Method for preparing basic chromium sulfate by using vanadium extraction chromium slag

A technology for extracting vanadium chromium slag and chromium sulfate, which is applied in the direction of chromium sulfate and process efficiency improvement, and can solve problems such as waste, waste of resources, environmental hazards, etc., and achieve the effect of short process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

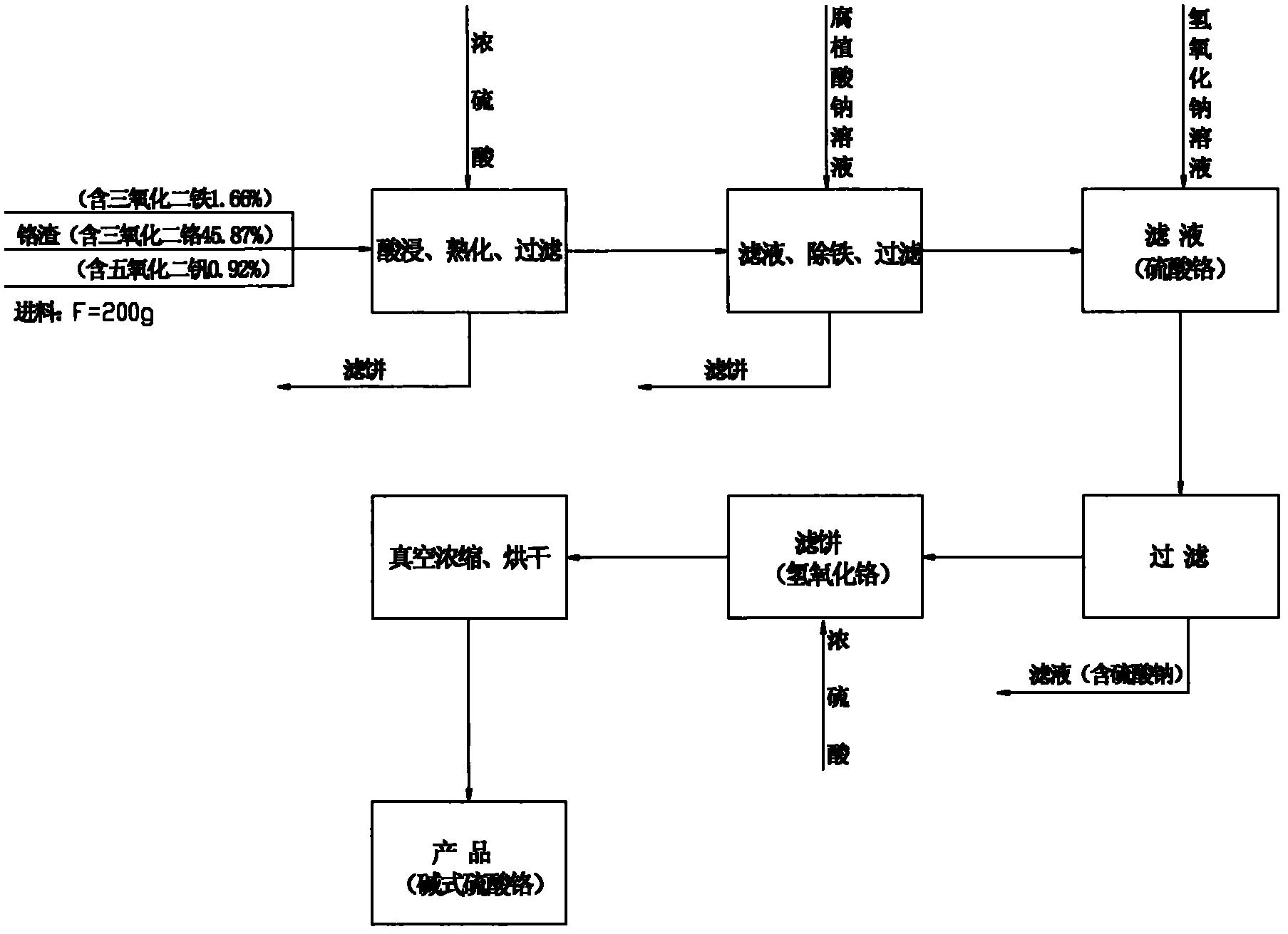

Method used

Image

Examples

example 1

[0019] Dry 200g of vanadium and chromium slag (containing 45.87% chromium) to make its moisture <5%, put it into the reaction kettle, add 50g of water for wetting, then add 160g of sulfuric acid with a concentration of 98%, and the stirring rate is 60 rpm / min, maintain the reaction temperature at 50°C, stir for 4 hours, then add 3000g of water to dissolve the reactants for more than 12 hours. Filter the water immersion and acid soluble matter to obtain 190g of leach acid residue and 3200g of filtrate; add 6g of sodium humate solution (2.6g of sodium humate and 3.4g of water) to the filtrate, stir for 0.5 hours, and filter to obtain 3193.5g of filtrate ( Chromium-containing 2.95%), add sodium hydroxide solution (sodium hydroxide 130g, water 370g) and adjust alkalinity to be 30%, obtain chromium hydroxide filter cake 132.8g through filtration, add concentrated sulfuric acid 66.4g reaction after vacuum drying then, obtain Basic chromium sulfate was 144.19g, and the yield of chro...

example 2

[0021] Dry 200g of vanadium and chromium slag (containing 45.87% chromium) to make its moisture <5%, put it into the reaction kettle, add 100g of water for wetting, then add 200g of sulfuric acid with a concentration of 98%, and the stirring speed is 60 rpm / min, maintain the reaction temperature at 90°C, stir for 4 hours, and then add 2000g of water to dissolve the reactants for more than 12 hours. Filter the water immersion and acid soluble matter to obtain 195g of leach acid residue and 2280g of filtrate; add 10g of sodium humate solution (including 4.4g of sodium humate and 5.6g of water) to the filtrate, stir for 0.5 hours, and filter to obtain 2278.5g of filtrate ( Chromium-containing 3.1%), add sodium hydroxide solution (sodium hydroxide 160g, water 370g) and adjust alkalinity to be 38.5%, obtain chromium hydroxide filter cake 139.6g through filtration, add concentrated sulfuric acid 100g reaction after vacuum drying then, obtain alkali Formula chromium sulfate 151.52g,...

example 3

[0023] Dry 200g of vanadium and chromium slag (containing 45.87% chromium) to make its moisture <5%, put it into the reaction kettle, add 200g of water for wetting, then add 200g of sulfuric acid with a concentration of 98%, and the stirring speed is 60 rpm / min, maintain the reaction temperature at 80°C, stir for 4 hours, then add 1600g of water to dissolve the reactants for more than 12 hours. Filter the water immersion and acid soluble matter to obtain 192g of acid leaching residue and 2000g of filtrate; add the filtrate to 12g of sodium humate solution (including 5.3g of sodium humate and 6.7g of water), stir for 1 hour, and filter to obtain a filtrate of 1998.5 g (containing chromium 3.0%), add sodium hydroxide solution (sodium hydroxide 190g, water 400g) to adjust the alkalinity to 45%, obtain chromium hydroxide filter cake 148.6g through filtration, then add concentrated sulfuric acid 148.6g to react after vacuum drying , Obtain 165.52 g of basic chromium sulfate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com