Low-molecular-weight chondroitin sulfate and preparation method thereof

A technology of chondroitin sulfate and low molecular weight, which is applied in the preparation of sugar derivatives, chemical instruments and methods, and medical preparations containing active ingredients, etc. It can solve the problems of insufficient research, narrow range of molecular weight distribution, and low catalytic efficiency. , to achieve the effects of short production cycle, narrow molecular weight distribution range and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

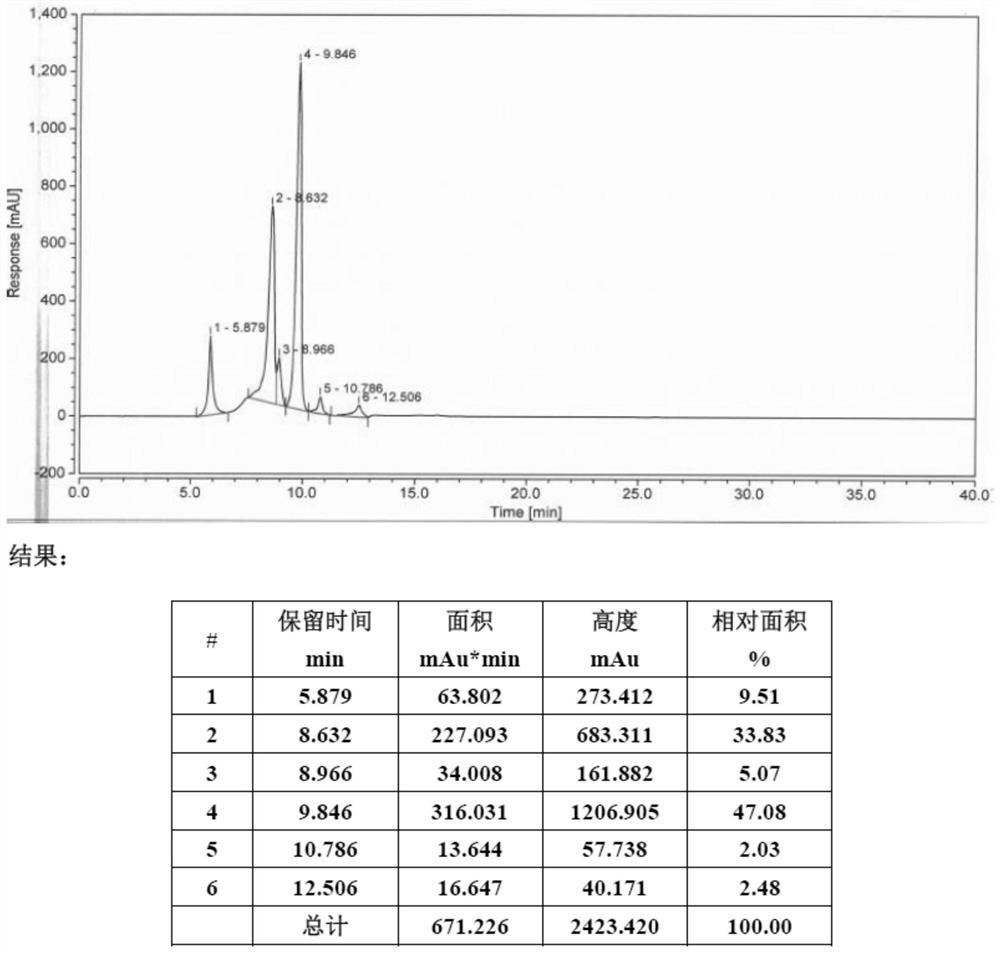

[0054] Embodiment 1 enzymolysis reaction

[0055] In a 5L glass beaker, add 2L of purified water, control the stirring speed to 400rpm, add 800g of shark bone chondroitin sulfate, after it is completely dissolved, use sodium hydroxide solution to adjust the pH to 7.0, add 200U / L of chondroitin sulfate lyase, Keep the system at 30°C and stir for reaction, react for 6 hours to check whether the average molecular weight is lower than 1000Da, if the reaction is not complete, extend the reaction time for 4 hours and continue the central control. Continue to react until the average molecular weight is lower than 1000Da and judged as qualified.

Embodiment 2

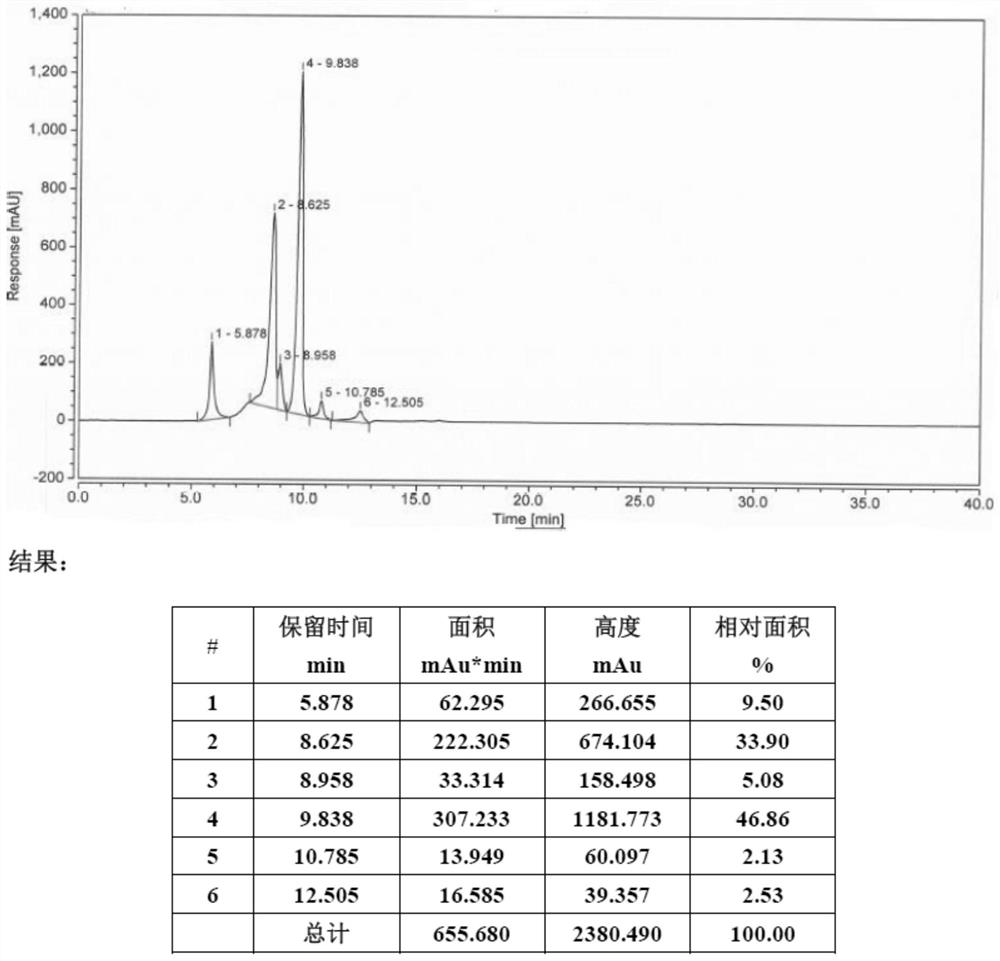

[0056] Embodiment 2 enzymolysis reaction

[0057] In a 5L glass beaker, add 2L of purified water, control the stirring speed to 700rpm, add 400g of shark bone chondroitin sulfate, after it is completely dissolved, use sodium hydroxide solution to adjust the pH to 6.5, add 300U / L of chondroitin sulfate lyase, Keep the system at 35°C and stir for reaction, react for 6 hours to check whether the average molecular weight is lower than 1000Da, if the reaction is not complete, extend the reaction time for 4 hours and continue the central control. Continue to react until the average molecular weight of the hydrolyzate is lower than 1000Da and judged as qualified.

Embodiment 3

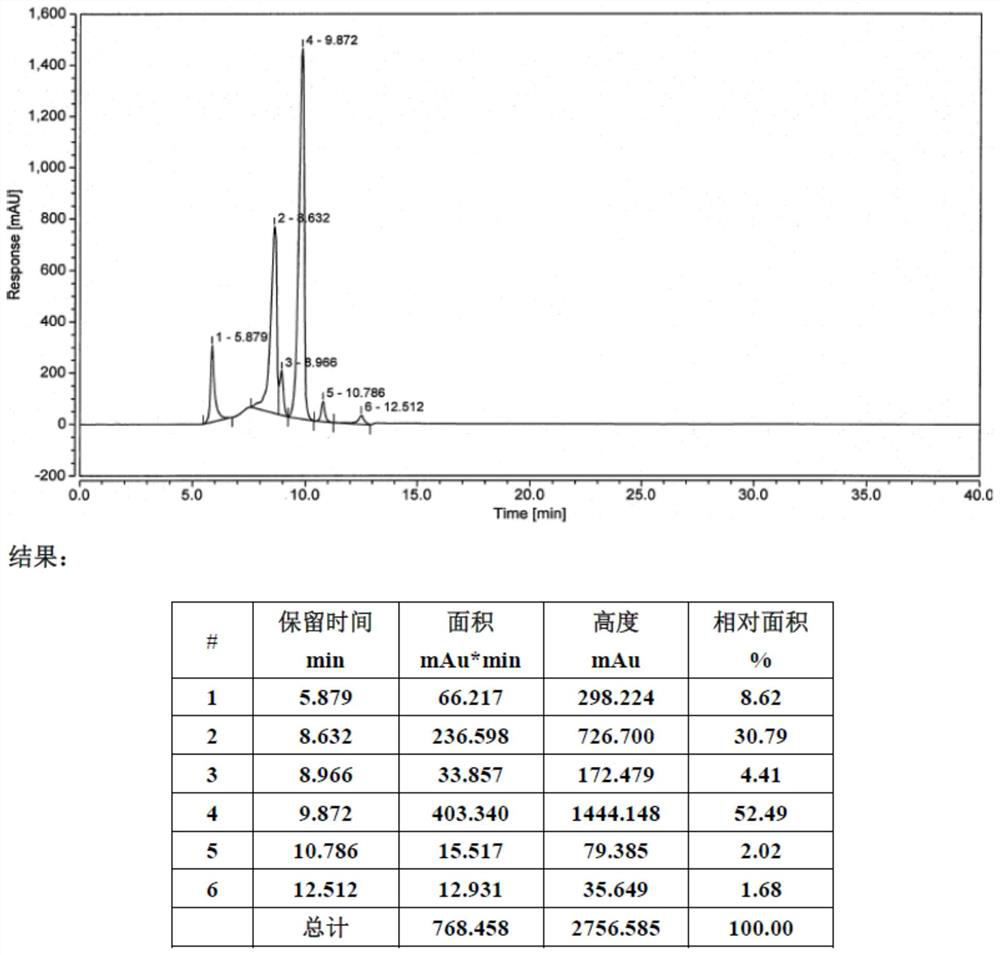

[0058] Embodiment 3 enzymolysis reaction

[0059] In a 5L glass beaker, add 2L of purified water, control the stirring speed to 100rpm, add 200g of shark bone chondroitin sulfate, after it is completely dissolved, use sodium hydroxide solution to adjust the pH to 8.0, add 100U / L of chondroitin sulfate lyase, Keep the system at 25°C and stir for reaction, react for 6 hours to check whether the average molecular weight is lower than 1000Da, if the reaction is not complete, extend the reaction time for 4 hours and continue the central control. Continue to react until the average molecular weight of the hydrolyzate is lower than 1000Da and judged as qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com