Transglutaminase fermentation culture medium pretreated by acidolysis or enzymolysis and preparation method and application thereof.

A technology of transglutaminase and fermentation medium is applied in the fields of microbial fermentation and enzyme engineering, and can solve the problems of low utilization rate of fish meal, low efficiency of fermentation and enzyme production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

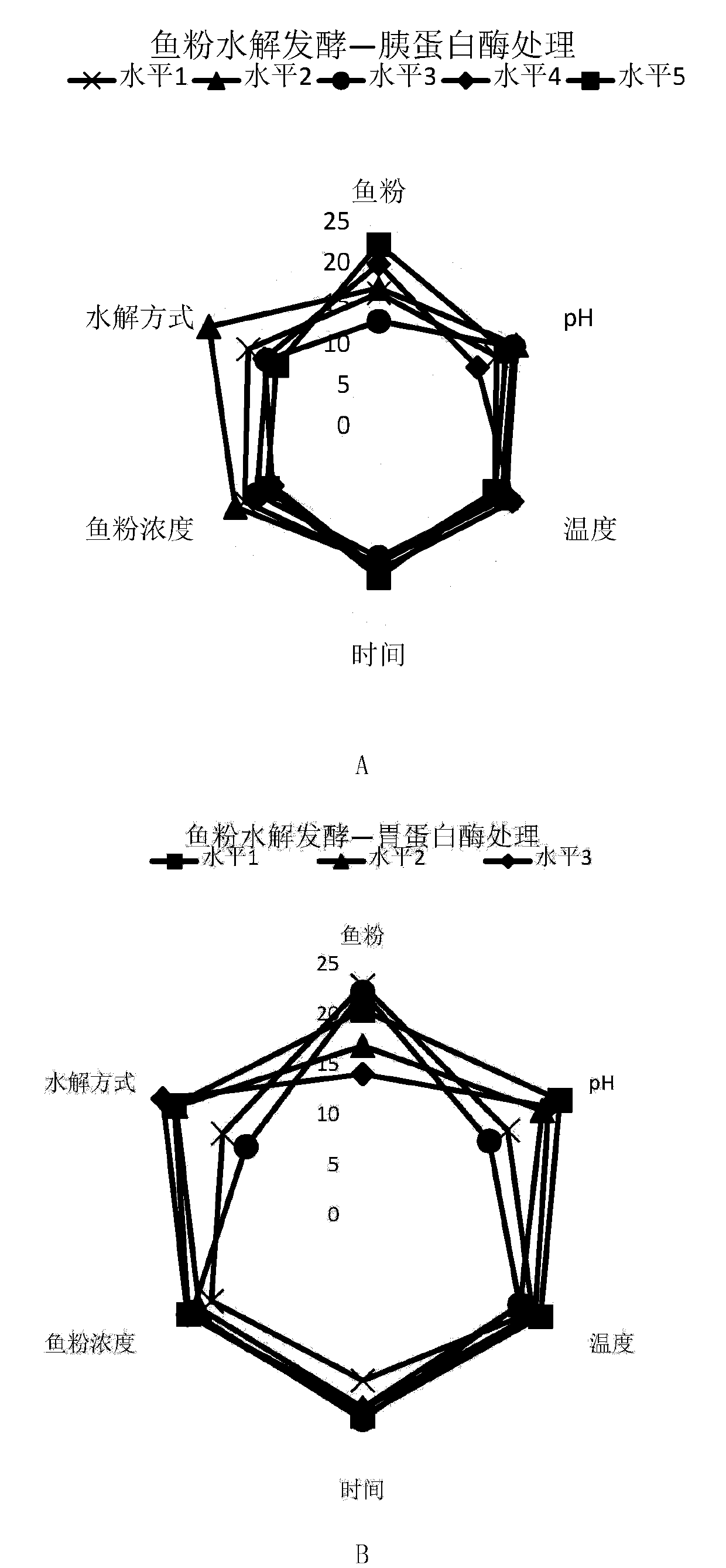

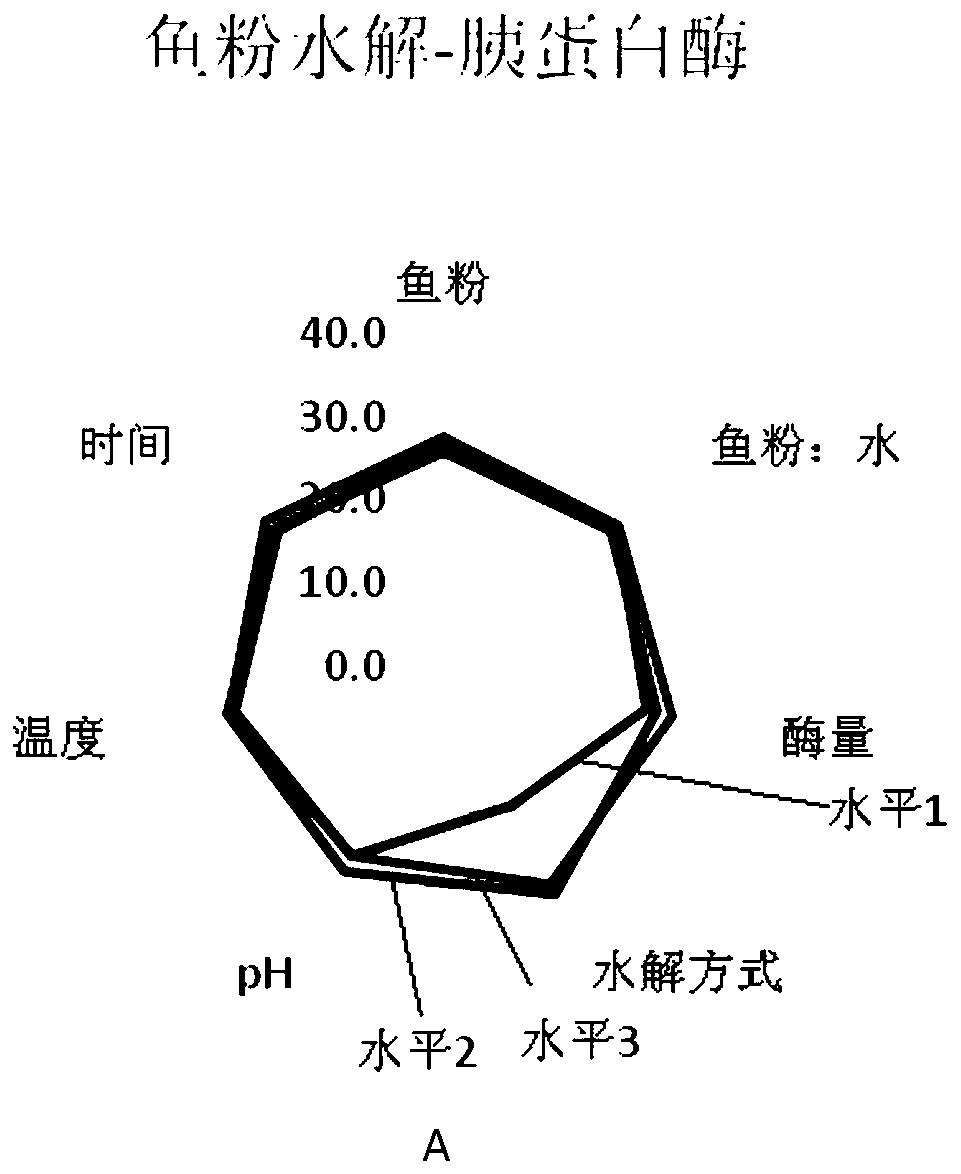

[0086] The preparation method of embodiment 1 transglutaminase fermentation medium

[0087] Follow the steps below.

[0088] 1) Ingredients: Weigh the fish meal and water and mix them evenly to obtain the mixing system 1;

[0089] 2) Adjust the pH: Stir the mixed system 1 with a magnetic stirrer, and adjust the corresponding pH to the range of 1.5-8.0pH with the corresponding acid to obtain the mixed system 2;

[0090] 3) Enzyme addition: adding hydrolytic enzymes according to the weight ratio to obtain the mixed system 3;

[0091] 4) Hydrolysis: After placing the mixed system 3 at the corresponding temperature of 35°C-50°C for a certain period of time, immediately inactivate the enzyme at ultra-high temperature, and obtain the transglutaminase fermentation medium to be used after cooling. Fishmeal ingredients pretreated by enzymatic hydrolysis, that is, the mixed system four.

[0092] 5) Preparation: transfer the mixed system IV to a container, and stir the mixed system IV...

Embodiment 2

[0106] The preparation of embodiment 2 transglutaminase fermentation medium

[0107] Follow the steps below.

[0108] 1) Ingredients: Weigh the fish meal and water and mix them evenly to obtain the mixing system 1;

[0109] 2) Adjust the pH: Stir the mixed system 1 with a magnetic stirrer, and adjust the corresponding pH to the range of 1.5-8.0pH with the corresponding acid to obtain the mixed system 2;

[0110] 3) Enzyme addition: adding hydrolytic enzymes according to the weight ratio to obtain the mixed system 3;

[0111] 4) Hydrolysis: after placing the mixed system 3 at the corresponding action temperature of 35°C-50°C for a certain period of time, the enzyme will be instantly inactivated by ultra-high temperature, and after cooling, obtain the transglutaminase fermentation medium to be used Fishmeal ingredients pretreated by enzymatic hydrolysis, that is, the mixed system four.

[0112] 5) Preparation: transfer the mixed system IV to a container, and stir the mixed sy...

Embodiment 3

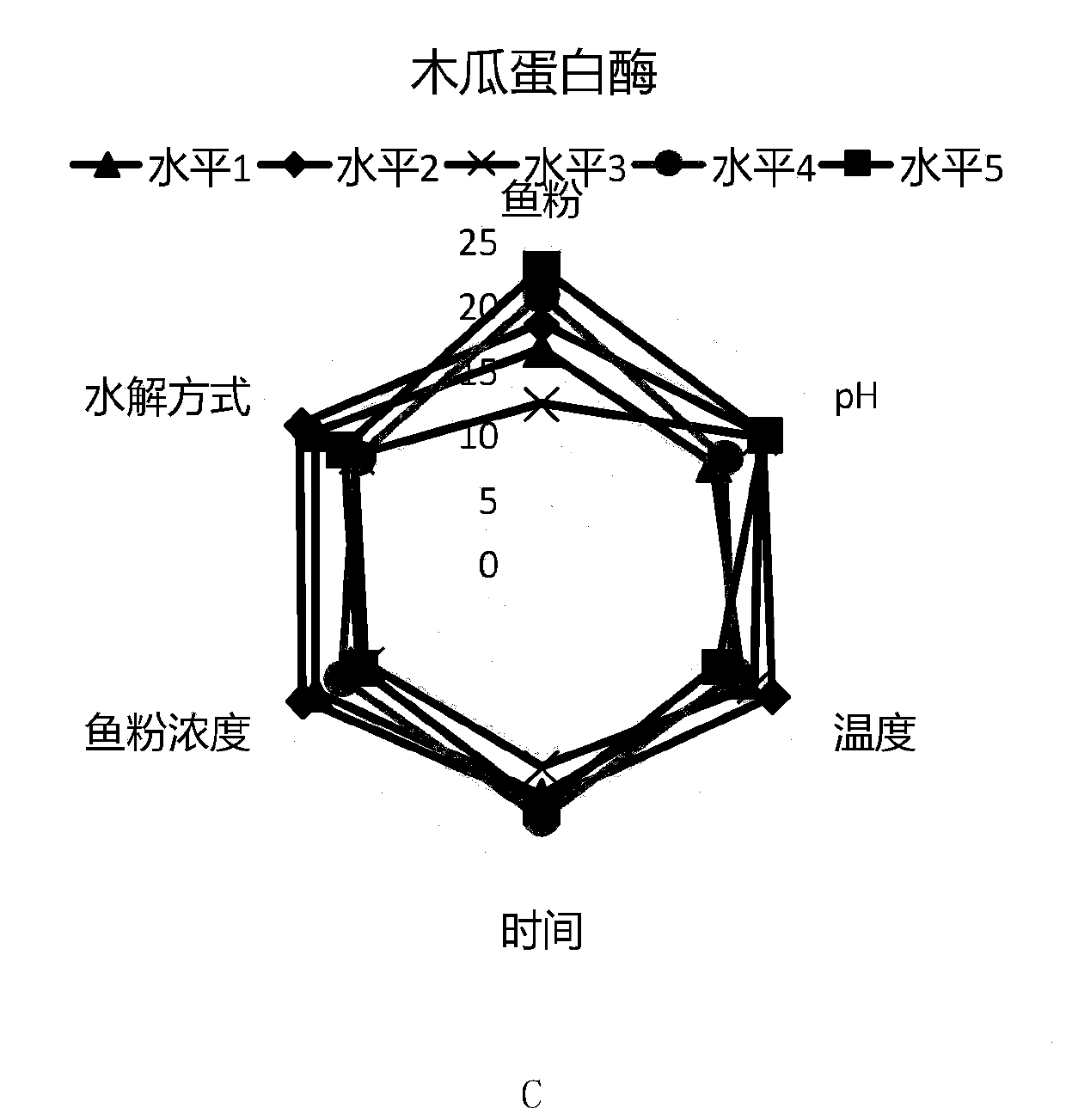

[0126] The preparation of embodiment 3 transglutaminase fermentation medium

[0127] Follow the steps below.

[0128] 1) Ingredients: Weigh the fish meal and water and mix them evenly to obtain the mixing system 1;

[0129] 2) Adjust the pH: Stir the mixed system 1 with a magnetic stirrer, and adjust the corresponding 1.5-8.0pH to the action pH range with the corresponding acid to obtain the mixed system 2;

[0130] 3) Enzyme addition: adding hydrolytic enzymes according to the weight ratio to obtain the mixed system 3;

[0131] 4) Hydrolysis: after placing the mixed system 3 at the corresponding temperature of 35°C-50°C for a certain period of time, immediately inactivate the enzyme at ultra-high temperature, and obtain the transglutaminase fermentation medium to be used after cooling. The enzymatically hydrolyzed fishmeal component, that is, the mixed system four.

[0132] 5) Preparation: transfer the mixed system IV to a container, and stir the mixed system IV with a mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com