Bacillus subtilis yielding mesothermal alpha-amylase

A Bacillus subtilis and amylase technology, applied in the field of microorganisms, can solve the problems of consumption of reagents, increase of technological process, poor enzyme stability, etc., and achieve the effects of wide pH value range, high enzyme production activity, and high enzyme activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

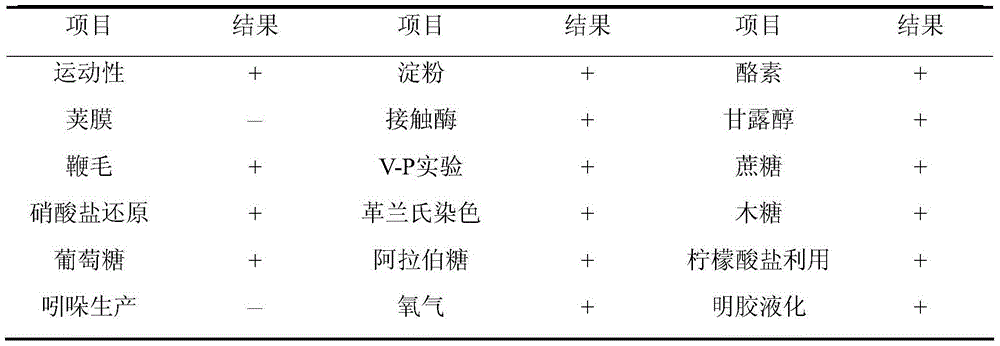

Image

Examples

Embodiment 1

[0024] Example 1: Ultraviolet-Lithium Chloride-Diethyl Sulfate Compound Mutagenesis Screening

[0025] (1) Preparation of bacterial suspension

[0026] Inoculate the single colony of the starting strain grown after streaking on the plate into the seed medium, culture at 37°C for 24 hours at 100 r / min, take 1 mL of the culture medium, centrifuge, wash twice with normal saline, and resuspend with 9 mL of normal saline middle.

[0027] (2) Ultraviolet-Lithium Chloride-Diethyl Sulfate Compound Mutagenesis

[0028] Place 3mL of bacterial suspension on a sterile plate, stir and irradiate for 60s under a UV lamp with a distance of 30cm and a power of 15w. After the irradiated bacterial solution was serially diluted (10 -1 -10 -5 ) on the lithium chloride plate, and the plate was diluted and coated with the bacteria solution without ultraviolet irradiation as a control. Wrap the uniformly coated plate above with black cloth or newspaper, incubate at 37°C for 48 hours, screen out ...

Embodiment 2

[0037] Embodiment 2: optimization of fermentation conditions

[0038] A preparation method for mesophilic α-amylase, comprising the steps of:

[0039] (1) Activation of bacteria

[0040] The well-preserved slant strain of Bacillus subtilis 304 was inoculated on the slant medium, cultured at 35°C for 30 hours to activate the strain, and activated 3 times in this way;

[0041] The slant medium consists of: beef extract 6g, sodium chloride 8g, peptone 15g, glucose 5g, agar 20g, distilled water 1000mL, pH value 6.5, sterilized at 121°C for 20min;

[0042] (2) Expanded cultivation of liquid seeds

[0043] ①First-level seed culture: Put the slant bacteria activated in step (1) into a 500 ml shake flask with 2 loops, the medium capacity is 100 ml, the rotary shaker is 250 rpm, the culture temperature is 35°C, and the culture time is 10h;

[0044] ②Cultivation of secondary seeds: Inoculate 10% of the primary seeds into 500 ml secondary seed shake flasks, and the cultivation condit...

Embodiment 3

[0061] Embodiment 3: the mensuration of amylase activity

[0062] (1) Definition of enzyme activity unit: 1 mL of crude enzyme solution, at 65°C and pH 5.0, liquefies 1 mg of soluble starch in 1 minute, which is 1 enzyme activity unit, expressed in U / mL.

[0063] (2) The amylase activity was determined by DNS method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com