Patents

Literature

60results about How to "High bacterial count" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing yeast culture by taking hulled spirit distilled grains as raw material

ActiveCN103549116AReduce crude fiber contentHigh nutritional valueFood processingAnimal feeding stuffYeastNutritive values

The invention discloses a process for preparing a yeast culture by taking hulled spirit distilled grains as a raw material. The process comprises the following steps: hulling the spirit distilled grains; preparing materials; activating a strain; inoculating and mixing; controlling temperature to ferment; performing enzymolysis and wall breaking, and the like. The hulls are separated by using a mechanical method, so that the coarse fiber content of the yeast culture product is reduced, and the nutritive value and the application range of the product are improved. The hulls which are separated from the spirit distilled grains can be used as a boiler fuel after being mixed with coal to provide a heat source for drying the product, so that the drying cost is reduced, comprehensive utilization is realized, and no pollution is caused. The coarse fiber content of the product is over 50 percent less than the coarse fiber contents of the conventional spirit distilled grains and similar products, the situation that the conventional spirit distilled grain product is only suitable for ruminating animals is solved, the application range of the product is expanded, and the development of the market is facilitated.

Owner:江苏益元泰生物技术有限公司

Active microbial agent for deodorizing livestock and poultry feces and preparation method thereof

InactiveCN105624072AImprove processing speedIncrease profitFungiBio-organic fraction processingMicrobial agentAnimal feces

The invention discloses an active microbial agent for deodorizing livestock and poultry feces. The active microbial agent comprises six types of strains, namely bacillus subtilis, bacillus cereus, arthrobacterium, streptomycete, saccharomycetes and lactic streptococci. The invention further discloses a preparation method of the active microbial agent for deodorizing livestock and poultry feces. The active microbial agent for deodorizing livestock and poultry feces and the preparation method thereof utilize synergism of the six types of feces degrading bacteria or deodorization bacteria and have the advantages of being novel in strain combination, stable in structure, great in enzyme activity, large in bacteria number and the like, meanwhile, the problems that in traditional compost treatment of livestock and poultry feces, feces-urine separation is required, feces degradation is low in speed, and the deodorizing effect is not obvious are solved, and the livestock and poultry feces treatment speed and utilization rate are raised.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Corn straw fermentation microorganism agent and preparation method and fermentation method thereof

ActiveCN103642726AReasonable formulaEasy to useBio-organic fraction processingFungiBacillus licheniformisBiotechnology

The invention discloses a corn straw fermentation microorganism agent which consists of phanerochaete chrysosporium, trichoderma koningii, bacillus subtilis, bacillus licheniformis and monilia tropicalis. The corn straw fermentation microorganism agent disclosed by the invention has the beneficial effects that the microorganism agent is reasonable in formula and convenient to use; the straw rotting speed is high; the corn straw fermentation microorganism agent has the characteristics of new combination, stable structure, high enzyme activity, high microbial content and the like. The corn straw fermentation microorganism agent can be used for performing high-efficiency and environment-friendly fermentation on corn straw materials, so that a feed can contain a large amount of microorganism live cells, clastic enzymes and other active components, and the utilization rate of the corn straw materials can be effectively increased. The practical significance of solving the problem of environment pollution is achieved; furthermore, the actual application values such as the protein content and the nutritional value in the corn straw materials can be improved; good preconditions are created for recycling application of corn straws.

Owner:TIANJIN OCEAN PAL CAROL BIOTECH

Bacillus licheniformis and method for producing alkali proteinase with sewage sludge as raw material

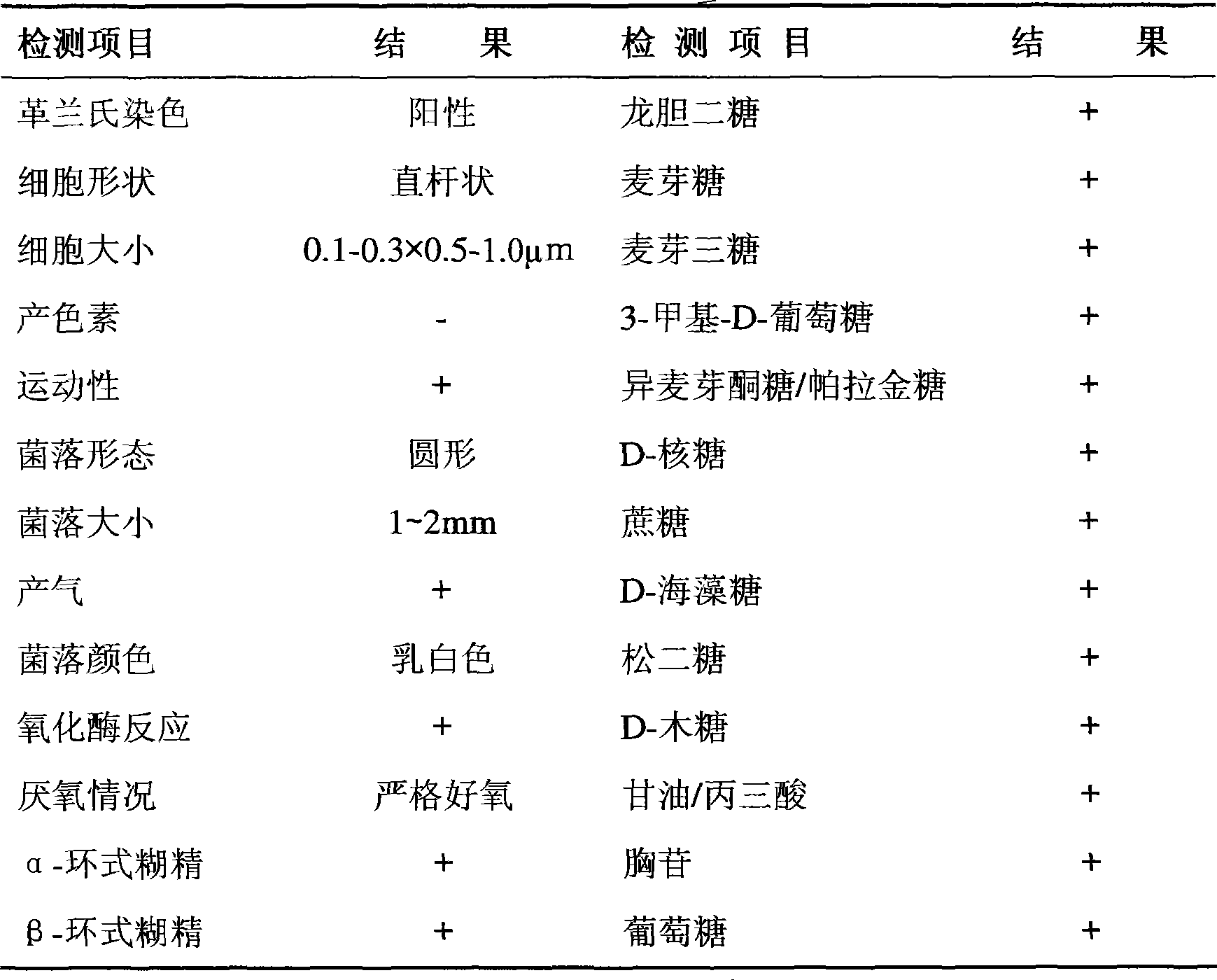

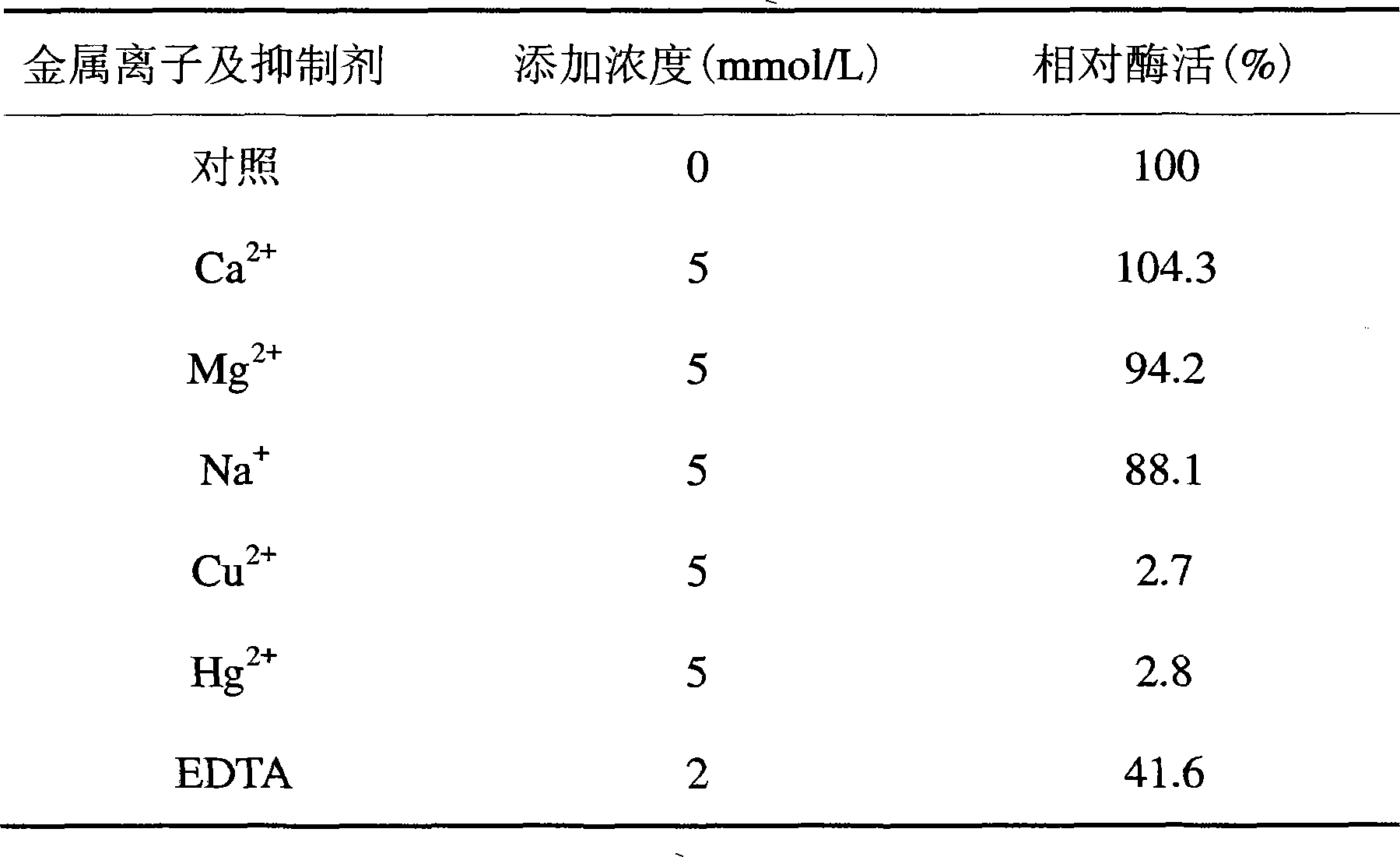

ActiveCN101245327AImprove enzyme production efficiencySuitable for growth and proliferationBacteriaMicroorganism based processesBacillus licheniformisProtease preparation

The invention discloses a bacillus licheniformis and a method for utilizing the sludge as raw material for producing alkaline protease. The bacillus licheniformis is gram-positive bacteria and is shaped like a straight rod, and the collection number is CGMCC 1970. The method for utilizing the bacillus licheniformis for producing the alkaline protease includes (1) the conditioning of a culture medium; (2) shaking culture; (3) the fermentation by a fermentation tank; and (4) the purification of the protease. The bacterial strain of the invention is utilized for producing the alkaline protease, which can not only dispose sludge, but also obtain the alkaline protease product with high additional value and lower cost. The method uses urban waste sludge to replace the traditional food culture medium for producing the alkaline protease product, which not only provides a new way for the resource disposal of urban sludge, but also can greatly reduce the price of the product and promote the industrial production and application of protease preparations.

Owner:山西卓奇水务有限公司

Microorganism-containing fertilizer produced by mycoderm method and production method of fertilizer

The invention provides to a microorganism-containing fertilizer produced by a mycoderm method and a production method of the fertilizer. In the prior art, microorganism bactericides, organic matters, chemical fertilizer and the like are mixed according to a preset formula, and the mixture is subjected to granulation, high-temperature drying, screen separation, cooling and the like so as to produce a finished product. In the production method provided by the invention, the fertilizer without bactericides is granulated, dried, screened and cooled; active bacterium powder is coated on the outer surface of the fertilizer particles at the tail end of the production line by using a film technology; and the microbial content of the whole fertilizer when in detection reaches the technical standard of national regulation so that a film fertilizer is formed. The method provided by the invention is used for producing the fertilizer with active bacterium.

Owner:杨庆理

Production method of straw and stalk microbial fermented feed

InactiveCN1460423AReduce the numberEasy to operateWaste water treatment from animal husbandryAnimal feeding stuffBiotechnologyMicroorganism

The present invention utilizes the crop waste material straw and stalk as raw material and adopts the bacillus, photosynthetic bacterium, microzyme, Aspergillus oryzae and seed liquor of basidiomycetes as beneficial microbial pool, and makes inoculation at room temp. to make the straw and stalk undergo the process of solid fermentation so as to obtain microbial fermented feed.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Method for producing microbial fermentation wet feed by utilizing beer yeast paste

The invention discloses a method for producing microbial fermentation wet feed by utilizing beer yeast paste. Bean pulp, corn slurry dry powder, corn germ meal, wheat bran and rice bran serve as solid fermentation raw materials, live yeast in the beer yeast paste serves as a main strain, bacillus subtilis, bacillus licheniformis, lactobacillus acidophilus and lactobacillus plantarum serve as auxiliary strains, and the microbial fermentation wet feed is produced. Beer yeast paste seed solution and seed solution of four bacteria are mixed and added into the solid fermentation raw materials, fully stirred and placed in an anaerobic container to be contained and fermented or placed on a fermentation bed to be stacked and fermented; through the fermentation process for 96-120 h, the mixture directly serves as feed or is dried at a low temperature of 60 DEG C and then smashed to 60 meshes through a pulverizer, and the microbial fermentation wet feed produced by utilizing the beer yeast paste is obtained. The produced microbial fermentation wet feed is simple in production process and low in cost, saves energy, is environmentally friendly and good in product quality, and obviously promotes growth of bred animals.

Owner:SHENYANG BOSHAN YINGSHENG BIOLOGICAL TECH CO LTD

Method of producing edible immobilized active probiotics

ActiveCN101691568AElevated bacterial countFor long-term storageImmobilised enzymesMetabolism disorderCarrier solutionProbiotic

The invention discloses a method of producing edible immobilized active probiotics, comprising the following steps: adding one kind of or various kinds of mature probiotics strains to immobilized carrier solution which is suitable for the growth and the propagation of the probiotics strains according to a certain proportion; adding dropwise the immobilized carrier solution which comprises one kind of or various kinds of probiotics strains into immobilized solution, or adding the immobilized solution to immobilized carrier to solidify the immobilized carrier. The solidified immobilized carrier which comprises one kind of or various kinds of probiotics strains is washed by sterile water and then is sealed to be cultured for 8-72 hours at 10-45 DEG C. The produced immobilized probiotics do not need to be separated and frozen to dry, can be taken directly as probiotics and can be put in other food to take. If being sealed to store at normal temperature for a long time, the immobilized probiotics can grow without stop.

Owner:哈尔滨美华生物技术股份有限公司

Preparation method of micro-storage straw feed

InactiveCN103070286AImproves nutritional value and digestibilityPromote activitiesFood processingAnimal feeding stuffEffective microorganismChemistry

Owner:武汉市绿丹茂科技股份有限公司

Production method of bacillus subtilis biological agent used for sodium humate-containing feed in medium

ActiveCN103184174AChoose appropriateNew technologyBacteriaAnimal feeding stuffBacterial strainFermentation

The invention relates to a microbe biological agent, and concretely relates to a production method of a bacillus subtilis biological agent used for a sodium humate-containing feed in a medium. The bacillus subtilis bacterial strain is subjected to first-stage solid seed culture and second-stage liquid seed fermentation culture to obtain a bacterial classification liquid. The bacterial classification liquid is inoculated in the medium which takes glucose, sodium humate, soybean meal, corn and wheat bran as raw materials for three-stage solid aerobic fermentation, the culture condition is adjusted to form spore, the spore can be treated, dried, and crushed to produce the bacillus subtilis biological agent. The biological agent contains more than or equal to 200 hundreds million / g of acillus subtilis, the pH value is 5.6-6.6, the moisture is less than or equal to 10%, and the granularity is greater than or equal to 100 meshes, the color presents special shallow grey or grey black, and the shelf life is 18 months. The biological agent can be taken as an additive application in aquatic product, and livestock and poultry culture, can increase the production performance and improve the culture environment.

Owner:SHENYANG BOSHAN YINGSHENG BIOLOGICAL TECH CO LTD

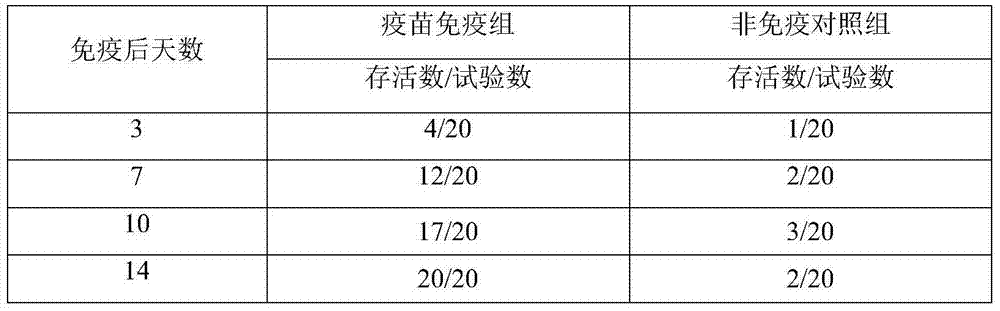

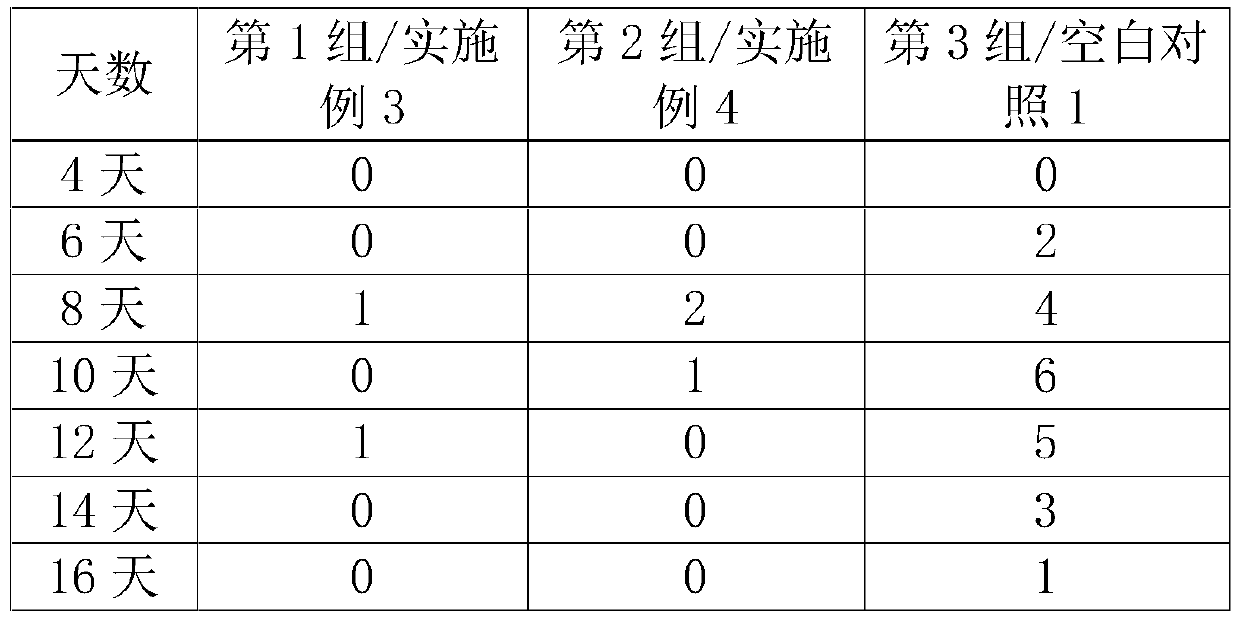

Salmonella pullorum SP9905 and application thereof

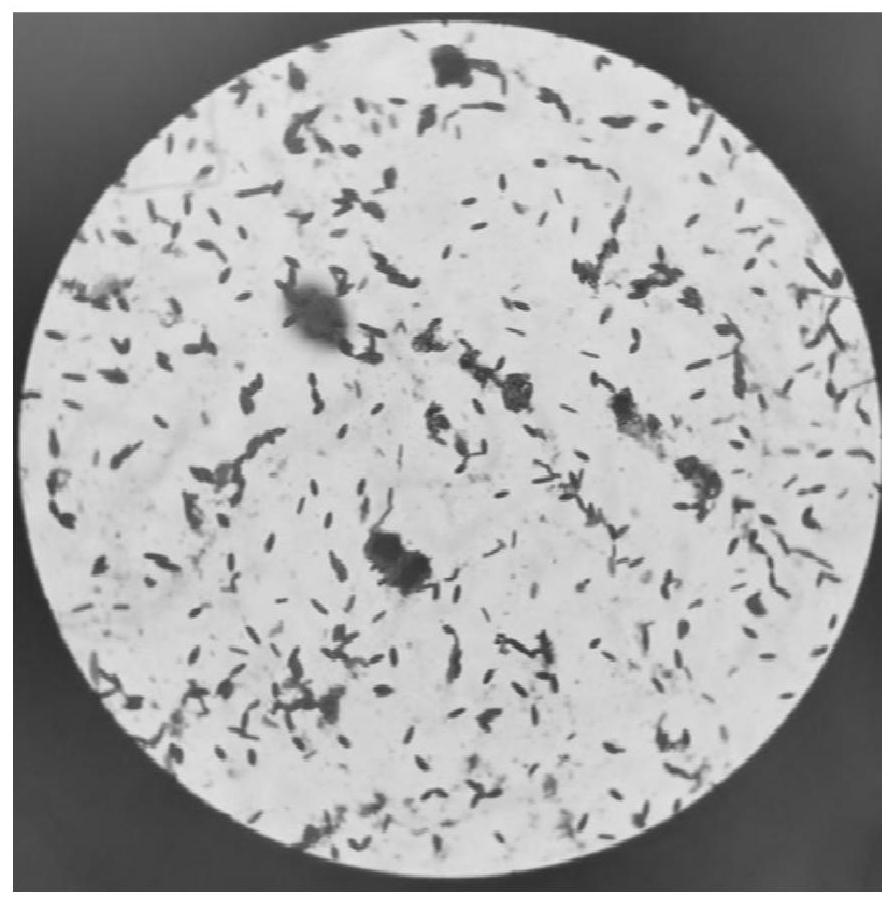

ActiveCN104774791AHigh bacterial countFreeze-drying has a low mortality rateAntibacterial agentsBacteriaSalmonella GallinarumFreeze-drying

The invention discloses a salmonella pullorum SP9905. The strain is preserved at China Center for Type Culture Collection with an address of Wuhan University on October 15, 2014 and the preservation number is CCTCC NO.M 2014478. The invention also discloses an application of the salmonella pullorum in preparation of a live vaccine. The vaccine provided by using salmonella pullorum SP9905 has the advantages of high viable count and low freeze-drying death rate; the product is safe and reliable; a strong protecting force can be generated in the fourteenth day due to an immune protection effect, the immune protective rate is 100% and a good protective capability (80-100%) can be obtained for the other serotype salmonella (salmonella enteritidis and salmonella gallinarum).

Owner:JIANGSU INST OF POULTRY SCI

Feed additive capable of enhancing production capacity and anti-disease capacities of animals

InactiveCN101595945AHigh purityHigh purity high purityAnimal feeding stuffAccessory food factorsAnimal scienceSide effect

A feed additive capable of enhancing the production capacity and the anti-disease capacities of animals relates to the feeds which prevent diseases of animals, in particular to the feed additive capable of enhancing the production capacity and the anti-disease capacities of animals and a preparation method thereof. The feed additive is prepared by mixing the following raw materials based on parts by weight: 1-5 of bacillus coagulans and 30-50 of grifola frondosa polysaccharide. The feed additive is characterized by reasonable mixing of various active ingredients, wide sources of raw materials and simple preparation process, and can safely and effectively prevent frequent infectious diseases and syndromes of the diseases of animals. The feed additive is environment-friendly, leaves no drug residues during use, has no toxic side effect, has little irritation on organisms, is uneasy to have drug resistance, accords with the idea of being green and healthy and completely solves the trouble of export restriction. The feed additive features high cure rate, low production cost and broad application range.

Owner:涂晓华

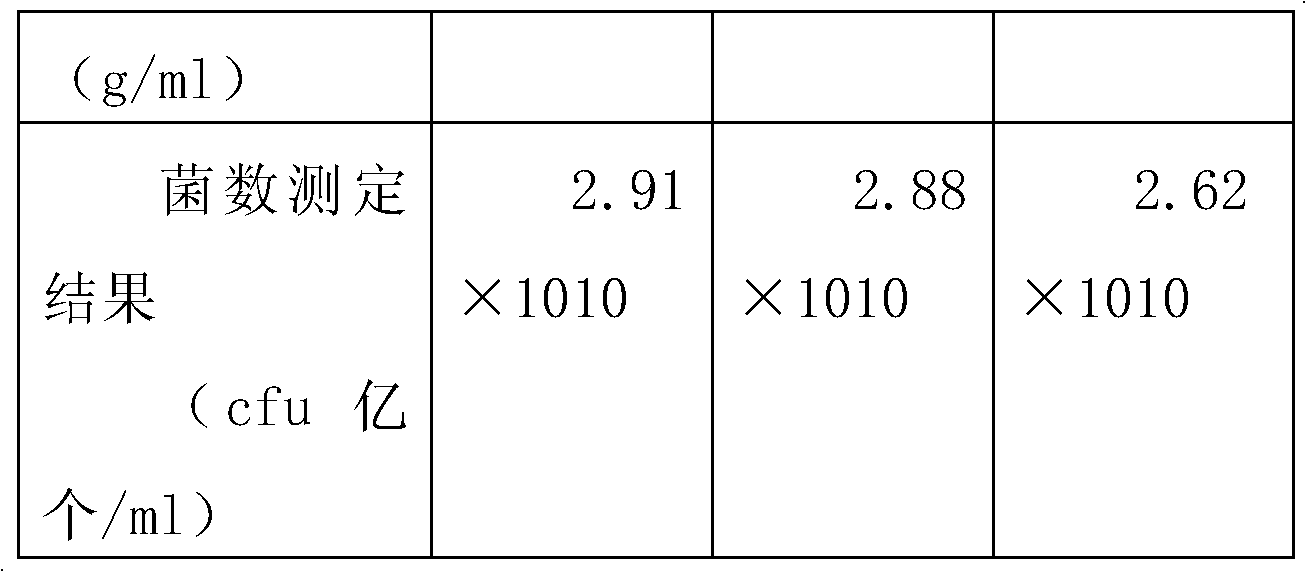

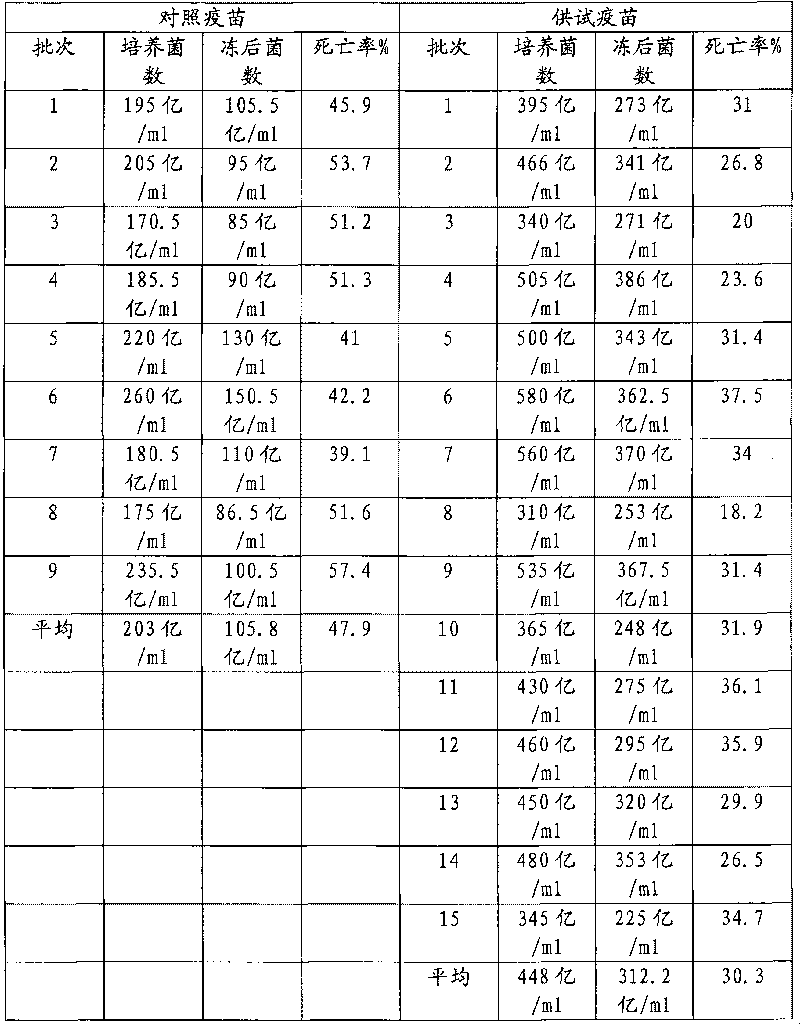

Method for preparing living paratyphoid vaccine for piglets and product thereof

ActiveCN101732706AReduce the number of bacteriaHigh bacterial countAntibacterial agentsAntibody medical ingredientsSucroseFreeze-drying

The invention discloses a method for producing living paratyphoid vaccine for piglets and a product thereof. The method comprises the following steps: (1) preparing primary strains; (2) preparing secondary strains; and (3) culturing bacterial liquid: inoculating the secondary strains into a culture medium for culturing, after culturing, immediately adding a stabilizing agent which is sterilized and preheated to 37 DEG C to ensure that the vaccine contains 1.5 percent of gelatin and 5 percent of sucrose, and mixing uniformly to obtain the bacterial liquid, wherein the culture medium in the step (3) consists of a common broth medium and a synthetic medium in the volume ratio of 2:1. In the living paratyphoid vaccine for piglets produced by the method, the cultured bacteria count is over 50 billion per milliliter; the maximum cultured bacteria count is 58 billion per milliliter; and the freeze-drying death rate is reduced to 20-40 percent. The method for producing the living paratyphoid vaccine for the piglets has the advantages of high bacterial count of the living vaccine, low freeze-drying death rate, easy production, high yield, low production cost, and the like.

Owner:哈药集团生物疫苗有限公司

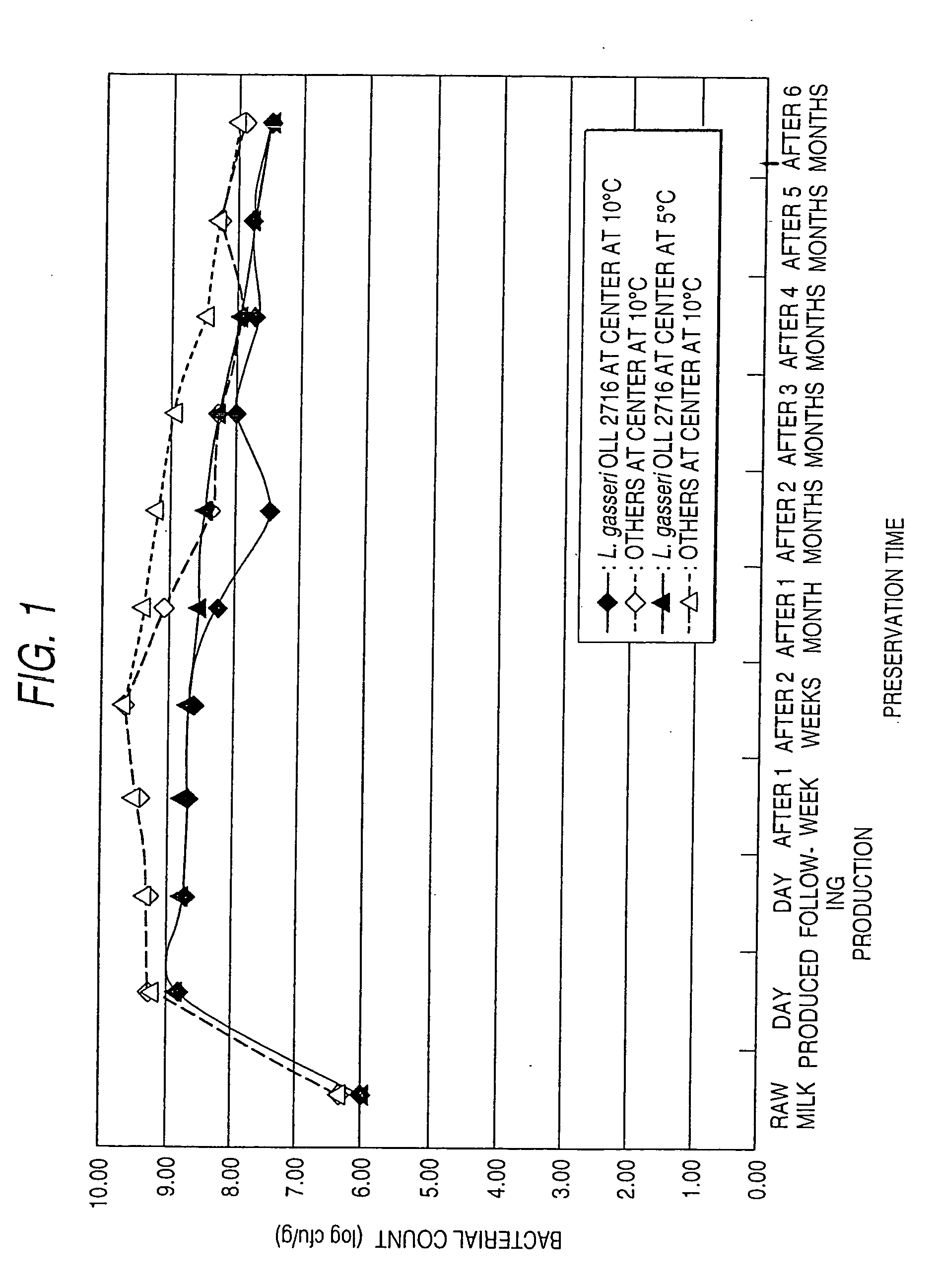

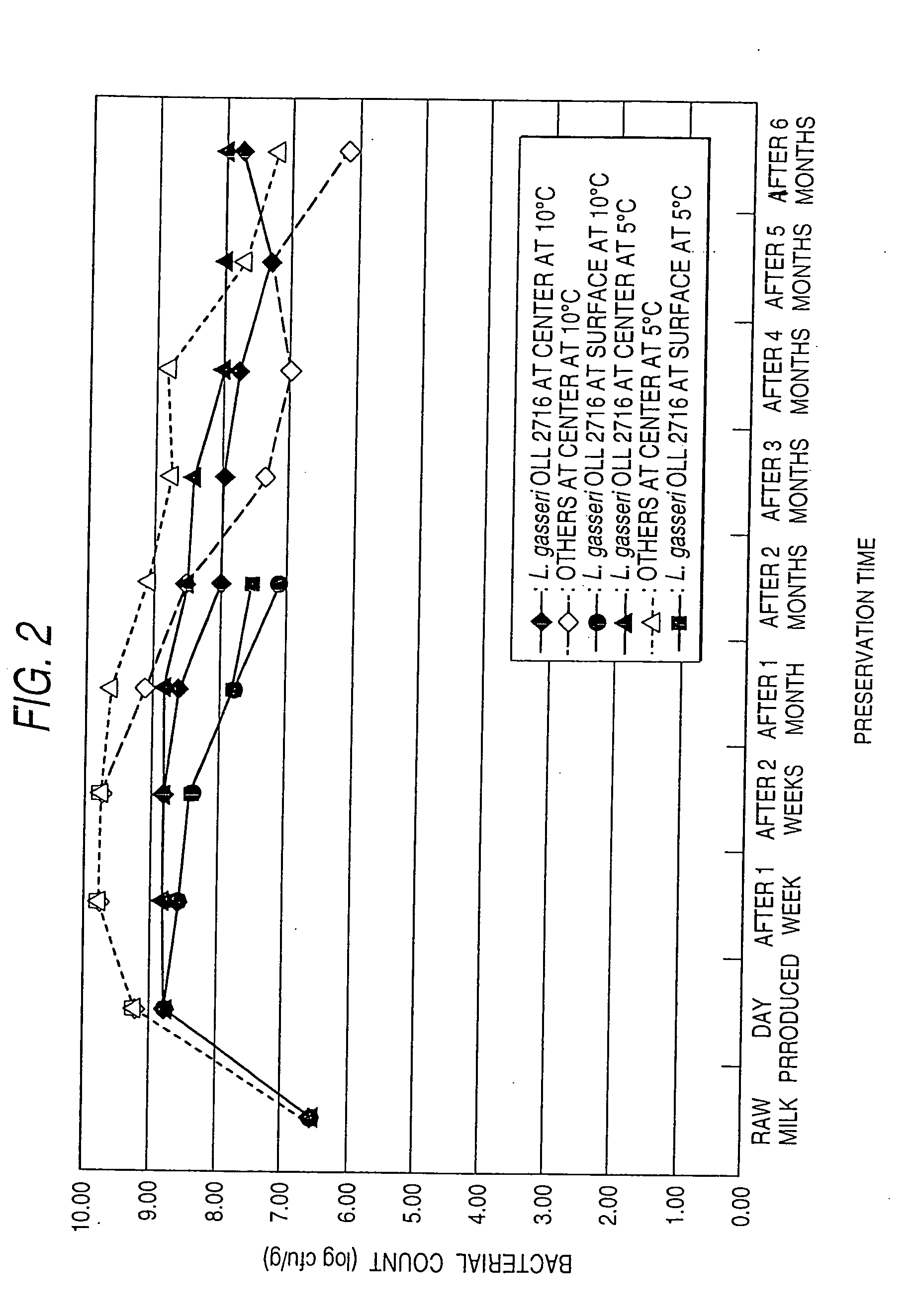

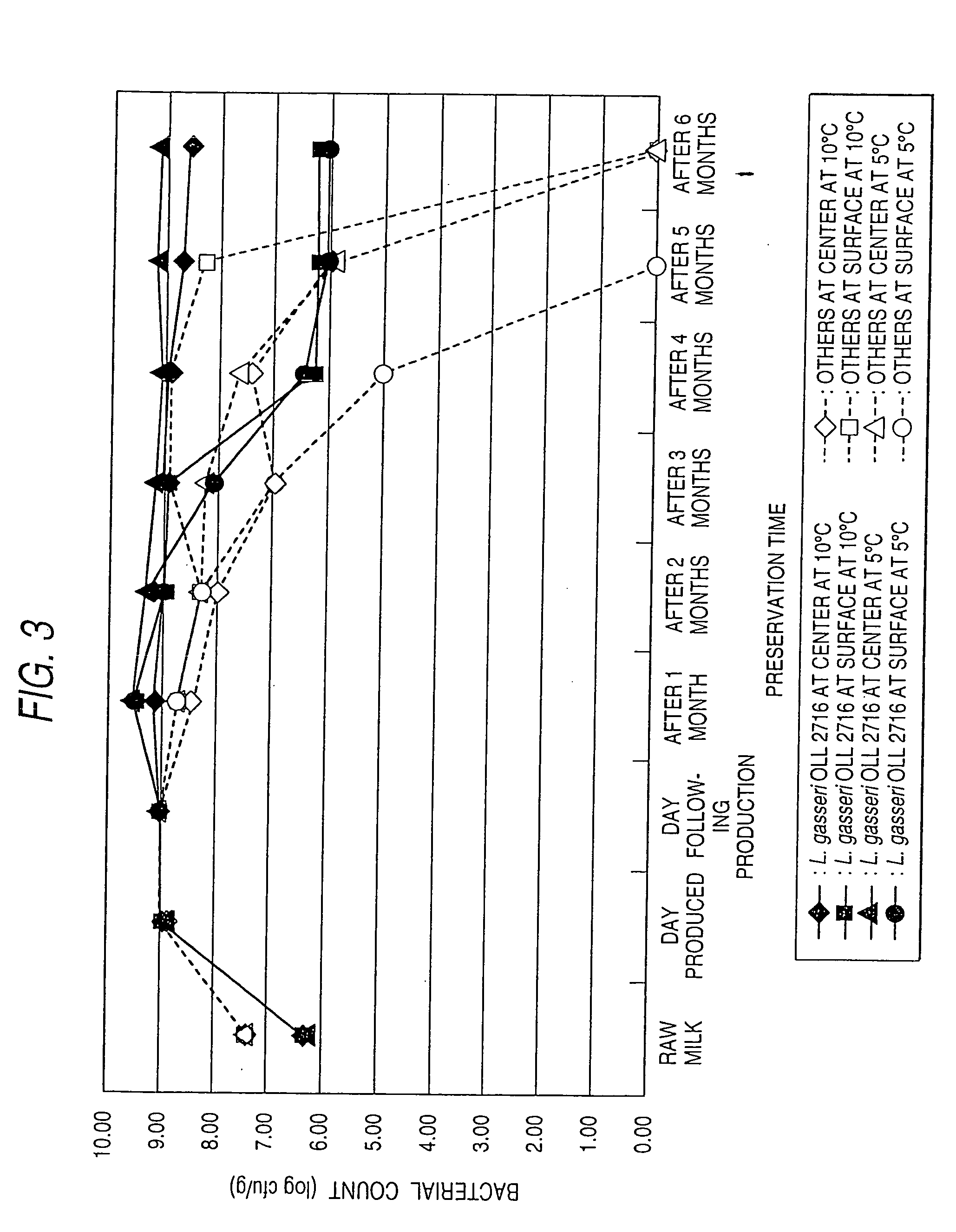

Cheese capable of disinfecting helicobacter pylori

InactiveUS20050163888A1High bacterial countAntibacterial agentsMilk preparationHelicobacter pyloriBiology

Natural cheese which comprises a lactic acid bacterium belonging to Lactobacillus gasseri having a disinfection potency against Helicobacter pylori, and a method for producing the natural cheese.

Owner:MEIJI CO LTD

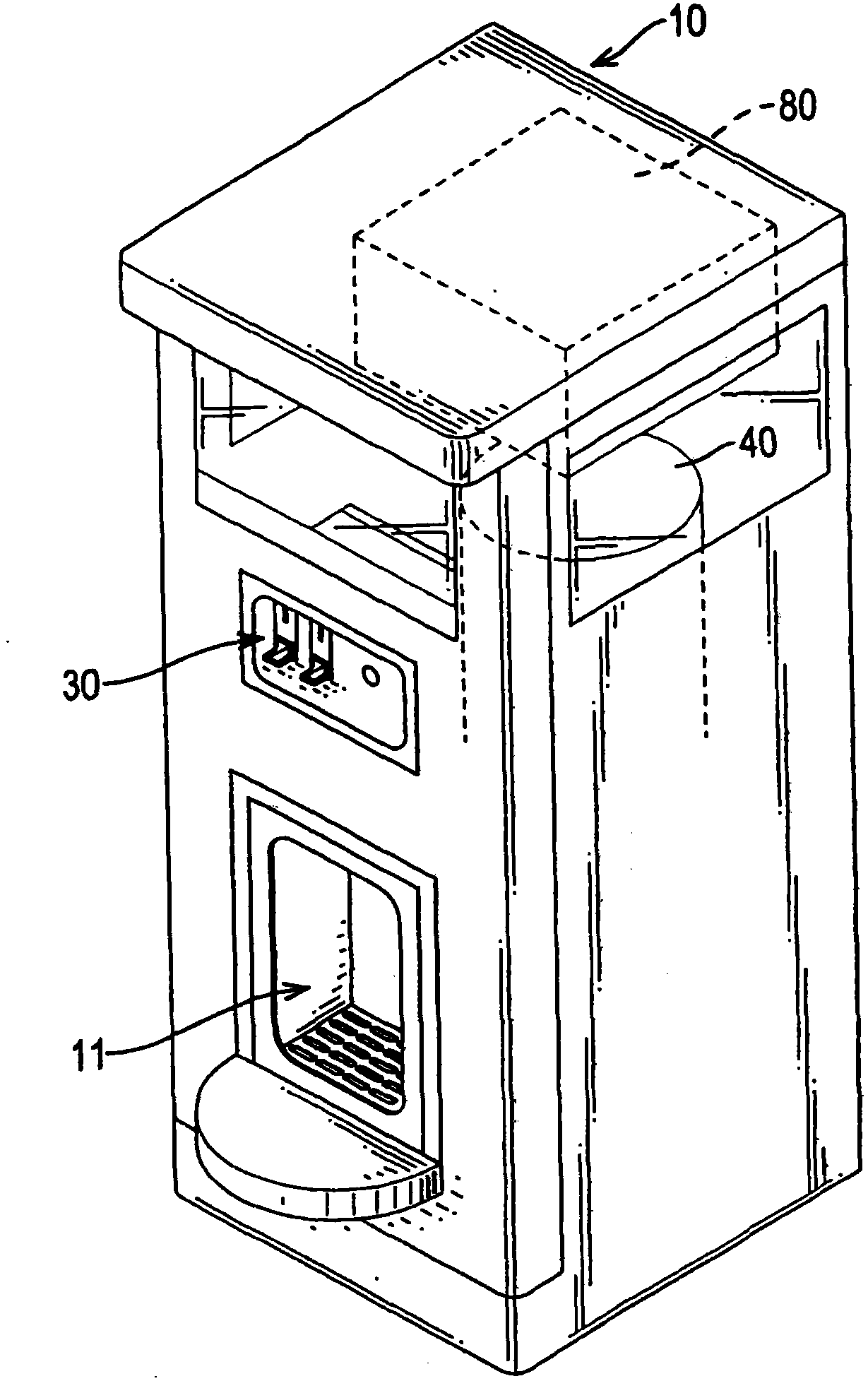

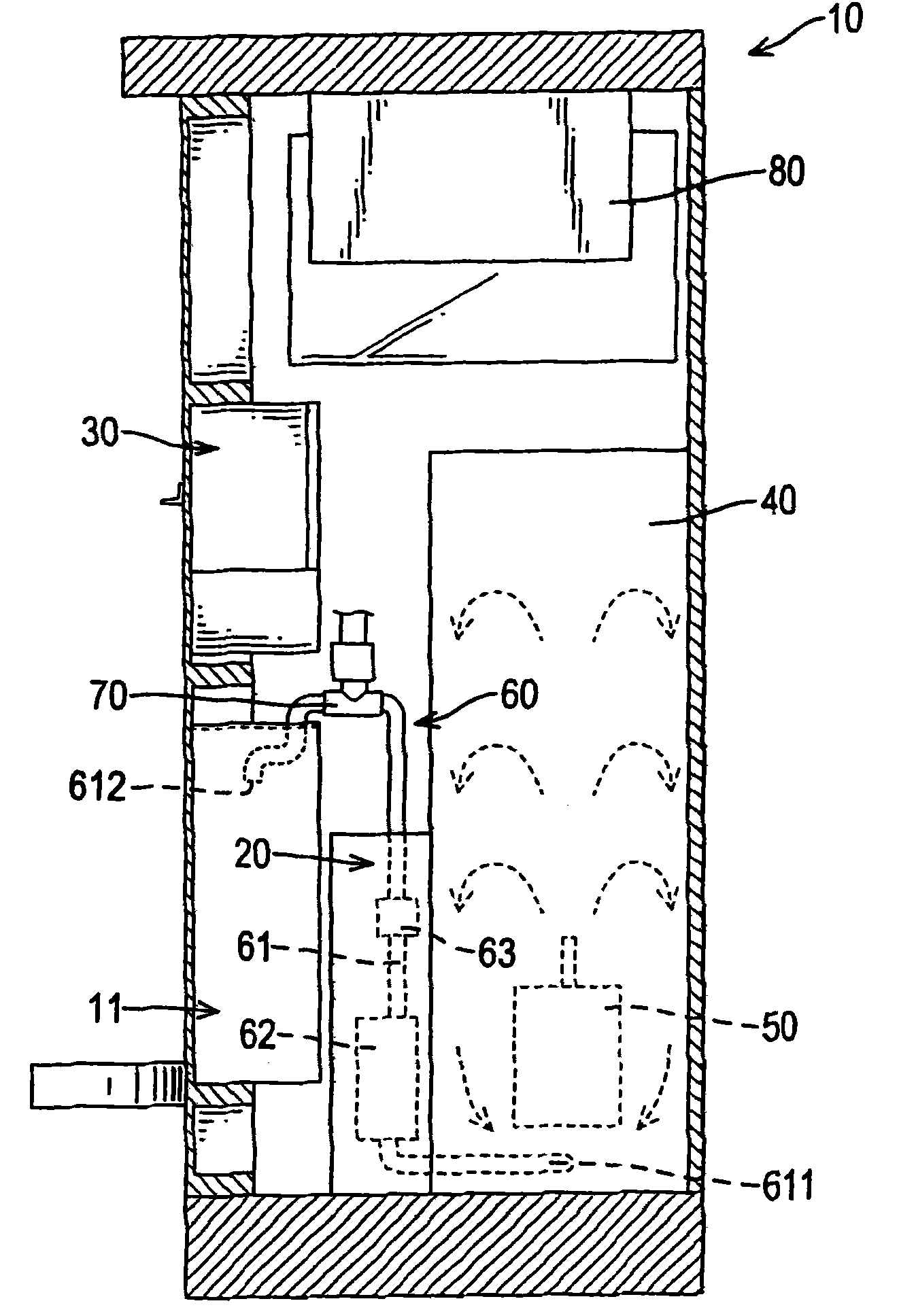

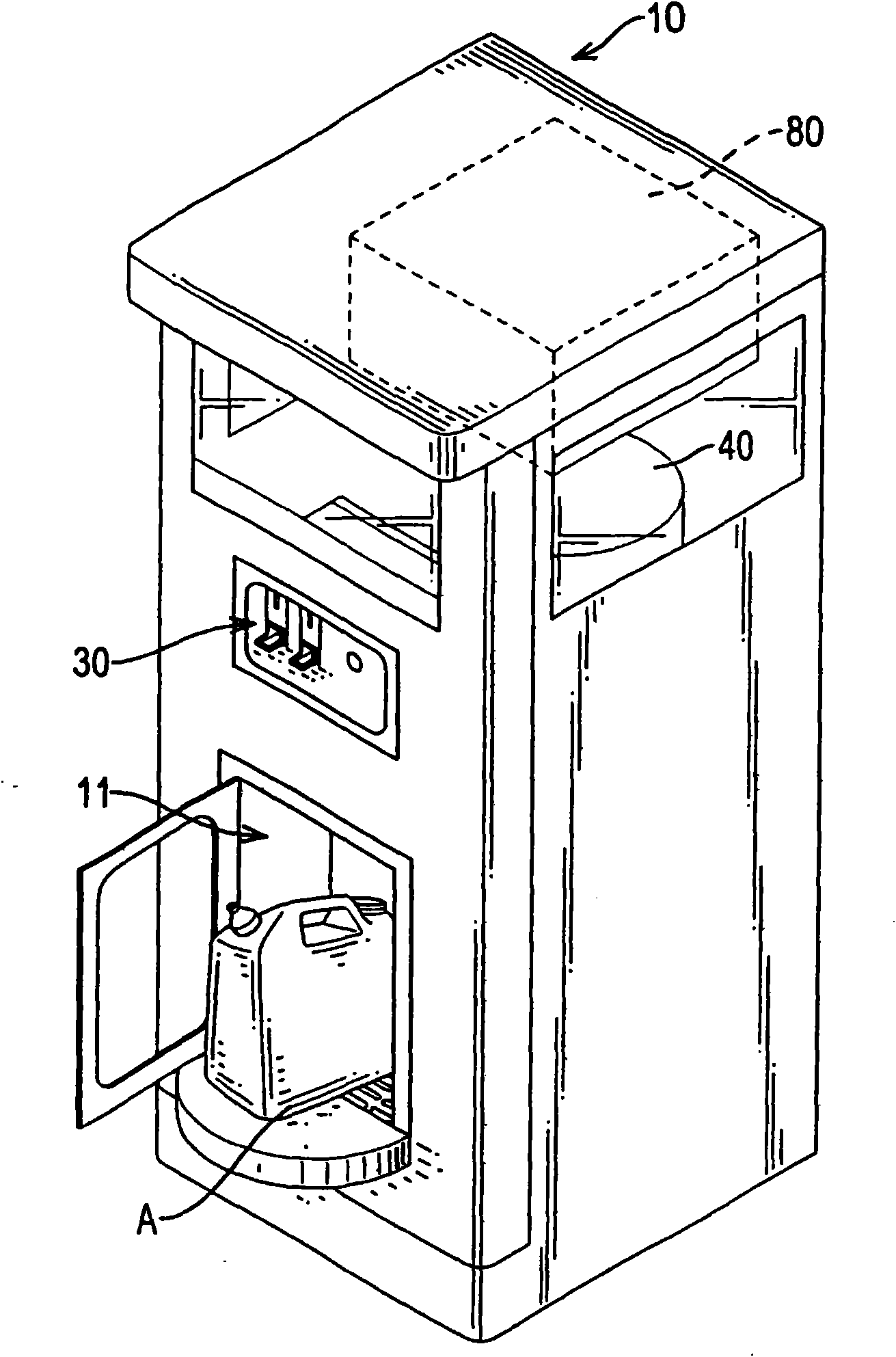

Automatic vending equipment for liquid fertilizer

InactiveCN102044113AImprove efficiencyImprove efficacyGaseous substancesApparatus for dispensing fluids/granular materialsControl unitStorage tank

Provided is automatic vending equipment for liquid fertilizer, comprising a cabinet in which are arranged a central control unit, a vending apparatus, a stock storage tank, an immersion pump and an extraction apparatus. The vending apparatus is electrically connected with the central control unit, and can accept purchase commands from users and transmit the commands to the central control unit. The stock storage tank is used to accommodate the liquid fertilizer. The immersion pump is arranged in the stock storage tank and electrically connected to the central control unit, so as to accept commands from the central control unit and drive the liquid fertilizer in the stock storage tank to circulate and convect up and down. The extraction apparatus is electrically connected with the central control unit and can accept commands from the central control unit to extract the liquid fertilizer from the stock chest storage tank.

Owner:游惠光

Preparation method of straw micro-storage feed

InactiveCN104489252APromote activitiesLarge amount of synthesisFood processingAnimal feeding stuffWater contentChemistry

The invention discloses a preparation method of a straw micro-storage feed, and is characterized in that the preparation method includes the following steps: (1) constructing a micro-storage cellar; (2) carrying out raw material pretreatment comprising sun-drying straw for 3-5 h to make the water content be 60%-70%, and cutting short into 2-3 cm; (3) preparing a fermentation agent: (4) weighing table salt according to 0.3% (weight percentage) of the straw dry basis amount, and evenly mixing into a fermentation bacterial powder; (5) laying a plastic film in the cellar, allowing the plastic film length to be 1-1.5 m higher than that the periphery of a cellar mouth; (6) sprinkling the crushed straw with the thickness of 20-30 cm at the bottom of the cellar, then sprinkling the prepared fermentation bacterial powder on the straw, and treading down with feet; and (7) allowing the micro-storage anaerobic fermentation time to be 7-8 days in summer, 10-12 days in spring and in autumn and 13-15 days in winter, checking whether the feed has a wine fragrance, and allowing for use. The nutritional value of the straw feed can be improved, and the feed has relatively high content of digestible proteins and has good palatability.

Owner:广西南宁劲能农业科技有限公司

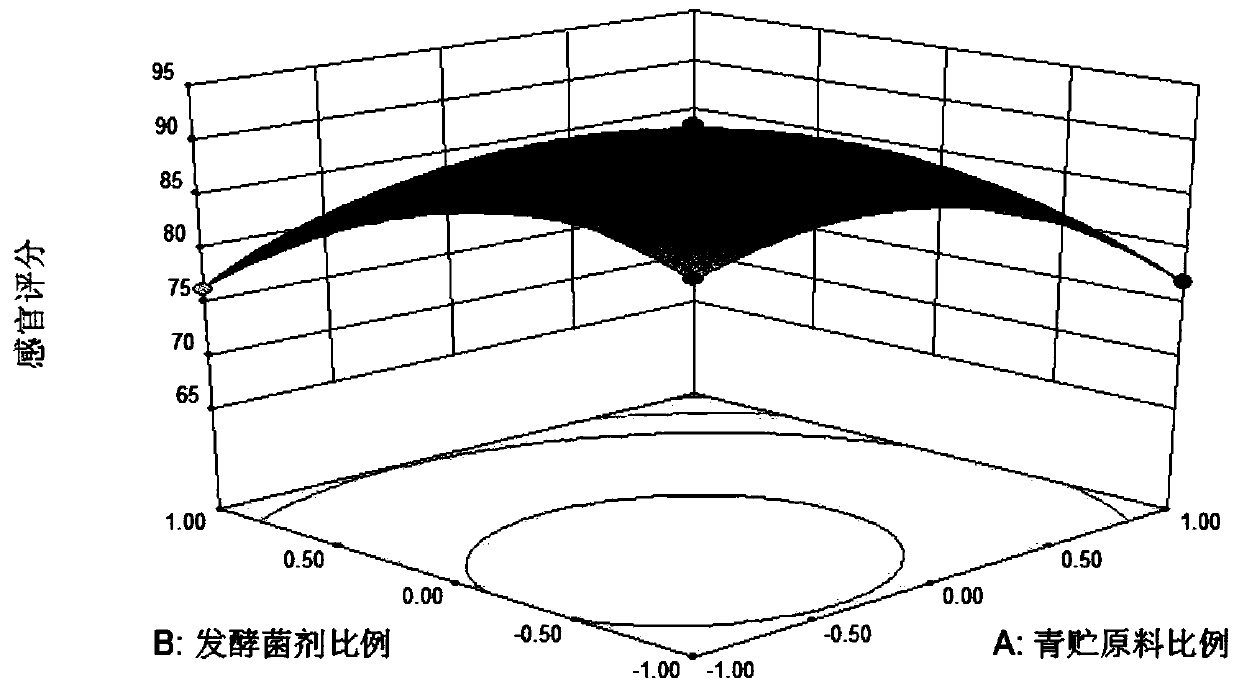

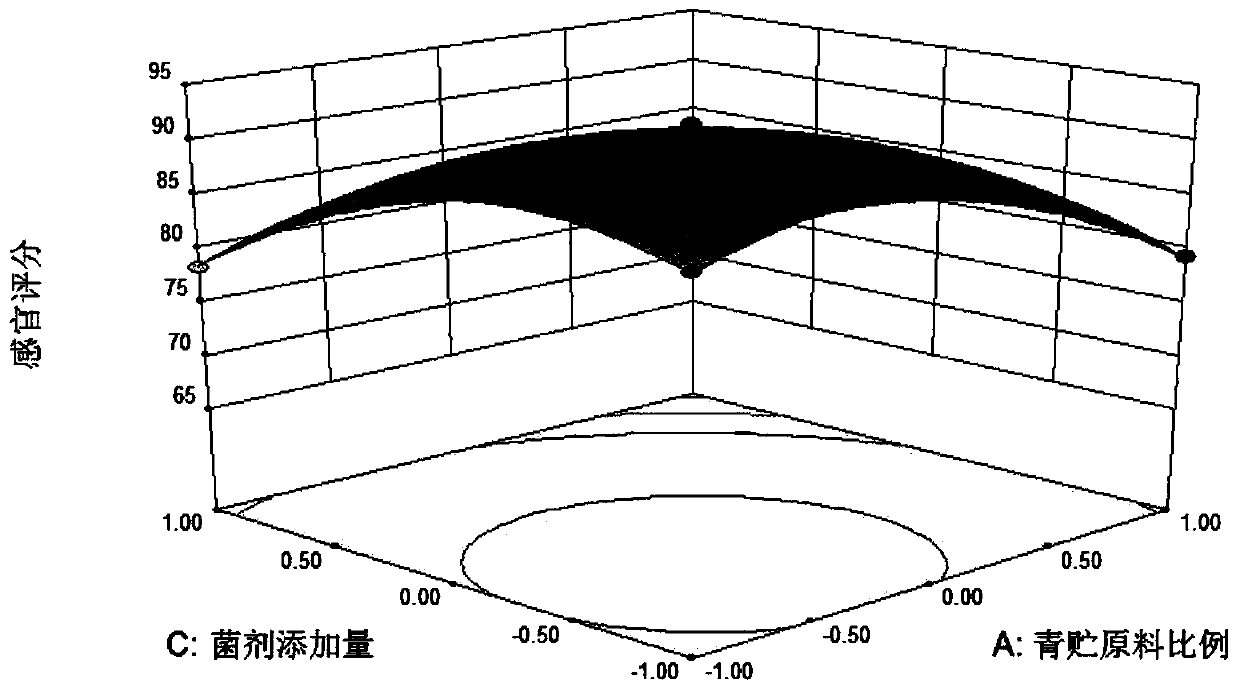

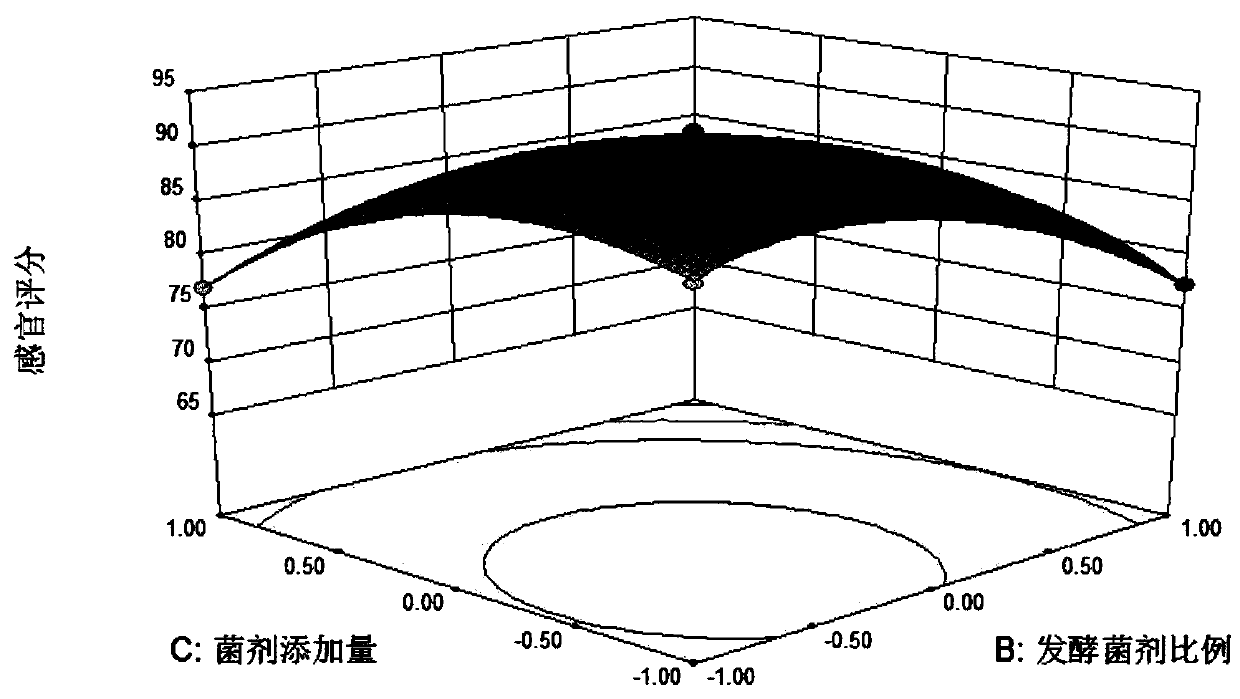

Ensiling method of feedstuff oilseed rapes

InactiveCN109997971AImprove conversion rateCombination newAnimal fodder preservationBiotechnologyCellulose

The invention discloses an ensiling method with fresh feedstuff oilseed rapes, maize straw and wheat straw as raw materials. According to the ensiling method, a compound fermentation microbial agent which is formed by combining five bacteria including candida utilis, aspergillus oryzae, enterococcus faecalis, bacillus subtilis and lactobacillus plantarum is utilized. According to the ensiling method, the five bacteria cooperatively act on the ensiling raw materials, a dominant bacterial population is quickly formed, cellulose and other macromolecule organic matter are degraded, crude protein and crude fat are effectively stored, the mouthfeel of the feedstuff is improved, and the ensiling method has outstanding technical advantages in application to feedstuff oilseed rape ensiling treatment. The ensiling method is very significant in increasing high-quality forage grass resources, reliving the situation of insufficient feedstuff supply, promoting development of area livestock husbandry, achieving targeted poverty alleviation and increasing incomes of farmers and herdsmen.

Owner:INST OF SOIL & FERTILIZER XINJIANG ACAD OF AGRI SCI

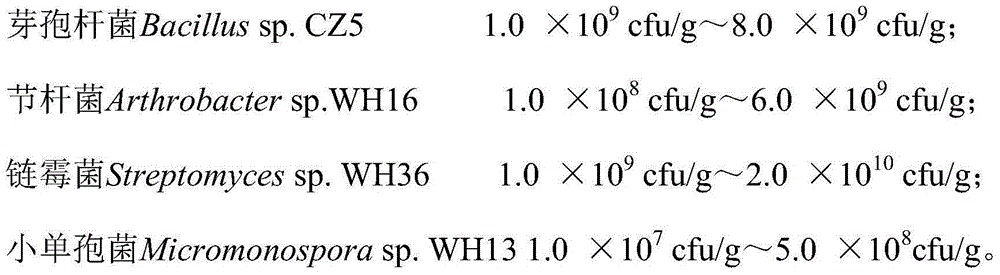

Compound bacterial agent applied to straw mulching and preparation method thereof

InactiveCN105238714ASimple methodCombination newBacteriaMicroorganism based processesMicromonospora sp.Decomposition

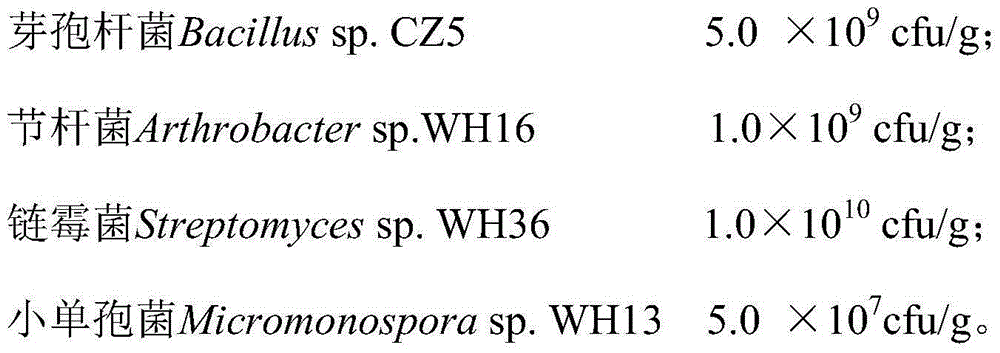

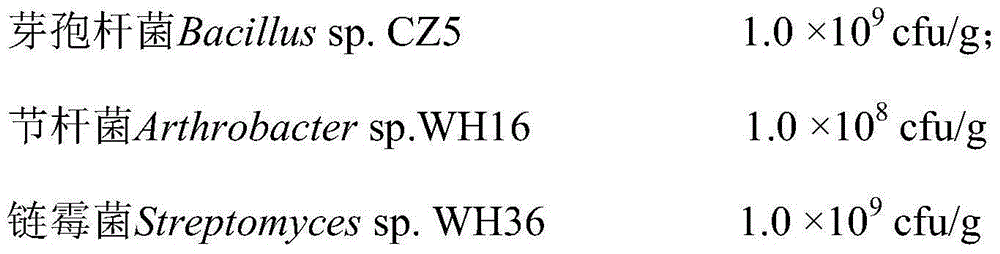

The invention discloses a compound bacterial agent applied to straw mulching. The compound bacterial agent comprises 1.0*10<9>cfu / g-8.0*10<9>cfu / g of Bacillus sp.CZ5, 1.0*10<8>cfu / g-6.0*10<9>cfu / g of Arthrobacter sp.WH16, 1.0*10<9>cfu / g-2.0*10<10>cfu / g of Streptomyces sp.WH36 and 1.0*10<7>cfu / g-5.0*10<8>cfu / g of Micromonospora sp.WH13. The invention further provides a preparation method of the compound bacterial agent applied to straw mulching. Compared with the prior art, the compound bacterial agent applied to straw mulching has the advantage that purposes of quick decomposition of straw, suppression of soil pathogens and increase of crop yield are achieved under synergistic effect of various straw degradation bacteria / biocontrol bacteria.

Owner:上海原本生物科技有限公司

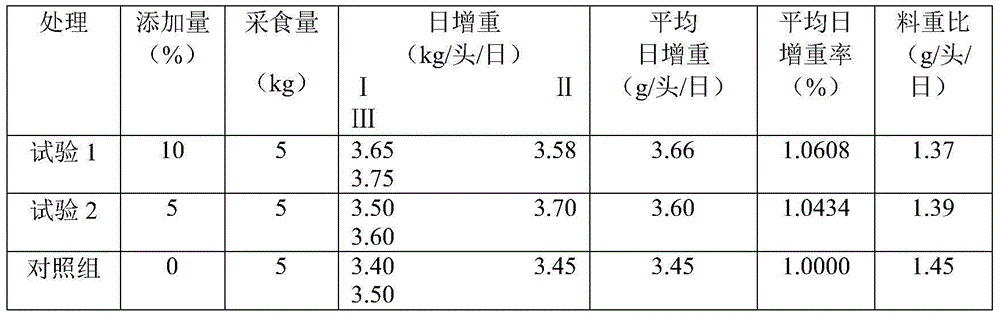

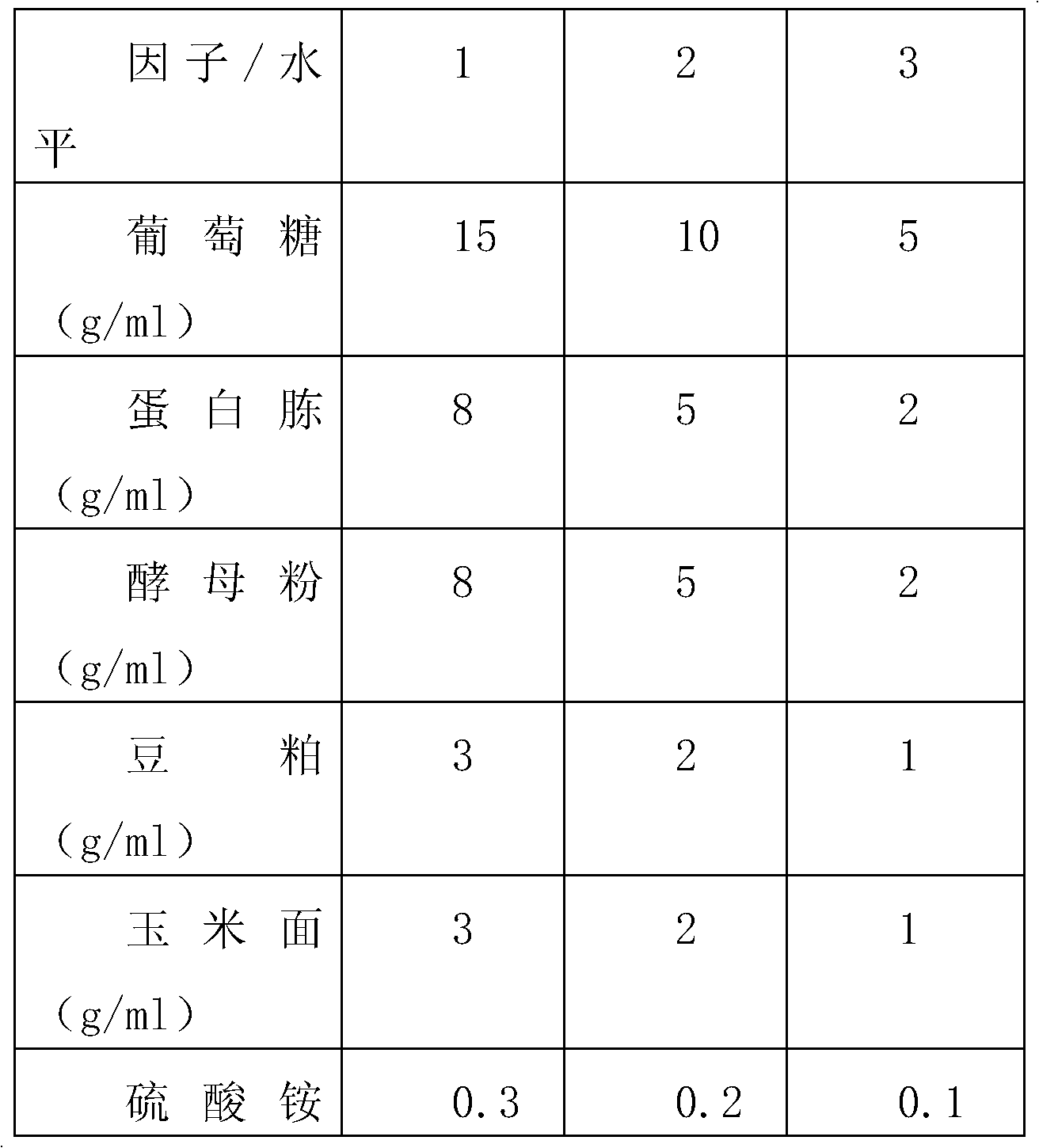

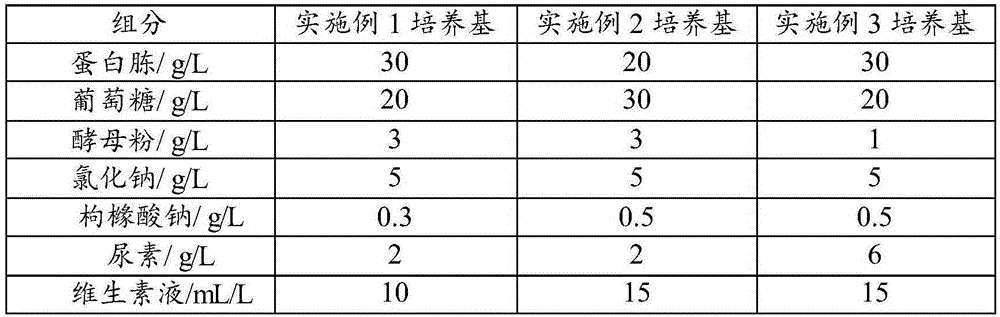

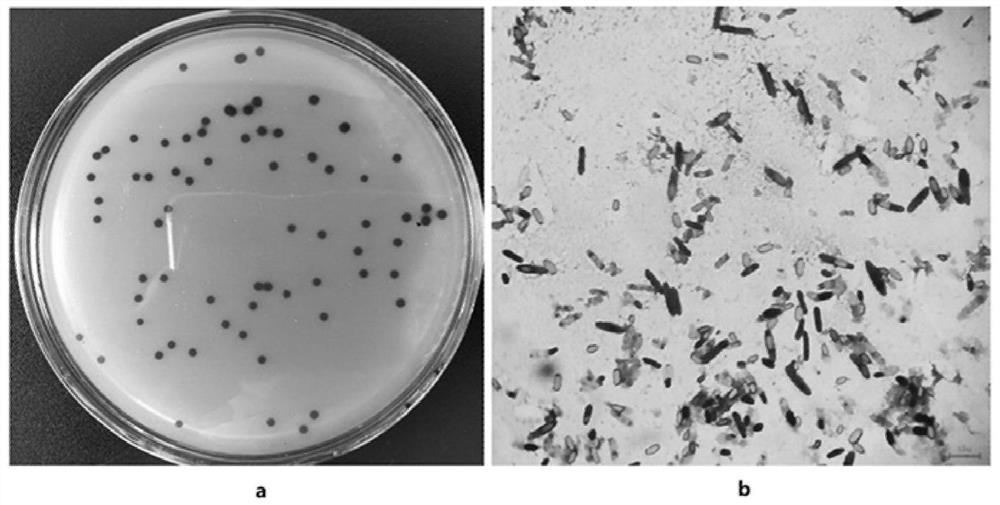

Pseudomonas aeruginosa fermentation medium, fermentation culture method thereof and vaccine preparation method

InactiveCN105420153AIncrease productionHigh viable countAntibacterial agentsBacteriaCitrate sodiumAeromonas veronii

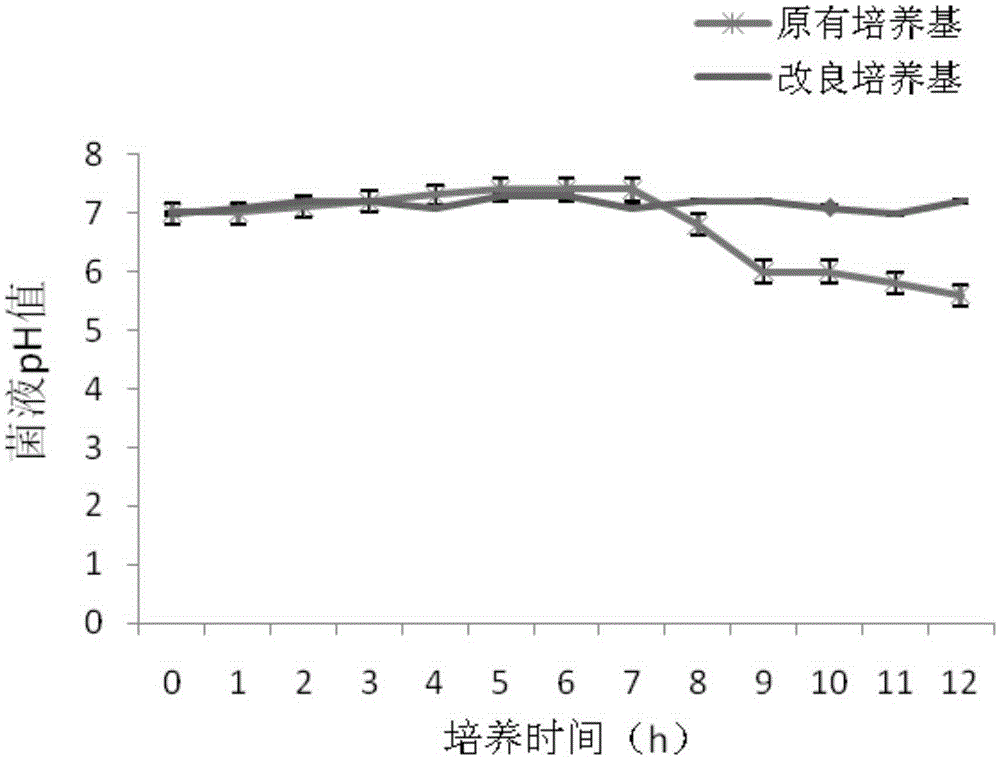

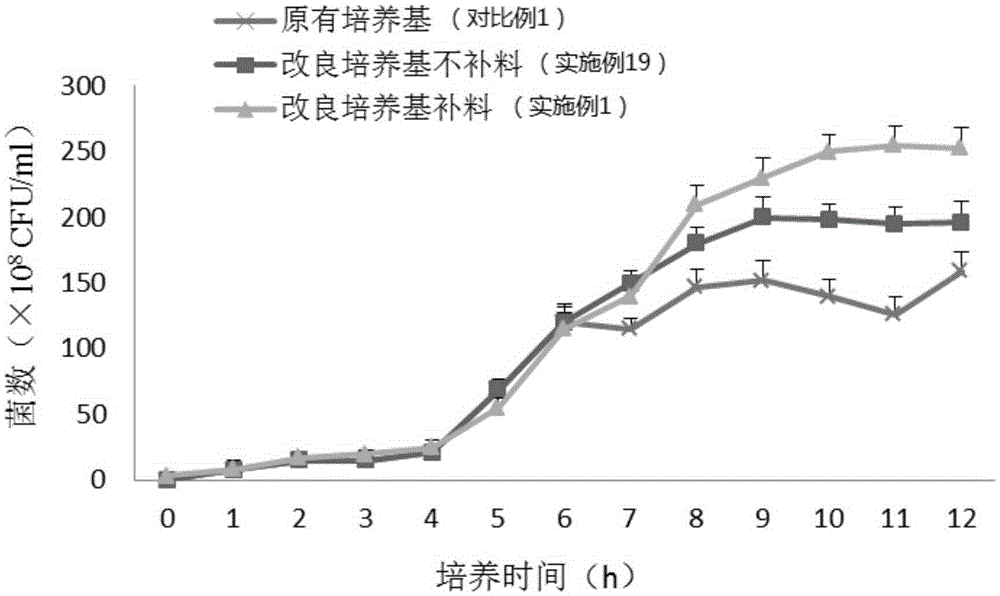

The invention relates to the technical field of fermentation culture, in particular to a pseudomonas aeruginosa fermentation medium, a fermentation culture method thereof and a vaccine preparation method. The fermentation medium comprises peptone, glucose, yeast powder, sodium chloride, Na2HPO4, KH2PO4, MgSO4, sodium citrate, urea and decavitamin B. The fermentation medium is suitable for high-density fermentation and growth of pseudomona aeruginosa, and the viable count of pseudomonas aeruginosa can be greatly increased; compared with an original traditional medium, the improved medium prolongs the logarithmic phase from 4-8 h to 4-10 h remarkably and increases the microbial content from 14-15.9 billion to 24-25 billion, the pH (potential of hydrogen) value is kept at 7.0, and the yield of pseudomonas aeruginosa is greatly increased.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Multi-stage fermentation production method for highly yielding spore clostridium butyricum

InactiveCN108531427APromote reproductionPromote the reproduction of bacteriaBacteriaMicroorganism based processesTemperature resistanceChemistry

The invention relates to the technical field of a clostridium butyricum fermentation process, in particular to a multi-stage fermentation production method for highly yielding spore clostridium butyricum. The method comprises the steps of seed liquid preparation, primary oxygen fermentation culture, secondary fermentation culture and adsorption drying, wherein glucose is supplemented in the secondary fermentation process; the temperature and the pH value are controlled in the whole process; the low-speed stirring fermentation culture is performed in the whole process; the dissolved oxygen riskis eliminated. The spore formation rate is a hundred percent; the microbial content of the clostridium butyricum of the bacterium liquid is high; the spore loss rate of the clostridium butyricum is low; the multi-stage fermentation is more favorable for the high-temperature resistance of the spores; the microbial content in the bacterium liquid is 2.5 to 3 billion / ml; the heat loss of the bacterium powder in the adsorption drying process is improved; the live spore number of clostridium butyricum in the bacterium powder is improved by 1 to 1.5 times; the microbial content in the bacterium powder reaches 0.4 to 0.5 billion / g; the live spore number and the butyrate content in the bacterium powder are improved; the product quality and the competitive power are improved; the obvious economicbenefits are realized.

Owner:ANHUI TECH BANK BIO TECH

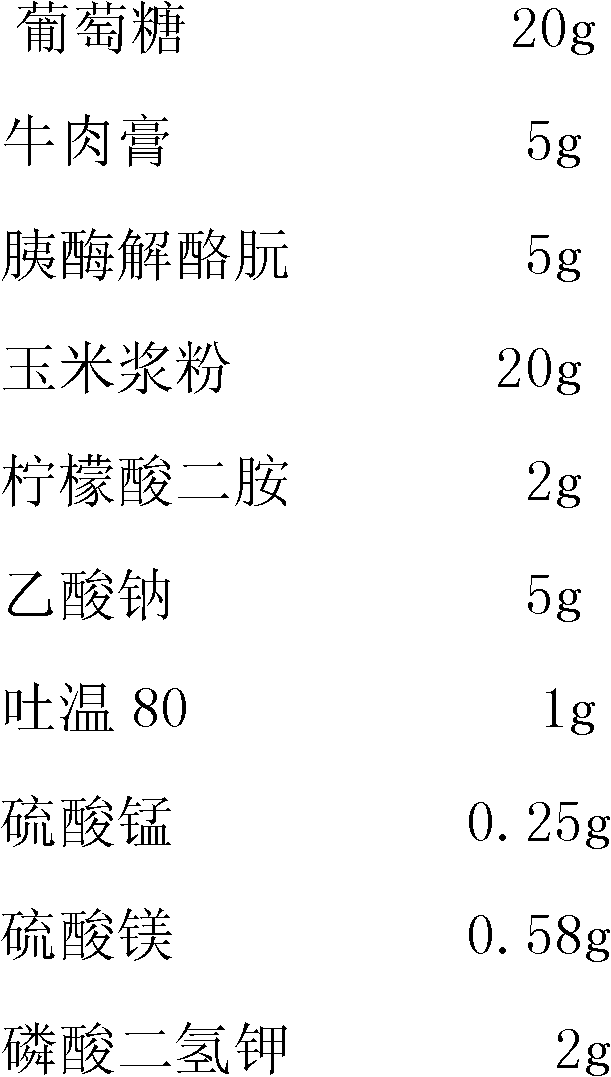

Method for high density culture of lactobacillus fermentum La-Y1, and application thereof

InactiveCN102807959ALow costHigh bacterial countBacteriaMicroorganism based processesSodium acetatePhosphate

The invention discloses a method for high density culture of a strain of lactobacillus fermentum La-Y1. The method comprises that: (1) fermentation conditions are a culture temperature of 37 DEG C, an initial pH value of 6.0, and an inoculation amount of the lactobacillus fermentum La-Y1 of 5%; and (2) fermentation medium components comprise, by weight, 2 parts of glucose, 0.5 part of beef extract, 0.5 part of casein peptone, 2 parts of corn steep powder, 0.2 part of ammonium citrate dibasic, 0.5 part of sodium acetate, 0.1 part of tween 80, 0.025 part of manganese sulfate, 0.058 part of magnesium sulfate, and 0.2 part of potassium dihydrogen phosphate. The present invention further discloses an application method of the lactobacillus fermentum La-Y1. With the present invention, the number of the lactobacillus fermentum La-Y1 in the culture medium of the present invention is relatively increased by more than 10 times compared with the number of the lactobacillus fermentum La-Y1 in a basic MRS culture medium, wherein the bacterial concentration is 3.05*10<10> cfu / mL. According to the present invention, beef extract content and casein peptone content in the culture medium of the present invention are only 0.5% so as to substantially reduce cost compared to the basic MRS culture medium, and realistic significances are provided for development of direct vat set starters.

Owner:绍兴市古煌酿酒有限公司

Disease-preventing insect-preventing environment-friendly microbial water-soluble fertilizer

PendingCN113135803AAvoid killingHigh bacterial countNitrogenous fertilisersOrganic fertilisersBiotechnologyDrip irrigation

The invention provides a disease-preventing insect-preventing environment-friendly microbial water-soluble fertilizer, and belongs to the technical field of agricultural fertilizers. The microbial water-soluble fertilizer is prepared from microbial flora, a nitrogen source, a carbon source, trace elements, sugar alcohol silicon, citric acid, compound amino acid, mineral source potassium fulvate, a coupling agent, protamine, alkaloid, tea saponin and purified water as raw materials. The obtained product is high in bacteria content, has obvious nitrogen fixation, phosphorus dissolving, potassium dissolving, growth promotion and effects, can provide nutrition for plants and improve soil, and also can prevent diseases and insects. The product can be applied to water and fertilizer integrated spray irrigation, drip irrigation, pouring irrigation and spraying in modern agriculture, has obvious soil improvement, growth promotion, disease prevention and insect prevention effects, can prevent generation of insect pests or kill larvae when the larvae generate, can achieve the effect of getting twofold results with half the effort with a small dosage, and is the best choice for producing green, environment-friendly and organic agricultural products.

Owner:深圳市绿色农业生物科技有限公司

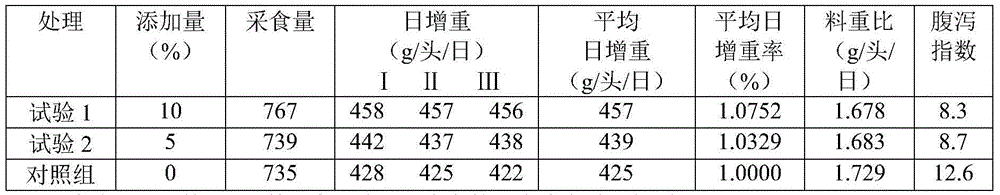

Compound preparation containing clostridium butyricum and pediococcus acidilactici as well as preparation method and application of compound preparation

ActiveCN112608861AImprove stabilityIncrease weight gainBacteriaClimate change adaptationBiotechnologyAquatic animal

The invention discloses a compound preparation containing clostridium butyricum and pediococcus acidilactici as well as a preparation method and application of the compound preparation. The compound preparation comprises clostridium butyricum with the bacterium content of 5-6*10<8> CFU / mL and pediococcus acidilactici with the bacterium content of 5.0-6.0*10<9> CFU / mL, wherein the clostridium butyricum adopts clostridium butyricum GBW-N1 with the preservation number of CGMCC No. 14499. The compound preparation is prepared by inoculating two strains in a staggered manner and carrying out fermentation culture in a designed fermentation culture medium for 16-22 hours, and fermentation liquor can be used after being filled. The compound preparation can well improve the weight gain rate, the survival rate and the growth performance of aquatic animals, is beneficial to improvement of aquaculture income, is good in stability and convenient to store, and thus has wide application value.

Owner:QINGDAO SHANGDE BIOTECH

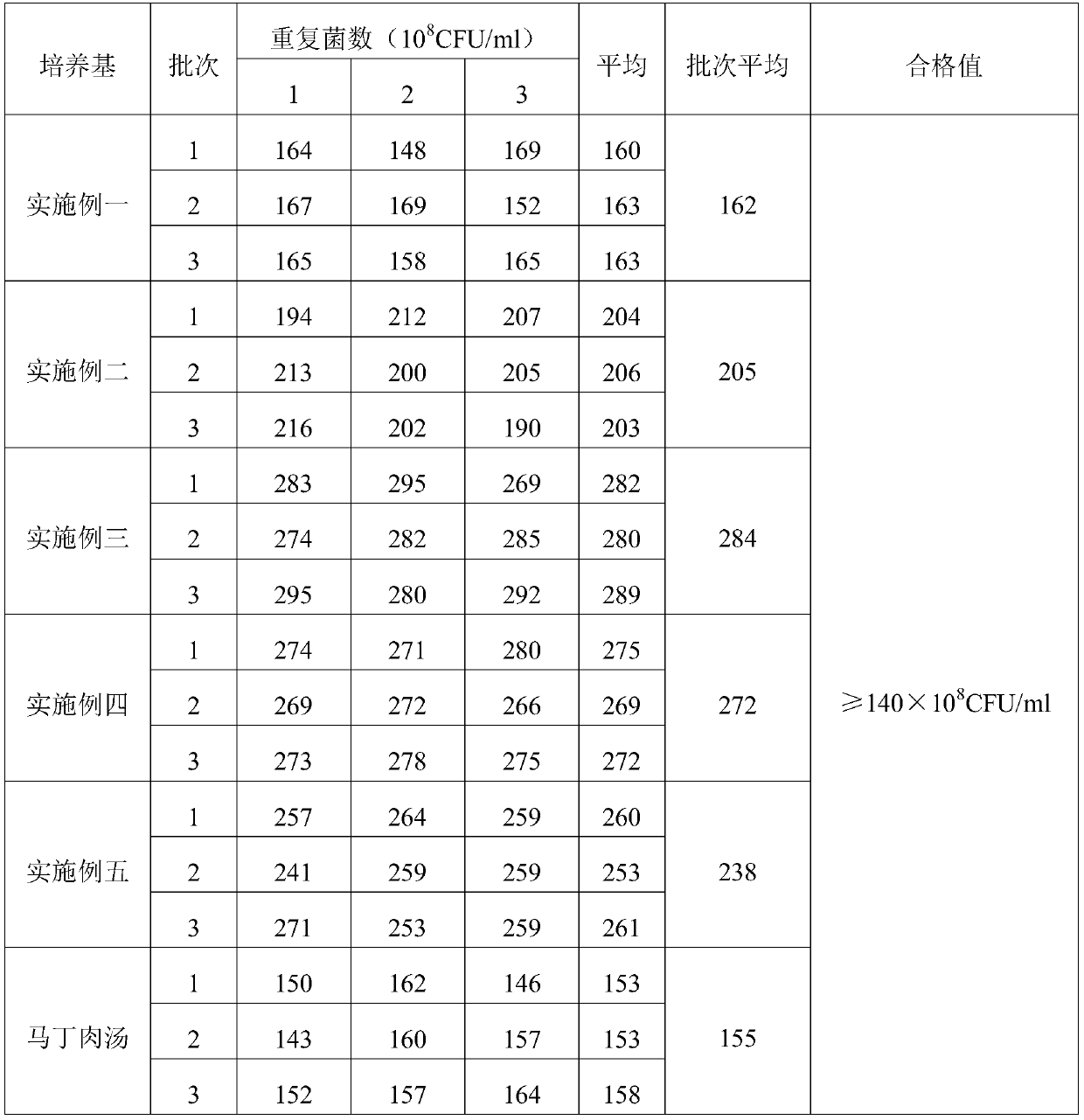

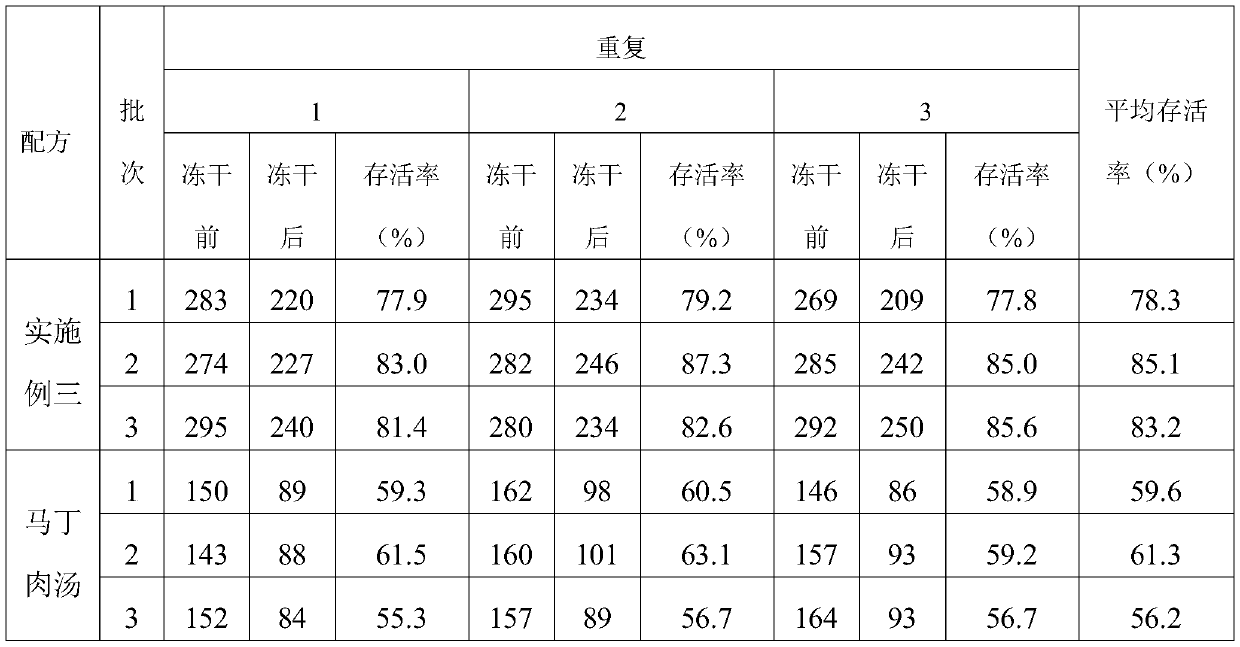

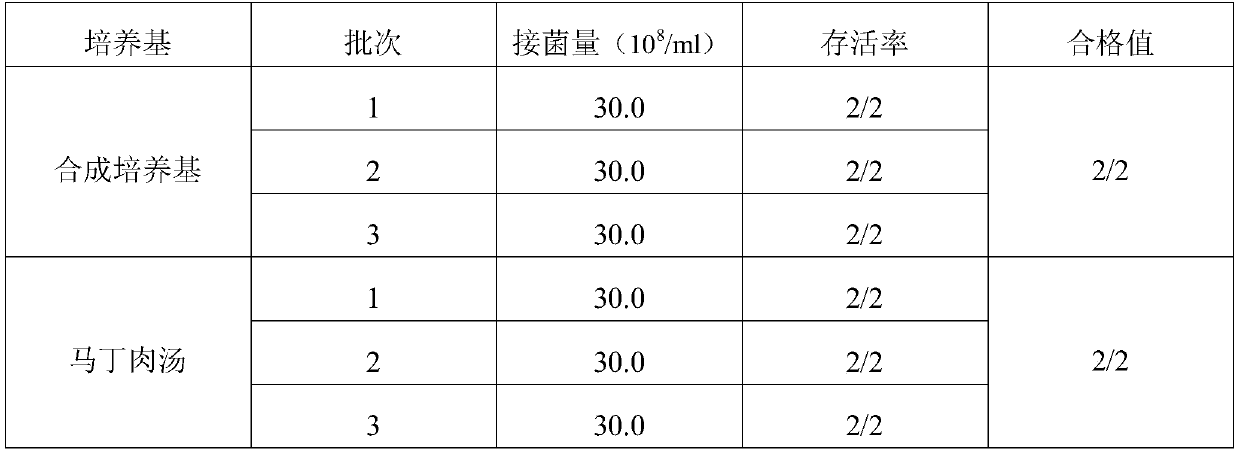

Swine pasteurellosis vaccine enrichment medium

PendingCN111040971APromote growth and reproductionRich in nutrientsBacteriaMicroorganism based processesBiotechnologyVaccine Production

The invention provides a swine pasteurellosis vaccine enrichment medium, and relates to the field of biology. The swine pasteurellosis vaccine enrichment medium is prepared from the following raw materials by weight: 20.0g of meat liver and stomach membrane digestive juice powder, 8.0g of bovine pancreas digestive juice, 10.0g of peptone, 5.0g of NaCl, 1.0g of a growth promoting factor, and purified water added to 1000ml. A preparation method of the swine pasteurellosis vaccine enrichment medium comprises the following steps: adding all the raw materials for preparing the swine pasteurellosisvaccine enrichment medium into purified water, fully dissolving the raw materials, and carrying out sterilization at 121 DEG C for 15 minutes for later use. The invention relates to an application ofa synthetic dry powder culture medium in swine pasteurellosis vaccine production. The synthetic dry powder culture medium has the beneficial effects that commercial raw materials can be selected, theculture medium is clear, the number of cultured bacteria is high, and the freeze-drying survival rate of the bacteria is increased.

Owner:青岛高科技工业园海博生物技术有限公司

Method capable of simultaneously accelerating decomposition of Sclerotinia scleotiorum and crop straws

The invention relates to a method capable of simultaneously accelerating decomposition of Sclerotinia scleotiorum and crop straws. The method comprises the following steps: (1) firstly, applying a spraying type complex fungicide: preparing a spraying type complex fungicide water solution by virtue of the spraying type complex fungicide and water, wherein the 15g of the spraying type complex fungicide is sprayed to each mu (a unit of area) of field, and the ratio of the spraying type complex fungicide to water is 15 grams to 15 liters; spraying oilseed rape straws returning to field with the spraying type complex fungicide water solution when the oilseed rape is harvested; standing for 3-5 days after the oilseed rape straws are sprayed with the spraying type complex fungicide water solution; (2) secondly, applying a compound microbial fertilizer, namely applying the compound microbial fertilizer before the oilseed rape is planted, wherein 10kg of the compound microbial fertilizer is applied to each mu of the field. The method has the advantages that the straws and Sclerotinia scleotiorum can be rapidly decomposed, the time and the labor are saved, the cost is low, soil-borne diseases such as Sclerotinia scleotiorum, clubroot and the like can be prevented, and the crop yield can be increased.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Movable fermentation method for preparing wet-state yeast culture by using rice husk removed white wine vinasse as raw materials

InactiveCN104957361AReduce crude fiber contentImprove nutritional value and application rangeFood processingAnimal feeding stuffNutrientHeating power

The invention relates to a movable fermentation method for preparing a wet-state yeast culture by using rice husk removed white wine vinasse as raw materials. The movable fermentation method comprises the following steps: removing rice husks from white wine vinasse, compounding materials, activating strains, performing inoculation and mixing, controlling temperature for fermentation, performing enzymolysis for breaking walls, and postprocessing products, wherein the step of postprocessing products comprises the steps of inspecting products, packaging inspected products and obtaining finished products. According to the movable fermentation method disclosed by the invention, a mechanical method is adopted for separating the rice husks, the content of crude fibers in the products is reduced, the nutrient value of the products is increased, and the application range of the products is extended. The rice husks separated from the white wine vinasse are mixed with coal to be used as boiler fuel, and a heat source is provided for warming the products, so that the cost of heating power is reduced, comprehensive utilization is realized, and the pollution is not caused. A bacteria-enzyme synergistic fermenting enzymolysis technology combining microzyme, protease and cellulose is adopted, so that the stability of the technology is good, mold pollution is not caused, and the products are safe. A temperature control technology by a two-step method is adopted, so that the cultured yeast count is high, the enzymolysis is thorough, the wall breaking of the yeast is sufficient, and the nutrient value is higher.

Owner:江苏益元泰生物技术有限公司

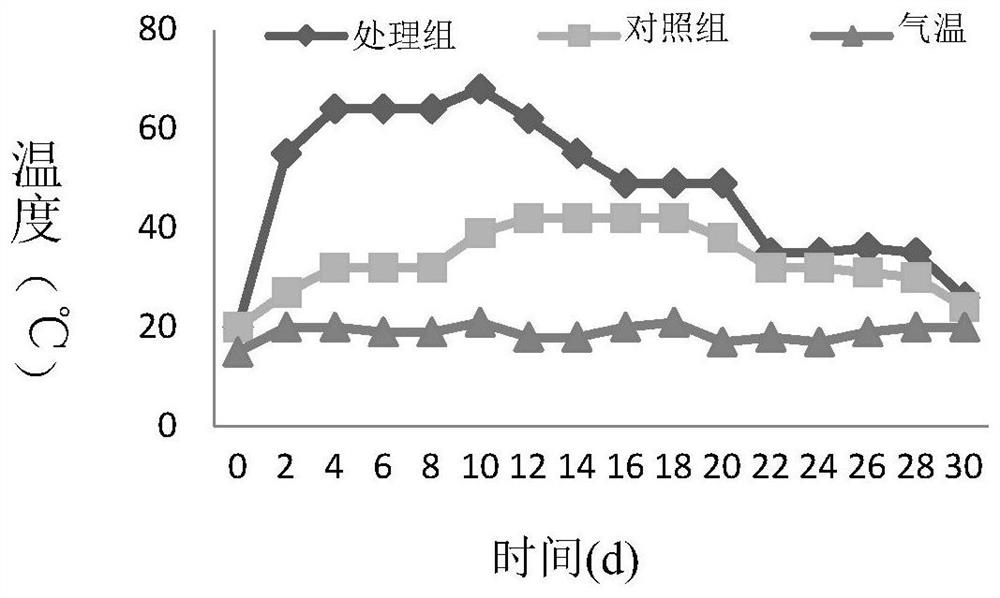

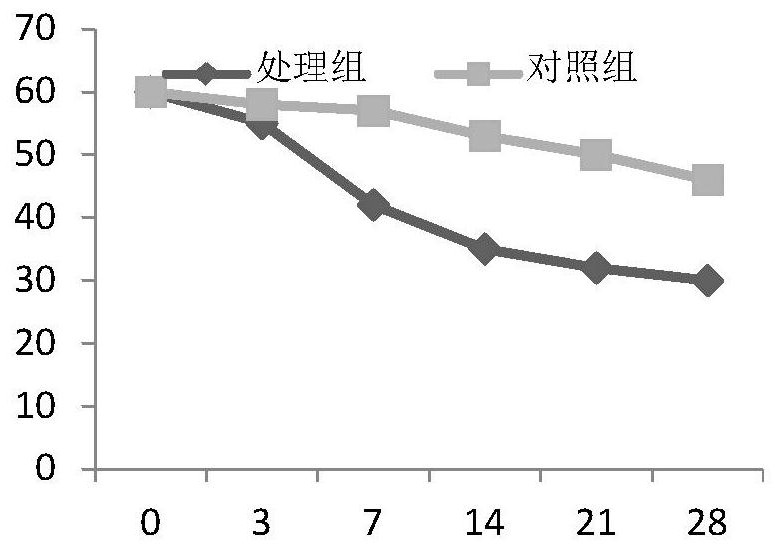

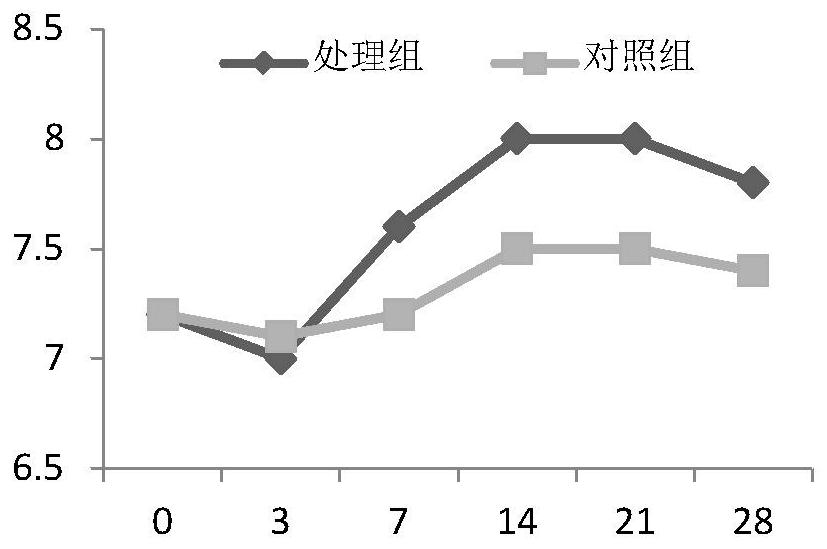

Organic material decomposing agent and preparation method thereof

PendingCN111621446AHigh bacterial countHigh enzyme activityBio-organic fraction processingFungiClostridialesEcosystem

The invention provides a preparation method and an application of an organic material decomposing agent. According to the organic material decomposing agent, a microbial composite strain composed of various functional microorganisms is mainly taken as a strain, and is subjected to liquid-solid multi-stage comprehensive fermentation, and comprehensively applied and transformed into the organic material decomposing agent, wherein the weight ratio of a clostridium butyricum strain, a saccharomyces cerevisiae strain, a lactobacillus plantarum strain and a bacillus subtilis strain is (10-15): (20-25): (10-20): (35-40); and product production simulates the process of compost heating-high temperature-cooling. When the organic material decomposing agent acts on livestock and poultry manure compost, the fermentation temperature rises rapidly, the highest temperature of compost is 76.5 DEG C, the high temperature period lasts for 12-16 days, the use is highly compatible with the microbial evolution process of natural compost, and functional bacteria reproduce rapidly to be dominant and play a role; and due to in-situ fermentation, a large number of proteases, cellulases and amylases are produced in the fermentation process to form a stable and efficient micro-ecosystem, which has a large number of bacteria and high enzyme activity, and functional bacteria and enzyme substances act together to rapidly achieve harmless treatment of livestock and poultry manure.

Owner:天津市圣世莱科技有限公司

Bdellovibrio preparation for preventing frog wryneck diseases and application thereof

PendingCN110169982AGuaranteed preventive functionIntegrity guaranteedAntibacterial agentsPowder deliveryDiseaseFreeze-drying

The invention discloses a bdellovibrio preparation for preventing frog wryneck diseases. Pathogenic bacteria capable of causing the frog wryneck diseases are taken as various mixed living host bacteria to culture bdellovibrio; then the uncracked host pathogenic bacteria are removed by filtration to obtain a bdellovibrio seed solution; then co-culture is carried out through various mixed inactivated host bacteria; the obtained bdellovibrio seed solution is firstly added with a freeze-drying protecting agent to be uniformly mixed, and then is added with a freeze-drying carrier to be mixed to obtain a preparation to be freeze-dried; finally, the bdellovibrio preparation is prepared by freeze-drying. The invention further discloses a preparation method and application of the bdellovibrio preparation. The bdellovibrio preparation can effectively prevent the frog wryneck diseases, obviously reduces the incidence rate, and has the advantages of environment-friendly effects and safe and efficient use.

Owner:XIAMEN HUIYING ANIMAL TECH +1

Extrusion granulation fermentation process of yeast culture by taking distillers grains without rice husks as raw materials

InactiveCN104982649AEfficient separationReduce cellulose contentFood processingAnimal feeding stuffMicrobiologyCellulase

An extrusion granulation fermentation process of a yeast culture by taking distillers grains without rice husks as raw materials comprises the steps of rice husk removing treatment of the distillers grains, batching, strain activating, inoculate mixing, temperature controlled fermentation, enzymolysis wall-braking, granulation, drying and product aftertreatment which comprises inspection, packaging and finished product obtaining. According to the extrusion granulation fermentation process of the yeast culture by taking the distillers grains without the rice husks as the raw materials, effective separation of rice husk compositions from nutritional ingredients such as protein in original distillers grains is achieved by adopting a screw extrusion machine, the cellulose content of products is reduced, and the nutritional value is improved. The rice husks separated from the distillers grains can be mixed with coal to be used as boiler fuel to provide the heat source for the products, the heat cost is reduced, comprehensive utilization is achieved, a bacterium-enzyme cooperative fermentation enzymolysis process by combining yeast and protease and cellulase is adopted, the process stability is good, fungus pollution does not exist, and the products are safe.

Owner:江苏益元泰生物技术有限公司

Petroleum hydrocarbon degrading bacterium and fermentation method thereof

ActiveCN109097309ALow costRealize industrial productionBacteriaMicroorganism based processesMicroorganismSludge

The invention discloses a petroleum hydrocarbon degrading bacterium and a fermentation method thereof. The petroleum hydrocarbon degrading bacterium is brevibacillus parabrevis with strain name of GWN-2, and is preserved in China General Microbiological Culture Collection Center with preservation number of CGMCC No. 13903. The degrading bacterium is characterized in that the gene sequence is shownin a sequence table. After inoculation and proliferation culture of the petroleum hydrocarbon degrading bacterium, a petroleum hydrocarbon degrading bacterium product capable of degrading oily sludgeis obtained, the oil content is reduced by about 80% after the oily sludge is treated for 20 days, and a novel approach is provided for treatment of the oily sludge in oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com