Processing method and application of fish meal in glutamine transaminase fermentation culture medium

A technology of transglutaminase and fermentation medium, which is applied in the fields of microbial fermentation and enzyme engineering, can solve the problems of low enzyme production, low utilization rate of fish meal components, low utilization rate of fish meal and the like, and achieves the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] The preparation method of the fermentation medium of transglutaminase is as follows (comprising the fish meal treatment step in the fermentation medium of hydrolyzed transglutaminase):

[0086] 1) Ingredients: Weigh the fish meal and water and mix them evenly to obtain the mixing system 1;

[0087] 2) Adjusting the pH: Stir the mixed system 1 with a magnetic stirrer, and adjust the pH to 3.0 with hydrochloric acid to obtain the mixed system 2;

[0088] 3) Hydrolysis: Put the mixed system 2 under the condition of 121° C. for 60 minutes, take it out, and obtain the fishmeal component in the transglutaminase fermentation medium after cooling, namely the mixed system 3.

[0089] 4) pH adjustment: Stir the mixed system 3 with a magnetic stirrer, and adjust the corresponding pH to the effective pH range as shown in Table 1 with hydrochloric acid or sodium hydroxide to obtain the mixed system 4;

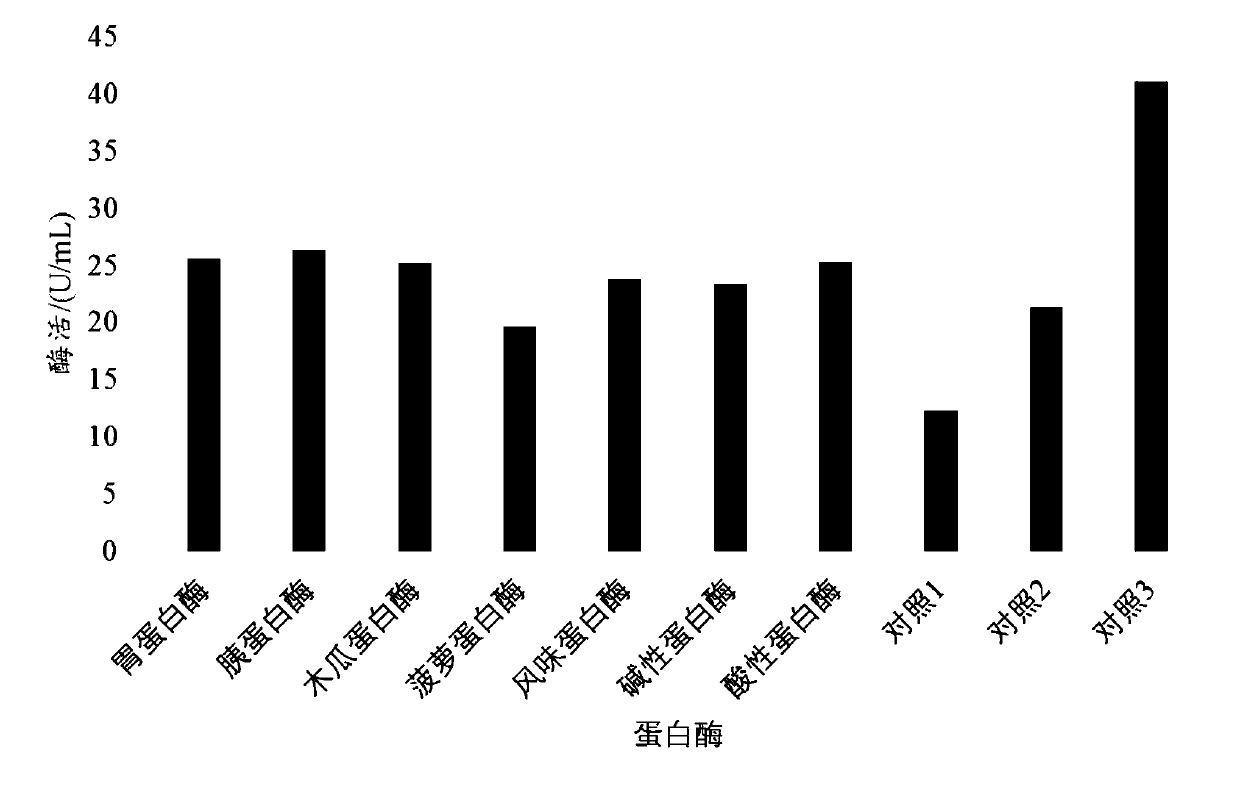

[0090] 5) Enzyme addition: adding hydrolase in proportion by weight to obtain m...

Embodiment 2

[0106] The preparation method of the fermentation medium of transglutaminase is as follows (comprising the fish meal treatment step in the fermentation medium of hydrolyzed transglutaminase):

[0107] 1) Ingredients: Weigh the fish meal and water and mix them evenly to obtain the mixing system 1;

[0108] 2) Adjusting the pH: Stir the mixed system 1 with a magnetic stirrer, and adjust the pH to 3.0 with hydrochloric acid to obtain the mixed system 2;

[0109] 3) Hydrolysis: Put the mixed system 2 under the condition of 121° C. for 60 minutes, take it out, and obtain the fishmeal component in the transglutaminase fermentation medium after cooling, namely the mixed system 3.

[0110] 4) pH adjustment: Stir the mixed system 3 with a magnetic stirrer, and adjust the corresponding pH to the action pH range as shown in Table 2 with hydrochloric acid or sodium hydroxide to obtain the mixed system 4;

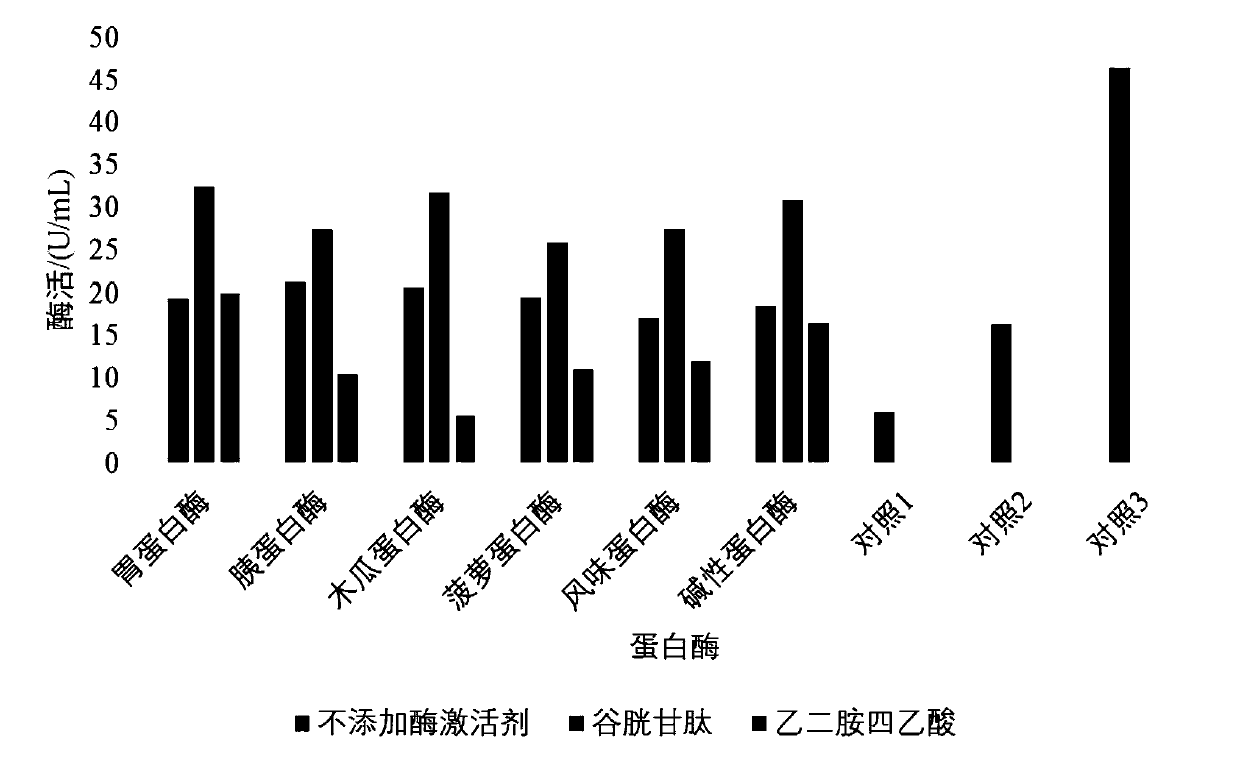

[0111] 5) Enzyme addition: adding hydrolase in proportion by weight to obtain mixe...

Embodiment 3

[0128] The preparation method of the fermentation medium of transglutaminase is as follows (comprising the fish meal treatment step in the fermentation medium of hydrolyzed transglutaminase):

[0129] 1) Ingredients: Weigh the fish meal and water and mix them evenly to obtain the mixing system 1;

[0130] 2) Adjusting the pH: Stir the mixed system 1 with a magnetic stirrer, and adjust the pH to 3.0 with hydrochloric acid to obtain the mixed system 2;

[0131] 3) Hydrolysis: Put the mixed system 2 under the condition of 121 degrees Celsius for 60 minutes, take it out, and obtain the fishmeal component in the transglutaminase fermentation medium after cooling, namely the mixed system 3.

[0132] 4) pH adjustment: Stir the mixed system 3 with a magnetic stirrer, and adjust the corresponding pH to the effective pH range as shown in Table 3 with hydrochloric acid or sodium hydroxide to obtain the mixed system 4;

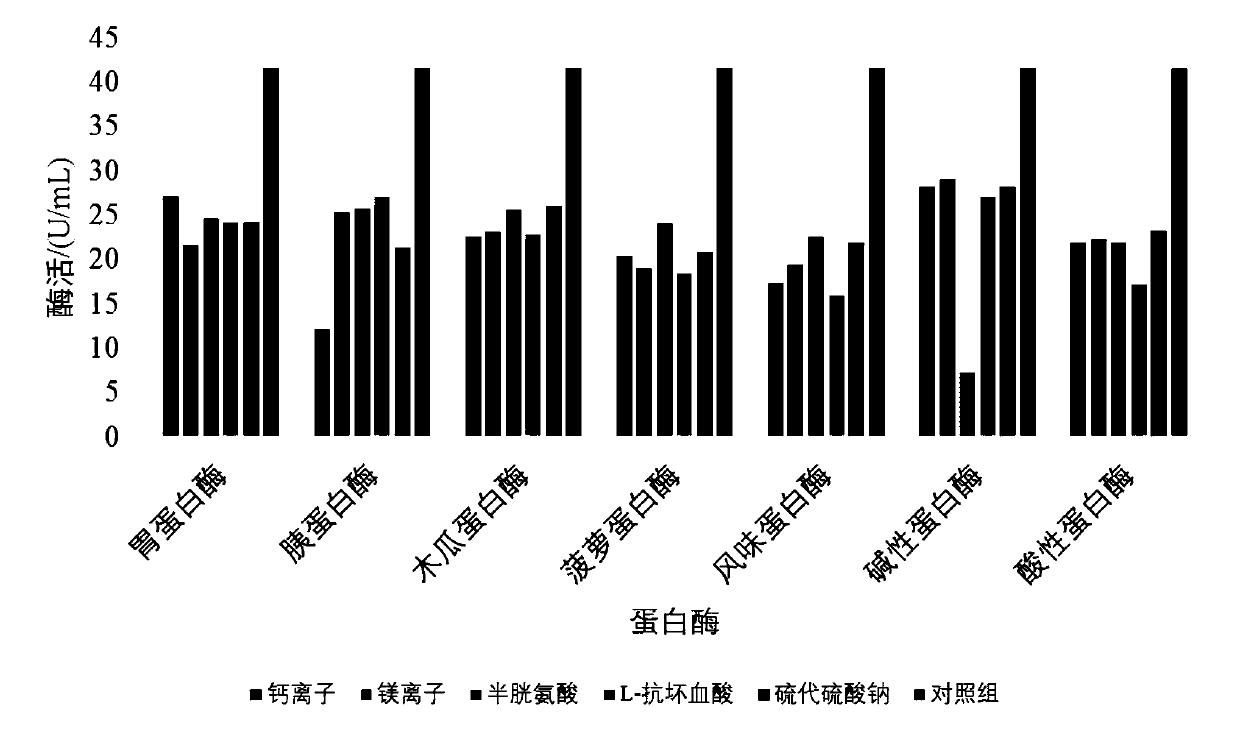

[0133] 5) Enzyme addition: adding hydrolase in proportion by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com