Recombinant Bacillus subtilis for producing chondroitinase and application thereof

A technology of Bacillus subtilis and chondroitin sulfate, which is applied in the field of bioengineering, can solve the problems of large loss of enzyme activity, cumbersome crushing process, and not easy to be broken completely, and achieves the effect of improving enzyme activity and wide application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

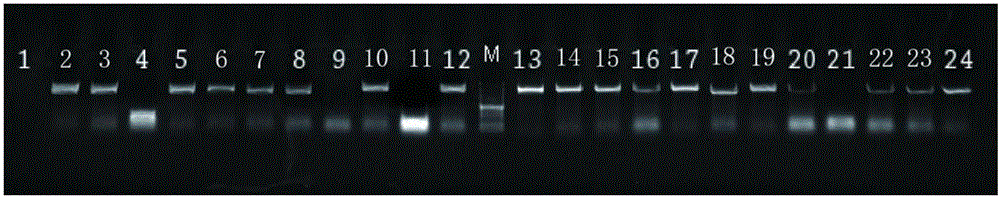

[0031] Example 1 Construction of recombinant plasmids P43-H6cslA1, Pppnk-H6cslA1, PcsfB-H6cslA1

[0032] Primers AmyX-F and AmyX-R were designed, and a standard PCR amplification system and program was used to amplify the obtained sequence as the signal peptide amyX shown in SEQID NO.5.

[0033] Design primers CSL-F2 and CSL-R2, use the genomic DNA of P.vulgaris ATCC6896 as a template, and use standard PCR amplification systems and procedures to amplify and obtain the chondroitin sulfate lyase gene cslABC (shown in SEQ ID NO.1) .

[0034] promoter P ppnk and P csfB Derived from Bacillus subtilis 168, the B. subtilis 168 strain was inoculated in 5ml LB liquid medium and cultured at 37°C and 200rpm for 16h. The bacteria were collected, and the genomic DNA of the B. subtilis 168 strain was extracted using a bacterial genome extraction kit. According to the published genome information sequence, primers Pppnk-F / Pppnk-R, PcsfB-F / PcsfB-R were designed respectively, using the e...

Embodiment 2

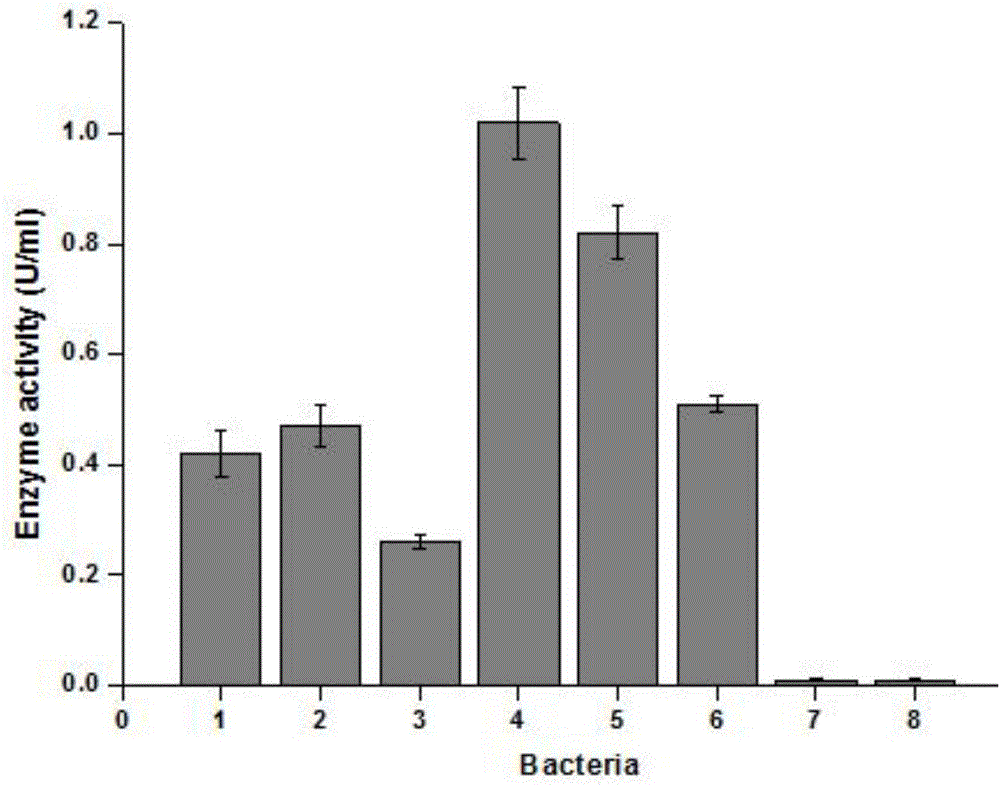

[0050] Embodiment 2 Shake flask culture and enzyme activity assay of 6 strains of recombinant Bacillus subtilis

[0051] The 6 recombinant Bacillus subtilis strains constructed above and the control bacteria B.subtilis 168 and B.subtilisWB600 were picked respectively, and the single clones were inoculated in 5 mL LB medium, and cultured overnight at 200 rpm at 37°C. After 16 hours, 10% of the inoculum was transferred to a 250 mL Erlenmeyer shaker flask. The culture medium was a fermentation medium with a filling volume of 25 mL, and cultured at 200 rpm at 37°C for 48 hours.

[0052] Take the 48h fermented liquid samples in each of 8 shake flasks and centrifuge at 5000×g at 4° C. for 5 min, retain the supernatant, and measure the crude enzyme activity in the supernatant. From attached figure 2 It can be seen that when using a strong constitutive promoter, a strong RBS and adding a histidine tag, the six recombinant Bacillus subtilis B.subtilis 168 / P43-H6cslA1; B.subtilis 168 / ...

Embodiment 3

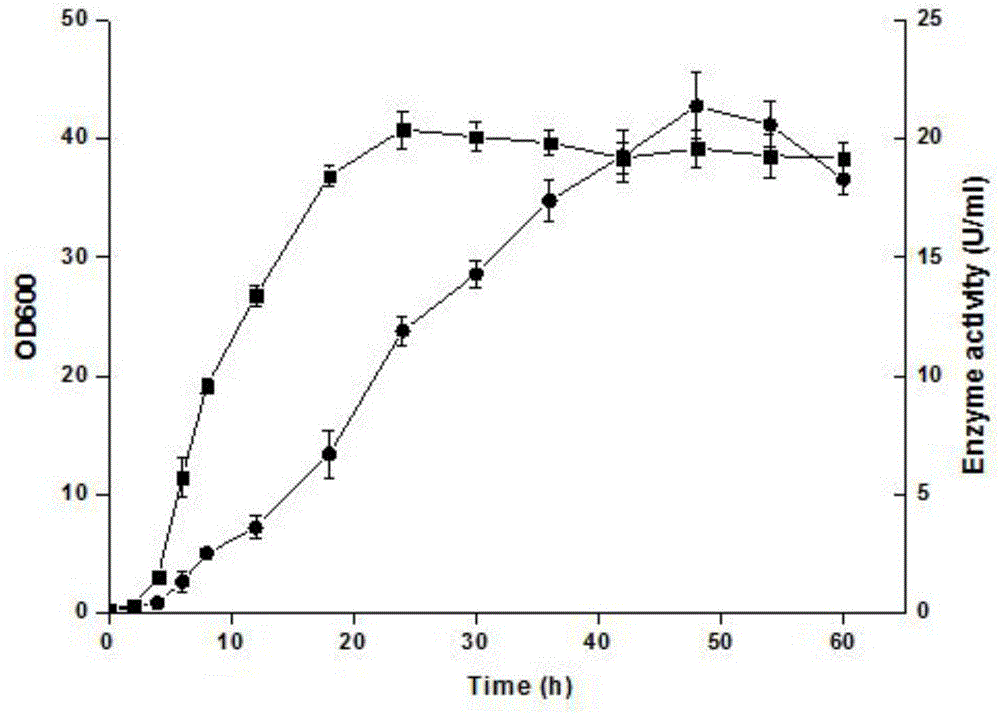

[0053] Embodiment 3 3L tank culture of recombinant Bacillus subtilis B.subtilisWB600 / P43-H6cslA1

[0054] Pick the recombinant Bacillus subtilis strain B. subtilis WB600 / P43-H6cslA1, inoculate a single clone in 15 mL LB medium, and culture overnight at 200 rpm at 37°C. After 16 hours, 10% of the inoculum was transferred to a 250ml Erlenmeyer flask with a liquid volume of 150mL, and then placed at 200rpm at 37°C for overnight cultivation as a seed solution. After 16 hours, 10% of the inoculum was transferred to a 3L fermenter with a liquid volume of 1.5L, cultured at a constant temperature of 37°C, with an aeration rate of 2vvm, and the pH was adjusted at 7.0 by 5M NaOH solution. The stirring speed was 400rpm for the first 4h, and then changed to 600rpm. At the 7th hour, when the initial sugar is exhausted, start feeding. The feeding rate is 10g / L / h for the 7th-9th hour, 15g / L / h for the 10th-12th hour, and 8g / L / h for the 13th-24th hour. After the 25th hour to the end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com