Bacillus licheniformis and method for producing alkali proteinase with sewage sludge as raw material

A technology of Bacillus licheniformis and protease, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problems of expensive raw materials, undiscovered production of alkaline protease, and high product prices, and achieves environmental safety and harmlessness. , to promote industrial production and application, the effect of high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. Isolation and purification of bacterial classification

[0035] Weigh 10 grams of concentrated sludge into a conical flask containing 90 mL of sterile water (with glass beads inside), shake and cultivate for 15 minutes at 28°C, 150 rpm, and dilute to 10 with sterile water. -5 , pipette 0.1mL of the diluted solution and evenly spread it on a casein medium plate, and cultivate it in a 28°C incubator for 3 days. Spread trichloroacetic acid solution evenly on the medium plate, pick single colonies with obvious hydrolysis circles and culture them repeatedly on the casein plate, and then separate, purify and store them. The ingredients of the casein medium used are: 20 g of casein, 20 g of agar powder, pH 9.0, and 1 L of distilled water. The slant preservation medium used was LB medium, and its composition was (g / L): 10 g of tryptone, 5 g of yeast extract, 10 g of NaCl, pH 7.4, and 1 L of distilled water.

Embodiment 2

[0036] Embodiment 2. strain identification

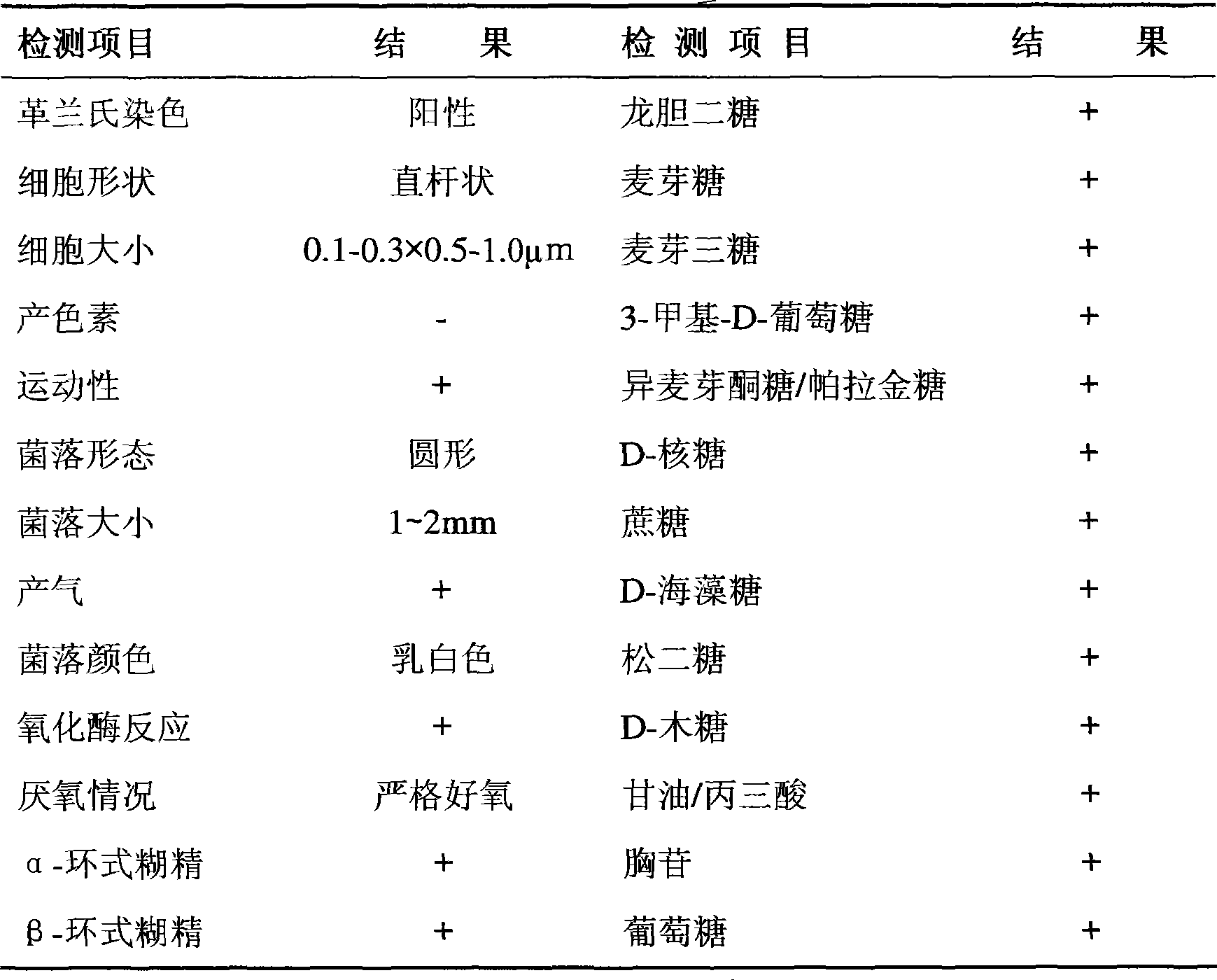

[0037] (1) Physiological and biochemical characteristics identification

[0038] See Table 1 for the identification results of physiological and biochemical characteristics of B.licheniformis HM-3.

[0039] Table 1. Physiological and biochemical characteristics of strain HM-3

[0040]

[0041] Note: + indicates that it can be used; - indicates that it cannot be used

[0042] (2) BIOLOG identification

[0043] The identification result of automatic microbial identification instrument (BIOLOG) showed that HM-3 was Bacillus licheniformis. The scanning electron microscope photo of Bacillus licheniformis HM-3 is shown in figure 1 .

Embodiment 3

[0044] Embodiment 3. bacillus licheniformis HM-3 takes sludge as raw material fermentation production alkaline protease

[0045] (1) Medium conditioning: adjust the solid content of urban sludge to 3%, add 0.2% foam enemy, and adjust the pH to 7.0 with NaOH, stir evenly, sterilize at 0.1KPa pressure and 121°C for 45 minutes, cool for later use.

[0046] (2) Shake flask culture: Pick a ring of bacterial lawn from the HM-3 slant medium and inoculate it into a conical flask filled with LB liquid medium, and carry out shake flask culture at 30°C and 100 rpm for 12 hours.

[0047](3) Fermentation: With the inoculum amount of 3%, the shake flask bacterial liquid was moved into a fermenter equipped with sludge with a solid content rate of 3%, and fermented. The conditions are: tank temperature 30°C, tank pressure 0.005 MPa, ventilation rate 1:1.0 (V / V / min), stirring speed 200 rpm, fermentation time 64 hours.

[0048] (4) Purification of protease: after the fermentation is completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com