Microorganism-containing fertilizer produced by mycoderm method and production method of fertilizer

A technology of microorganisms and biofilms, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of increasing equipment investment, product production costs, difficulty in maintaining stable and consistent product quality, and difficulty in determining and controlling the number of deaths. The output is stable and controllable, the product quality is stable and reliable, and the biological activity of microorganisms is fully exerted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

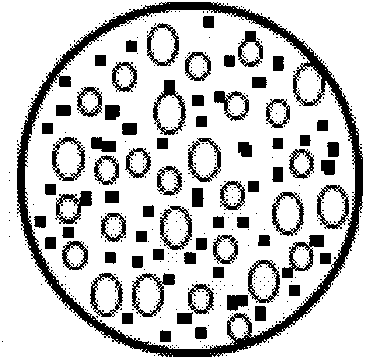

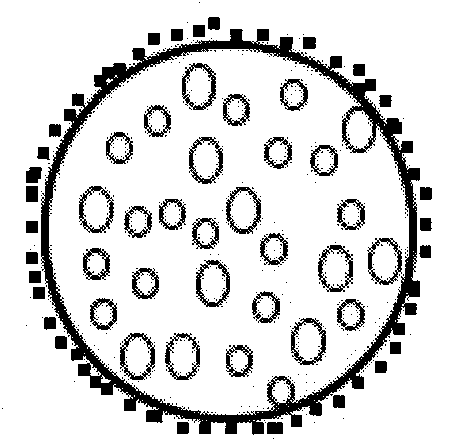

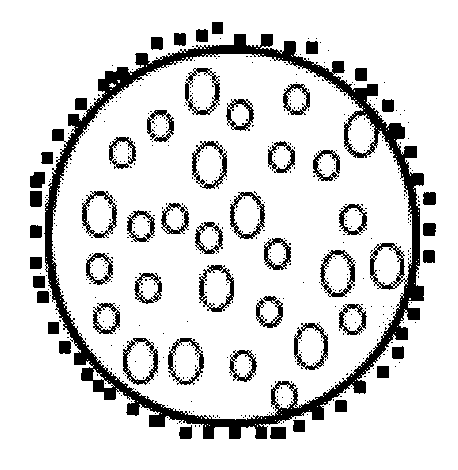

[0024] The chemical compound fertilizer containing microorganisms produced by the biofilm method uses agricultural beneficial microorganisms Bacillus bacillus, such as Bacillus subtilis, as the production strain, and adopts a liquid fermentation process: traditional processes such as fermentation, separation, adsorption, and low-temperature drying are used to make the fertilizer containing Active dry bacteria powder with high bacterial count and small particle size:

[0025] 1. Add the film-forming agent described in the dry bacteria powder: for example, 3 kg of active dry bacteria powder, add 50 grams of carboxymethyl cellulose or polyvinyl alcohol gelatin, mix well, put it into a mixer, add water for 3 kg to make a coating agent with a certain viscosity. Use the traditional compound fertilizer production line to make granular compound fertilizer fertilizer through traditional formulas and processes such as batching, mixing, granulating, drying, sieving, cooling, etc. Note th...

Embodiment 2

[0028] The chemical compound fertilizer containing microorganisms produced by the biofilm method described in Example 1, in the processing process, if a certain proportion of organic matter is added to the ingredients of the compound fertilizer production line, such as 10%, 20% or 30% organic matter, For example feces meal or bone meal, blood meal, all the other steps are according to the method for embodiment 1, then the product produced is the bio-organic fertilizer of certain proportion (10%, 20% or 30%) quality.

Embodiment 3

[0030] The chemical compound fertilizer that contains microorganism that embodiment 1 biofilm method manufactures, in processing, if adopt certain proportion (1:2,1:5 or 1:10) organic matter and pure chemical fertilizer, and all the other steps are according to the method of embodiment 1, as described in embodiment 2, the product that just can produce is the biological organic and inorganic compound fertilizer of a certain proportion (10%, 20% or 30%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com