Method for producing mannanase by lactobacillus brevis

A mannanase, Lactobacillus brevis technology, applied in the directions of microorganism-based methods, glycosylases, biochemical equipment and methods, etc., can solve the problem of lack of Lactobacillus brevis and other problems, and achieve the promotion of health care products and feed production. , Easy to operate, high enzymatic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: the method for present embodiment Lactobacillus brevis to produce mannanase is carried out according to the following steps: one, Lactobacillus brevis (Lactobacillus brevis) HDRS8 is inoculated in polysaccharide carbon source konjac flour culture medium, at a temperature of Cultivate at 28-36°C for 45-55 hours to obtain a fermented liquid; 2. centrifuge the fermented liquid obtained in step 1, discard the precipitate and leave the supernatant to obtain a crude enzyme liquid containing mannanase.

[0010] The Lactobacillus brevis HDRS8 described in this embodiment (from "Study on Isolation, Identification and Culture Conditions of Bacteriocin-Producing Lactic Acid Bacteria") is a chemoheterotrophic lactic acid bacterium, which is isolated from sauerkraut fermentation broth.

[0011] Centrifugation conditions in Step 2 of this embodiment: centrifuge for 15-20 min at a rotational speed of 6000-8000 r / min.

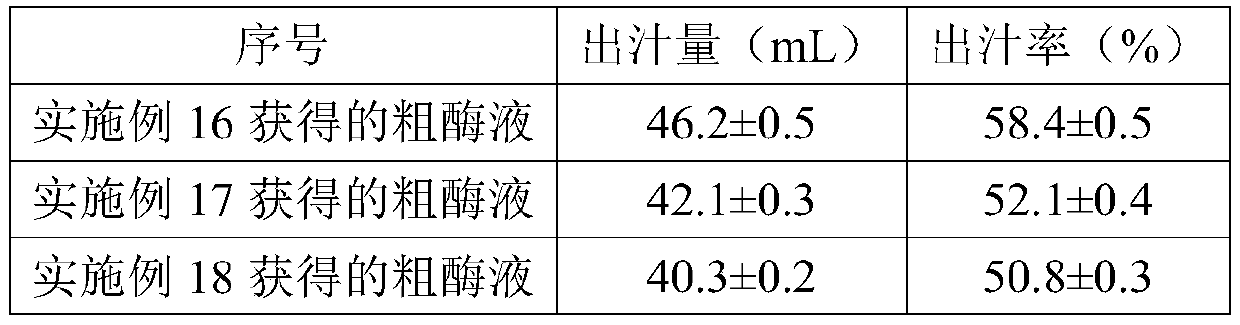

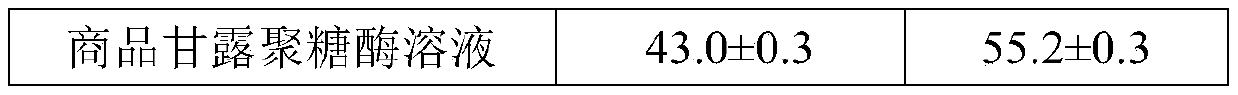

[0012] The activity of mannanase in the c...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the bacterial liquid concentration of Lactobacillus brevis (Lactobacillus brevis) HDRS8 in the polysaccharide carbon source medium is 2.8 × 10 6 ~4.2×10 6 individual / mL. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step 1, the bacterial liquid concentration of Lactobacillus brevis (Lactobacillus brevis) HDRS8 in the polysaccharide carbon source medium is 2.8 * 10 6 ~4.2×10 6 individual / mL. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com