Plant proteinase extraction method and obtained plant proteinase

A plant protease and extraction method technology, applied in the direction of hydrolytic enzymes, etc., can solve the problems of low purity of papain, low enzyme activity and purity, and low extraction specificity, and achieve good enzyme activity and purity, and purification effect Good, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

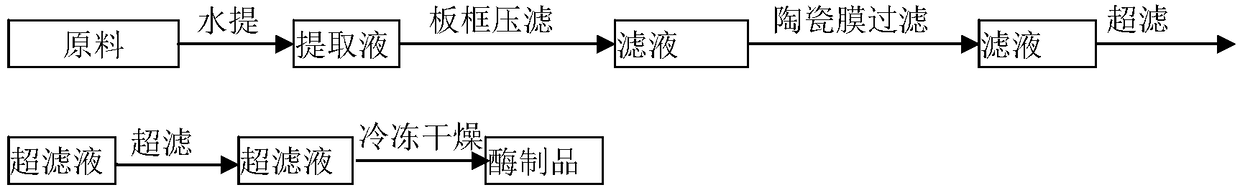

[0043] A kind of extraction method of papain, described method is made up of the following steps:

[0044] Mix papaya pulp and process water at a material-to-liquid ratio of 1:10, add enzyme protection agents sodium benzoate and EDTA-2Na, and the mass fractions of the sodium benzoate and the EDTA-2Na in the mixed solution are 0.1% to 0.1%. 0.2%, stirred and reacted for 1.5h to obtain the extract;

[0045] The obtained extract is filtered through a plate and frame filter press and a ceramic membrane successively, the filter cloth aperture of the plate and frame filter press is 150 mesh, and the aperture of the ceramic membrane is 50nm;

[0046] Using an ultrafiltration membrane with a molecular weight cut-off of 50KDa to carry out the first ultrafiltration treatment on the filtrate, collecting the filtrate, and using an ultrafiltration membrane with a molecular weight cut-off of 10KDa to carry out the second ultrafiltration treatment on the filtrate to collect the retentate;

...

Embodiment 2

[0049] A method for extracting mogrosin protease, the method is composed of the following steps:

[0050] Wash and crush fresh Luo Han Guo, centrifuge to remove slag to obtain Luo Han fruit juice, mix Luo Han fruit juice with process water at a material-to-liquid ratio of 1:10, and stir for 1.5 hours to obtain the extract;

[0051] The obtained extract is filtered through a plate and frame filter press and a ceramic membrane successively, the filter cloth aperture of the plate and frame filter press is 150 mesh, and the aperture of the ceramic membrane is 200nm;

[0052] Using an ultrafiltration membrane with a molecular weight cut-off of 50KDa to carry out the first ultrafiltration treatment on the filtrate, collecting the filtrate, and using an ultrafiltration membrane with a molecular weight cut-off of 10KDa to carry out the second ultrafiltration treatment on the filtrate to collect the retentate;

[0053] The retentate is concentrated to obtain a concentrated solution, an...

Embodiment 3

[0055] A kind of extraction method of actinidia protease, described method is made up of the following steps:

[0056] Mix crushed kiwi fruit with pH = 4.5, 24% NaCl aqueous solution with a mass fraction of 1:5, stir for 1.5 hours, and separate solid and liquid after low-temperature precipitation for 6 hours. The buffer is redissolved to obtain the extract;

[0057] The obtained extract is filtered through a plate and frame filter press and a ceramic membrane successively, the filter cloth aperture of the plate and frame filter press is 100 mesh, and the aperture of the ceramic membrane is 100nm;

[0058] Using an ultrafiltration membrane with a molecular weight cut-off of 50KDa to carry out the first ultrafiltration treatment on the filtrate, collecting the filtrate, and using an ultrafiltration membrane with a molecular weight cut-off of 10KDa to carry out the second ultrafiltration treatment on the filtrate to collect the retentate;

[0059] The retentate is concentrated t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com