Patents

Literature

67results about "Chromium sulfates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesis of carbon-coated redox materials with controlled size

ActiveUS20040033360A1Low costReduce the numberMaterial nanotechnologyHybrid capacitorsCross-linkRedox

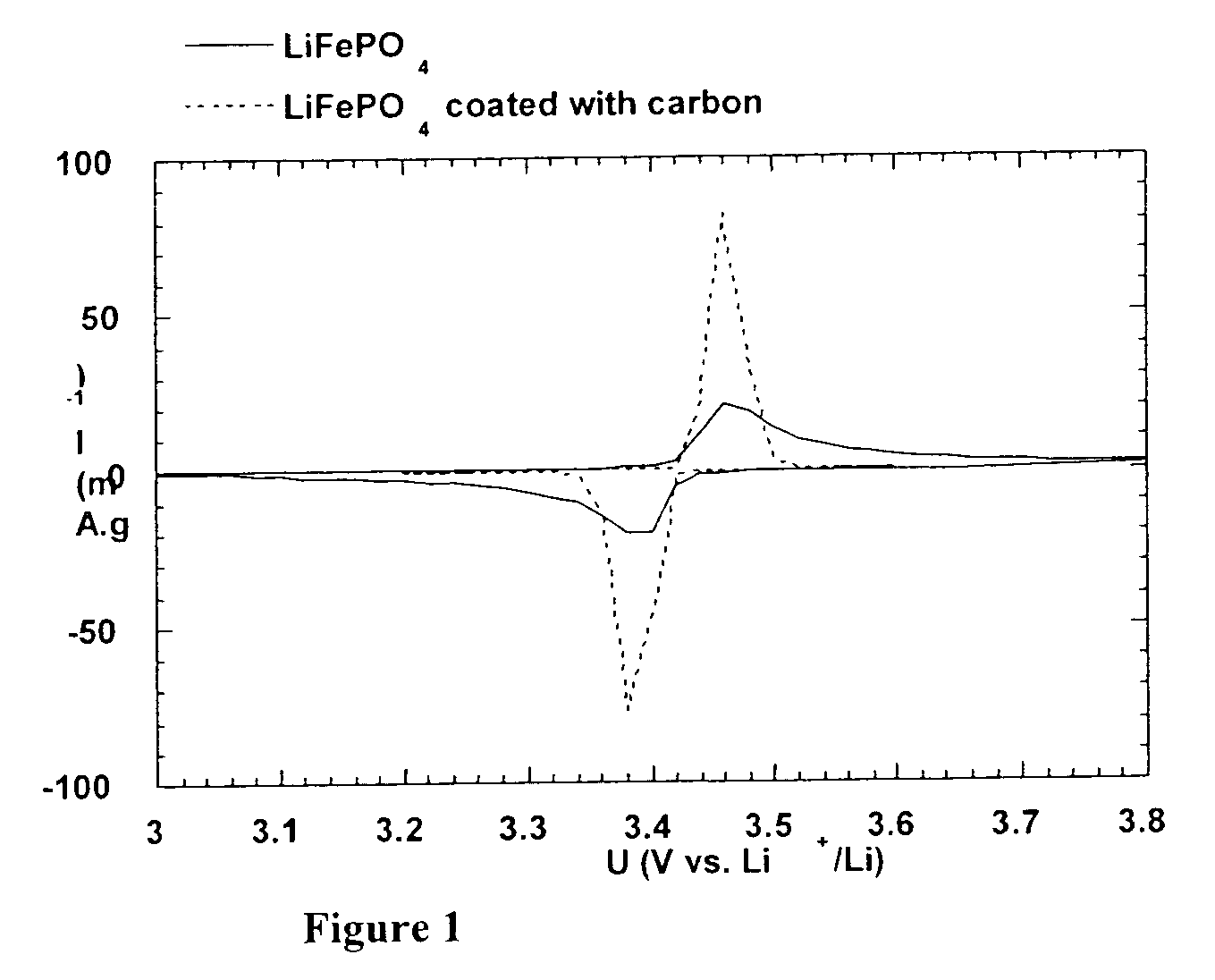

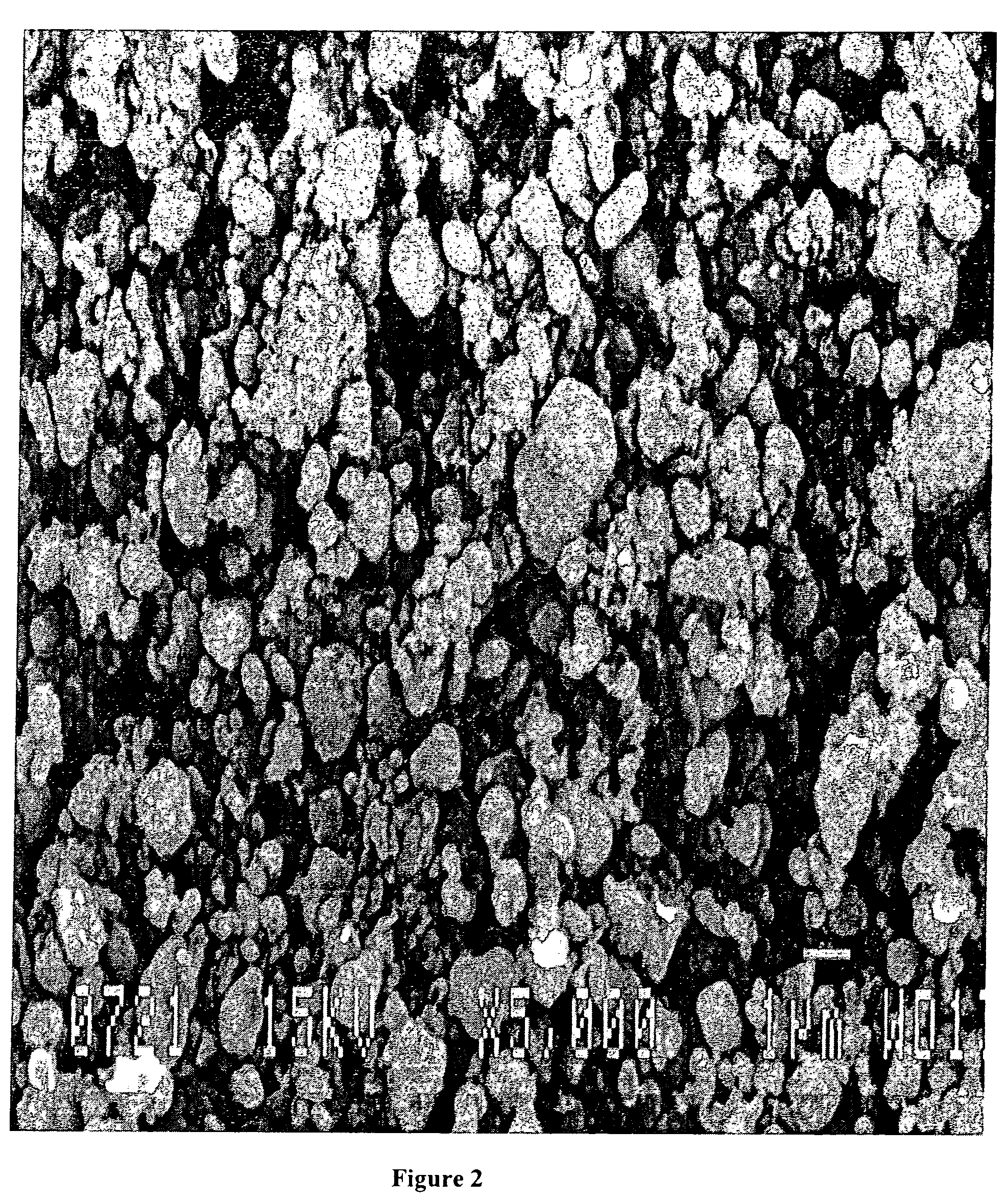

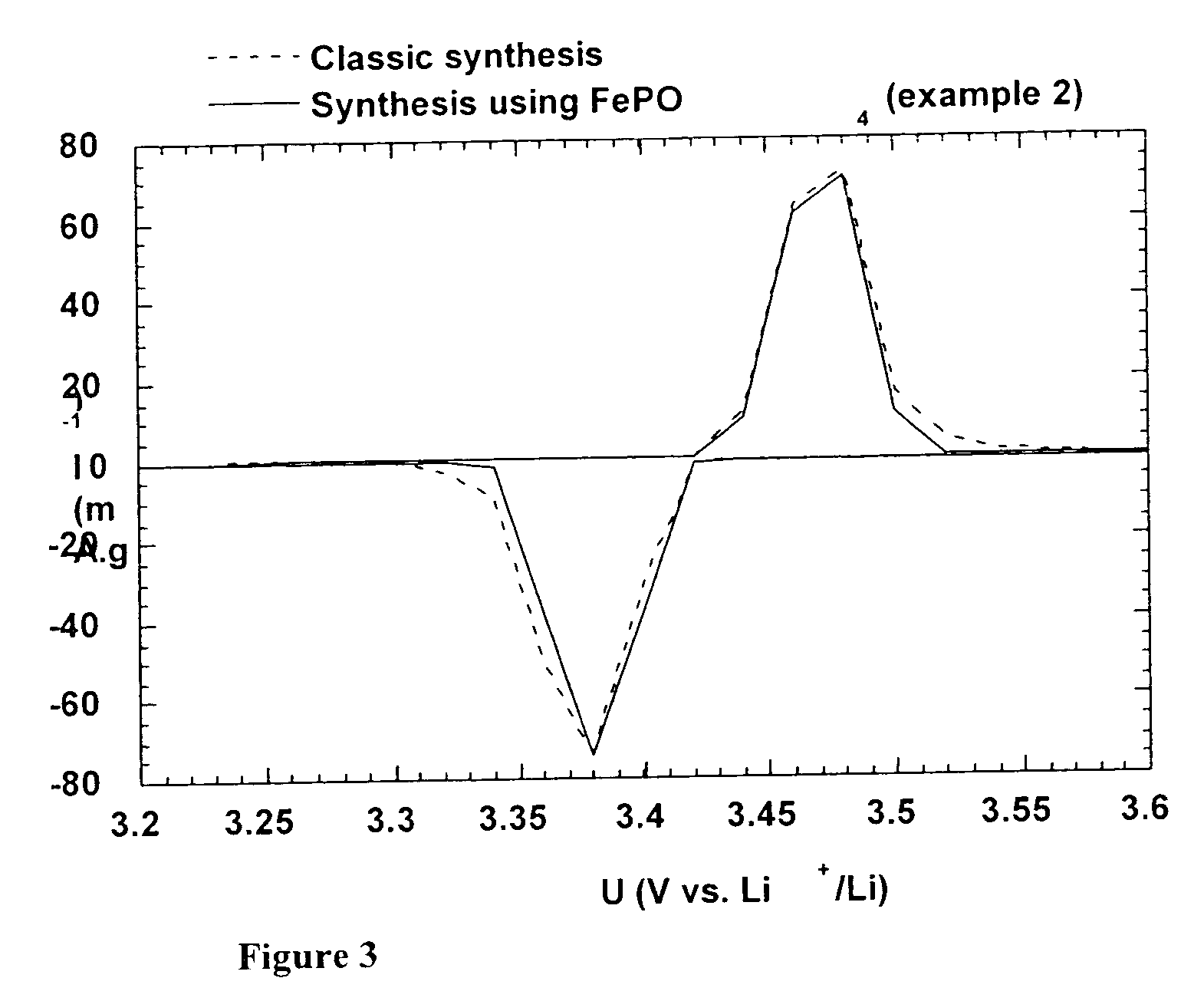

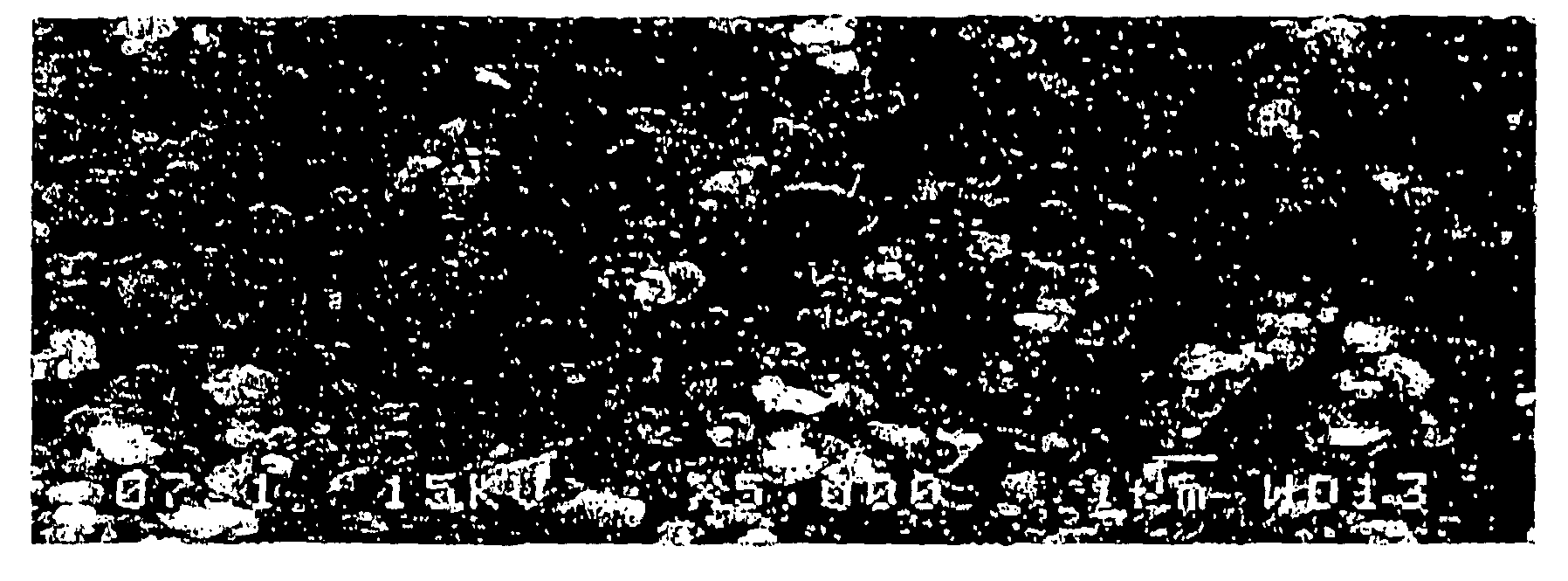

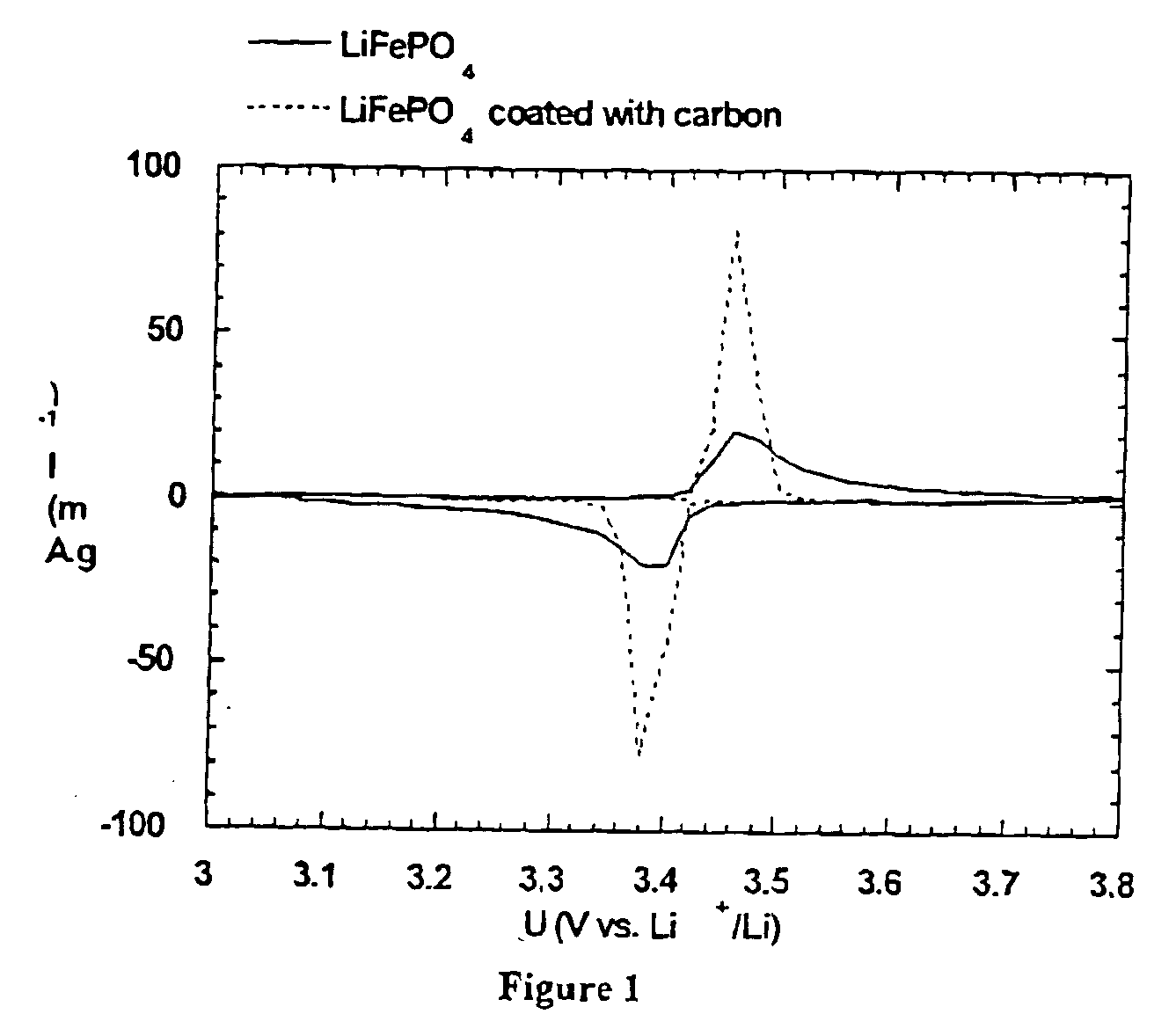

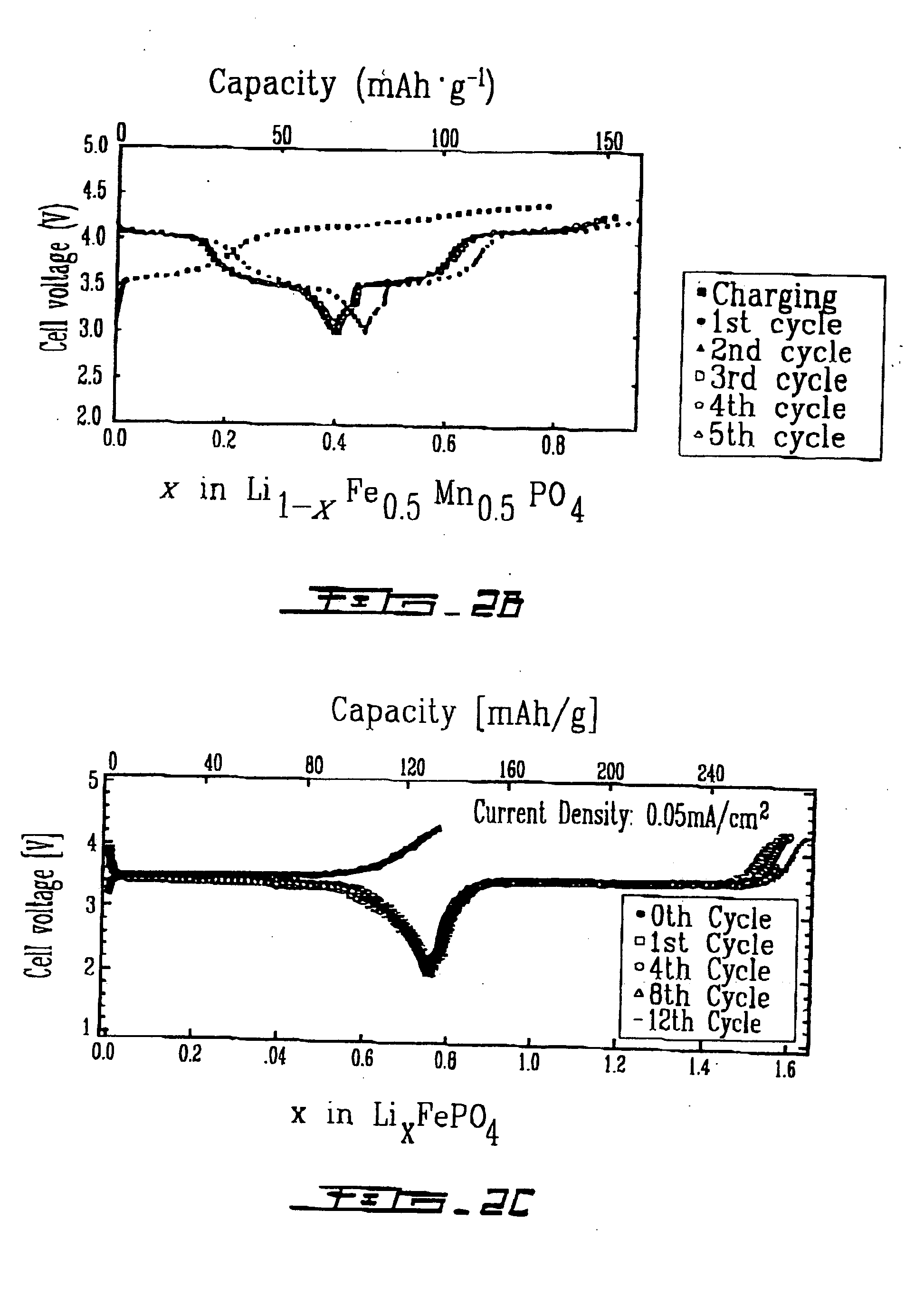

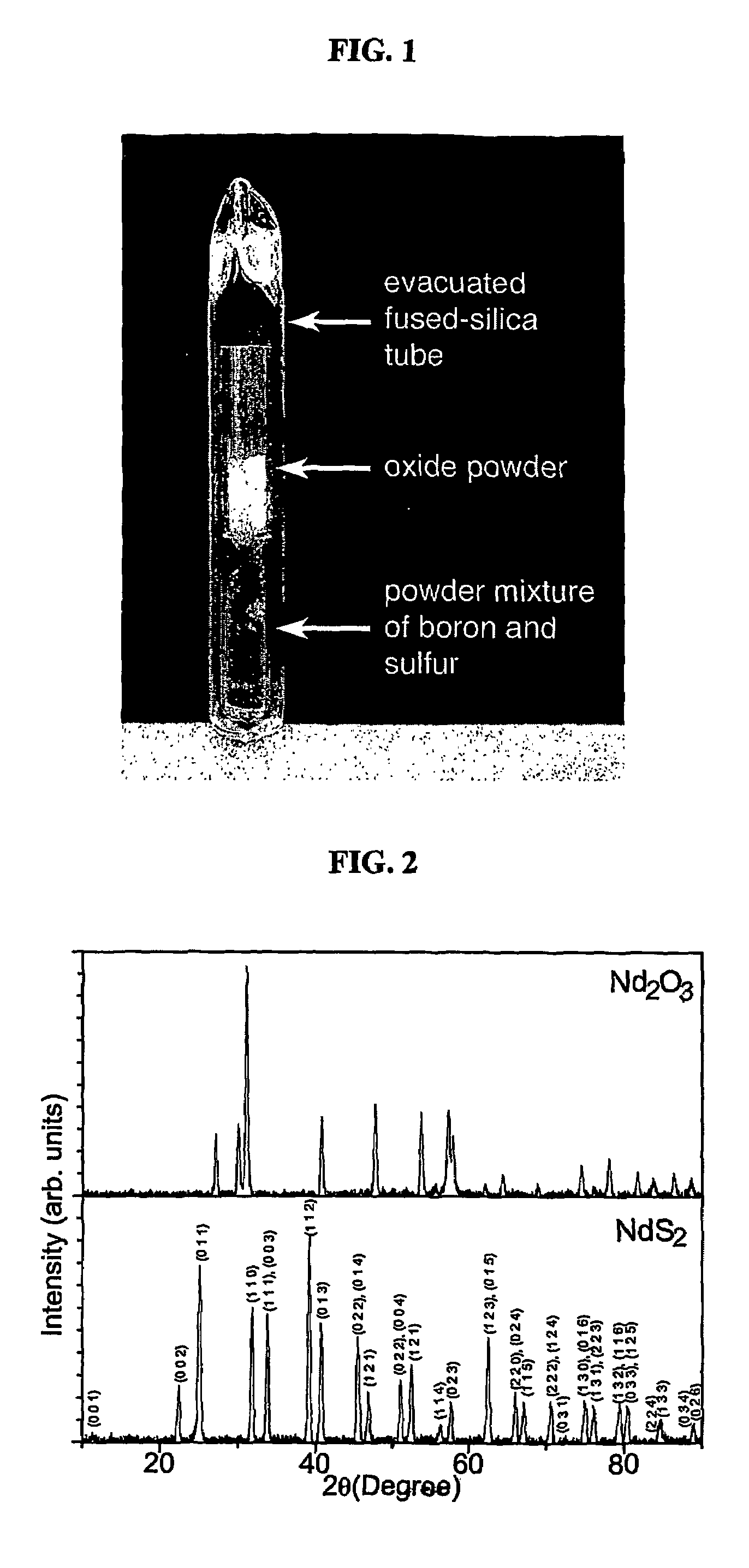

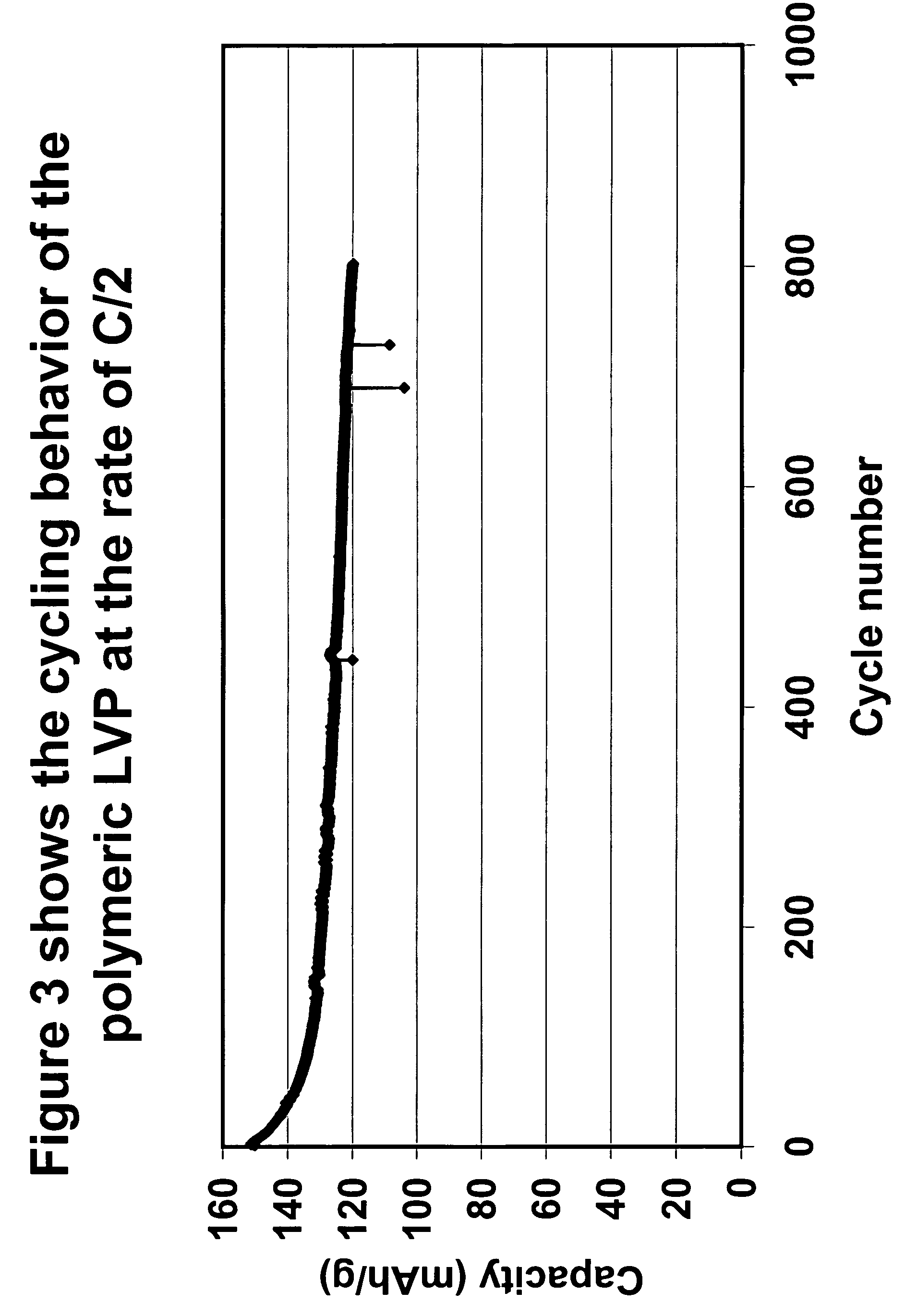

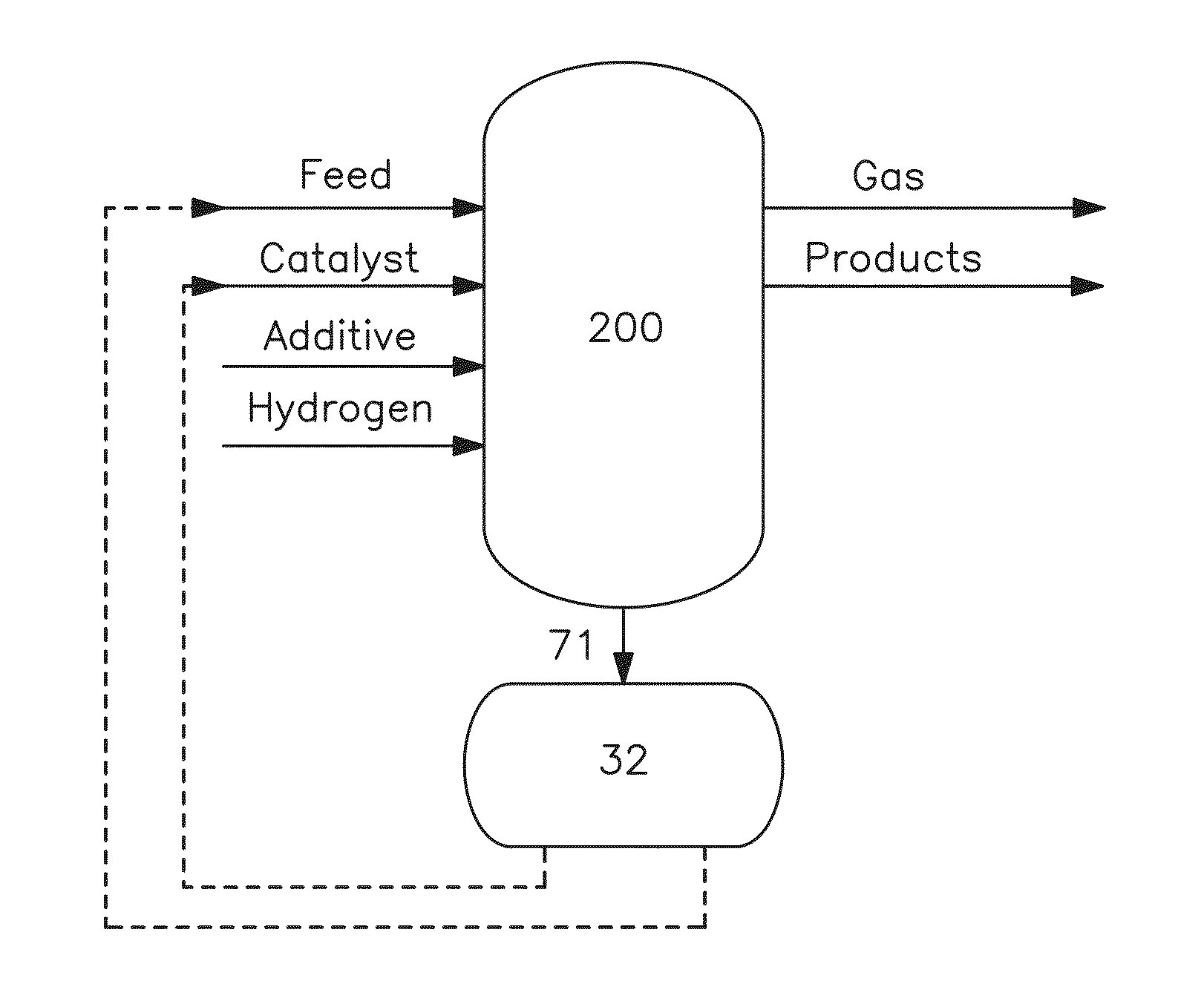

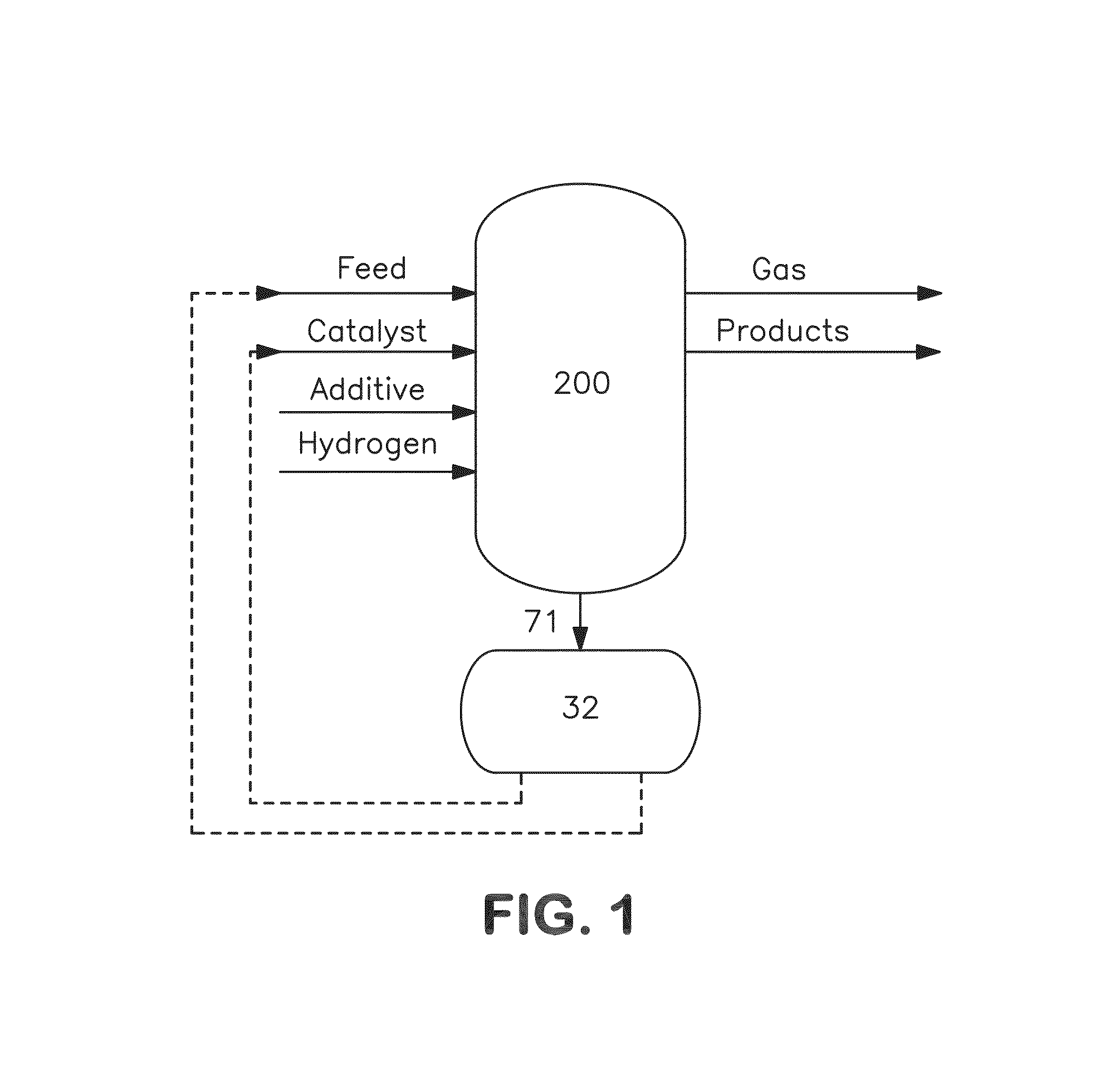

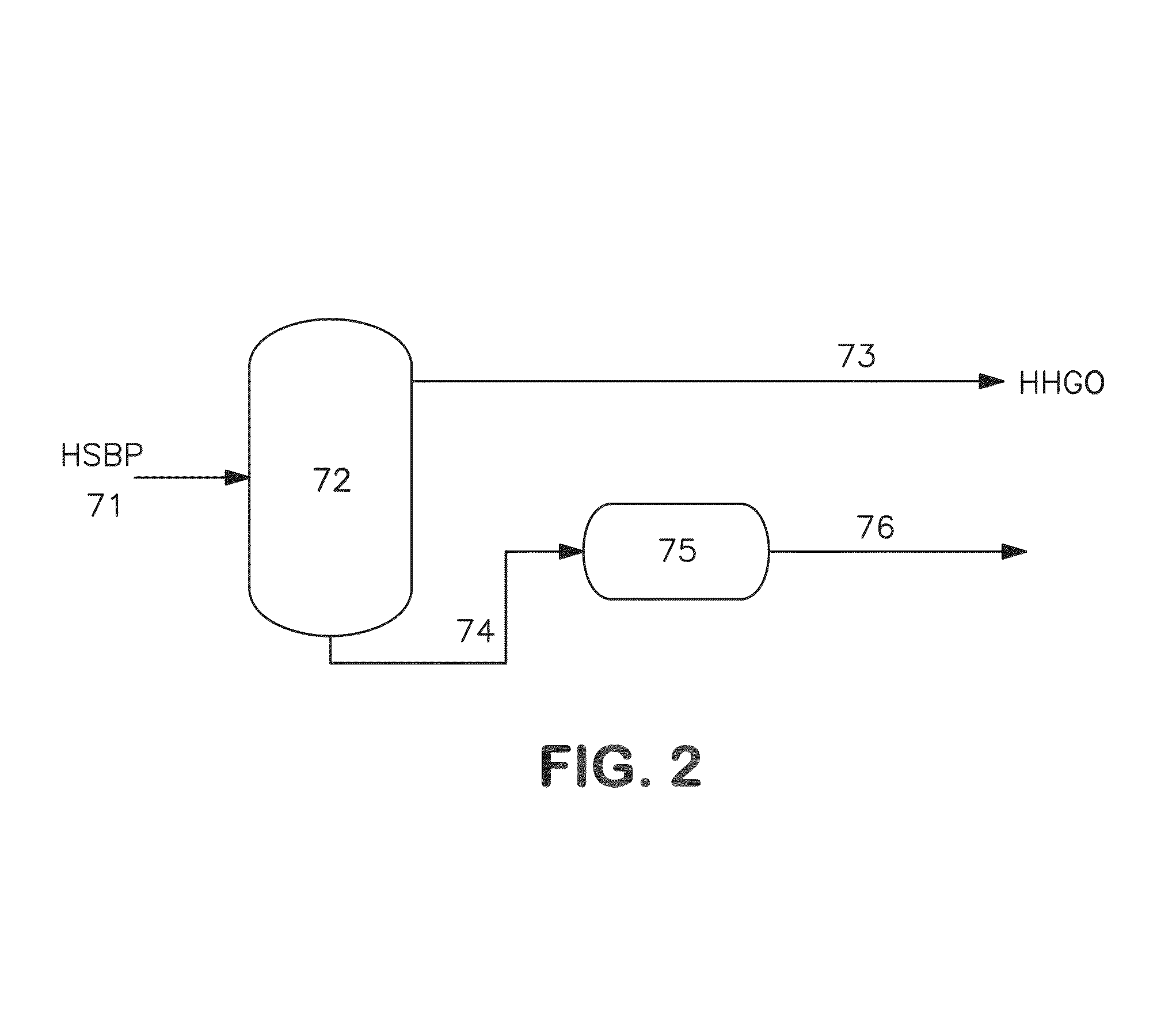

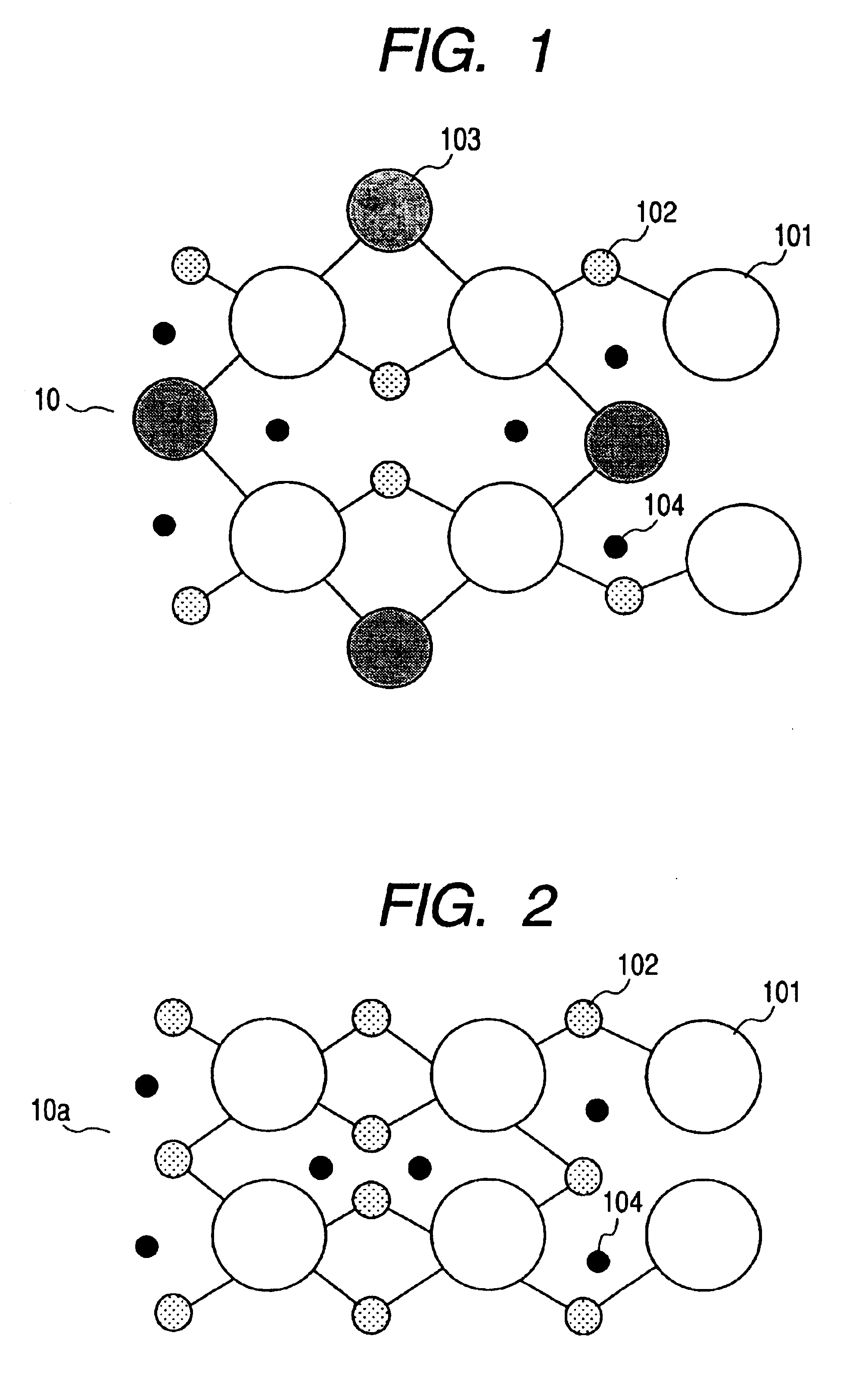

A method for the synthesis of compounds of the formula C-LixM1-yM'y(XO4)n, where C represents carbon cross-linked with the compound LixM1-yM'y(XO4)n, in which x, y and n are numbers such as 0<=x<=2, 0<=y<=0.6, and 1<=n<=1.5, M is a transition metal or a mixture of transition metals from the first period of the periodic table, M' is an element with fixed valency selected among Mg<2+>, Ca<2+>, Al<3+>, Zn<2+> or a combination of these same elements and X is chosen among S, P and Si, by bringing into equilibrium, in the required proportions, the mixture of precursors, with a gaseous atmosphere, the synthesis taking place by reaction and bringing into equilibrium, in the required proportions, the mixture of the precursors, the procedure comprising at least one pyrolysis step of the carbon source compound in such a way as to obtain a compound in which the electronic conductivity measured on a sample of powder compressed at a pressure of 3750 Kg.cm<-2 >is greater than 10<-8 >S.cm<-1>. The materials obtained have excellent electrical conductivity, as well a very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Synthesis method for carbon material based on lixm1-ym'(xo4)n

InactiveUS20040086445A1Improve performanceLow costHybrid capacitorsElectrolytic capacitorsElectrical conductorSynthesis methods

Method of synthesis for a material made of particles having a core and a coating and / or being connected to each other by carbon cross-linking, the core of these particles containing at least one compound of formula LixM1-yM'y(XO4)n, in which x,y and n are numbers such as 0<=x<=2, 0<=y<=0.6 and 1<=n<=1.5, M is a transition metal, M' is an element with fixed valency, and the synthesis is carried out by reaction and bringing into equilibrium the mixture of precursors, with a reducing gaseous atmosphere, in such a way as to bring the transition metal or metals to the desired valency level, the synthesis being carried out in the presence of a source of carbon called carbon conductor, which is subjected to pyrolysis. The materials obtained have excellent electrical conductivity as well as very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Cathode materials for secondary (rechargeable) lithium batteries

InactiveUS20050003274A1Cell electrodesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAlkali ionsRechargeable cell

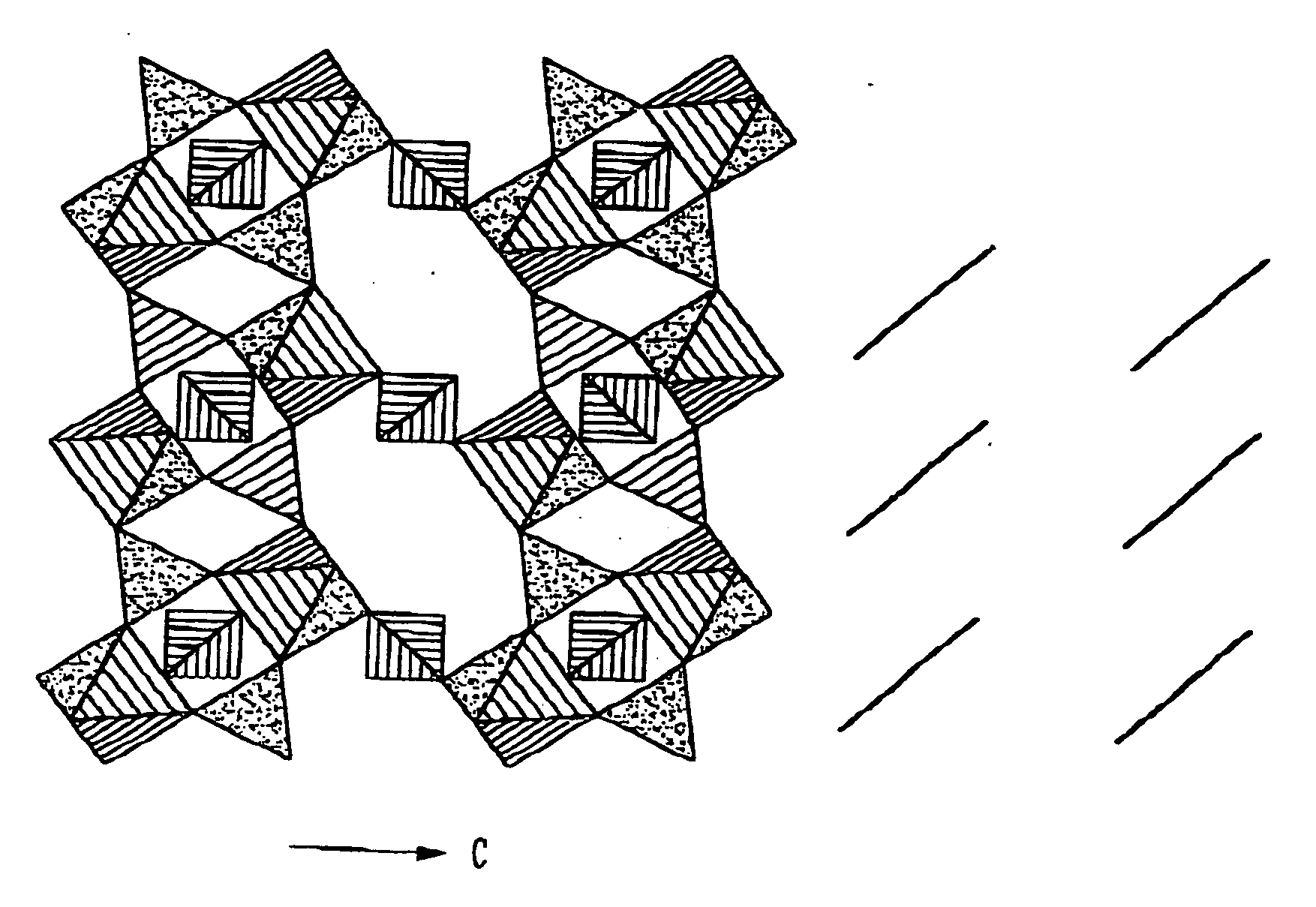

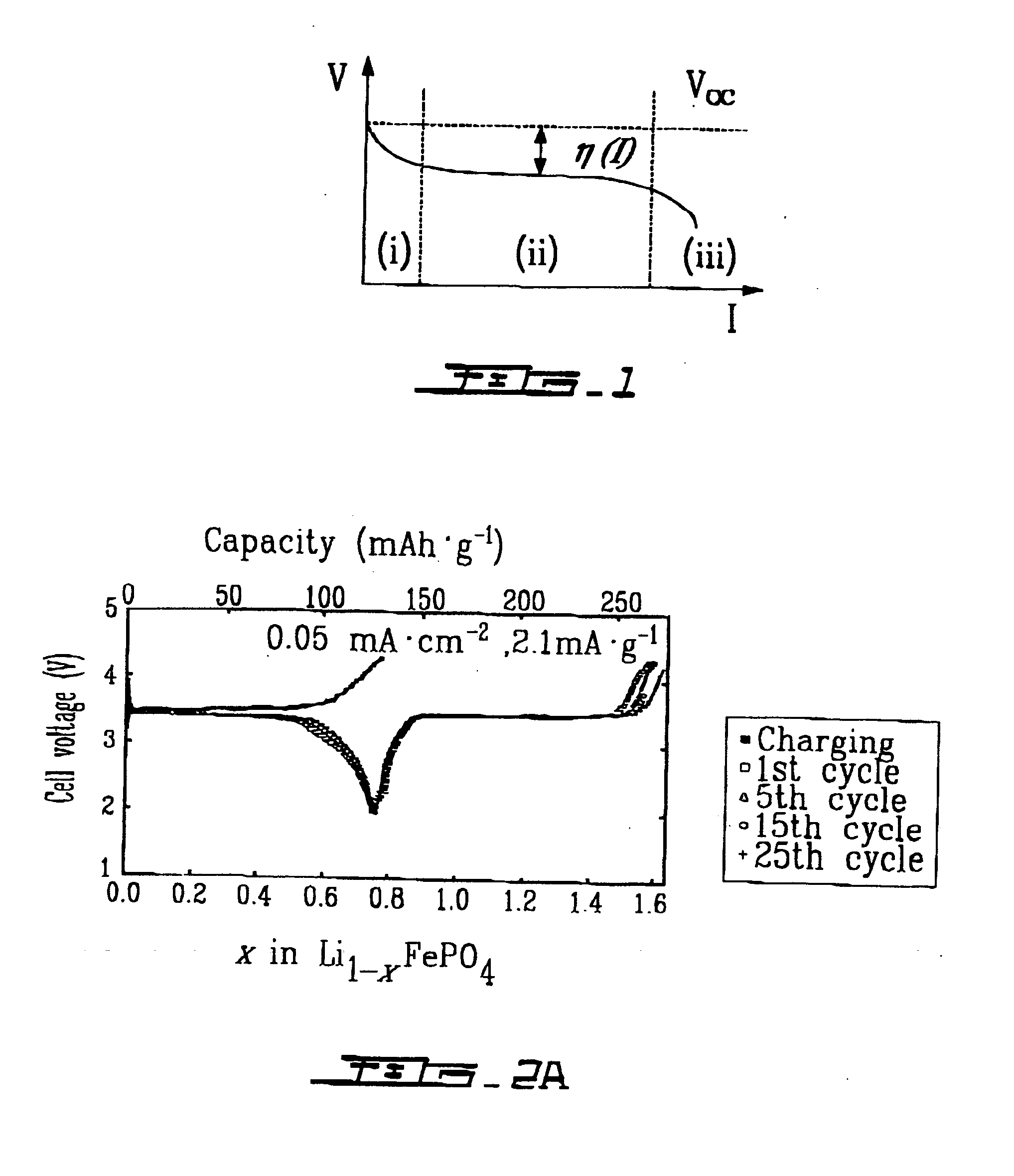

The invention relates to materials for use as electrodes in an alkali-ion secondary (rechargeable) battery, particularly a lithium-ion battery. The invention provides transition-metal compounds having the ordered-olivine, a modified olivine, or the rhombohedral NASICON structure and the polyanion (PO4)3− as at least one constituent for use as electrode material for alkali-ion rechargeable batteries.

Owner:HYDRO QUEBEC CORP

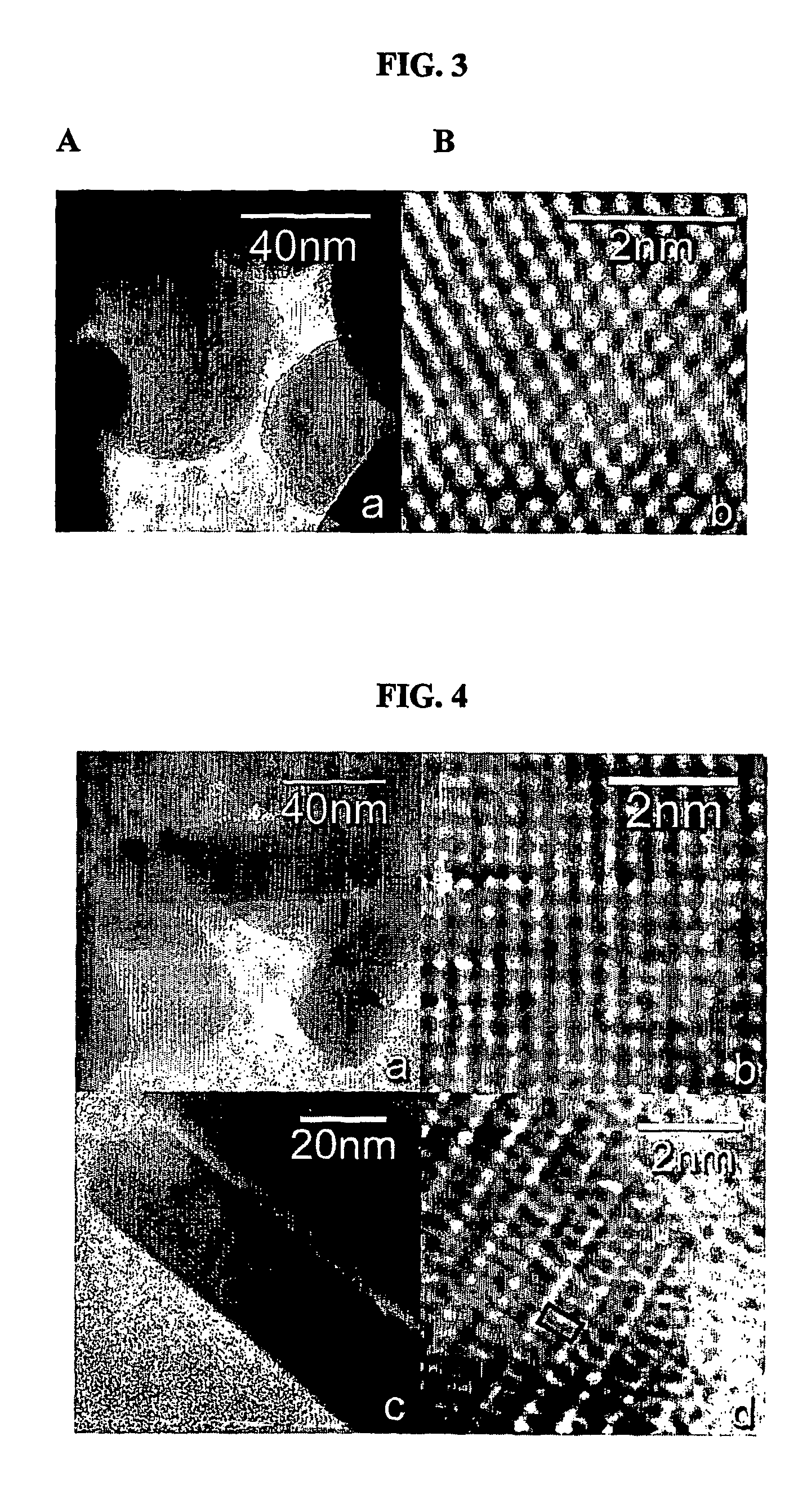

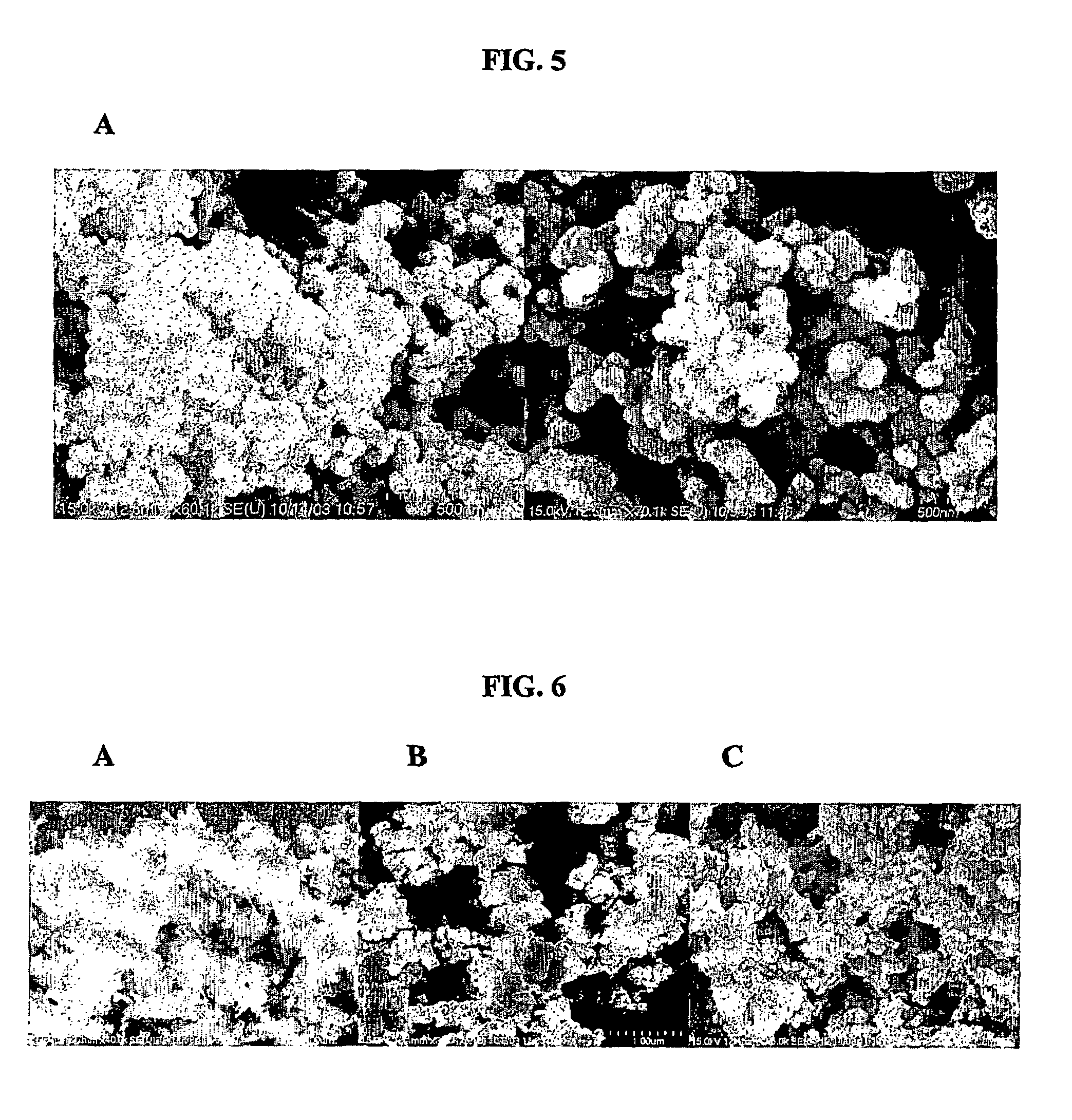

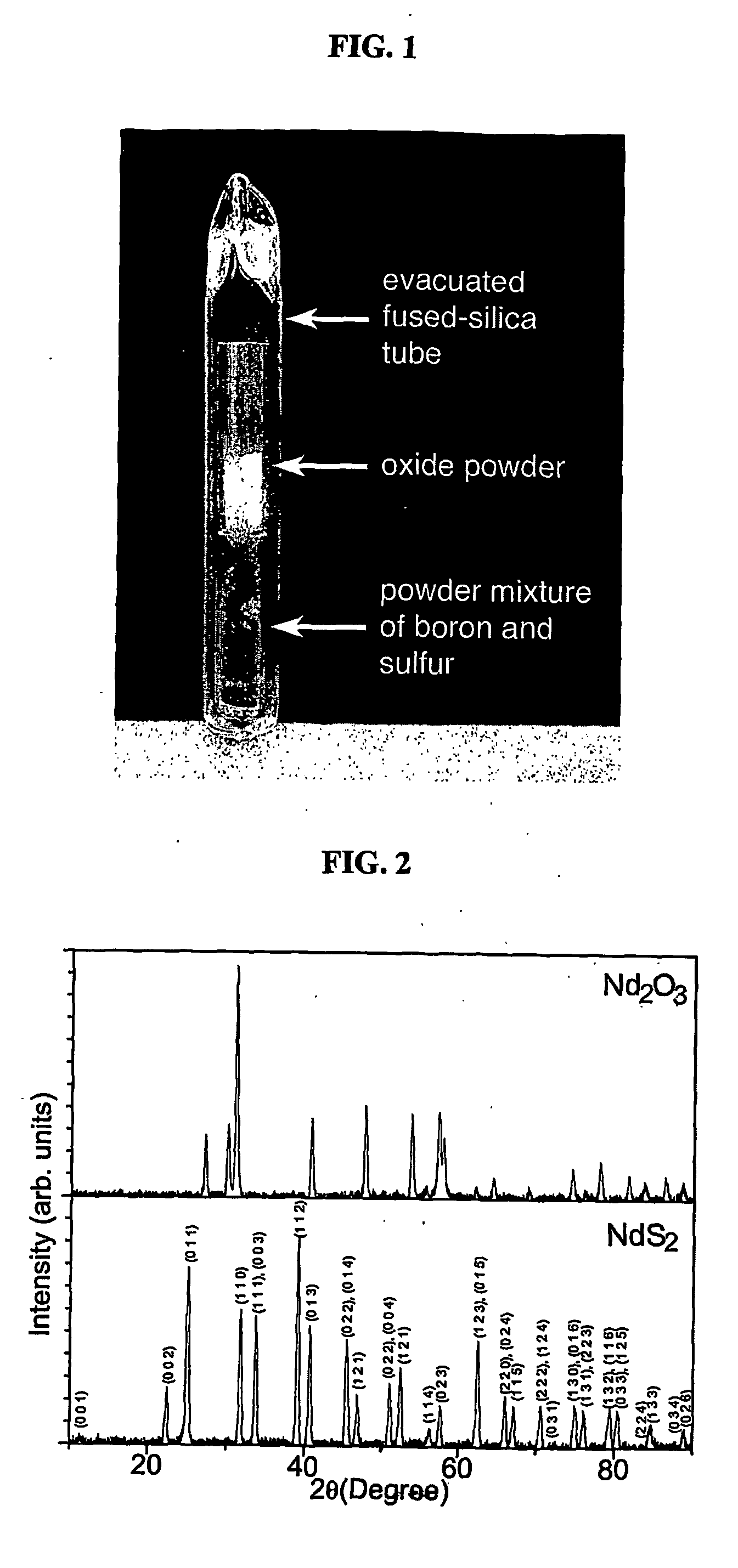

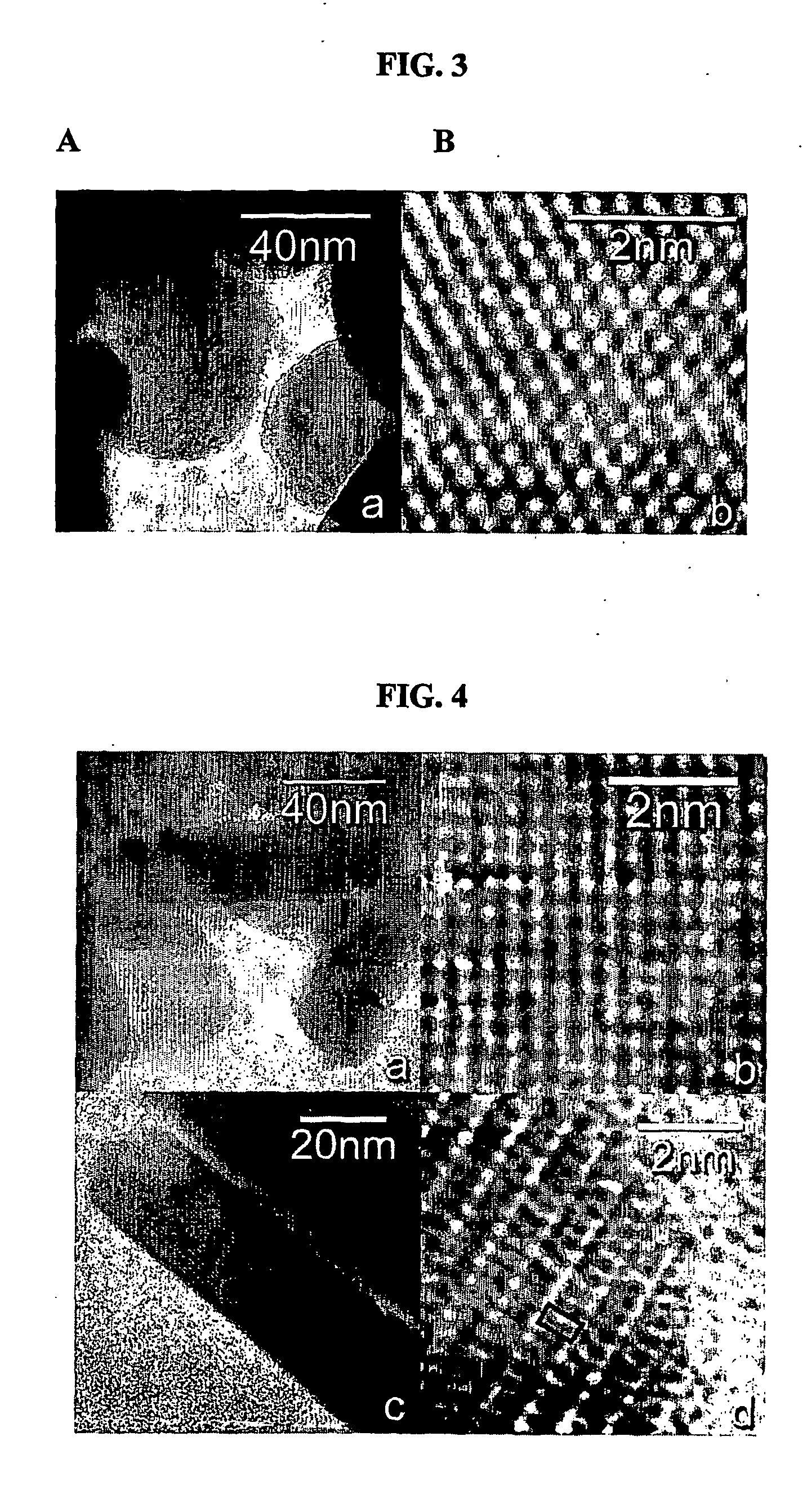

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

InactiveUS20060239882A1Rare earth metal sulfidesSelenium/tellurium compundsSufficient timeNanoparticle

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

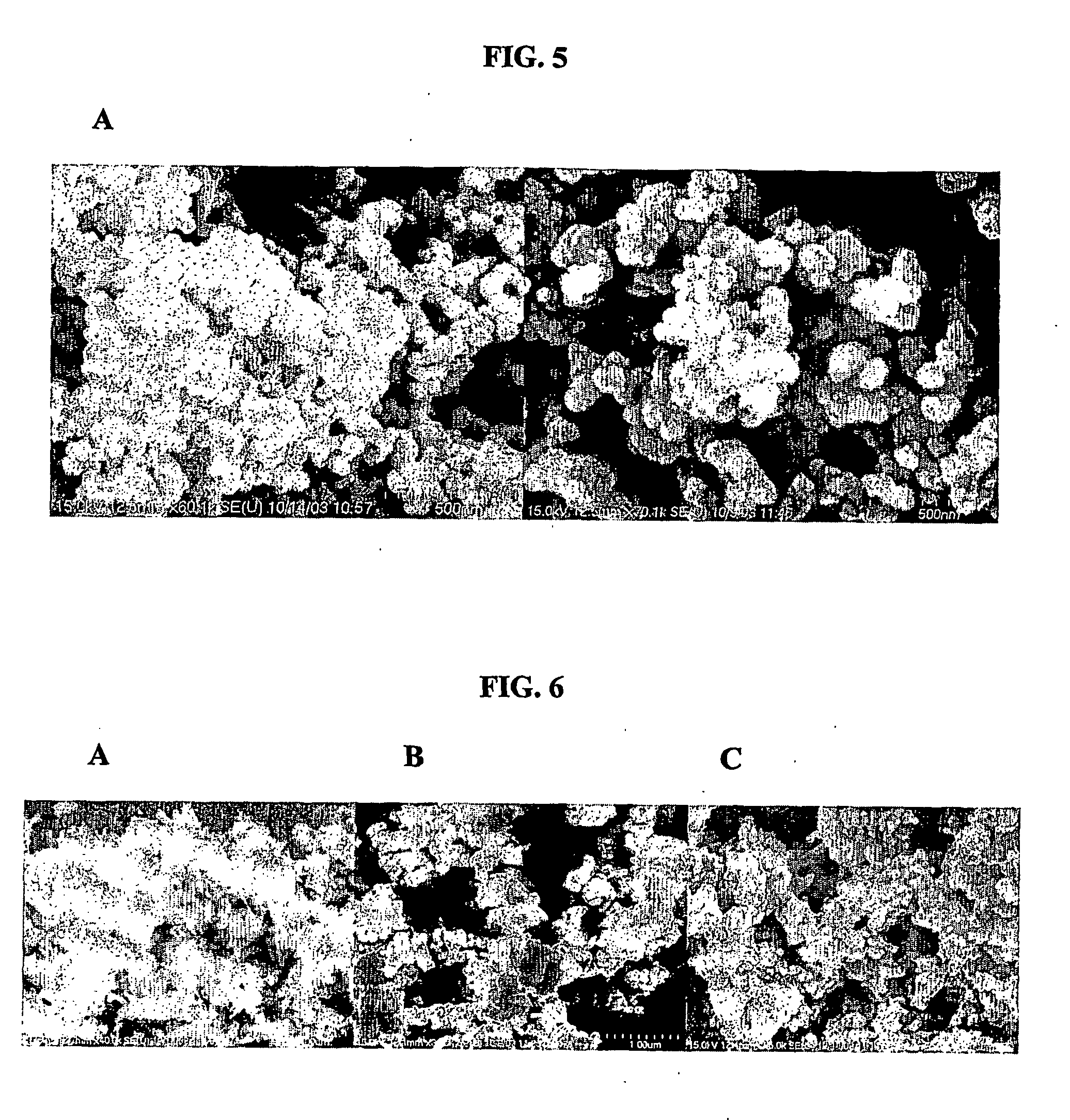

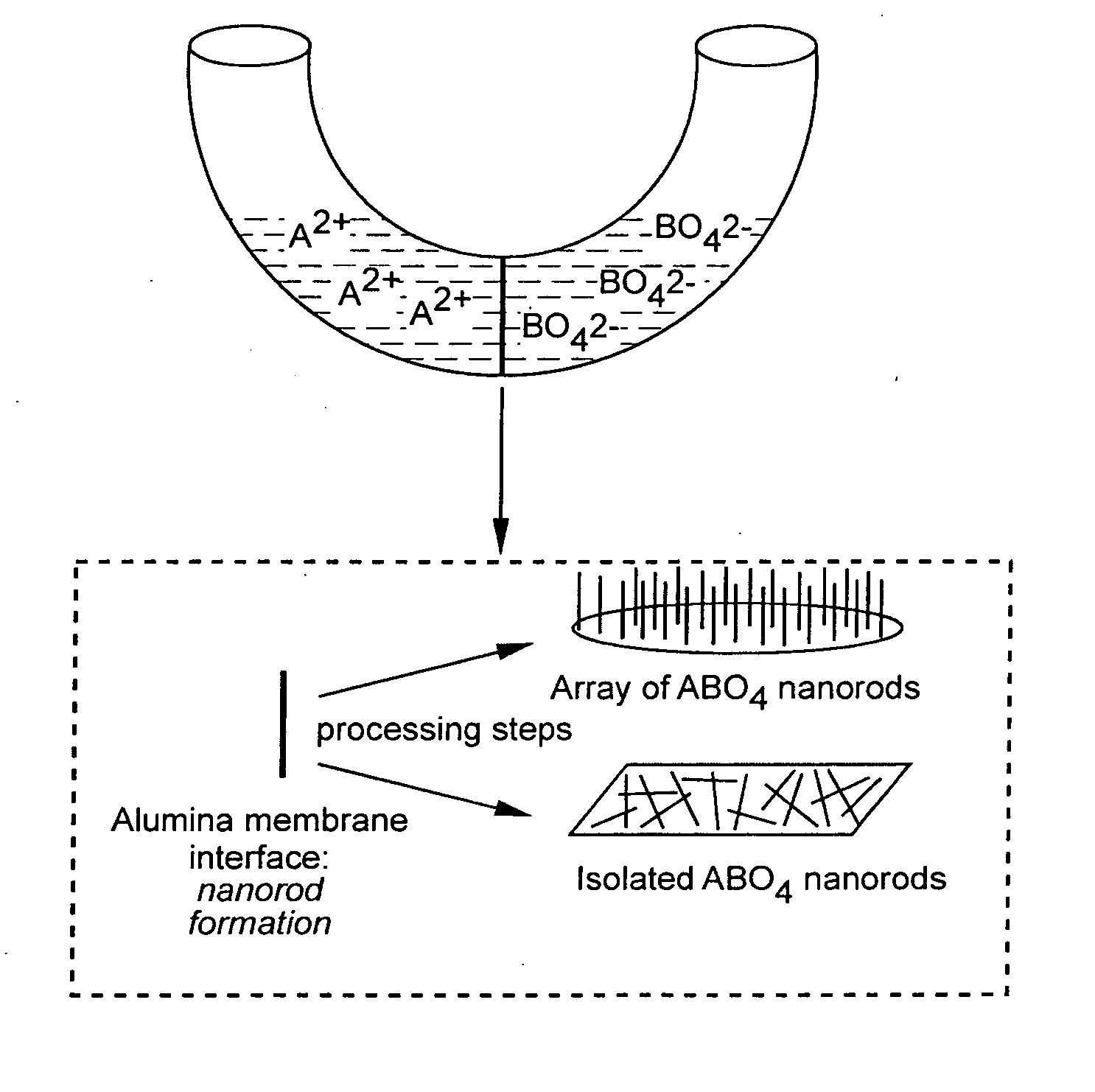

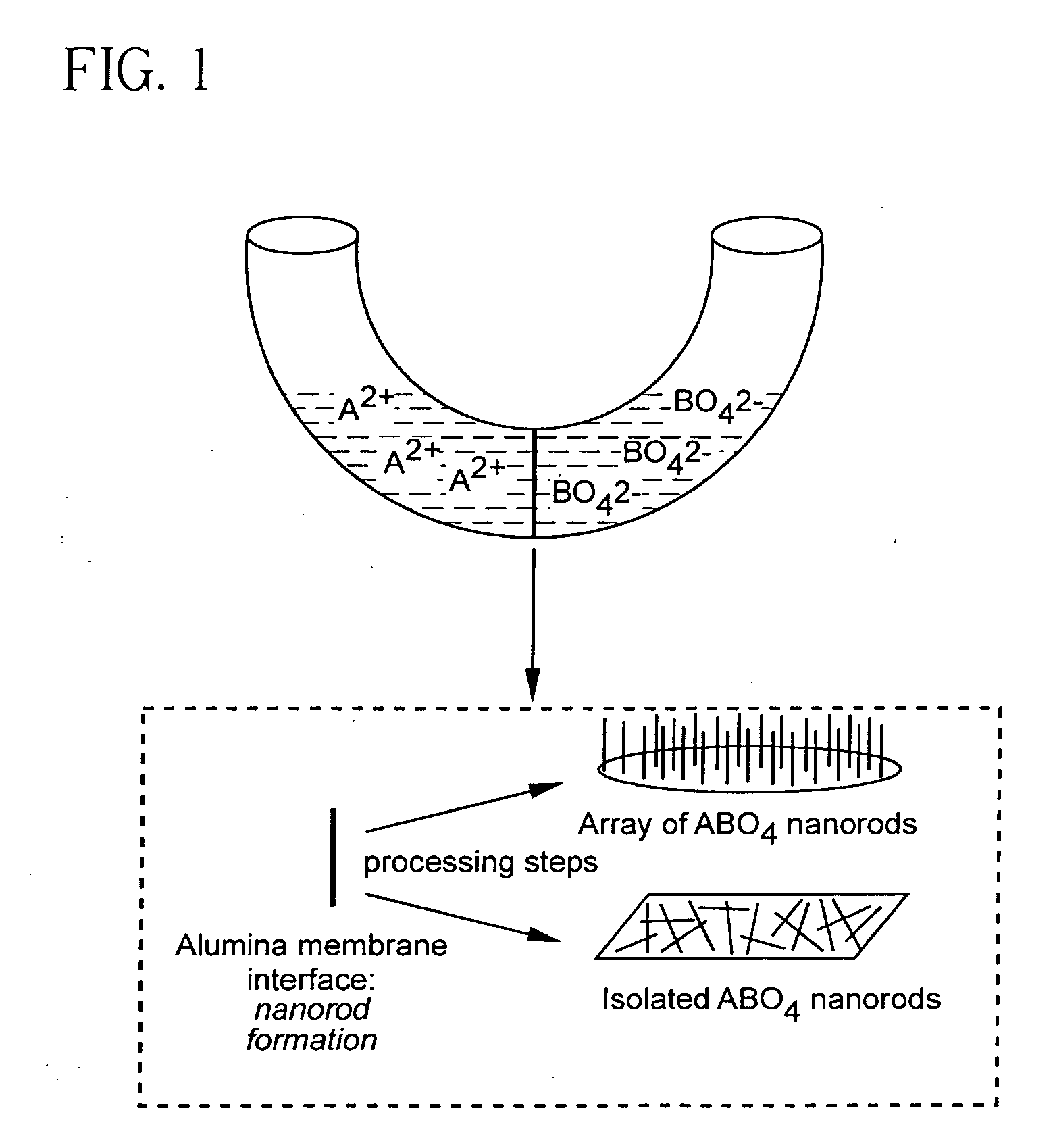

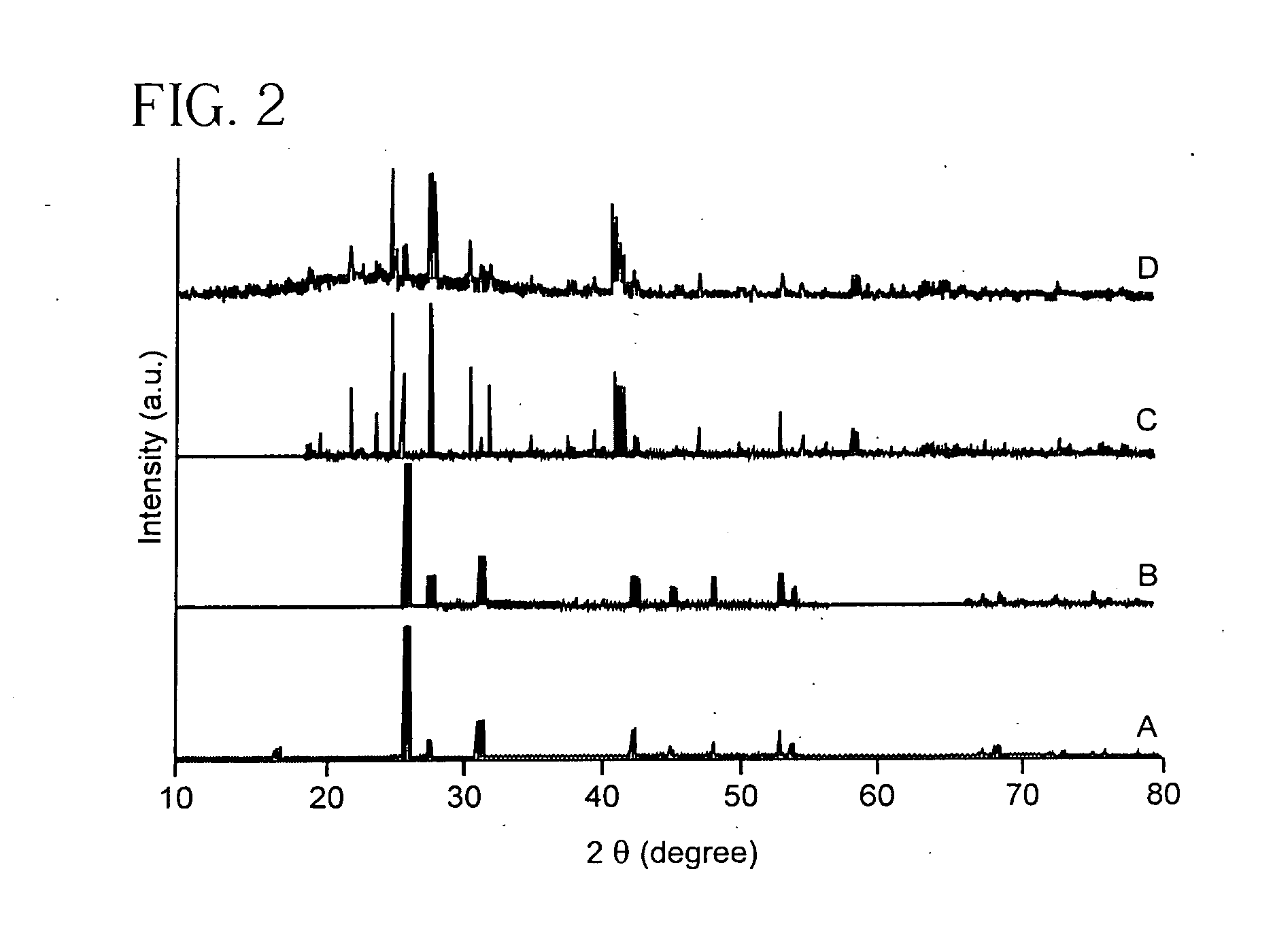

Metal oxide and metal fluoride nanostructures and methods of making same

InactiveUS20070113779A1Easy to controlOvercomes shortcomingMercury oxidesAlkali metal oxides/hydroxidesSingle crystalNanostructure

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

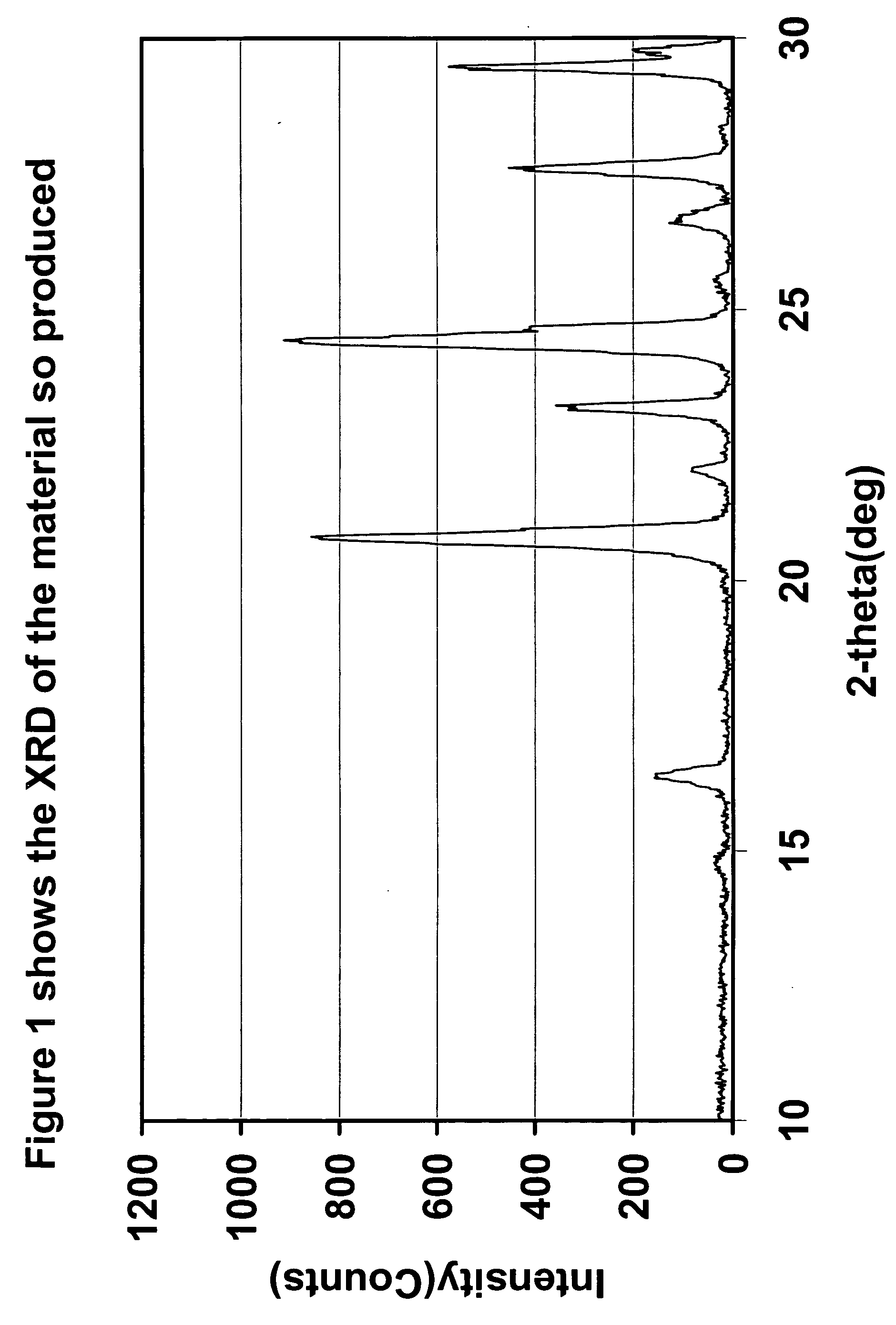

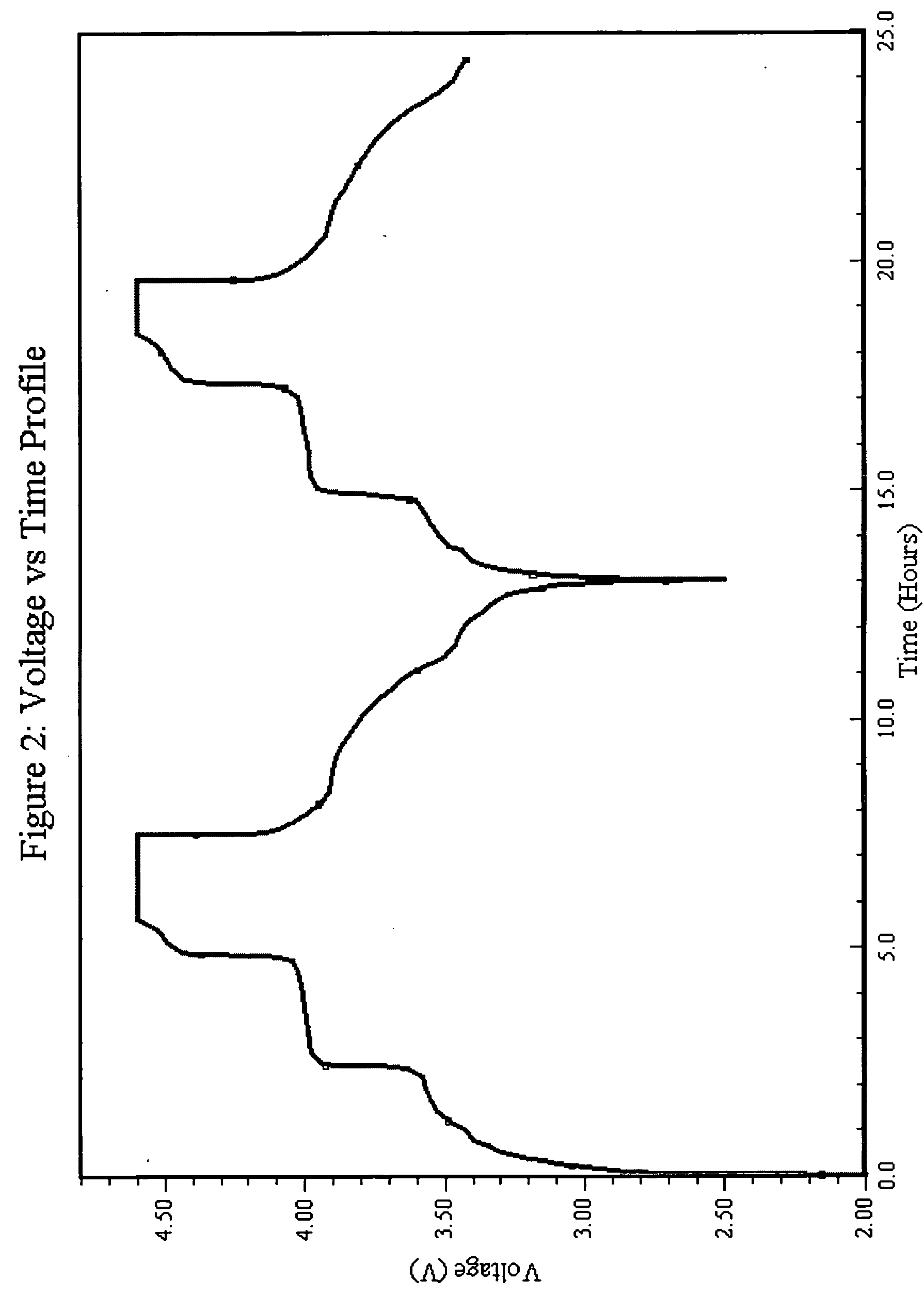

Synthesis of cathode active materials

The present invention relates to a method for preparing an electroactive metal polyanion or a mixed metal polyanion comprising forming a slurry comprising a polymeric material, a solvent, a polyanion source or alkali metal polyanion source and at least one metal ion source; heating said slurry at a temperature and for a time sufficient to remove the solvent and form an essentially dried mixture; and heating said mixture at a temperature and for a time sufficient to produce an electroactive metal polyanion or electroactive mixed metal polyanion. In an alternative embodiment the present invention relates to a method for preparing a metal polyanion or a mixed metal polyanion which comprises mixing a polymeric material with a polyanion source or alternatively an alkali metal polyanion source and a source of at least one metal ion to produce a fine mixture and heating the mixture to a temperature higher than the melting point of the polymeric material, milling the resulting material and then heating the milled material. It is another object of the invention to provide electrochemically active materials produced by said methods. The electrochemically active materials so produced are useful in making electrodes and batteries.

Owner:LITHIUM WERKS TECH BV +1

Antibacterial Agent Composed of Silver-Containing Aluminum Sulfate Hydroxide Particles and Use Thereof

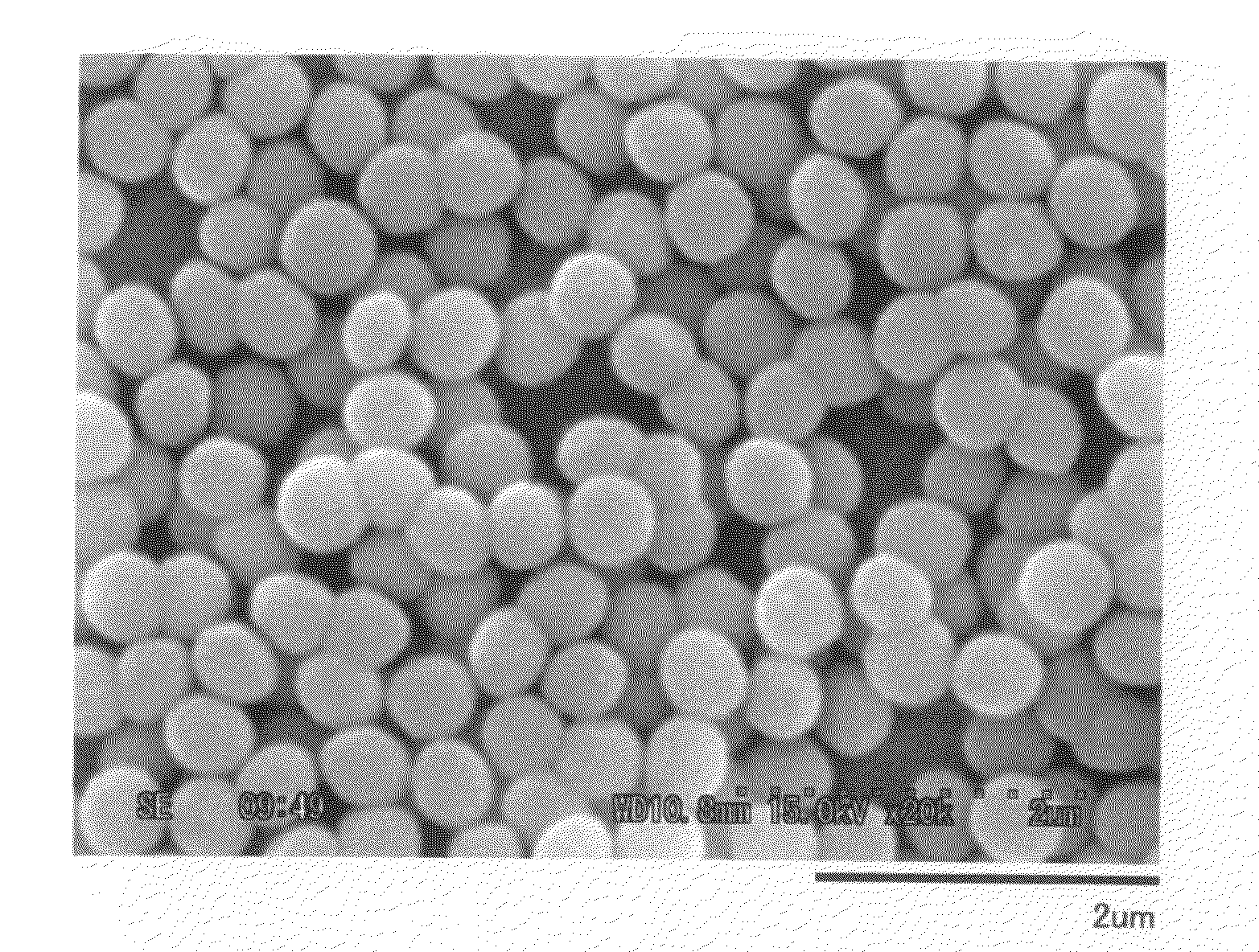

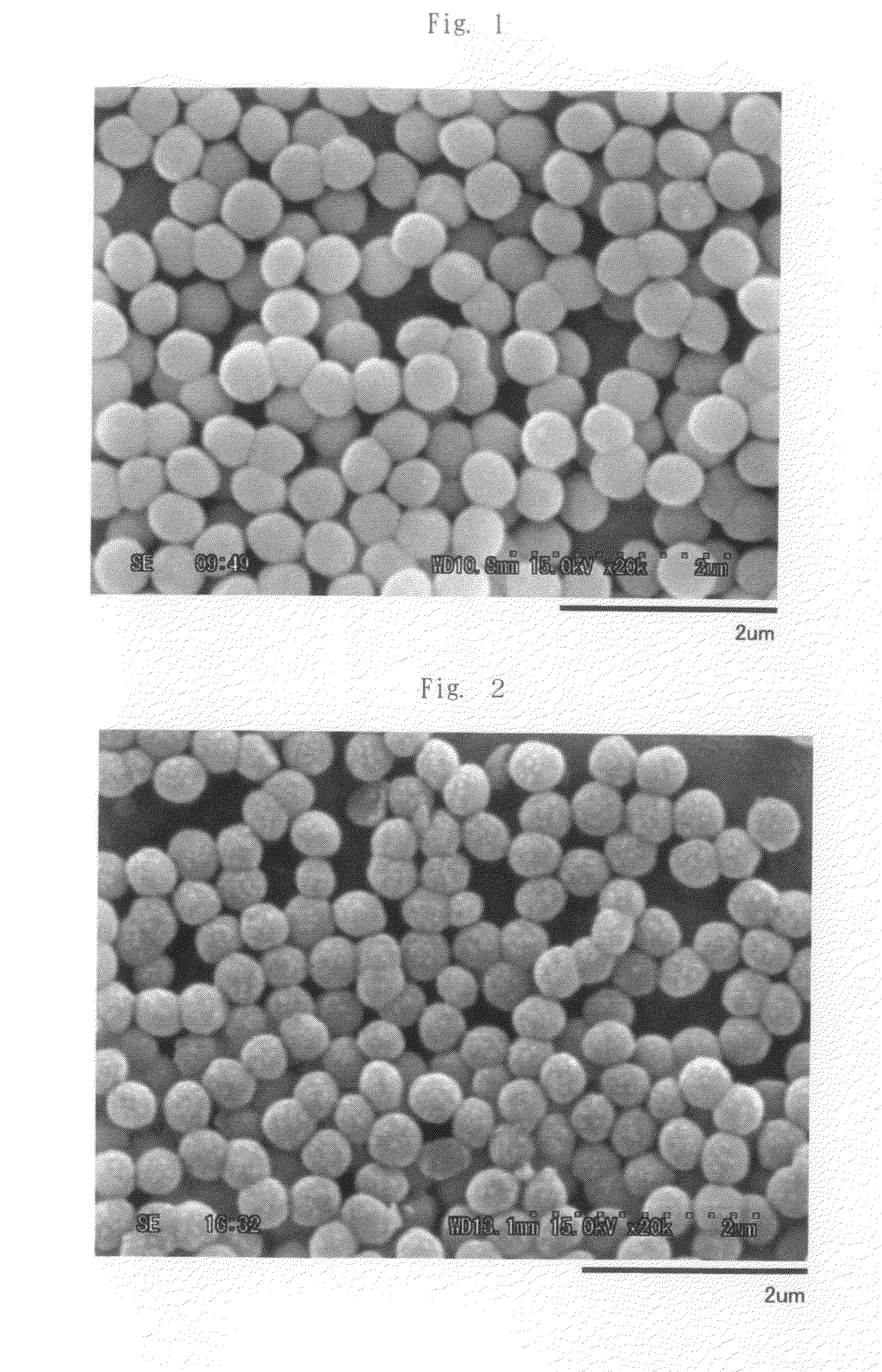

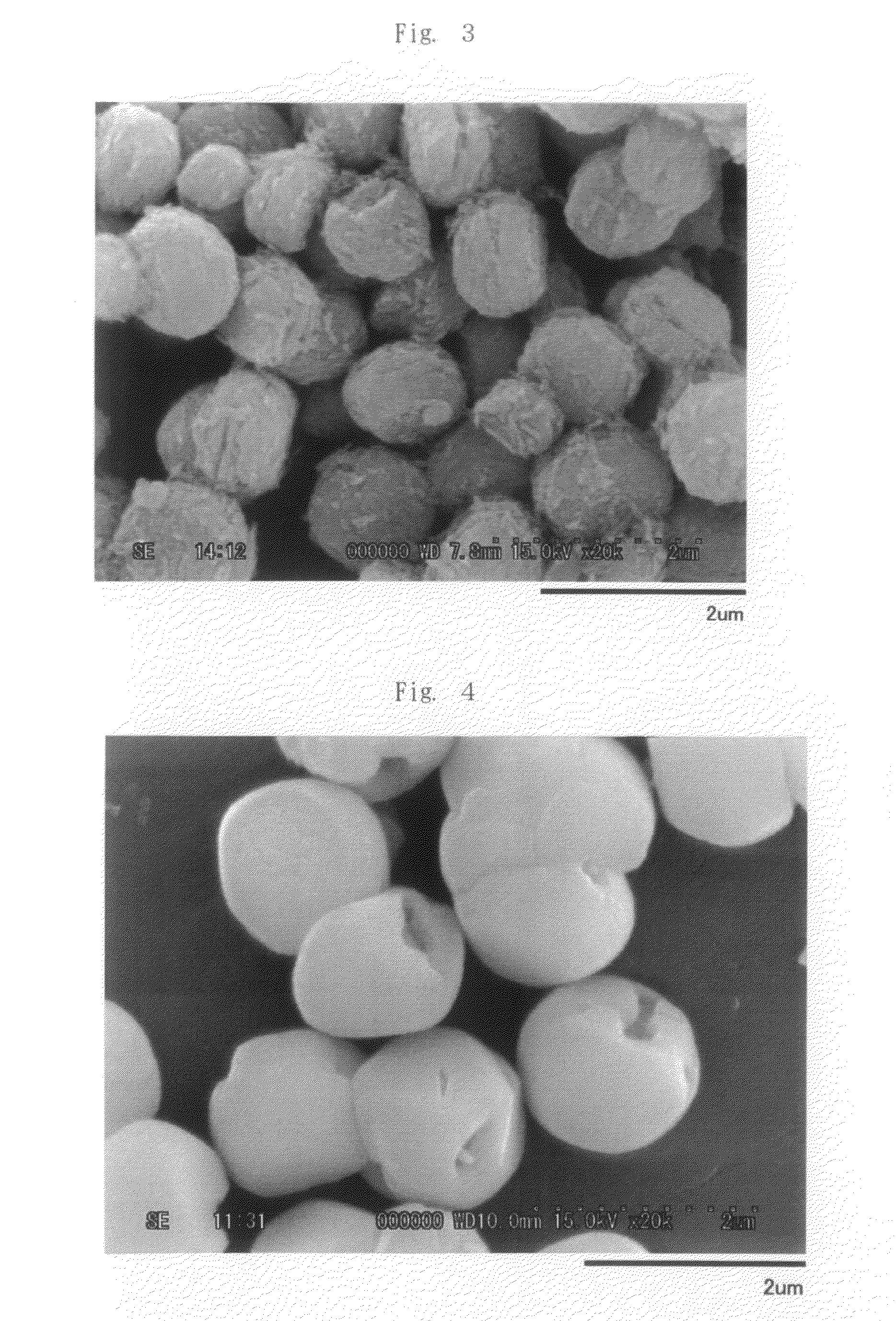

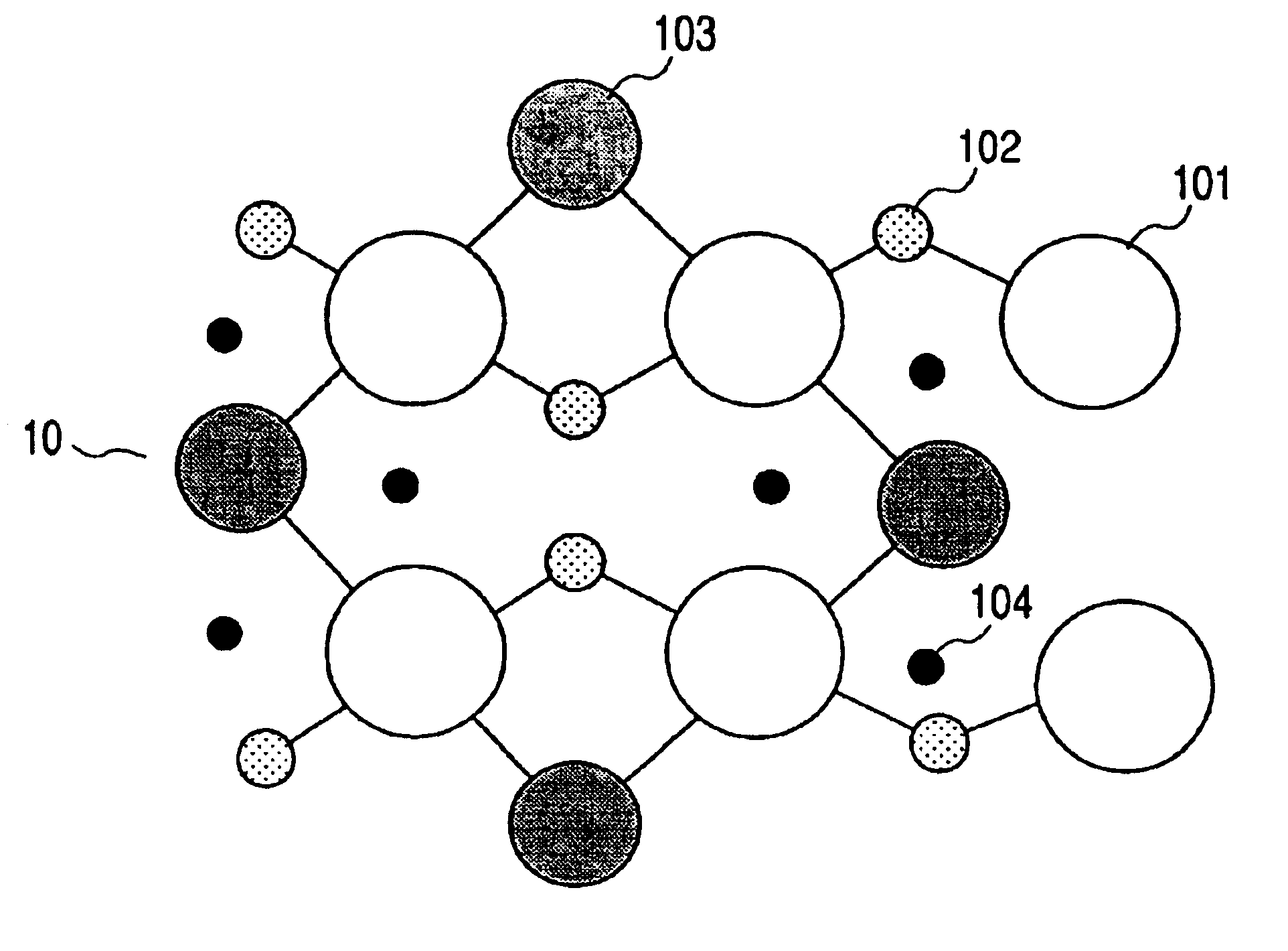

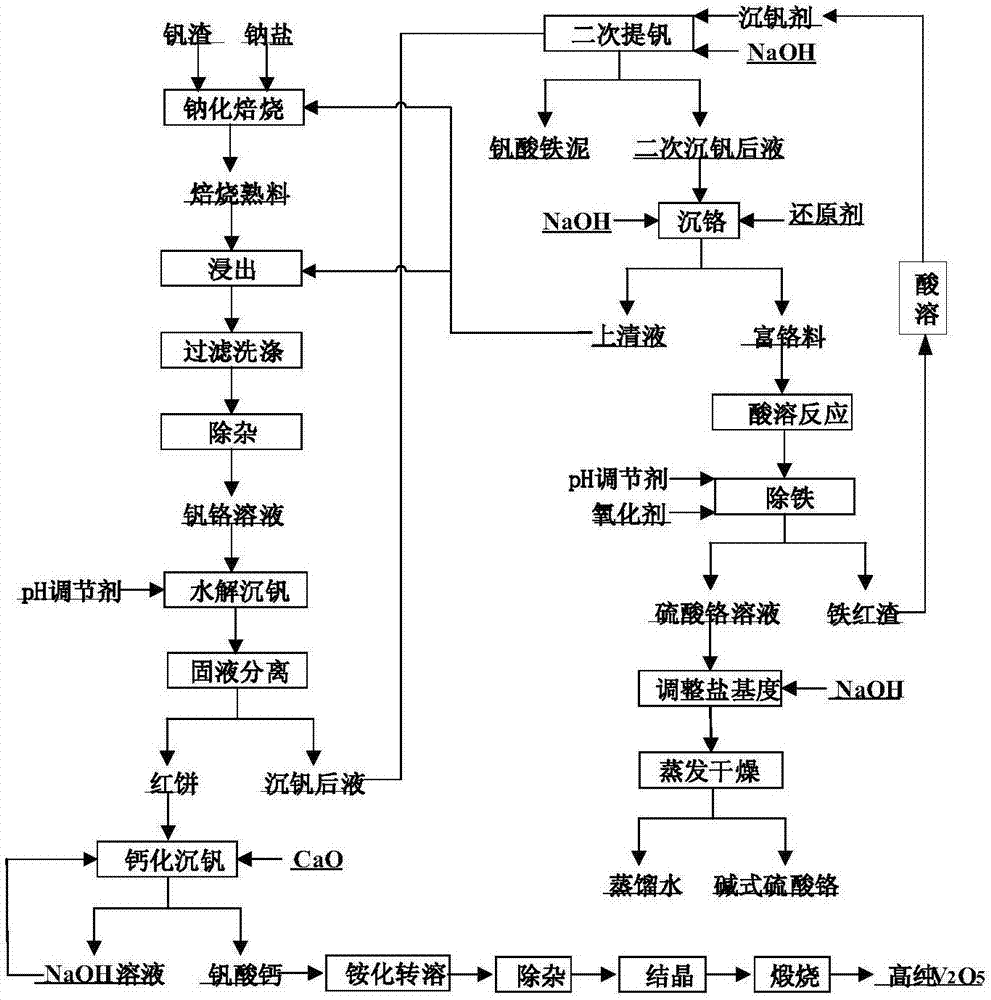

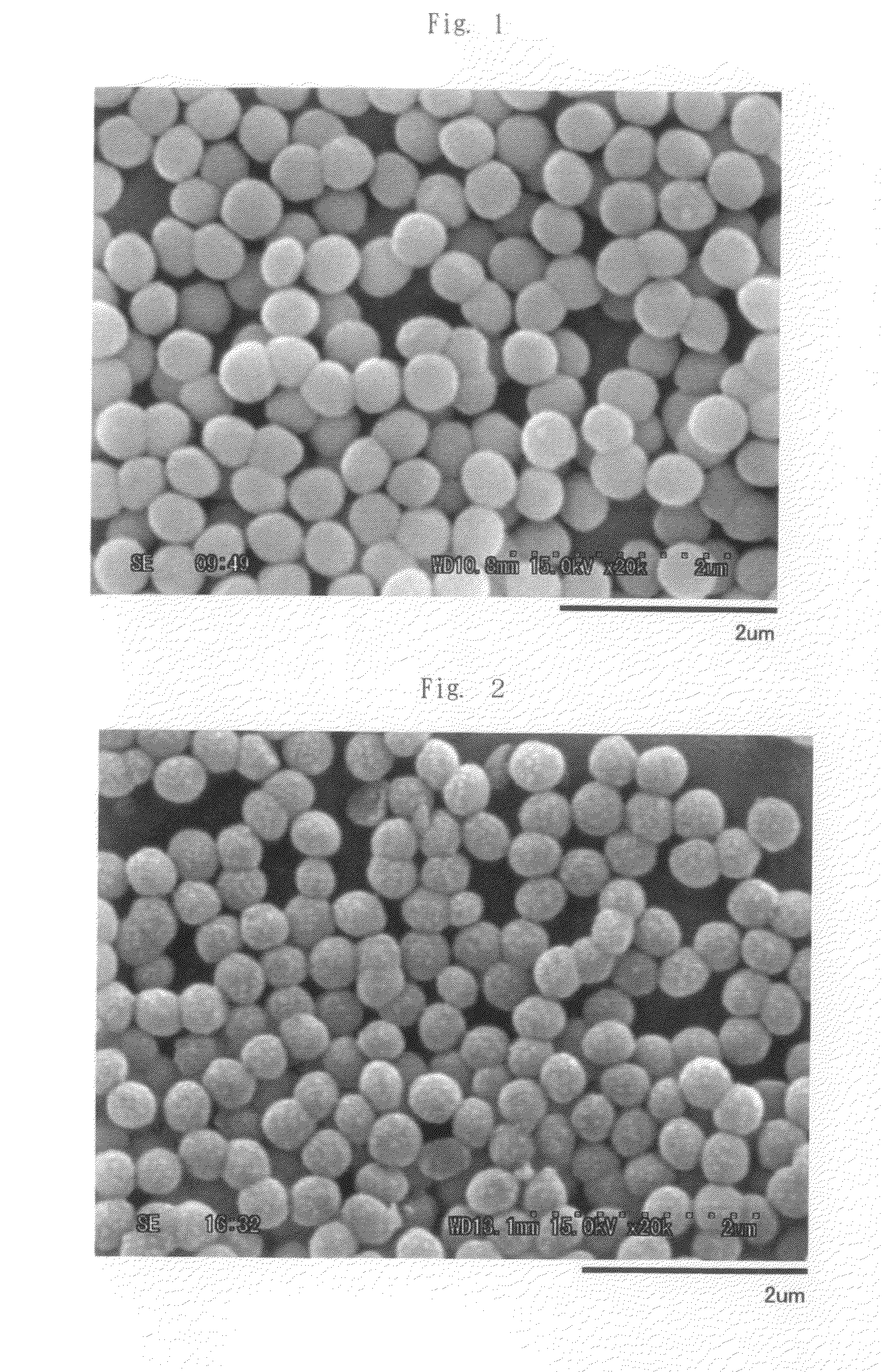

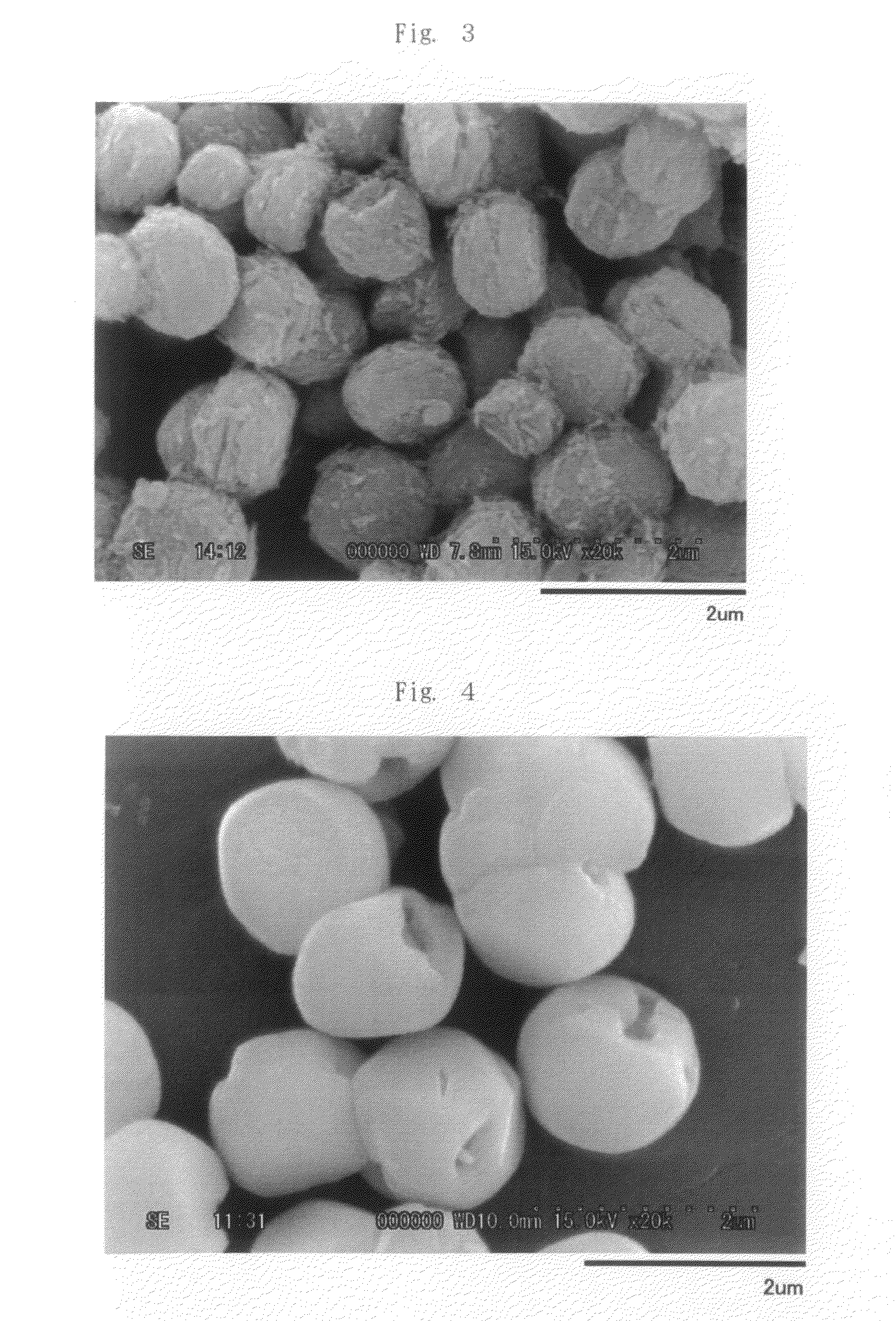

ActiveUS20090047311A1Good dispersibilityHigh transparencyCosmetic preparationsInorganic active ingredientsAluminium sulfateCompound (substance)

An antibacterial agent composed of silver-containing aluminum sulfate hydroxide particles represented by the following formula (X-I) or (Y-I).(AgaBb-a)bAlcAx(SO4)y(OH)z.pH2O (X-I)[AgaBb-a]b[Ti3-cAlc](SO4)y(OH)z.pH2O (Y-I)The above antibacterial agent of the present invention provides antibacterial molded articles and further antifungal agents, cosmetics, antibacterial paper, antibacterial deodorizing sprays and agricultural chemicals when it is mixed with a resin.

Owner:KYOWA CHEM IND

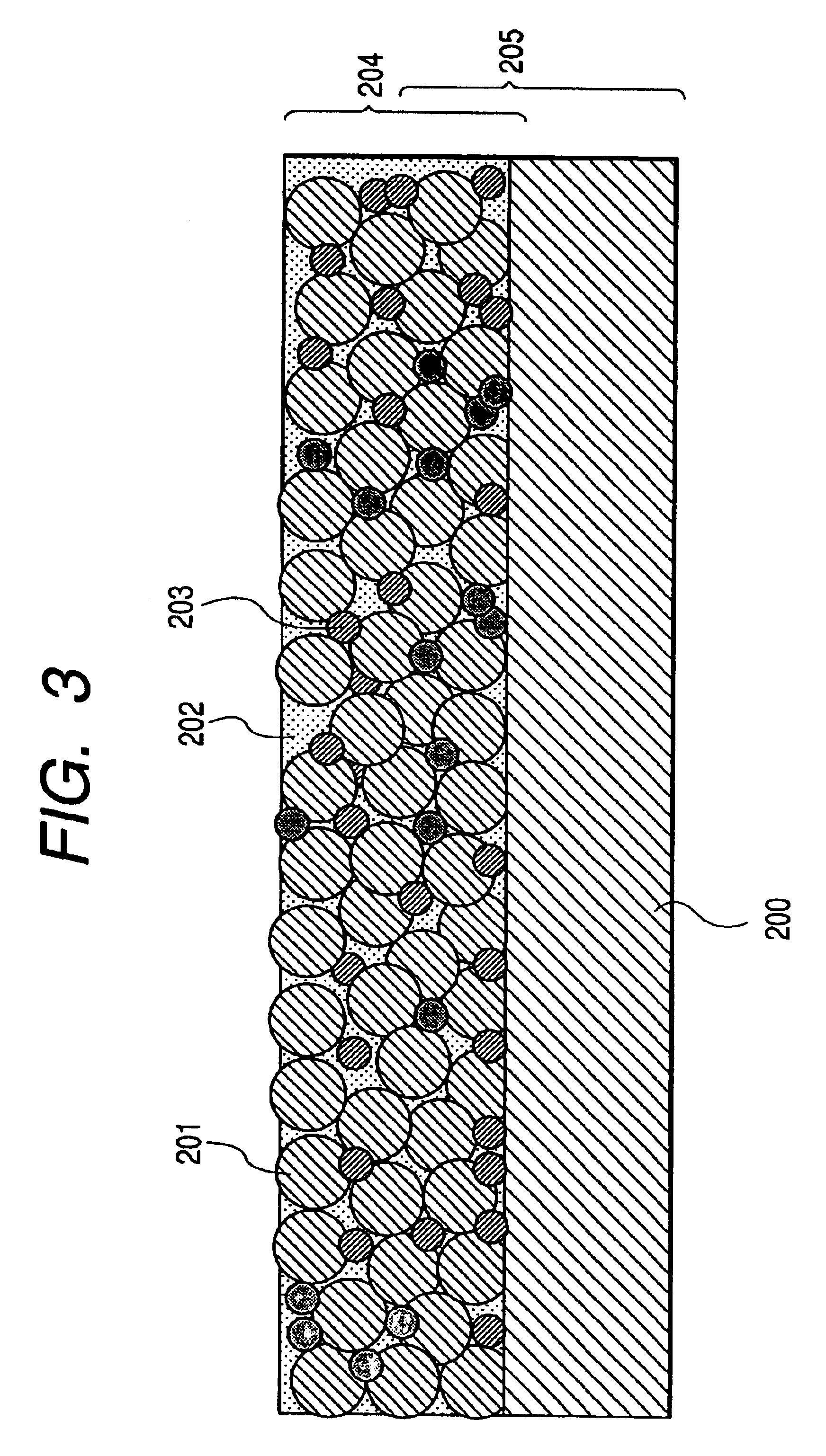

Powder material, electrode structure, production processes thereof, and secondary lithium battery

InactiveUS6932955B2Increase capacityImprove efficiencyMaterial nanotechnologyCell electrodesSulfurOxygen

Owner:CANON KK

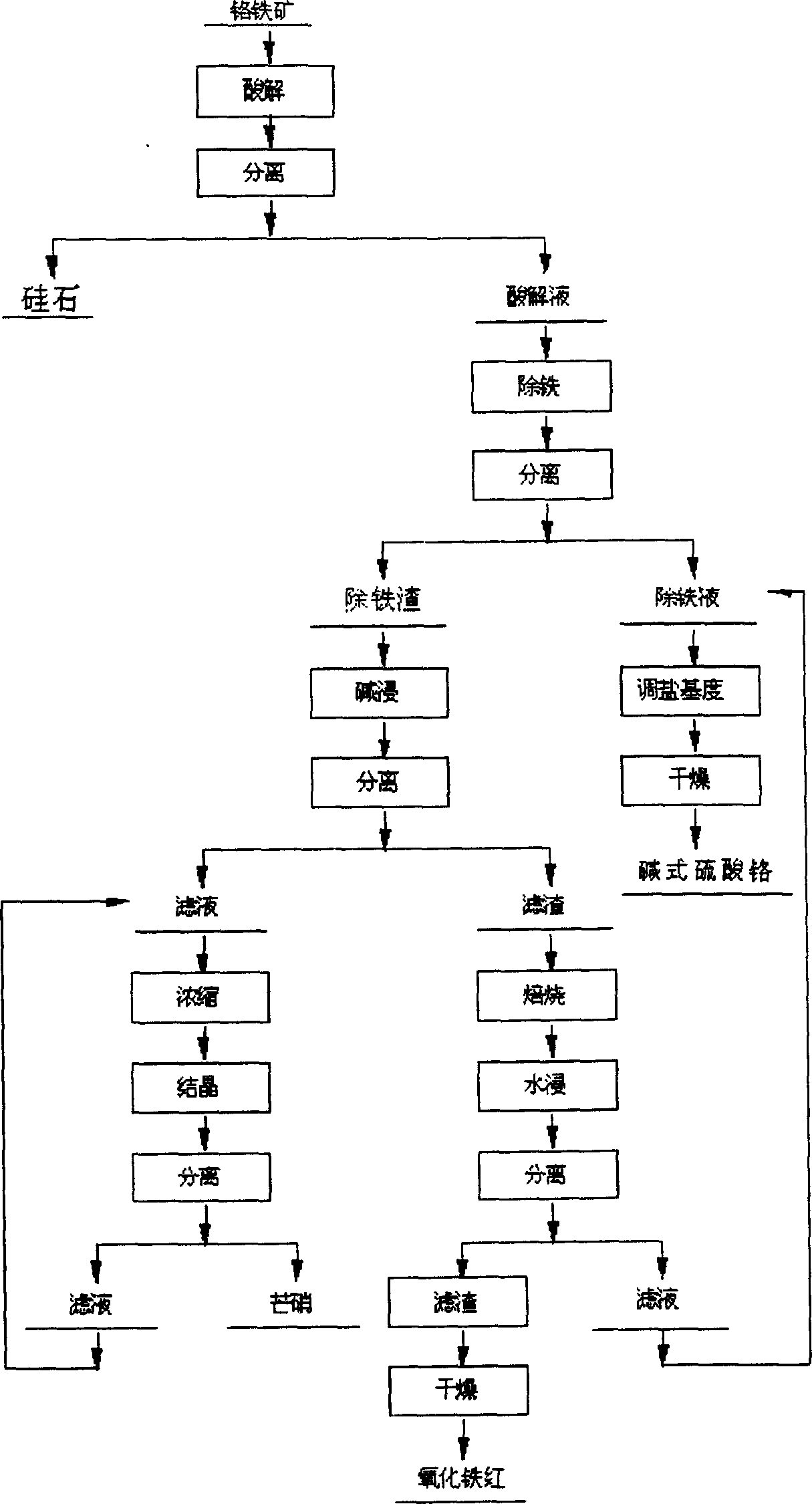

Prepn of chromium subsulfate

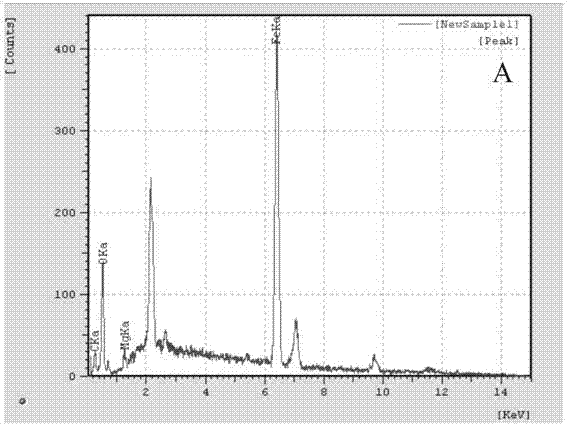

InactiveCN1526646AAddress serious hazardsOptimize process flowTanning treatmentChromium sulfatesBrown iron oxideFree acid

The preparation process of chromium subsulfate with chromite as material includes grinding; reacting with sulfuric acid at 110-170deg.c via stirring and under the presence of catalyst for 1-8 hr; filtering to separate filtrate and slag silica; regulating the free acid value of the filtrate with alkali to 0.8-3.1 %, adding crystal seed calcium salt, magnesium salt or chromium oxide and ferric oxide under stirring at 130-190 deg.c for 30-120 min; filtering to eliminate iron-containing slag, neutralizing the filtered mother liquid with sodium carbonate to base content of 33 %, and drying the mother liquid to obtain product chromium subsulfate; with the iron-eliminating filtered slag being produced into iron oxide red via conventional technological process. The said process is short, exhausts no toxic effluent, no slag and no waste gas, and has no environmental pollution.

Owner:史培阳 +2

Method for preparing chromium sulfate basic by utilizing residual liquor obtained during menadione production

The invention discloses a method for preparing chromium sulfate basic by utilizing residual liquor obtained during menadione production. The method comprises the following steps: uniformly mixing the concentrated residual liquor with industrial sugar according to a certain molar ratio, and reacting in a pressure reactor for 0.5-4 hours at the temperature of 100 to 300 DEG C under the pressure of 0 to 4MPa; completely reducing a small amount of unreacted hexavalent chromium in the feed liquid into trivalent chromium by using a reducing agent after the reaction is ended; regulating the basicity of the feed liquid by using an alkaline solution, filtering, performing spray drying on the filtrate, thus obtaining the chromium sulfate basic product. According to the method disclosed by the invention, a pressure-conditioned curing reaction is adopted, residual organic matters in the menadione residual liquor can be effectively removed, and the quality of chromium powder is improved. The method disclosed by the invention is simple in process, high in reaction rate, low in energy consumption, clean and environment-friendly.

Owner:SICHUAN YINHE CHEM

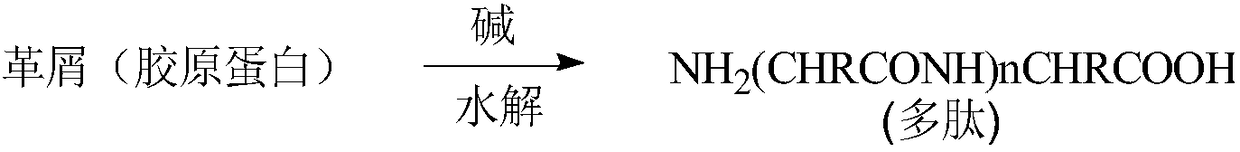

Preparation method for preparing foliage fertilizer raw material from leather making chromium containing leather meal

ActiveCN108409452ANo secondary pollutionIncrease hydrolysis rateNitrogenous fertilisersChromium sulfatesCalcium hydroxideGeneration rate

The invention relates to a preparation method for preparing a foliage fertilizer raw material from leather making chromium containing leather meal. The preparation method comprises the following steps: weighing 15g of leather making chromium containing leather meal in a three-necked flask, adding 5-8 times of water, adding 4%-10% of sodium hydroxide (on the basis of the weight of leather meal), 4%-7% of calcium hydroxide and 0.5%-1.4% of self-made mixed bases A, wherein the hydrolysis time is 8-16 h, and the stirring hydrolysis temperature is 70-95 DEG C, and filtering filter residue, therebyobtaining a filtrate A; adding 5-8 times of water in the obtained filtrate, adding 1-4% of sodium hydroxide, 1-2% of 3-isocyanatopropyltriethoxysilane, 3-5% of aluminium diethylphosphinate and 1-4% ofmatters A, wherein the stirring hydrolysis time is 7-12 h, and the hydrolysis temperature is 75 DEG C, precipitating and filtering, thereby obtaining a filtrate B; and merging the filtrate A and thefiltrate B, thereby obtaining the foliage fertilizer raw material from leather making chromium containing leather meal. The obtained filtrates are low in chromium content, the product hydrolysis rateis high, the waste residue generation rate is low, and secondary pollution can be reduced.

Owner:晋江全杰生物科技有限公司

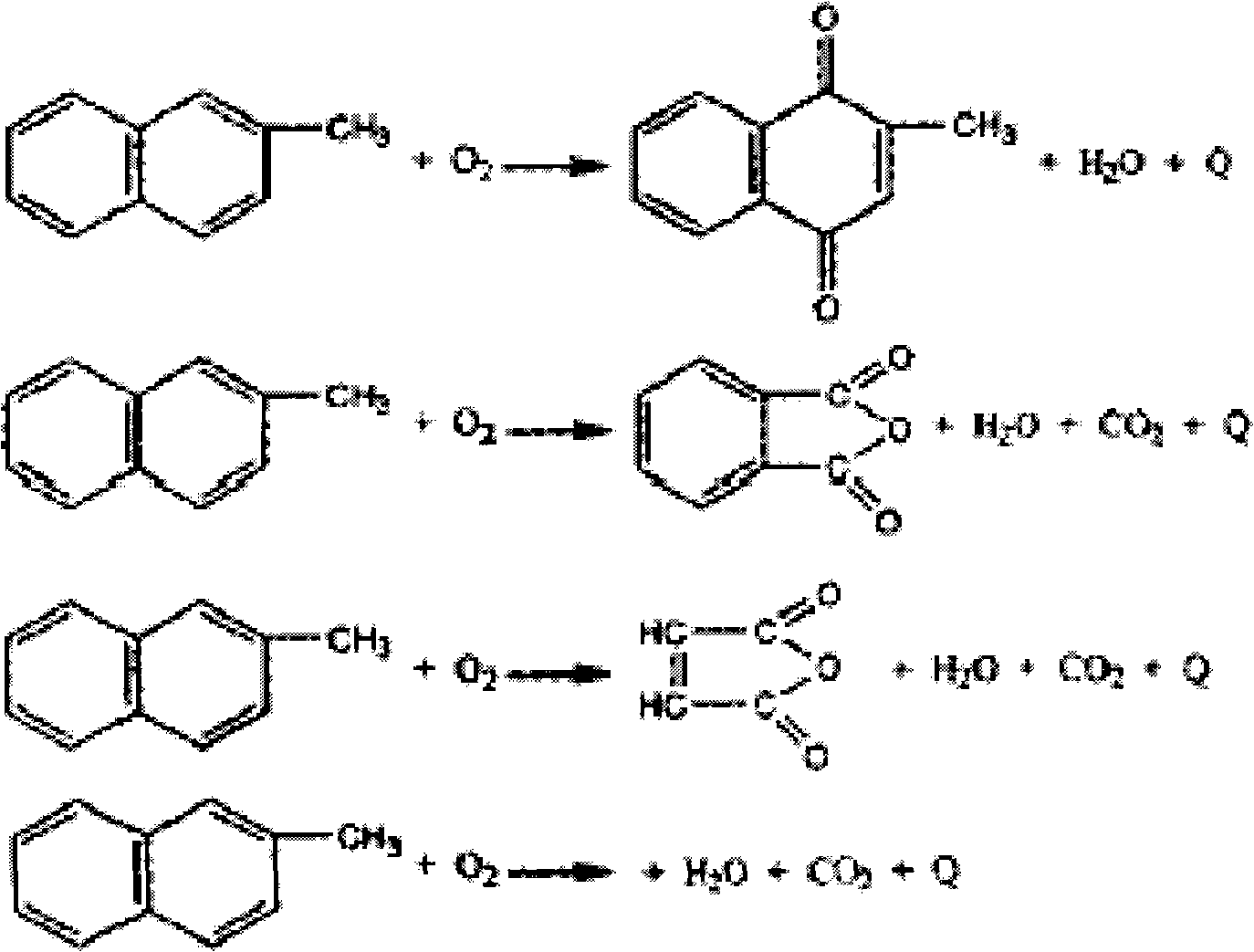

Method for coproduction of chrome tanning agent and menadione

InactiveCN101348425AEmission reductionHigh technical contentQuinone preparation by oxidationChromium sulfatesResource utilizationMenadione

The invention discloses the production of menadione, in particular disclosing a method for manufacturing menadione through combining with a chrome tanning agent. The method is characterized in that the method comprises the following (1) a step of preparing menadione, during which, methylnaphthalene, water and EL series emulsifying agents are added in a first reaction bulb; moreover, sodium bichromade and water are added in a second reaction bulb, and concentrated sulfuric acid is added slowly while stirring for cooling down; then prepared red liquor is slowly dripped into the first reaction bulb while stirring, and is filtered and dried so as to obtain bright yellow crystallized menadione powder; and (2) a step of preparing basic chrome sulphate, during which, the mother liquor obtained during preparing menadione is taken out, and sodium bichromade and dextrose solution are added in order; and chrome tanning agent basic chrome sulphate is obtained after spray drying. Through adopting a chrome tanning agent basic chrome sulphate production device to carry out joint production for menadione, the method realizes maximization of resource utilization; moreover, the method greatly reduces production cost for both sides and the release of waste liquids.

Owner:SHANDONG DAHUA GUANGJI BIOCHEM ENG

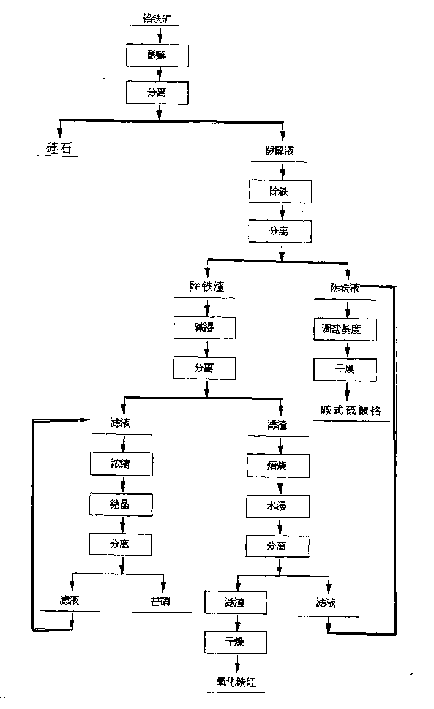

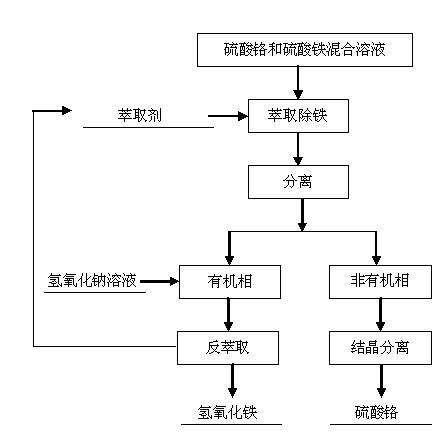

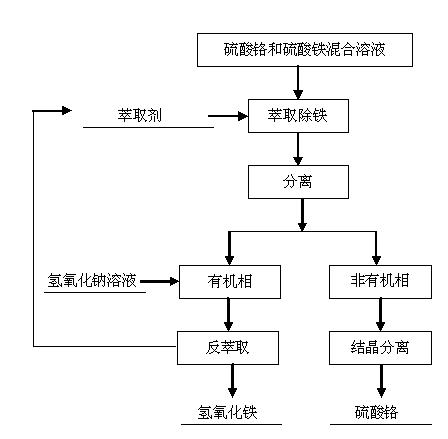

Method for separating chromium ions and iron ions in multicomponent solution

InactiveCN101974688AShort processNo "three wastes" dischargeProcess efficiency improvementChromium sulfatesFerric hydroxideIron sulfate

The invention provides a method for separating chromium ions and iron ions in a multicomponent solution, comprising the following steps of: with a mixed solution of chromic sulfate and ferric sulfate, generated by leaching out chromite by using sulfuric acid, as a raw material, adding an extractant to carry out extraction; obtaining an inorganic phase of a chromic sulfate solution and obtaining organic phases of the extractant and the ferric sulfate after extraction; then carrying out back extraction on the organic phases by using a sodium hydroxide solution and regulating a pH value to be 9-10 to obtain ferric hydroxide, a sodium sulfate solution and an extractant; recycling the extractant, and preparing the chromic sulfate by utilizing the extracted chromic sulfate solution and adopting a direct crystallization method; and preparing iron oxide red pigment by utilizing the ferric hydroxide as a raw material through a high-temperature crystallization method. Compared with the traditional technology for removing iron from the mixed solution of the chromic sulfate and the ferric sulfate, the invention has the most remarkable advantages that a process flow is short without three waste emission and extractant is recycled. Iron oxide red as a by-product does not contain hexavalent chromium and can be applied to industries of buildings, coatings, vehicles and the like.

Owner:NORTHEASTERN UNIV

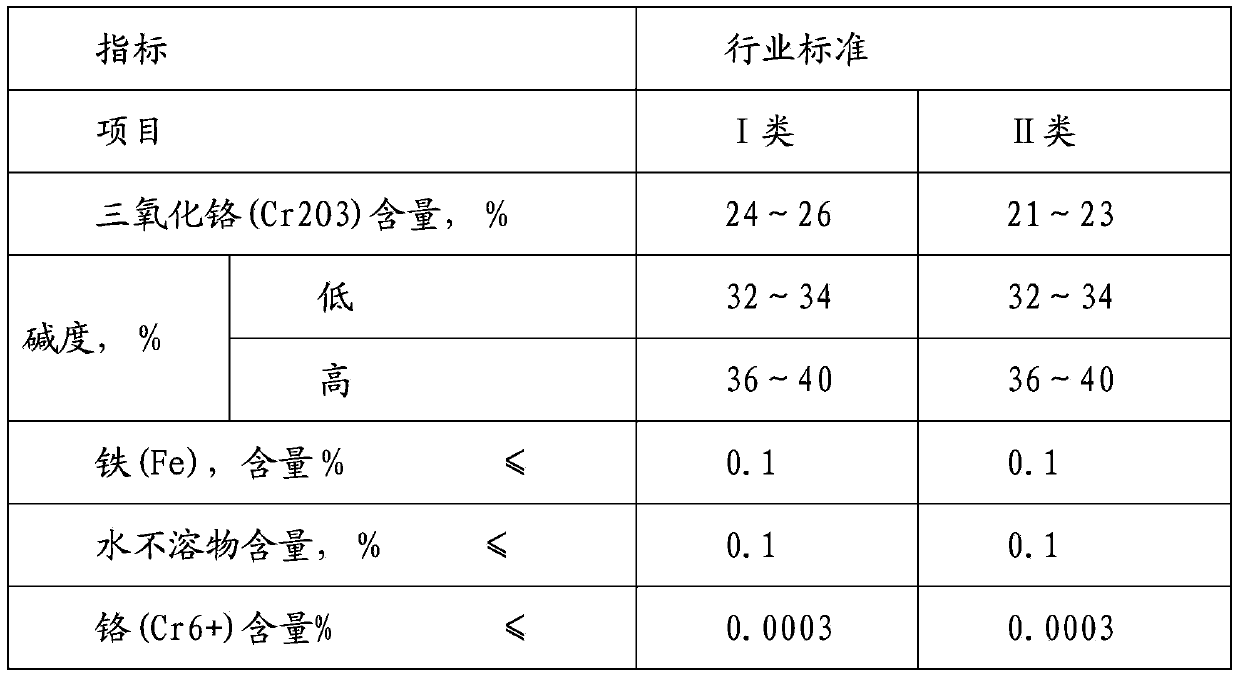

Method for utilizing chrome-vanadium solution to produce vanadium product and chromium sulfate basic

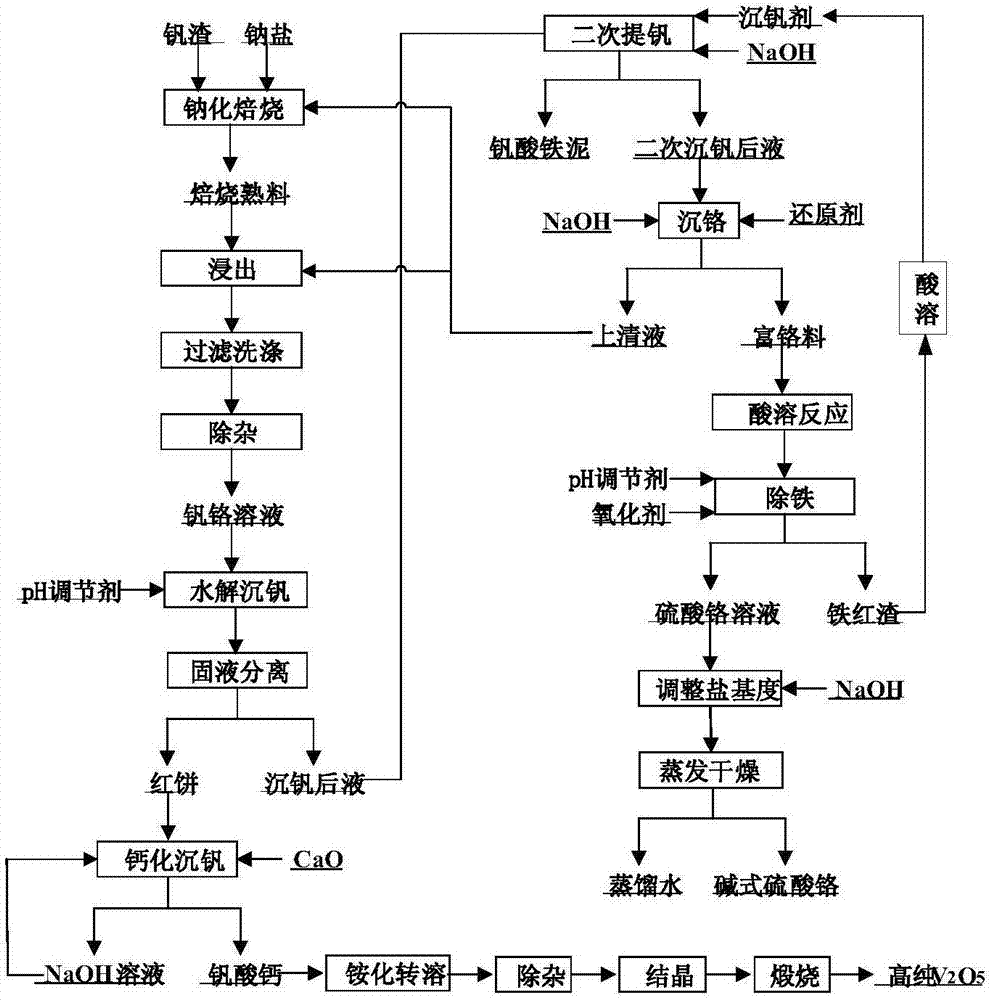

ActiveCN107954474AFe content is smallEfficient recyclingVanadium oxidesProcess efficiency improvementSulfateCalcification

The invention relates to a method for utilizing a chrome-vanadium solution to produce a vanadium product and chromium sulfate basic. Through the steps of hydrolysis vanadium depositing, a calcification reaction, enriching of chrome, preparing of chromium sulfate basic and the like, a high-purity vanadium product and a chromium sulfate basic product are obtained, the concentration of the obtain vanadium product can reach 99.5% or above, the content of Cr2O3 in chromium sulfate basic can reach 24-26%, the content of a sundry Fe is smaller than 0.1%, the recovery rate of chrome and vanadium can reach 99.5% or above, and the purposes of efficiently extracting and separating chrome and vanadium are achieved. The production process is clean, saline water and NaOH mother liquor generated in the preparing process can return to a system for use, and no ammonia-nitrogen wastewater is generated in the whole process. The technology is feasible, the equipment is simple, the production cost is low,the automation is easy to implement, the economic benefit is high, and the application prospect is good.

Owner:HEBEI IRON AND STEEL

Antibacterial agent composed of silver-containing aluminum sulfate hydroxide particles and use thereof

ActiveUS8394392B2Good dispersibilityHigh transparencyCosmetic preparationsInorganic active ingredientsAluminium sulfateCompound (substance)

An antibacterial agent composed of silver-containing aluminum sulfate hydroxide particles represented by the following formula (X-I) or (Y-I).(AgaBb-a)bAlcAx(SO4)y(OH)z.pH2O (X-I)[AgaBb-a]b[Ti3-cAlc](SO4)y(OH)z.pH2O (Y-I)The above antibacterial agent of the present invention provides antibacterial molded articles and further antifungal agents, cosmetics, antibacterial paper, antibacterial deodorizing sprays and agricultural chemicals when it is mixed with a resin.

Owner:KYOWA CHEM IND

Process for preparing chromic anhydride and dichromate by carbon ferrochrome liquid phase method

The invention relates to a process for preparing chromic anhydride and dichromate by a carbon ferrochrome liquid phase method and belongs to the technical field of preparation of chromic compounds, ferrum-series pigments, silicone new materials, photovoltaic new materials and new-energy chemical-industry new materials from industrial metallurgical products. The process disclosed by the invention is advanced, energy-saving and environment-friendly and is free of emission of waste residues, waste gases and waste water. Products such as the chromic compounds, the pigments, new energy sources and new-energy-source silicon-carbon battery materials are produced from ferrochrome by a liquid phase method in one time without high pressure and high temperature, so that a series of novel high-end industry chains are formed, and the original situation that the ferrochrome is single in use and pure in production is thoroughly changed; the out-of-date production process that heavy pollution generated by the original chromate compound roasting production heavily harms environment is changed, and the production of chromic anhydride, dichromate and the chromic compounds can be in a energy-saving, environment-friendly and high-benefit development path; and the field of diversified development and application of ferrochrome industry is extremely extended, the international competitiveness of enterprises is greatly enhanced, and the optimized upgrading and developing of national industries are promoted, so that the process is of far reaching importance. The process meets the modern requirements on environment-friendly development of economy and has very good enterprise economic benefit, perfection benefit and social benefit.

Owner:唐翔

Metal oxide and metal fluoride nanostructures and methods of making same

InactiveUS7575735B2Easy to controlOvercomes shortcomingMercury oxidesAlkali metal oxides/hydroxidesSingle crystalFluoride

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

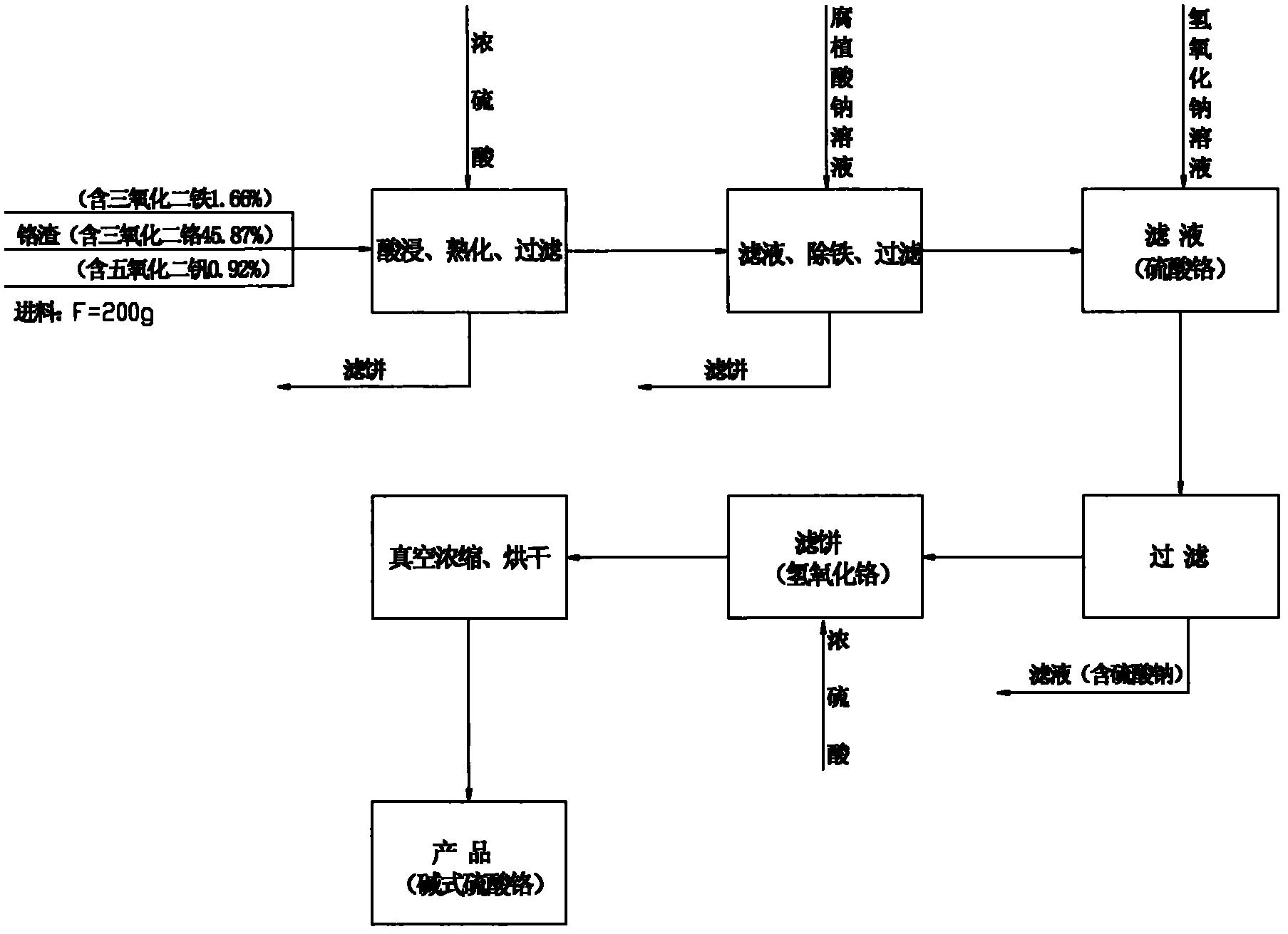

Method for preparing basic chromium sulfate by using vanadium extraction chromium slag

InactiveCN103131865AResolve Defects That Don't Get RecycledShort processProcess efficiency improvementChromium sulfatesSlagToxic material

The invention relates to a method for preparing basic chromium sulfate by using vanadium extraction chromium slag, which adopts vanadium extraction chromium slag as raw materials; certain amounts of water and sulfuric acid are added; and the basic chromium sulfate is prepared by steps of reaction, curing, filtration, vacuum concentration, drying, and the like. The Cr2O3 content in the product is stabilized at 27%; the basicity is 30%-45%; the iron content is less than 0.1%. The whole process of the invention is short in flow, causes no discharge of toxic waste water, waste residues, and waste gas, and solves the problem of environment harm in the prior art.

Owner:四川格瑞化工科技发展有限公司

Clean, energy-saving and environment-friendly chromium compound manufacturing technology by utilizing carbon ferrochrome

The invention relates to a clean, energy-saving and environment-friendly chromium compound manufacturing technology by utilizing carbon ferrochrome. The clean, energy-saving and environment-friendly chromium compound manufacturing technology disclosed by the invention is advanced, energy-saving and environment-friendly, fuel coal, high temperature and high pressure are not needed, products such as chromium compound, pigment, new energy and silicon carbon battery new materials can be produced in one time by taking ferrochrome as a raw material and adopting a liquid phase method, a series of new high-end industry chains can be formed, and the situations of single application and simple production of original products can be completely changed; a backward production technology which can generate high pollution during original chromate compound production and has great harm to the environment can be changed, and an energy-saving, environment-friendly and high-efficiency development way is guided for chromium compound production; the diversified development and application field of ferrochrome industry are greatly expanded, the international competitiveness of enterprises is greatly enhanced, and important significance is obtained in promoting the optimization, the upgrading and the development of national industries.

Owner:唐翔

Method for preparing basic chromium sulfate-chrome tanning agent by using lignite wax as reducing agent

InactiveCN103613134AImprove performanceReduced neutral salt contentTanning treatmentChromium sulfatesWaxReaction temperature

The invention discloses a method for preparing a basic chromium sulfate-chrome tanning agent by using lignite wax as a reducing agent. The method comprises the processes of primary oxidation, secondary oxidation and oxidation liquid modulation, wherein the primary oxidation comprises the steps of acidizing the lignite wax for 1 hour and then stirring and oxidizing for 4-6 hours; the secondary oxidation comprises the steps of acidizing the primary oxidation liquid for 20-40 minutes and then stirring and oxidizing for 2-3 hours; the method further comprises the steps of adding the primary oxidation liquid and the secondary oxidation liquid into a reaction kettle, determining the adding amount of an oxidizing agent and a reducing agent, adding the oxidizing agent and the reducing agent into the reaction kettle sequentially and slowly, strictly controlling the reaction temperature at 105-115 DEG C, stirring and oxidizing for 1-2 hours, standing, ageing, spray-drying and forming to obtain the basic chromium sulfate-chrome tanning agent. Compared with the pure sugar reducing agent, the neutral salt content of the basic chromium sulfate-chrome tanning agent is reduced by above 30 percent, the chrome absorption quantity of leather is enhanced, and the plumpness and humidity-resistant and heat-resistant stability of the leather are improved. The basic chromium sulfate-chrome tanning agent comprises organic micromolecular acid with a good masking effect, particularly sulfonated phthalic acid, so that the leather is plump and soft, and has elasticity, natural brightness and wax feel.

Owner:南通金庆美术图案设计有限公司

Chromium(iii)-containing aqueous solution and process for production of same

InactiveCN102143913AHigh glossMetallic material coating processesChromium sulfatesOrganic acidAqueous medium

A chromium(III)-containing aqueous solution which permits various molar ratios of acid radicals to Cr and which is useful as a trivalent-chromium source or replenisher for surface treatment baths for various metals, characterized by containing a chromium(III) composite salt which is formed by conducting the reduction of chromic acid while making two or more acids present either simultaneously or successively, said acids being selected from among inorganic acids (excluding chromic acid) and organic acids; and a process for the production of a chromium(III)-containing aqueous solution which comprises bringing chromic acid into contact with an acid other than chromic acid and / or an organic reducing agent in an aqueous medium to conduct the reduction of chromic acid, characterized in that the reduction of chromic acid is conducted in a state wherein at least two acids are present as the acid other than chromic acid either simultaneously or successively, said acids being selected from among inorganic acids and organic acids.

Owner:NIPPON CHECMICAL IND CO LTD

Method for preparing basic chromium sulfate from chromium-contained wastewater

The invention discloses a method for preparing basic chromium sulfate from chromium-contained wastewater. The method includes: adding excessive oxidizing agent into the chromium-contained wastewater to heat the chromium-contained wastewater up, adding alkaline liquor to adjust the pH (potential of hydrogen) value to be alkaline, filtering to remove heavy metal sediments in the chromium-contained wastewater, adding sulfuric acid into obtained filter liquor to adjust the pH value to be acidic, and adding oxalic acid till a chromium sulfate solution is obtained; adding alkaline liquor into the chromium sulfate solution with stirring so as to react to obtain syrup type viscous liquid, cooling to crystallize, centrifuging to obtain liquid basic chromium sulfate, and subjecting the liquid basicchromium sulfate to concentrating, washing, drying, smashing and screening to obtain solid basic chromium sulfate. According to the method, minute amount of heavy metal ions is removed by extracting principal components in the chromium-contained wastewater, and suitable conditions are furtherly chosen to prepare the basic chromium sulfate finally. The method for preparing the basic chromium sulfate from the chromium-contained wastewater is simple in technology, low in cost and high in product yield, and is not only capable of providing a new technical solution for recovery of the chromium-contained wastewater, but also is capable of preparing the basic chromium sulfate which is stable in state, high in purity and less in impurities.

Owner:XINGJIA BIO ENG CO LTD

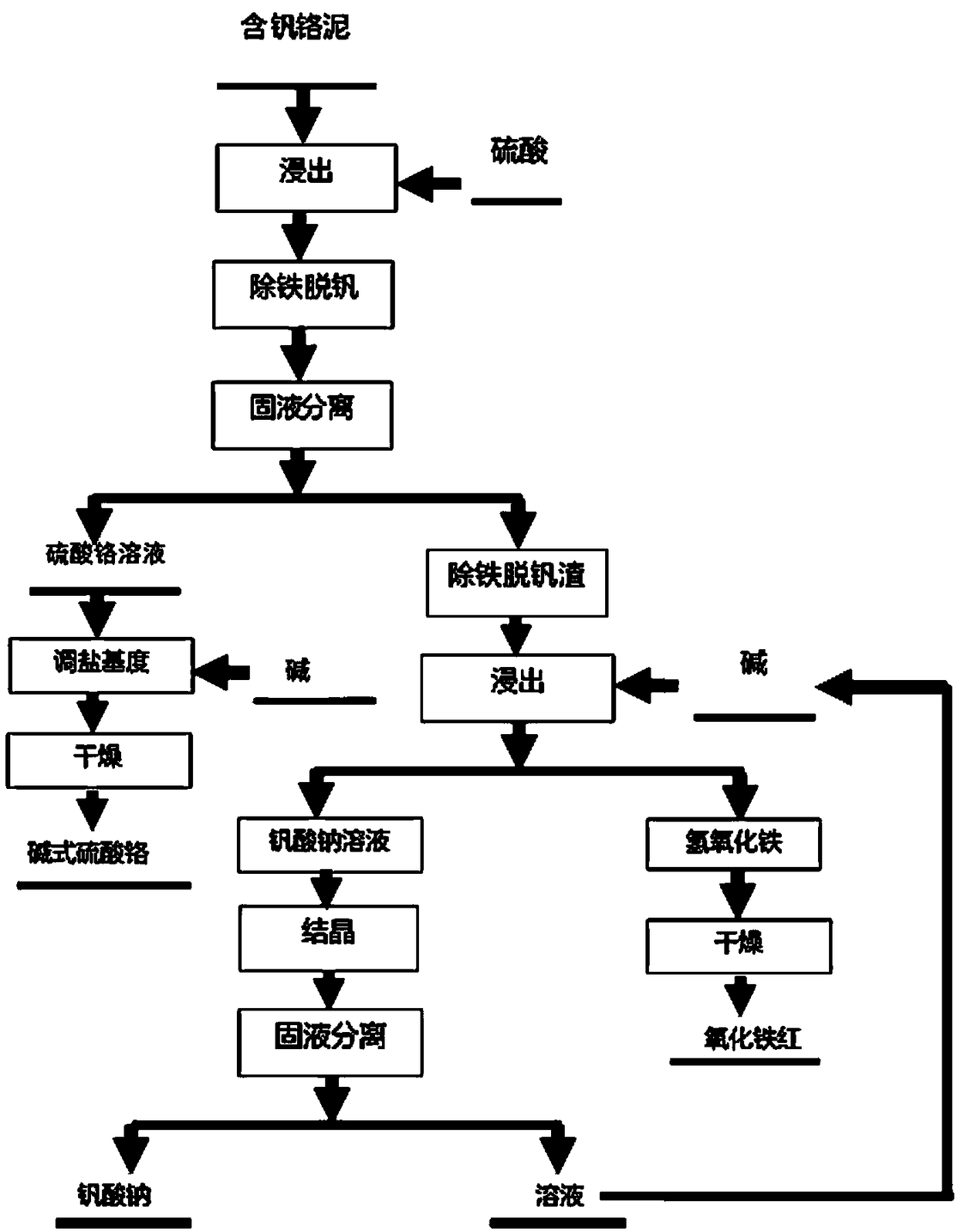

New method for recycling vanadium, iron and chromium elements from vanadium and chromium-containing sludge

InactiveCN108998676AImprove resource utilizationNo waste dischargeFerric oxidesVanadium compoundsFerric hydroxideResource utilization

The invention provides a new method for recycling vanadium, iron and chromium elements from vanadium and chromium-containing sludge. The method comprises the steps of completely migrating valuable metal elements in the vanadium and chromium-containing sludge into leaching solutions with an enhanced leaching method by taking sulfuric acid as leaching agents, and then performing iron and vanadium removal treatment at high temperature under high pressure to obtain relatively pure chromium sulfate solutions; performing drying treatment to the chromium sulfate solutions to obtain chromium sulfate products; alkaline-leaching iron and vanadium removal products to obtain ferric hydroxide and sodium vanadate solutions; and crystallizing the sodium vanadate solutions to obtain sodium vanadate products, and preparing iron oxide red products through high temperature drying of the ferric hydroxide. The new method is high in resource utilization rate, has no three-waste discharge problem, and is a clean and resource recovery new production technology.

Owner:阜新安兴科技有限公司

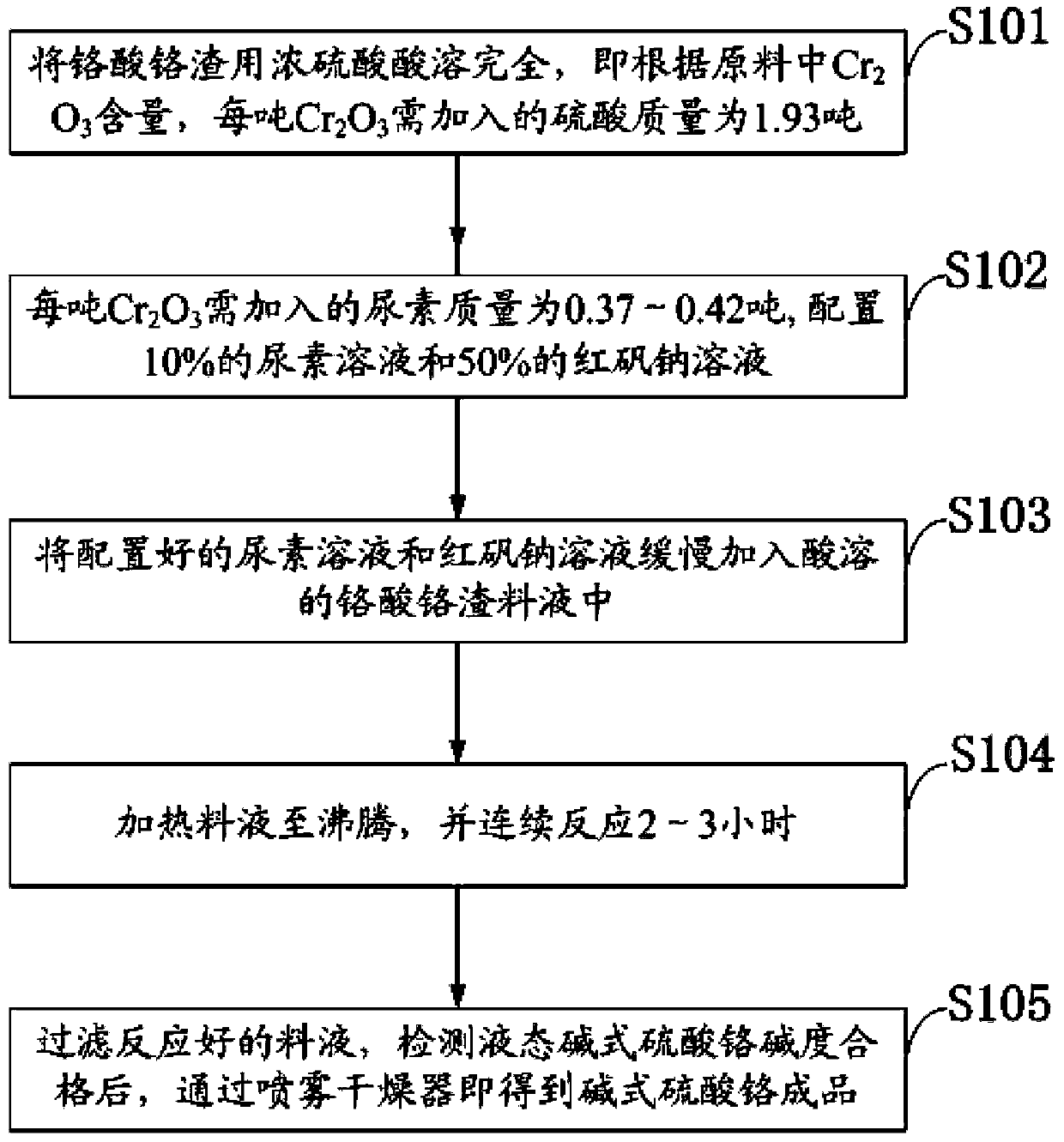

Method for producing basic chrome sulphate with dichromiumtris (chromate) slag

ActiveCN103466708AReduce unit consumptionReduced environmental benefitsChromium sulfatesAlkalinitySlag

The invention discloses a method for producing basic chrome sulphate with dichromiumtris (chromate) slag. The method for producing basic chrome sulphate with the dichromiumtris (chromate) slag comprises the following steps of completely dissolving the dichromiumtris (chromate) slag with concentrated sulfuric acid, that is, adding 1.93t sulfuric acid per ton of Cr2O3 according to a Cr2O3 content in a raw material, adding 0.37-0.42t urea per ton of Cr2O3 to prepare a 10% urea solution and a 50% sodium bichromate solution, slowly adding the prepared urea solution and the sodium bichromate solution into acid soluble dichromiumtris (chromate) slag slurry, heating the slurry to be boiled, performing continuous reaction for 2-3h, filtering the reacted slurry, and after alkalinity of liquid basic chrome sulphate is detected to be qualified, obtaining a basic chrome sulphate finish product through a spray dryer. The method takes the waste dichromiumtris (chromate) slag as a raw material, is environment-friendly, saves resources, reduces unit consumption, produces obvious economic benefits, and provides an energy-saving, environment-friendly and synergetic novel production technology.

Owner:GANSU JINSHI CHEM

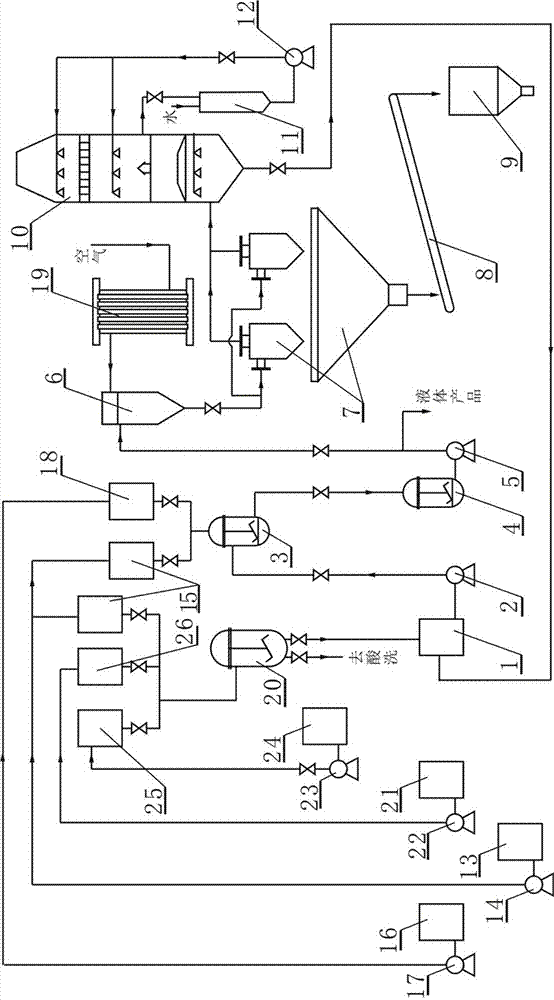

Method and device for producing chromium tanning agent by using oxidized waste liquid obtained from S wax production

ActiveCN103642951AStrong transposition effectImprove waterproof performanceTanning treatmentChromium sulfatesLiquid wasteChromium trioxide

The invention discloses a method and device for producing a chromium tanning agent by using oxidized waste liquid obtained from S wax production. The method comprises the steps of carrying out acidification and two-stage oxidation on raw materials, namely lignite wax, sodium bichromate, chromic anhydride (chromium trioxide, CrO3) and sulfuric acid, so as to obtain the oxidized waste liquid; treating the oxidized waste liquid by using glucose serving as a reducing agent in a manner that glucose cooperates with sodium bichromate, so as to obtain a chromium tanning solution; drying and dewatering the chromium tanning solution, thereby obtaining the chromium tanning agent. The device comprises an oxidized waste liquid storage tank, an oxidized liquid reduction device, a chromium tanning agent recovery device, a high-position liquid supplying device and a supporting liquid distribution device. According to the method, the chromium tanning agent (alkaline chromic sulfate-chromium powder tanning agent) is prepared through reducing the chromium-containing oxidized waste liquid, formed during the production of S wax from lignite wax, by using glucose which cooperates with sodium bichromate, and tanned leather is plump, soft and elastic. According to the method and the device, the process is simple and energy-saving, the consumption of sulfuric acid and glucose is low, and the device is easy to implement, so that the large-scale, continuous and automated production can be realized.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Carbon ferrochrome liquid phase method for preparing new energy battery raw material and new energy source hydrogen process

The invention relates to a carbon ferrochrome liquid phase method for preparing a new energy battery raw material and a new energy source hydrogen process. The process is advanced, energy saving and environmentally friendly, free from fire coal and high temperature and high pressure, the new energy source, a plurality of new energy source battery materials, pigments, chemical engineering chromium salt and the like products can be produced in disposable by using ferrochrome as the raw material by using the liquid phase method, a series of new high-end industry chains are formed, the situations that the original product use is single in use and the production is pure are changed, the enterprise international competitiveness is greatly enhanced, the upgrading and optimization and development of the nation industry are promoted, and the process has important significance.

Owner:唐翔

Method for producing basic chromic sulfate by utilizing tannery waste chromium mud

ActiveCN106315675AAvoid pollutionSolve pollutionChromium trioxideChromium sulfatesFiltrationWater circulation

The invention discloses a method for producing basic chromic sulfate by utilizing tannery waste chromium mud. The method comprises the following steps: airing and drying waste chromium mud, uniformly mixing the dried chromium mud and sodium hydroxide in a rotary kiln, and adding an oxidant for roasting; performing water circulation suction filtration washing on the roasted materials, and removing impurities, thereby obtaining a sodium chromate solution; adding sulfuric acid into the obtained solution for reacting, thereby obtaining sodium dichromate; continuously adding sulfuric acid for reacting, slowly adding cane sugar, and reacting, thereby obtaining liquid basic chromic sulfate; and finally, drying the basic chromic sulfate solution, thereby obtaining the powdered basic chromic sulfate. According to the technical scheme of the invention, the waste chromium mud is fully utilized, and changed into valuable things to be recycled, and the resources and the energy are saved. The problem of chromium pollution in tannery industry is solved, and the tannery cost can be reduced. The chromium pollution is solved, and meanwhile, the economic benefits and social benefits of enterprises are obviously improved.

Owner:菏泽泓泽贸易有限公司

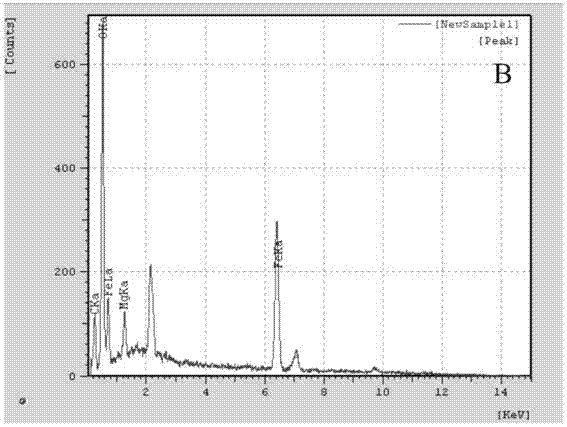

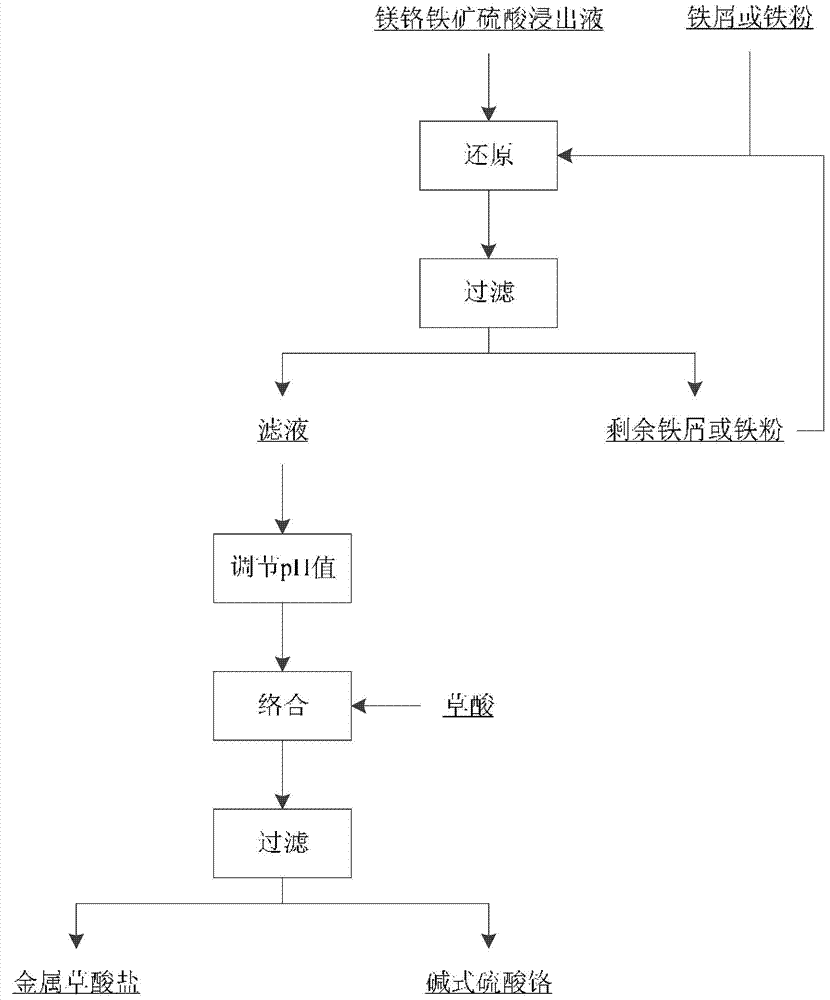

Method for preparing basic chrome sulphate by magnochromite sulphuric acid leaching solution

The invention discloses a method for preparing basic chrome sulphate by magnochromite sulphuric acid leaching solution, which belongs to the technical field of mineral processing. The method disclosed by the invention comprises the following steps of: adjusting the temperature of the magnochromite sulphuric acid leaching solution to 40-90 DEG C and keeping the temperature constant, adding excessive iron chips or iron powder and continuously stirring, and stopping heating and stirring after Fe<3+> is not contained in the reaction solution; filtering and taking the filtrate, and recycling the remainder iron chips; adjusting the pH value of the filtrate to an interval from 1 to 4 by basic solution, slowly adding oxalic acid solids with an amount which is 1.0-1.8 times of amount of substance of a theoretical value, controlling the pH value of the solution, and always keeping the pH value in an interval of an initial level + / -0.5; after adding, continuing to stir for 5-20 minutes, filtering to obtain the residue of metal oxalates, adding the basic solution in the filtrate to neutralize, adjusting until the basicity is 33+ / -1%, and drying the mother solution to obtain basic chrome sulphate. The method disclosed by the invention is capable of removing iron and magnesium in the magnochromite sulphuric acid leaching solution simultaneously in a reactor, thus reducing process flow, saving equipment space, and achieving low cost and no Cr(VI) generation.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com