Compound bacterial agent applied to straw mulching and preparation method thereof

A compound bacterial agent and straw technology, which is applied in biochemical equipment and methods, microorganism-based methods, bacteria, etc., can solve the problem of inability to achieve fast and efficient straw decomposition effects, single microbial metabolism type and function, and difficulty in large-scale promotion To achieve the effect of promoting sustainable development, reducing environmental pollution, and improving the efficiency of straw decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

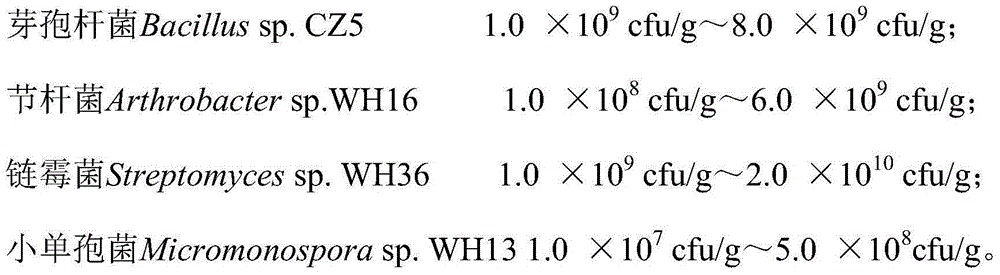

[0027] Composition of complex microbial agent

[0028]

[0029]

[0030] The bacterial agent with the above composition is prepared by the following steps:

[0031] 1) Carrier preparation: uniformly mix attapulgite (200 mesh), peat (200 mesh) and vermiculite (200 mesh) according to the mass ratio of 2.5:0.5:1 to obtain a carrier, and set aside;

[0032] 2) Preparation of protective agent: uniformly mix trehalose (200 mesh) and sodium glutamate (200 mesh) according to a mass ratio of 1:1.5 to obtain a protective agent, and set aside;

[0033] 3) Fermentation of single strains: four strains of Bacillus sp.CZ5, Arthrobacter sp.WH16, Streptomyces sp.WH36 and Micromonospora sp.WH13 were respectively fermented to obtain fermentation broth.

[0034] Bacillus subtilis was cultured in LBG medium (0.5% glucose, 1% peptone, 0.5% yeast extract, 1% sodium chloride); 1% inoculum was inoculated in LBG liquid medium, 180 rpm, and cultured for 24 hours.

[0035] Streptomyces chestnutus...

Embodiment 2

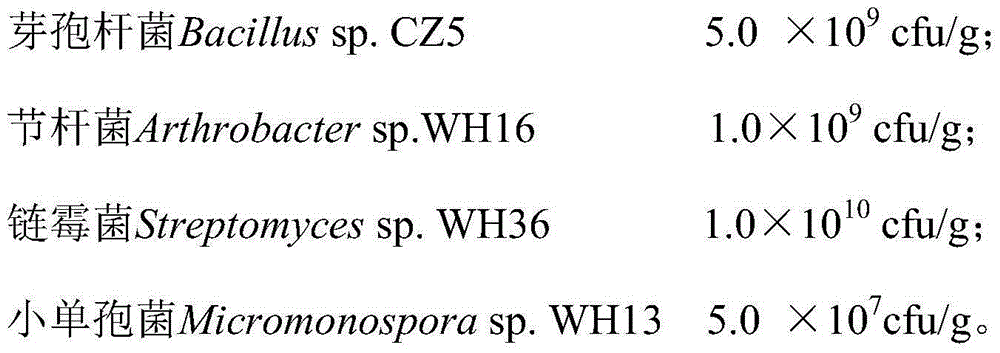

[0058] Composition of complex microbial agent

[0059]

[0060]

[0061] The bacterial agent with the above composition is prepared by the following steps

[0062] 1) Carrier preparation: uniformly mix attapulgite (300 mesh), peat (300 mesh) and vermiculite (300 mesh) according to the mass ratio of 2.5:0.8:1 to obtain a carrier, and set aside;

[0063] 2) Preparation of protective agent: uniformly mix trehalose (300 mesh) and sodium glutamate (300 mesh) according to a mass ratio of 1:1.8 to obtain a protective agent, and set aside;

[0064] 3) Single-strain fermentation: four strains of Bacillus sp.CZ5, Arthrobacter sp.WH16, Streptomycessp.WH36 and Micromonospora sp.WH13 were fermented respectively to obtain fermentation broth.

[0065] Bacillus subtilis was cultured in LBG medium (0.5% glucose, 1% peptone, 0.5% yeast extract, 1% sodium chloride); 1.5% inoculum was inoculated in LBG liquid medium, 190 rpm, and cultured for 30 h.

[0066] Streptomyces chestnutus uses SC...

Embodiment 3

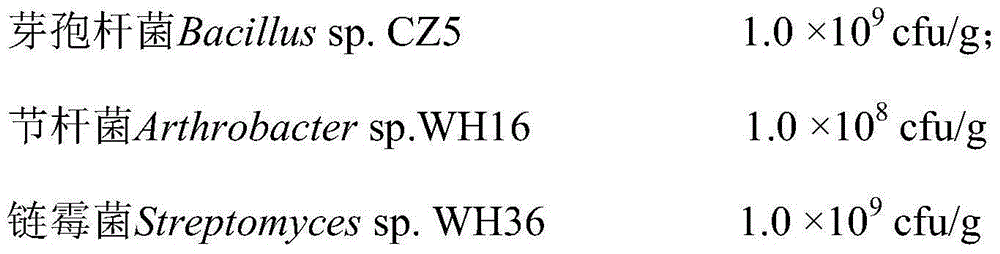

[0089] Composition of complex microbial agent

[0090]

[0091] The bacterial agent with the above composition is prepared by the following steps

[0092] 1) Carrier preparation: uniformly mix attapulgite (400 mesh), peat (400 mesh) and vermiculite (400 mesh) according to the mass ratio of 2.5:1:1 to obtain a carrier, and set aside;

[0093] 2) Preparation of protective agent: uniformly mix trehalose (400 mesh) and sodium glutamate (400 mesh) according to a mass ratio of 1:2 to obtain a protective agent, and set aside;

[0094] 3) Single-strain fermentation: four strains of Bacillus sp.CZ5, Arthrobacter sp.WH16, Streptomycessp.WH36 and Micromonospora sp.WH13 were fermented respectively to obtain fermentation broth.

[0095] Bacillus subtilis was cultured in LBG medium (0.5% glucose, 1% peptone, 0.5% yeast extract, 1% sodium chloride); 2% inoculum was inoculated in LBG liquid medium, 200 rpm, and cultured for 36 hours.

[0096]Streptomyces chestnutus uses SCP medium (1.0% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com