Genetic engineering bacterium for producing 4-hydroxyisoleucine and application thereof

A technology of hydroxyisoleucine and genetically engineered bacteria, applied in the field of genetic engineering, can solve the problems of low 4-HIL yield and the like, and achieve the effect of improving enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Construction of a bacterial strain expressing Bacillus thuringiensis derived Btido

[0024] The isoleucine dioxygenase encoding gene Btido shown in SEQ ID NO.1 was synthesized by chemical total synthesis. The construct contains Btido and is driven by the strong promoter P tacM The recombinant expression vector pJYW-5-Btido that controls its expression, wherein the expression vector pJYW-5 has been disclosed in the patent with publication number CN103834679B. The recombinant plasmid was transformed into the L-isoleucine producing strain SN01 (published in the paper of ApplMicrobiol Biotechnol, 2015, 99(9):3851-3863) to obtain the recombinant engineering strain SN02.

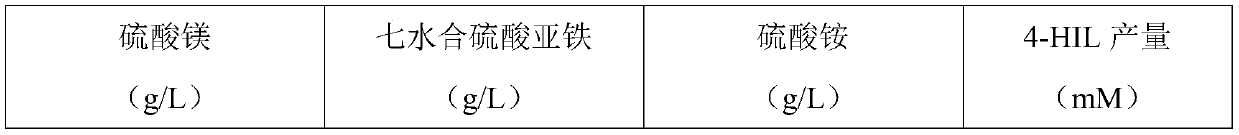

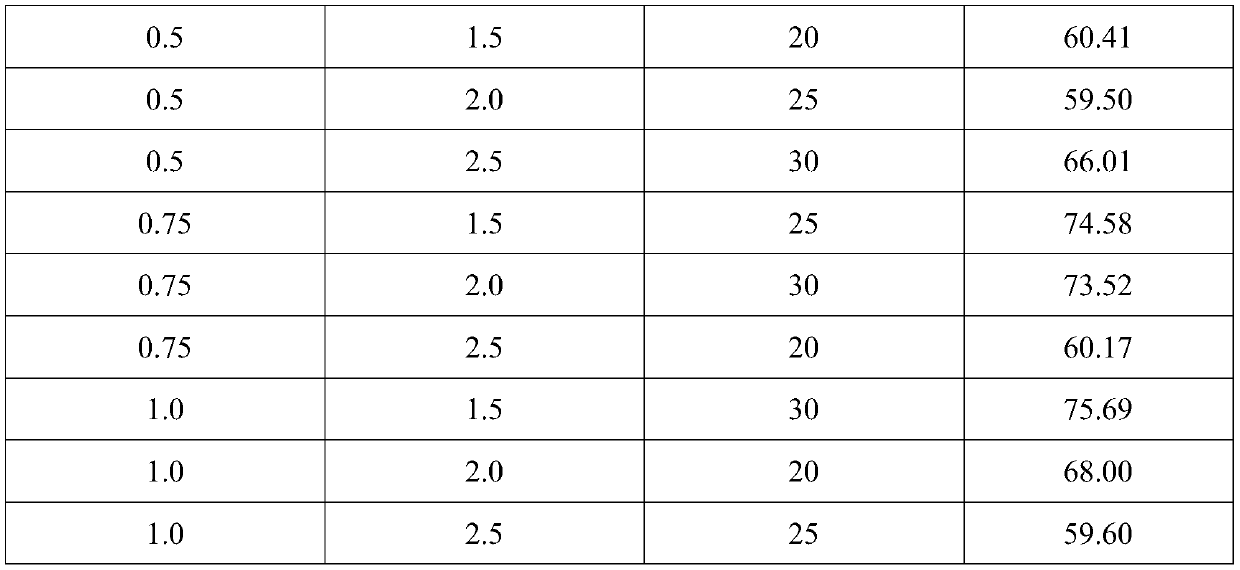

[0025] Press bacterial strain SN02 according to final OD 562 The inoculum size of 1.8 is inoculated in the fermentation medium, wherein, the fermentation medium composition is: glucose 140g / L, (NH 4 ) 2 SO 4 20g / L, corn syrup 10g / L, KH 2 PO 4 1g / L, MgSO 4 0.5g / L, FeSO 4 0.5g / L, CaCO 3...

Embodiment 2

[0027]Example 2 Constructing the bacterial strain expressing Bwido derived from Bacillus westerii

[0028] The isoleucine dioxygenase encoding gene Bwido shown in SEQ ID NO.2 was synthesized by chemical total synthesis. The construct contained Bwido and was driven by the strong promoter P tacM The recombinant expression vector pJYW-5-Bwido, which controls its expression, transforms the recombinant plasmid into Corynebacterium glutamicum SN01 to obtain the recombinant engineering strain SZ01.

[0029] Fermentation was carried out under the same fermentation conditions as in Example 1, and the results showed that under the same fermentation time, the output of 4-HIL synthesized by SZ01 fermentation was 38.42mM (5.65g / L), the total amount of 4-HIL and L-isoleucine is 78.45mM.

Embodiment 3

[0030] Example 3 Construction of a strain that co-expresses Btido and mqo and knocks out aceA

[0031] The Btido shown in SEQ ID NO.1 and the mqo shown in SEQ ID NO.3 were connected to the plasmid pJYW-5 to obtain the recombinant plasmid pJYW-5-Btido-mqo. The upstream homology arm fragment of aceA, the kanamycin resistance gene with loxP site, and the downstream homology arm fragment of aceA were sequentially connected to the vector pBlueScript to construct the knockout plasmid pBS-aceA. The knockout plasmid pBS-aceA was transformed into Corynebacterium glutamicum SN01 to knock out the aceA gene. Then, the plasmid pDTW109 was transformed into the aceA-knockout Corynebacterium glutamicum SN01, and the kanamycin resistance gene fragment remaining on the genome was removed. The gene knockout method and the pDTW109 plasmid sequence have been disclosed in the patent publication number CN103409446A. The recombinant plasmid pJYW-5-Btido-mqo was transformed into aceA knockout Coryne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com