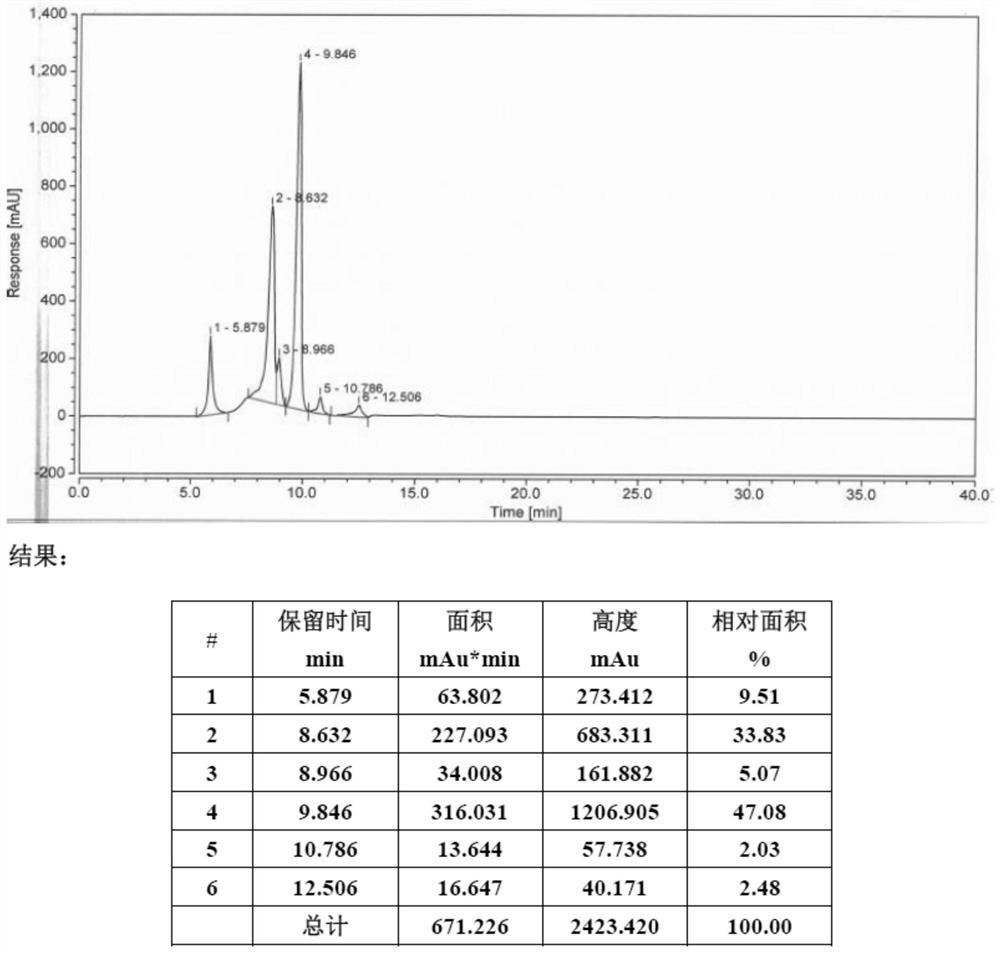

InactiveCN111741963AGood specificityHigh enzyme activityEsterified saccharide compoundsCosmetic preparationsProtein contentOligosaccharide

The invention discloses a low-molecular-weight chondroitin sulfate and a preparation method thereof. Macromolecular chondroitin sulfate is used as a raw material, and the low-molecular-weight chondroitin sulfate having average molecular weight of less than 1000 daltons is produced through a production process comprising chondroitin sulfate lyase degradation, deproteinization, filtration sterilization, drying, and the like. According to the low-molecular-weight chondroitin sulfate, the molecular weight distribution range is narrow, the content of chondroitin sulfate disaccharide is 43-60%, thecontent of chondroitin sulfate tetrasaccharide is 30-45%, the sum of contents of the chondroitin sulfate disaccharide and the chondroitin sulfate tetrasaccharide is greater than 87%, the total contentof oligosaccharides in the low-molecular-weight chondroitin sulfate is 97% or above, and the protein content is not more than 0.5%. Compared with common marketed macromolecular chondroitin sulfate, the product has a more obvious repairing effect on chondrocytes damaged by 1mM hydrogen peroxide at a concentration of 50-100 [mu]g / mL, has a strong repairing ability and a repair rate between 14% and23%, can be used to treat joint injuries, and is an important raw material for medical products, healthcare products, cosmetics, food, etc..

Owner:NANJING HANXIN PHARMA TECH CO LTD

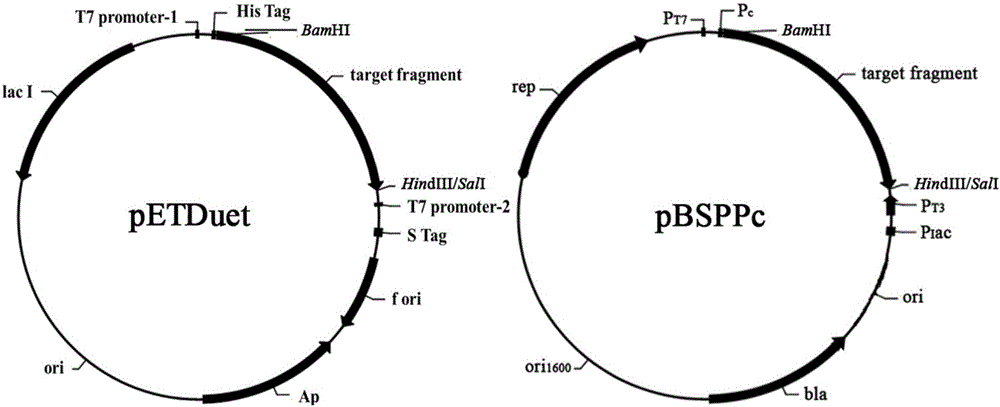

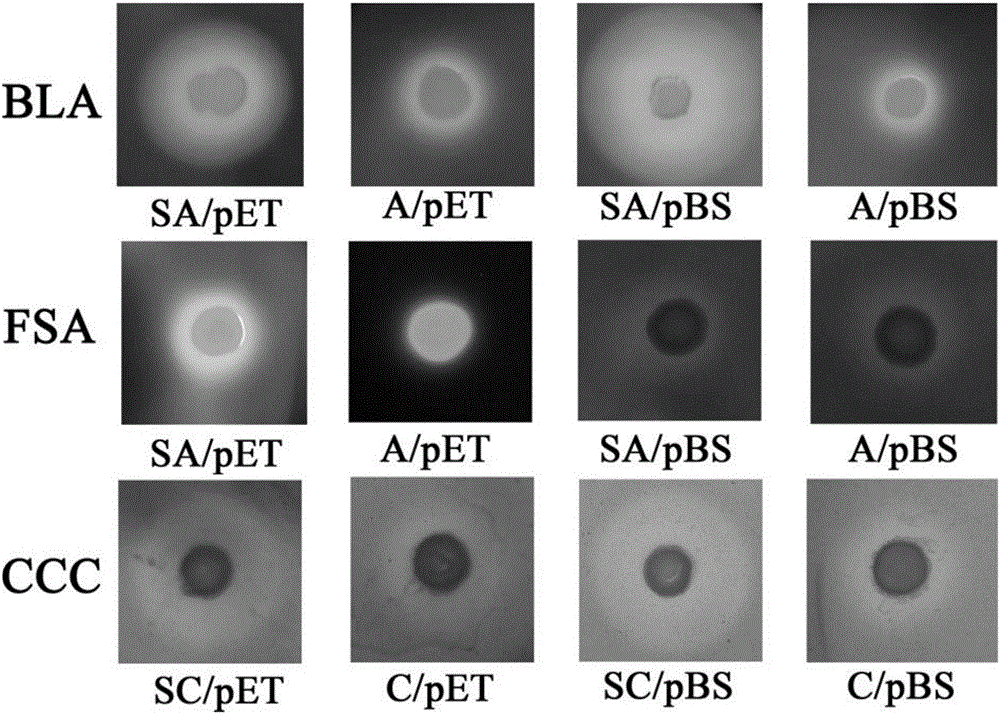

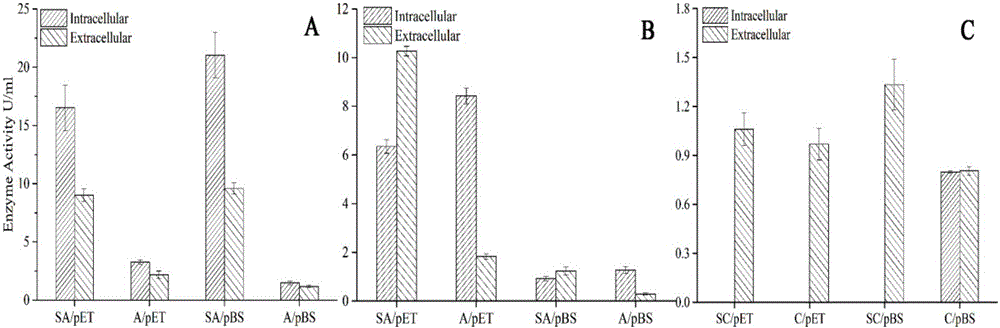

Actinomycete signal peptide for expressing intracellular protein to extracellular position and application thereof

InactiveCN105924507AHigh enzyme activityIncrease enzyme activityMicroorganism based processesNucleic acid vectorCellulaseHigh activity

The invention discloses an actinomycete signal peptide for expressing intracellular protein to an extracellular position. The actinomycete signal peptide is named as Kp-SP, and is from a Kocuria sp.3-3 strain; the nucleotide sequence of the actinomycete signal peptide is shown as SEQ ID No.1, and the amino acid sequence is shown as SEQ ID No.7. The invention also discloses application of the signal peptide to the expression of amylase or cellulose by using the built recombinant escherichia coli. The signal peptide has the capability of secreting foreign protein to the extracellular position in a normal expression carrier, so that the protein expression quantity is increased; the enzyme activity is obviously improved; in addition, the foreign protein extracellular secretion capability is also realized in the constitutive expression carrier pBSPPc; an effective path is provided for producing high-activity secretion protein. As a basic gene engineering technology, the invention provides the favorable conditions for the industrial protein production; the protein expression quantity and the enzyme activity are enhanced; the separation cost is reduced; great application prospects are realized in the protein industrial production aspect.

Owner:SHANDONG UNIV

Preparation method of high-temperature xylanase

InactiveCN101525607AHigh enzyme activityThe separation and purification process is simpleHydrolasesMicroorganism based processesAmmonium sulfateChemistry

The invention relates to the field of biotechnology. A preparation method of high-temperature xylanase comprises the following steps: (1) preparation of crude enzyme: inoculating Thermobifida halotolerans YIM 90462<T> into liquid seed culture medium with inoculum size by 5 to 10 percent of volume, shaking culturing, transferring the Thermobifida halotolerans YIM 90462<T> into liquid fermentation medium by 5 to 10 percent of volume and obtaining crude enzyme; (2) concentrating the volume of the crude enzyme to 1 / 6 of original volume thereof by an ultra-filtration membrane package with molecular weight cut-off of 10 KDa; (3) adding ammonium sulfate into the concentrated enzyme to lead the saturation thereof to be 50 percent, obtaining precipitates by centrifugation and dissolving the precipitates in buffer solution; (4) taking supernatant fluid from the obtained liquid by centrifugation, adding the supernatant fluid into a Butyl-Sepharose chromatography column which is balanced by Tris-HCl buffer solution containing 0.3M of ammonium sulfate and having pH of 8.0; (5) taking supernatant fluid from the obtained liquid by centrifugation, adding the supernatant fluid into a Phenyl-Sepharose chromatography column which is balanced by Tris-HCl buffer solution containing 0.3M of ammonium sulfate and having pH of 8.0 and eluting the supernatant fluid with Tris-HCl buffer solution which does not contain ammonium sulfate and has pH of 8.0; (6) adding the supernatant fluid into Q-Sepharose chromatography column which is balanced by Tris-HCl buffer solution having pH of 8.0, collecting eluting peaks successively according to retention time, and remaining active components of the xylanase; and finally obtaining the xylanase with the activation of 573U / ml and purification yield of 9 percent.

Owner:YUNNAN UNIV

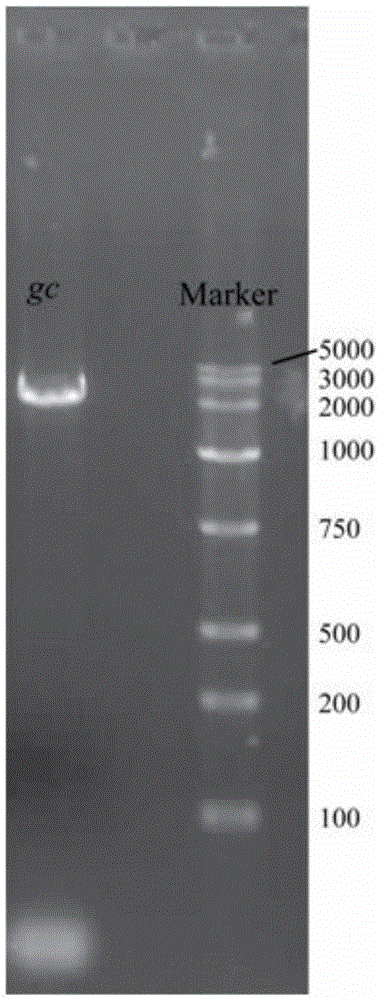

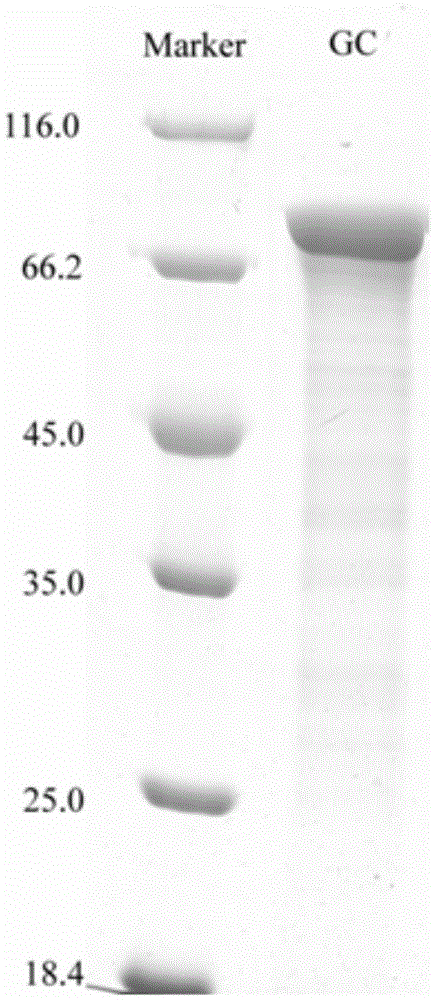

Ocean alginate lyase, expression gene thereof and application of ocean alginate lyase

InactiveCN105647898AHigh enzyme activityBroad application prospectsBacteriaMicroorganism based processesBiologyAmino acid

The invention relates to an ocean alginate lyase, an expression gene thereof and application of the ocean alginate lyase. Nucleotide sequences of ocean alginate lyase genes gc are shown as SEQ ID NO.1, and amino acid sequences of the ocean alginate lyase GC with codes of the ocean alginate lyase genes gc are shown as SEQ ID NO.2. The ocean alginate lyase, the expression gene and the application have the advantages that the alginate lyase GC is obtained for the first time, and a three-dimensional structure of the ocean alginate lyase GC is analyzed by the aid of crystals obtained by a crystallization method from the ocean alginate lyase; crystal structures of the ocean alginate lyase GC can have broad application prospects in the aspects of modifying substrates in industrial enzyme preparations, improving the enzyme activity and the like.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com