Patents

Literature

92results about How to "No "three wastes" discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

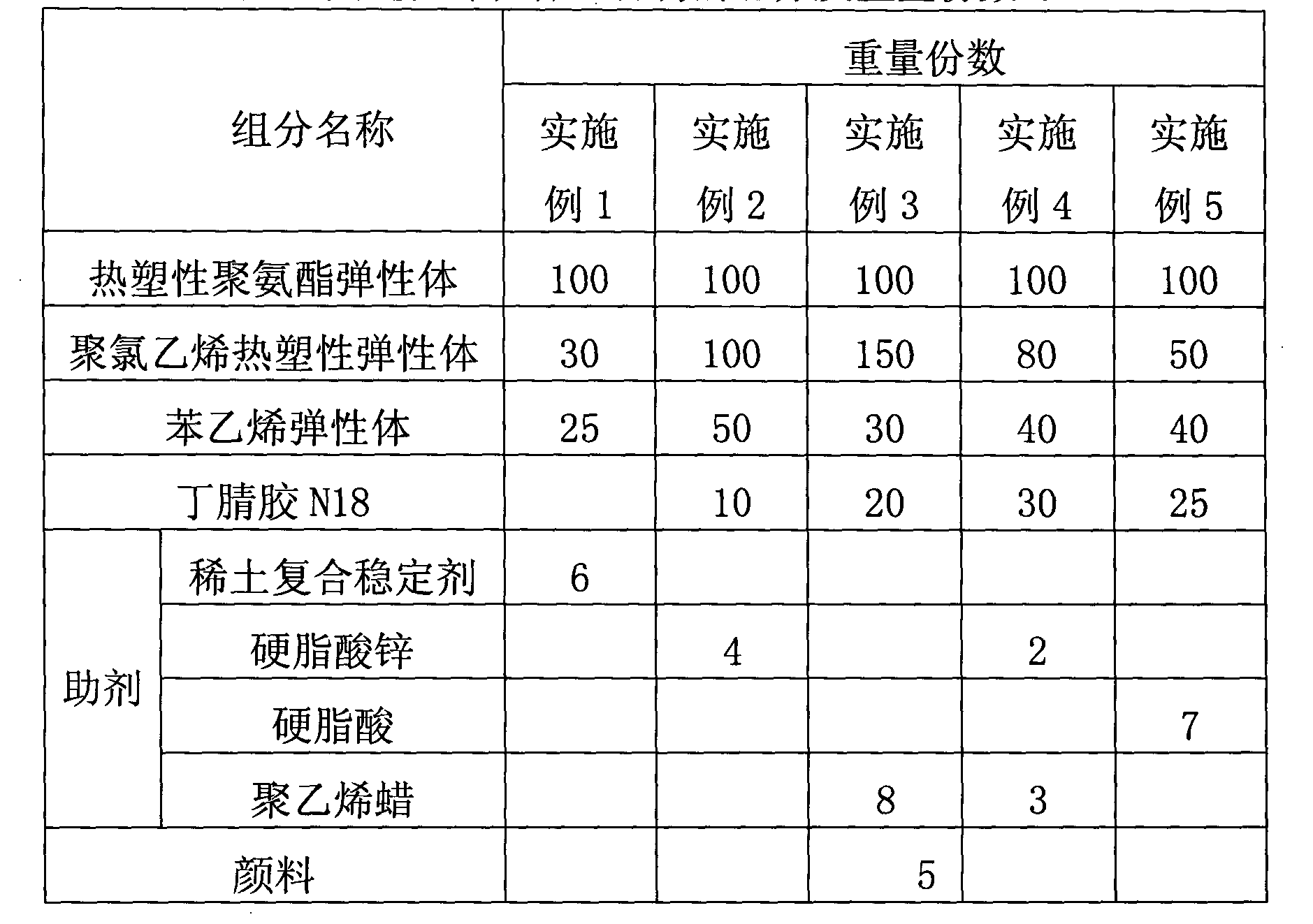

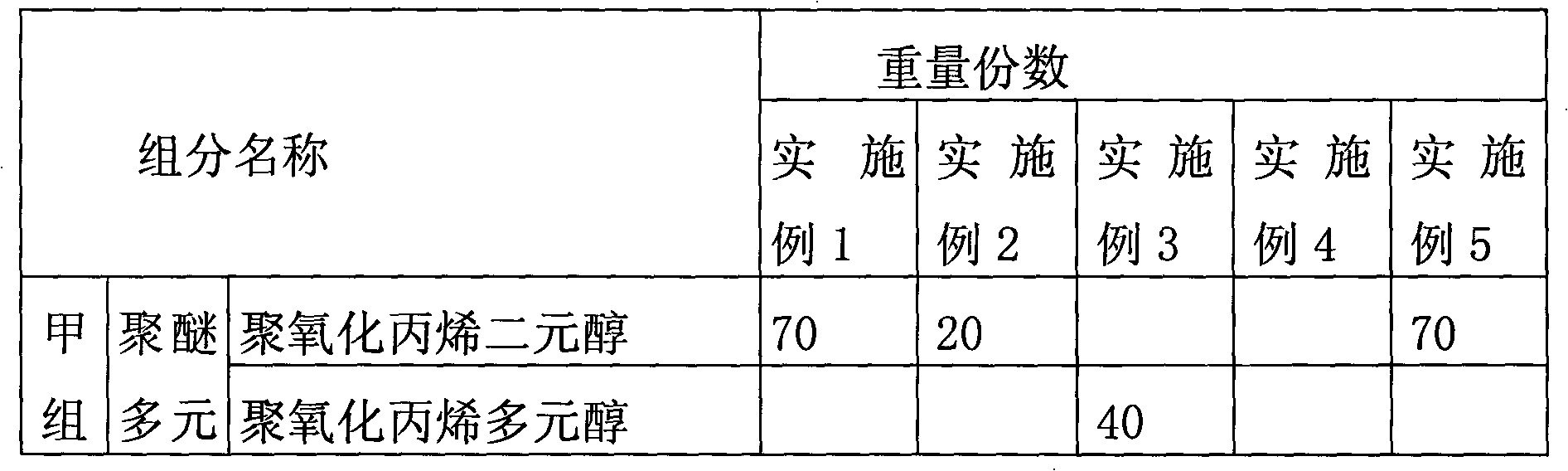

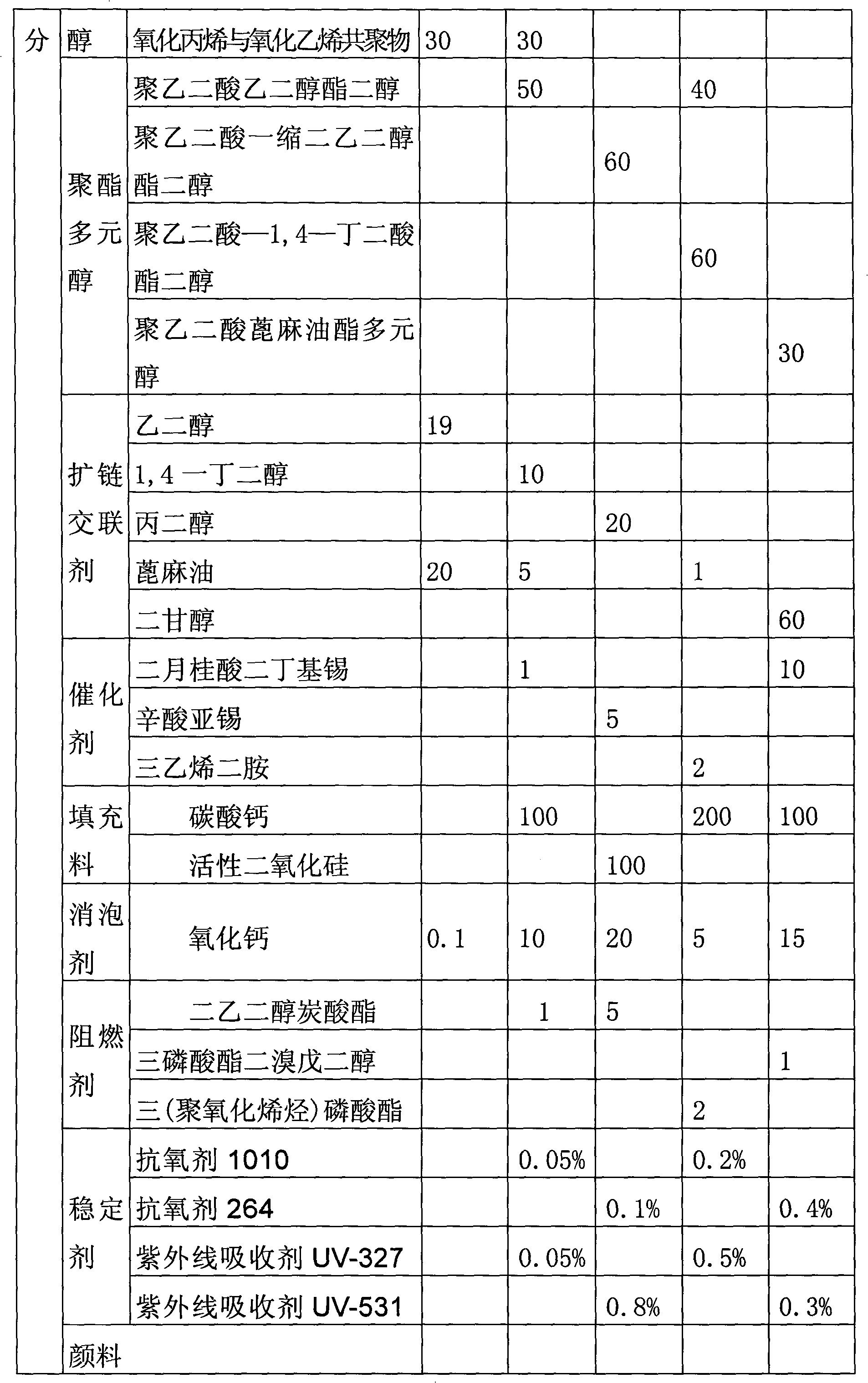

Thermoplastic elastomer composition

The invention discloses a thermoplastic elastomer composition which is plasticated by the following main components by weight: 100 parts of polyurethane thermoplastic elastomers, 30-150 parts of polyvinyl chloride thermoplastic elastomers, 25-50 parts of styrene elastomers, 0-30 parts of blend and 4-8 parts of auxiliaries, wherein the auxiliary is any one or more of a composite rare-earth stabilizer, zinc stearate, calcium stearate, stearic acid or polyethylene wax; and the blend is butyronitrile N18. The invention selects the thermoplastic elastomers with similar polarity and complementary properties to be synthesized and used and selects compatilizers to organically combine several best molecules with different structures, so that the generated novel thermoplastic elastomer has superior performance and appropriate price, can meet the requirements of market products and has wide application range because the product has the technical advantages of excellent oil resistance, resistance to low temperature of minus 35 DEG C, acid-alkali resistance, aging resistance and lower proportion than the vulcanized products with the same price.

Owner:营口巨成教学科技开发有限公司 +1

Method for producing high-flowability pregelatinized starch

InactiveCN102134281AImprove liquidityLoose structurePharmaceutical non-active ingredientsFood preparationQuality controlMixed materials

The invention provides high-flowability pregelatinized starch and a method for preparing the same by mechanical activation, which belong to the technical field of starch modification processing. The method comprises the following steps: uniformly mixing starch and a certain amount of flow aid in a high-speed mixer uniformly, pre-drying the starch by using heat generated in a high-speed mixing process, and controlling the water content in the starch to be lower than 15 percent; and placing the uniformly mixed materials in a ball mill containing a milling medium, well regulating the temperature for constant-temperature dissolution in water, performing mechanical activation for a certain time period, taking the starch out, and sieving the starch with a 80 to 100-mesh sieve. The method has the advantages of simple process and equipment, small investment, environmentally-friendly process, low production cost, easy product quality control and the like. The prepared product has the characteristics of high flowability, loose structure, uniform particles and precision control over pregelatinization degree and can be widely used in industrials and fields of foods, pharmaceuticals, chemicals and the like.

Owner:GUANGXI UNIV +2

Method for synthesizing thiofide NS by oxygen oxidation method

The invention discloses a method for synthesizing thiofide NS by an oxygen oxidation method. The method comprises the following steps of: adding promoter MBT and ammonia water in the molar ratio of 1:2-7 into a three-neck flask, dissolving and adding in a high-pressure oxidation kettle, dissolving the catalyst of copper sulfate with the ammonia water and adding into the high-pressure oxidation kettle, reacting at a temperature of 40-70 DEG C, introducing oxygen in the high-pressure oxidization kettle at a reaction pressure of 0.2-0.7MPa, adding tert-butylamine into the high-temperature oxidation kettle by using a constant-pressure sampling pump, reacting continuously for 0.2-0.7h after oxygen introduction, maintaining the pressure of the high-pressure oxidation kettle, stopping reaction; storing mother liquor into a sealed flask after filtering, preparing for reuse, washing and drying the product to obtain the thiofide NS with a product purity of above 98 percent. The invention has the advantages that the method has simple process and is easy to industrialized, the products have good quality and high yield as the mother liquor can be recycled and a small amount of tert-butylamine is consumed, and no three wastes are discharged in the synthesizing process.

Owner:KEMAI CHEM

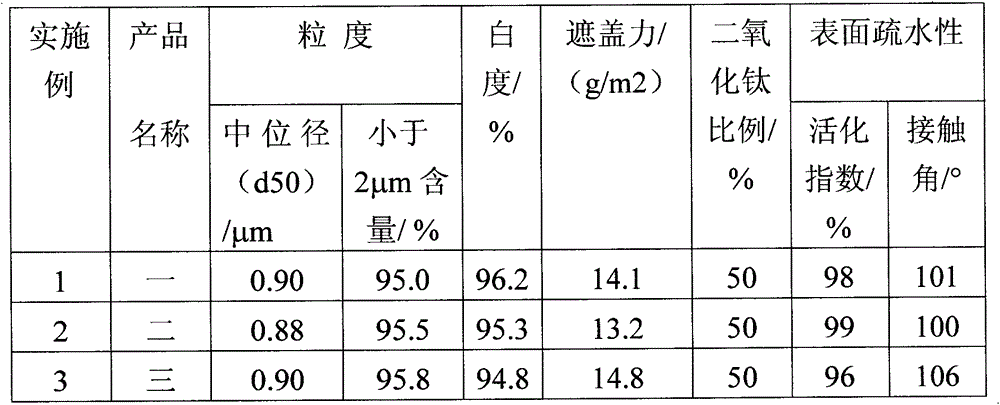

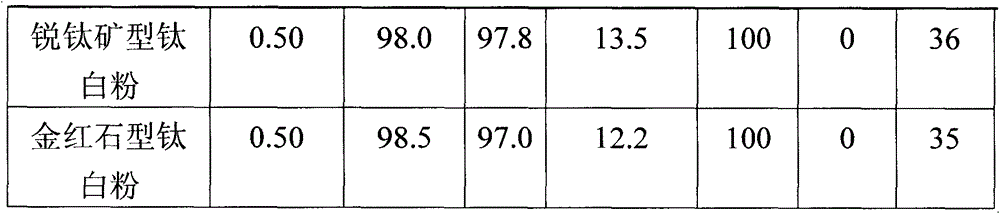

Preparation method for white mineral-titanium dioxide composite powder pigment

InactiveCN104098932AHydrophobicGood compatibilityPigment treatment with non-polymer organic compoundsSlurryEnergy consumption

The invention discloses a preparation method for a white mineral-titanium dioxide composite powder pigment. The white mineral-titanium dioxide composite powder pigment is prepared by firstly preparing slurries respectively from a white mineral powder and pigment-grade titanium dioxide with water, employing an organic modifier to perform surface modification, regulating the pH value, then uniformly mixing the prepared slurries, and performing strong stirring, press filtering and drying. The preparation method comprises the following advantages that 1) energy consumption is relatively low in the preparation process; 2) the surface of the prepared composite particle has hydrophobicity, and the particle is good in compatibility with organic matrix; 3) the preparation technology is simple, especially solid-liquid separation is easy to realize, and large-scale production is easy to realize; and 4) the production process is clean, no three wastes (waste gas, waste water and industrial residue) are discharged, and environment is not polluted.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

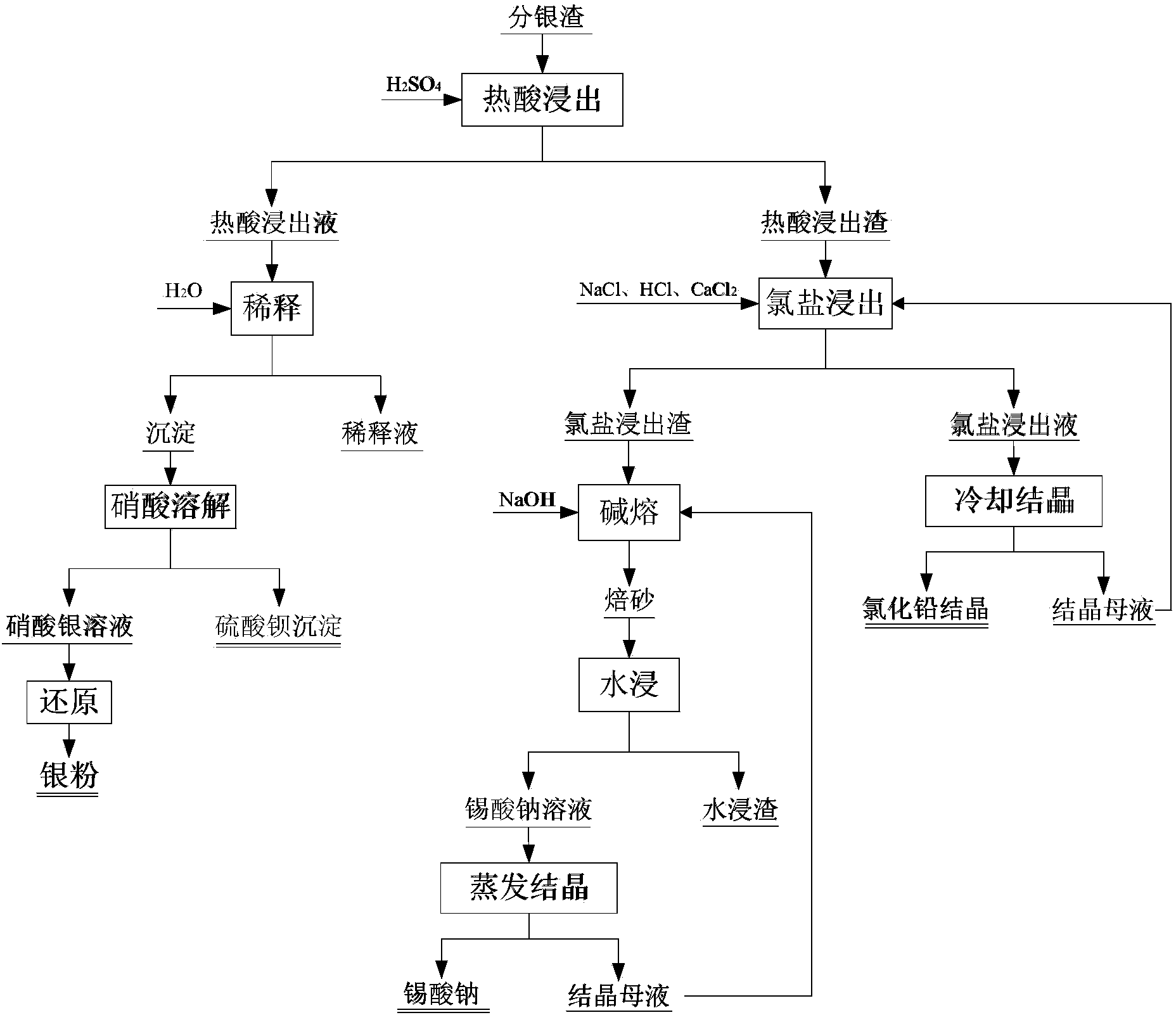

Method for comprehensively recovering valuable metals from copper anode sludge silver separating slag

The invention relates to a copper anode sludge silver separating slag reutilization technique, particularly a method for comprehensively recovering valuable metals from copper anode sludge silver separating slag. The method comprises the following steps: carrying out hot acid leaching on silver separating slag, filtering to obtain a hot acid leaching solution containing silver and barium and hot acid leaching slag containing tin and lead; diluting the hot acid leaching solution with water, filtering to obtain a precipitate, dissolving the precipitate with nitric acid, and filtering to obtain a barium sulfate precipitate and a silver nitrate solution; reducing the solution to obtain silver powder; leaching the hot acid leaching slag with acidic chlorine salt, filtering to obtain a chlorine salt leaching solution and chlorine salt leaching slag; cooling the chlorine salt leaching solution to crystallize and precipitate lead chloride; and carrying out alkali fusion, water immersion and evaporation crystallization on the chlorine salt leaching slag to obtain sodium stannate. The method can effectively recover all the valuable metals with higher content in the silver separating slag, and the recovery rates of the lead, silver, tin and barium are respectively up to higher than 97%, 92%, 90% and 95%. The method has the characteristics of simple technique, no emission of three wastes, high metal recovery rate and the like, and is suitable for large-scale industrial production.

Owner:JIANGXI UNIV OF SCI & TECH

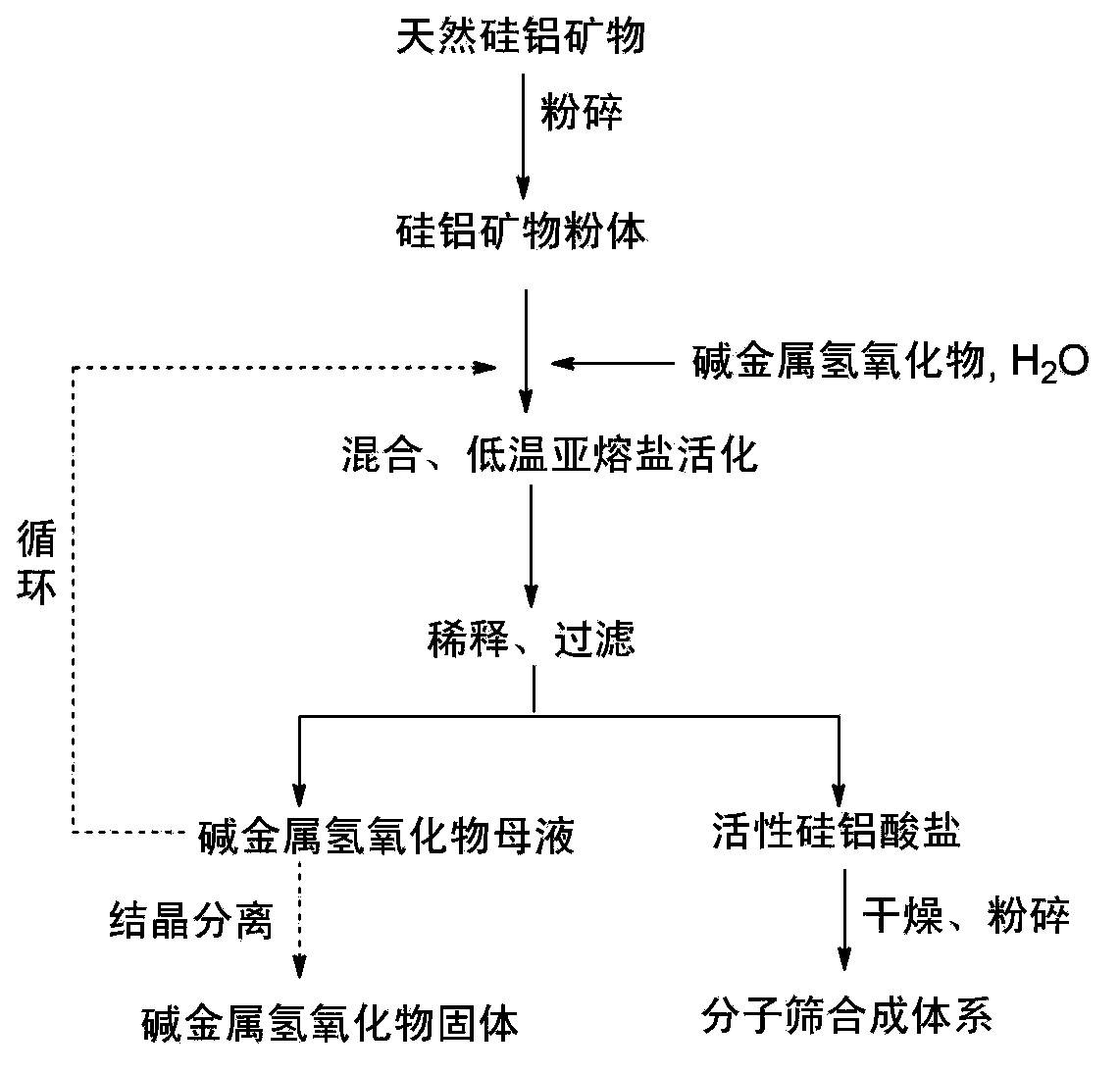

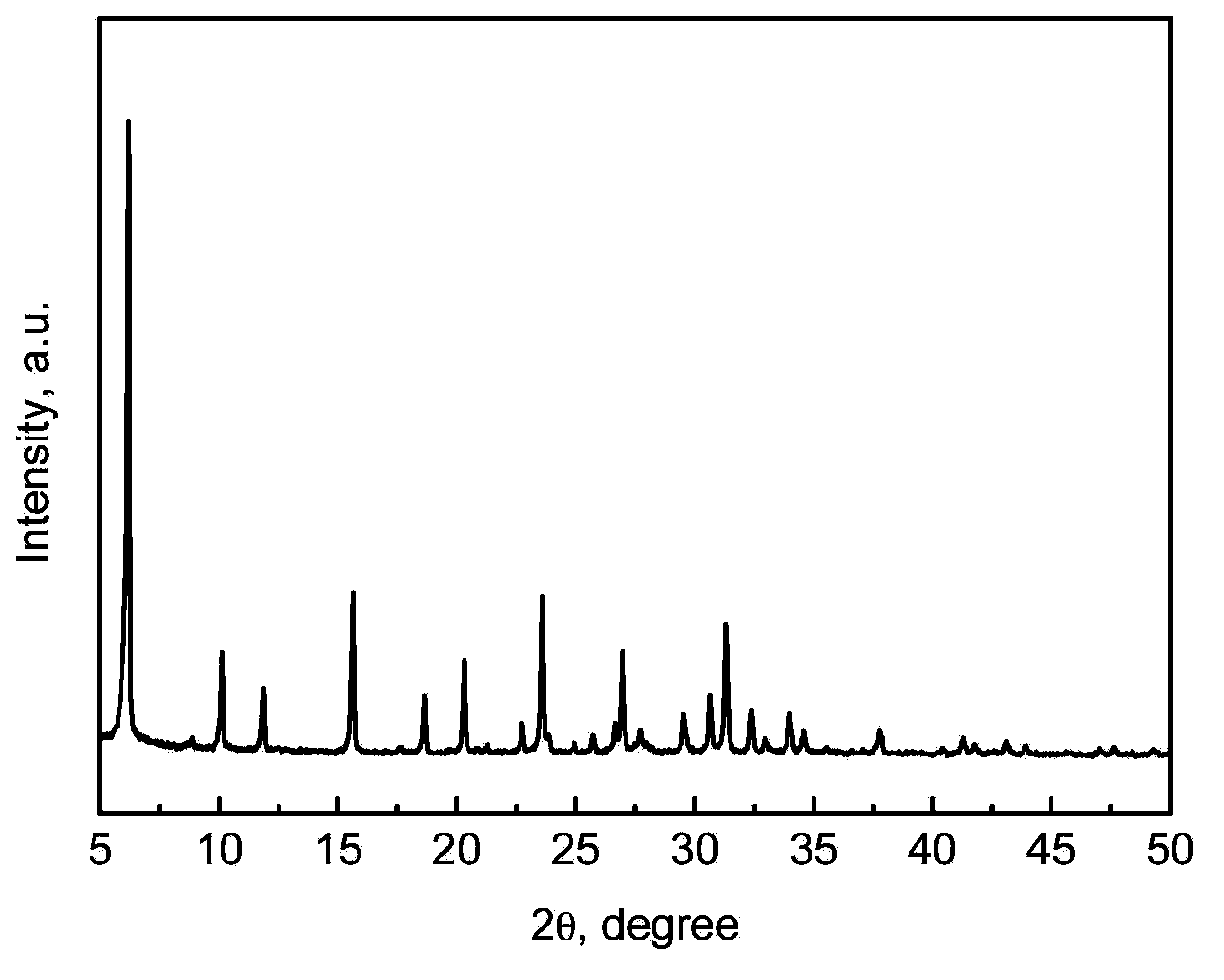

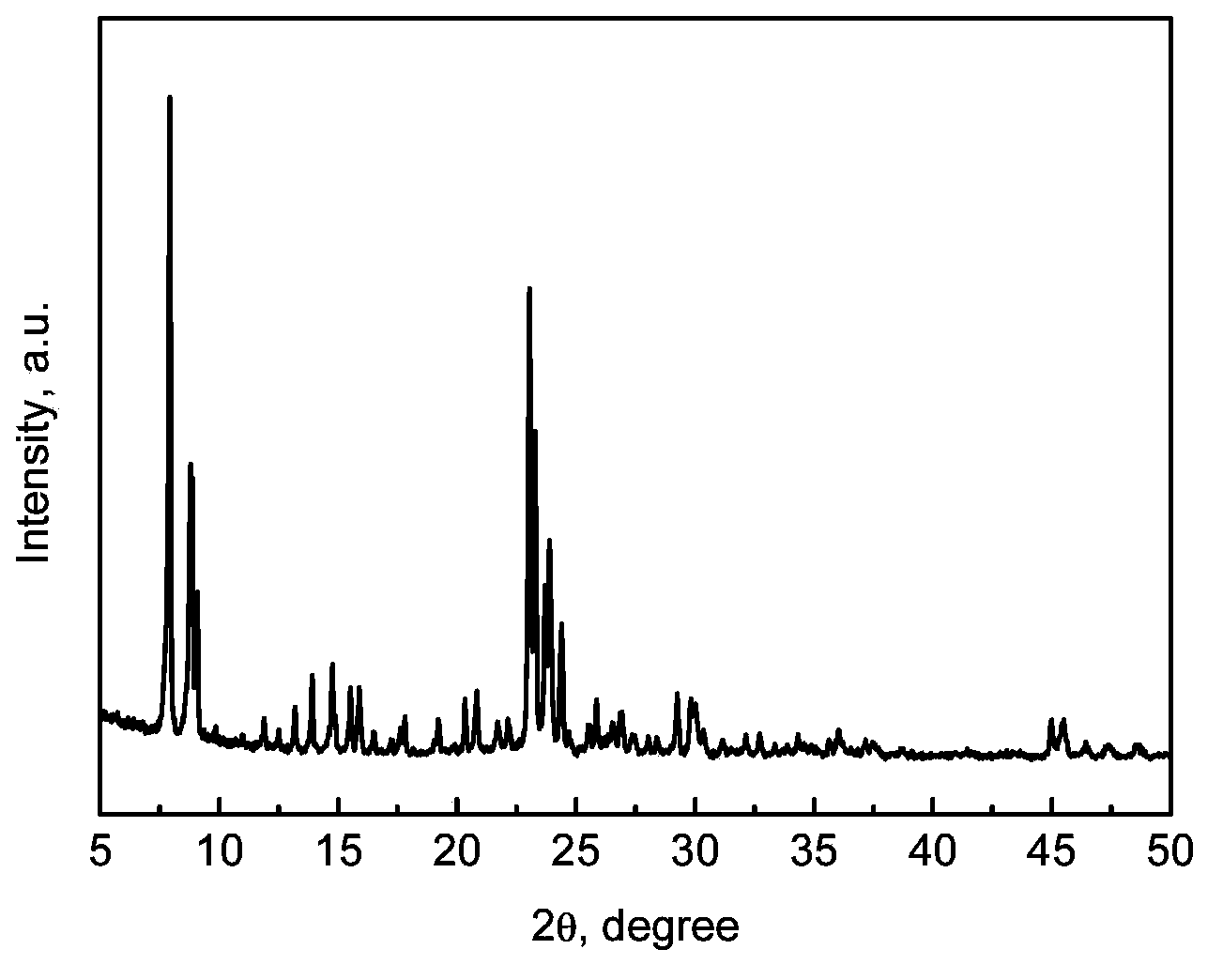

Preparation method for active aluminosilicate

InactiveCN103570032AWide variety of sourcesSimple processAluminium silicatesFaujasite aluminosilicate zeoliteHigh concentrationDecomposition

Belonging to the comprehensive utilization field of natural minerals, the invention provides a preparation method for active aluminosilicate. The method makes use of a sub-molten salt system to activate natural a silicon-aluminum mineral at low energy consumption and efficiently utilizes the activation product. The method adopts a high concentration alkaline solution as a medium to perform liquid phase activation reaction on a natural silicon-aluminum mineral so as to destroy the crystal structure of the natural silicon-aluminum mineral, thus forming the high activity aluminosilicate able to be used for molecular sieve synthesis. The decomposition temperature of the mineral is far below the roasting temperature of traditional thermal activation and alkali fusion activation, the crystal structure of the mineral can be fully destroyed at low temperature, simultaneous extraction of silicon and aluminum in the natural silicon-aluminum mineral can be realized, and the process is easy to operate. The method provided by the invention also extends the range of raw materials for molecular sieve preparation, not only greatly reduces the molecular sieve production cost, but also provides an effective way for high value added utilization of natural silicon-aluminum minerals.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Mechanical activation and enhancement method for preparing cellulose acetate-butyrate or cellulose acetate-propionate

The invention relates to the field of cellulose processing, and in particularly relates to a mechanical activation and enhancement method for preparing cellulose acetate-butyrate or cellulose acetate-propionate. The method comprises the following steps: weighing reactants including cellulose, butyric acid, acetic anhydride and a catalyst in a ratio of 10g:(30-100g):(10-30g):(0.1-0.5g), putting all the reactants into a ball mill, controlling the ratio of the reactants to pellets at 100g:(100-300ml), controlling the temperature of a circulating water bath at 50-80 DEG C, stirring at a low speed to perform an acylation reaction for 1-4 hours to obtain a crude product, separating the crude product and the pellets, standing the crude product in 50% ethanol water to separate out a solid, separating the separated solid, and washing the separated solid with deionized water until the solid is neutral, thereby obtaining a cellulose acetate-butyrate or cellulose acetate-propionate product. Compared with the existing method for producing cellulose acetate-butyrate or cellulose acetate-propionate, the method disclosed by the invention has the characteristics of simple process, high efficiency, no pollution, high product quality and the like.

Owner:福建鸿燕化工有限公司

Method for synthesizing rubber vulcanization accelerator DM by oxygen oxidization

The invention discloses a method for synthesizing rubber vulcanization accelerator DM by oxygen oxidization. The process of the method comprises: adding a 95 to 99 mass percent accelerator MBT and a 10 to 25 mass percent aqueous ammonia into a three-neck flask in a molar ratio of 1:2-7 to dissolve the 95 to 99 mass percent accelerator MBT under the conditions of a temperature of 35 to 45 DEG C and a stirring speed of 10 to 100 r / min; after the MBT dissolves completely, adding the solution into a high-pressure oxidizing kettle; dissolving a copper sulfate catalyst in 10 to 20 grams of 10 to 25 mass percent of aqueous ammonia (the molar ratio of the catalyst to the MBT is 0.001-0.007:1) and adding the solution into the high-pressure oxidizing kettle; introducing oxygen into the high-pressure oxidizing kettle under the conditions of a reaction temperature of 40 to 70 DEG C and a stirring speed of 300 to 1,000 r / min to perform reaction for 1 to 5 hours under a condition of a reaction pressure of 0.2 to 0.7MPa till 0.2 to 0.7 hour after the oxygen introduction is stopped, wherein if the pressure in the high-pressure oxidizing kettle keeps constant, the reaction is finished; after the reaction is finished, reducing the pressure in the high-pressure oxidizing kettle to normal pressure; washing and drying the product to obtain a rubber vulcanization accelerator DM product; and distilling mother solution to recycle the aqueous ammonia. The purity of the product is up to over 98 percent. The invention has the advantages that: the method is simple in process and easy to industrialize; due to the recycling of the aqueous ammonia, the product has high quality and yield; and the synthesis process is free from the discharge of 'three wastes'.

Owner:内蒙古科迈化工有限公司

Vehicle shock absorber piston rod spraying technology

ActiveCN103147033AImprove bindingGood coating strengthMolten spray coatingWorking environmentPiston rod

The invention relates to a vehicle shock absorber piston rod spraying technology. The vehicle shock absorber piston rod spraying technology comprises the following steps of: coarse grinding, degreasing, surface roughening, non-spraying surface protection, preheating, spraying and fine grinding. When a piston rod is treated according to the spraying technology provided by the invention, the performances such as the binding force, the coating intensity, the coating thickness, the abrasion resistance, the corrosion resistance and the like of a coating of the piston rod are all superior to those of a durionise layer, and the cost performance of the coating is also superior to that of the durionise layer, so that the technology is a precedence technology used for replacing a durionise technology; and particularly, the technology does not pollute the environment, is beneficial to improvement of the working environment and the health and the safety of an operator. The technology has the advantages that production period is short, production efficiency is high, defective rate is low, the treated vehicle shock absorber piston rod has good rust-proof performance, good abrasion resistance and long service life; moreover, automation operation is easily realized, production efficiency is high and the production cost is lowered.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

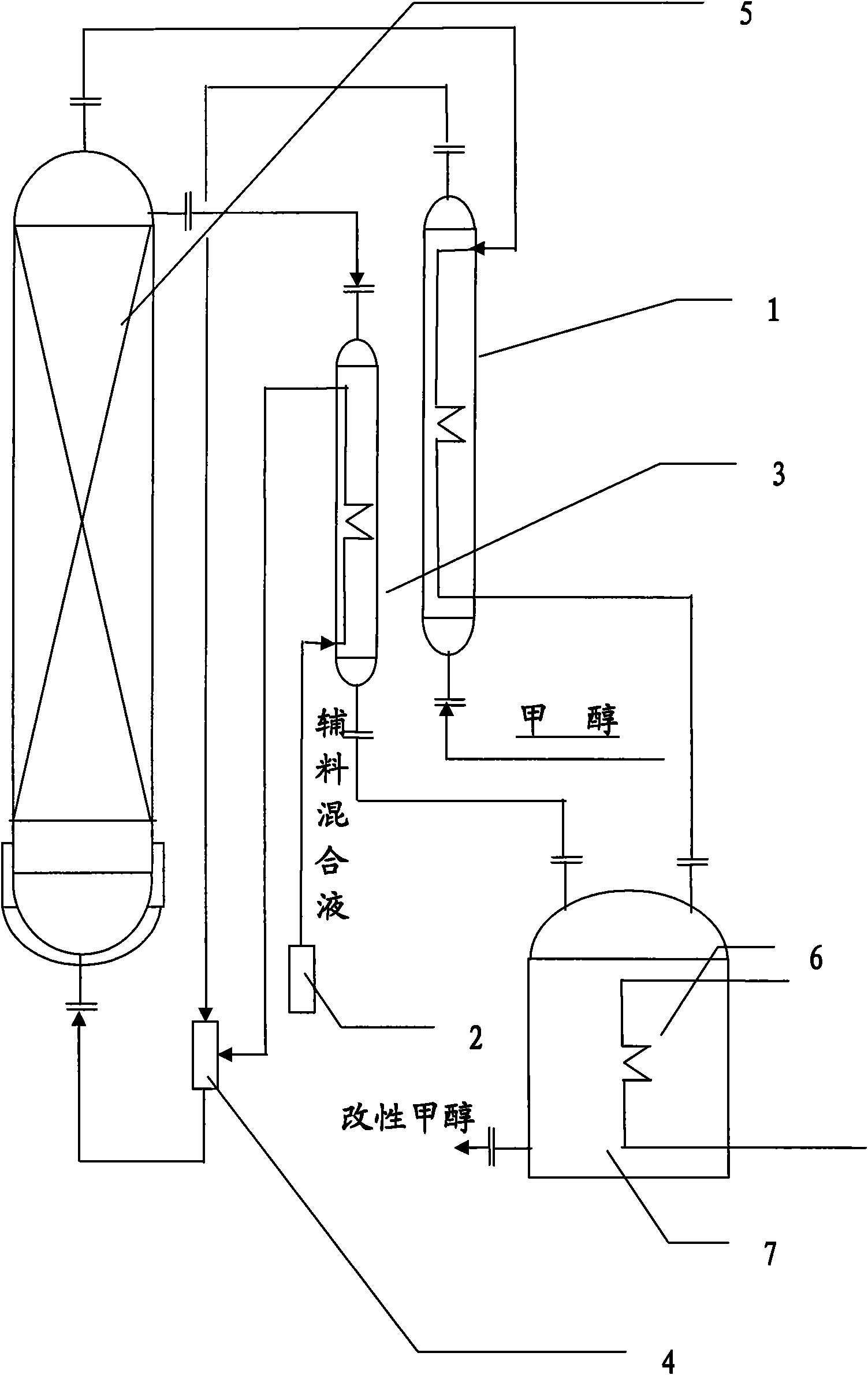

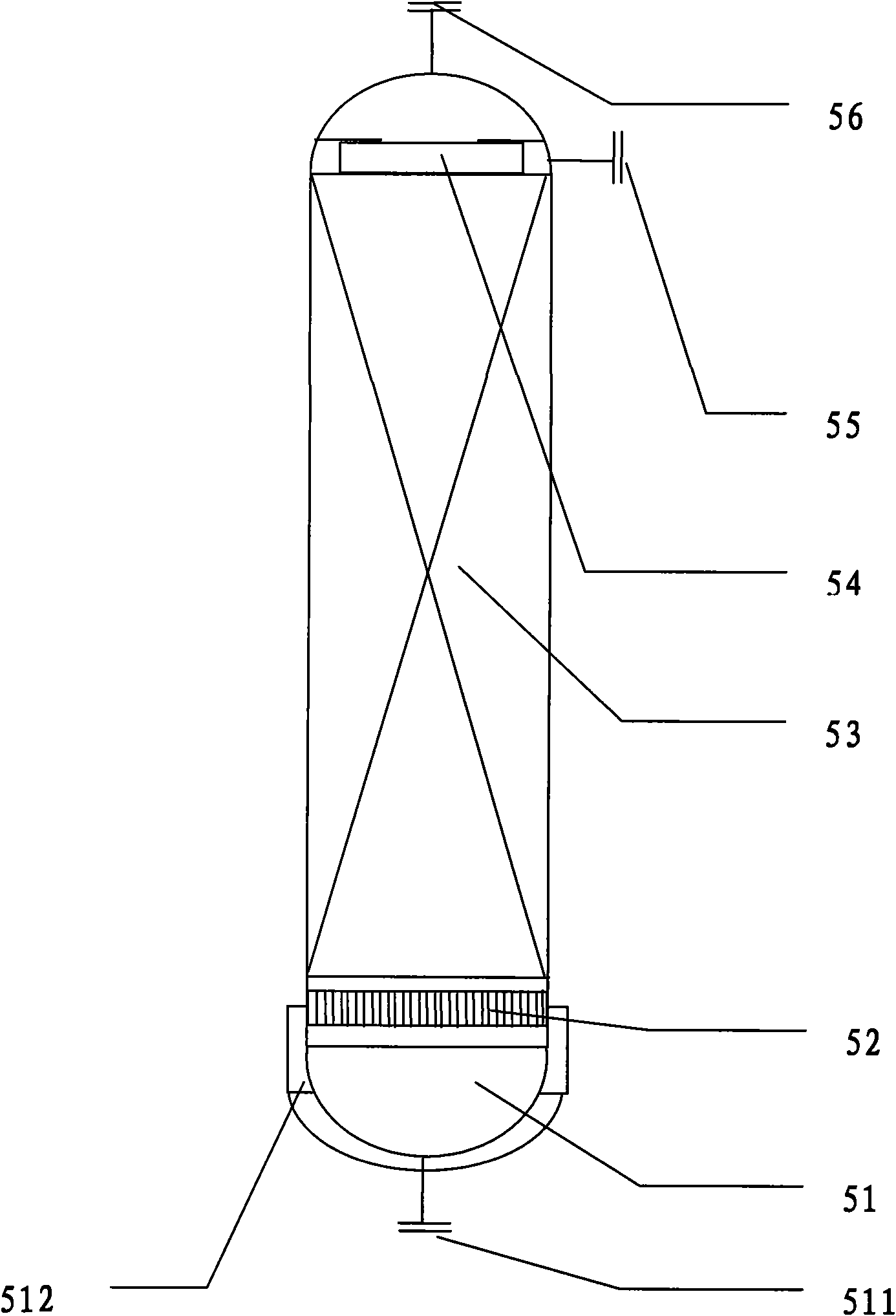

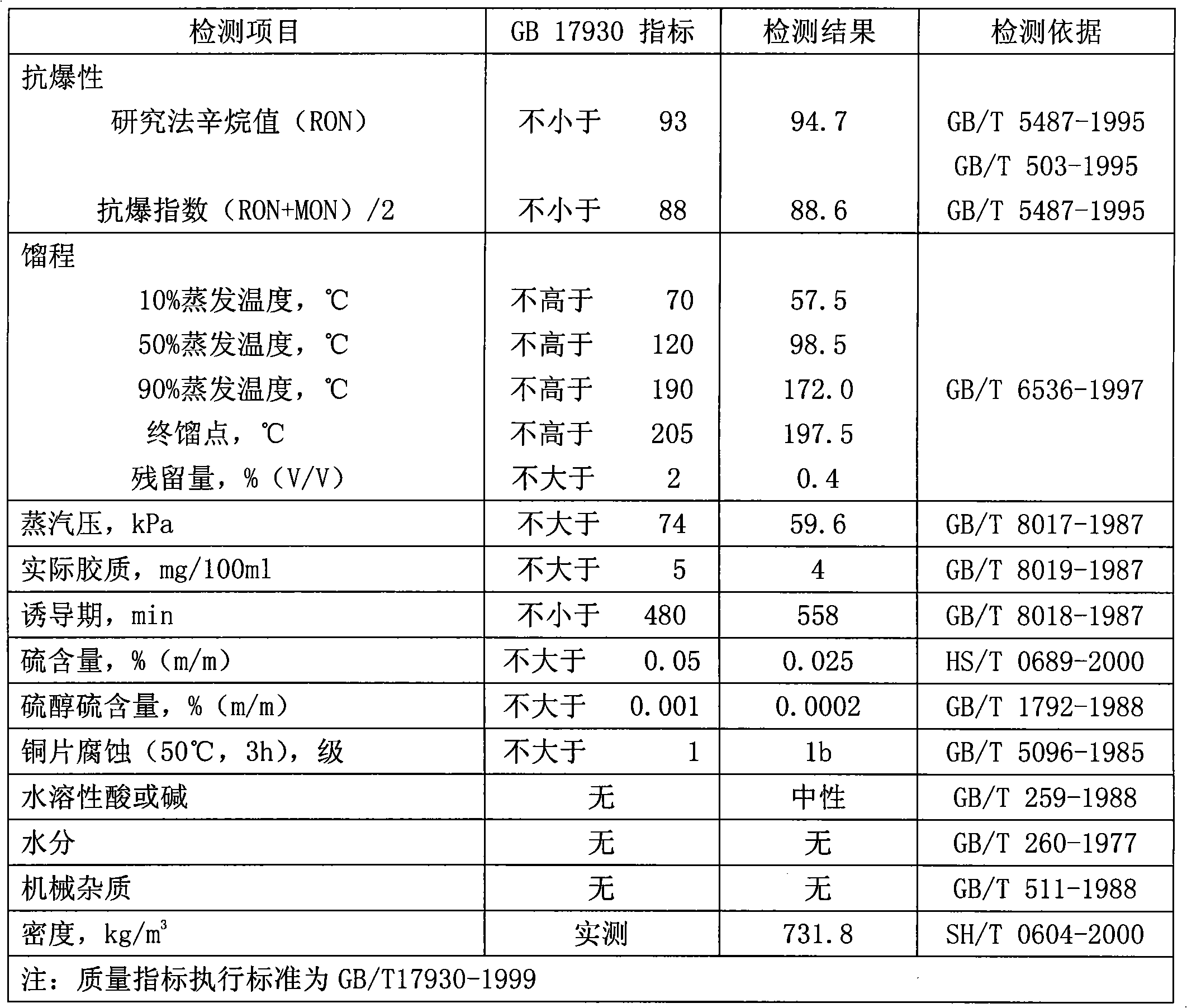

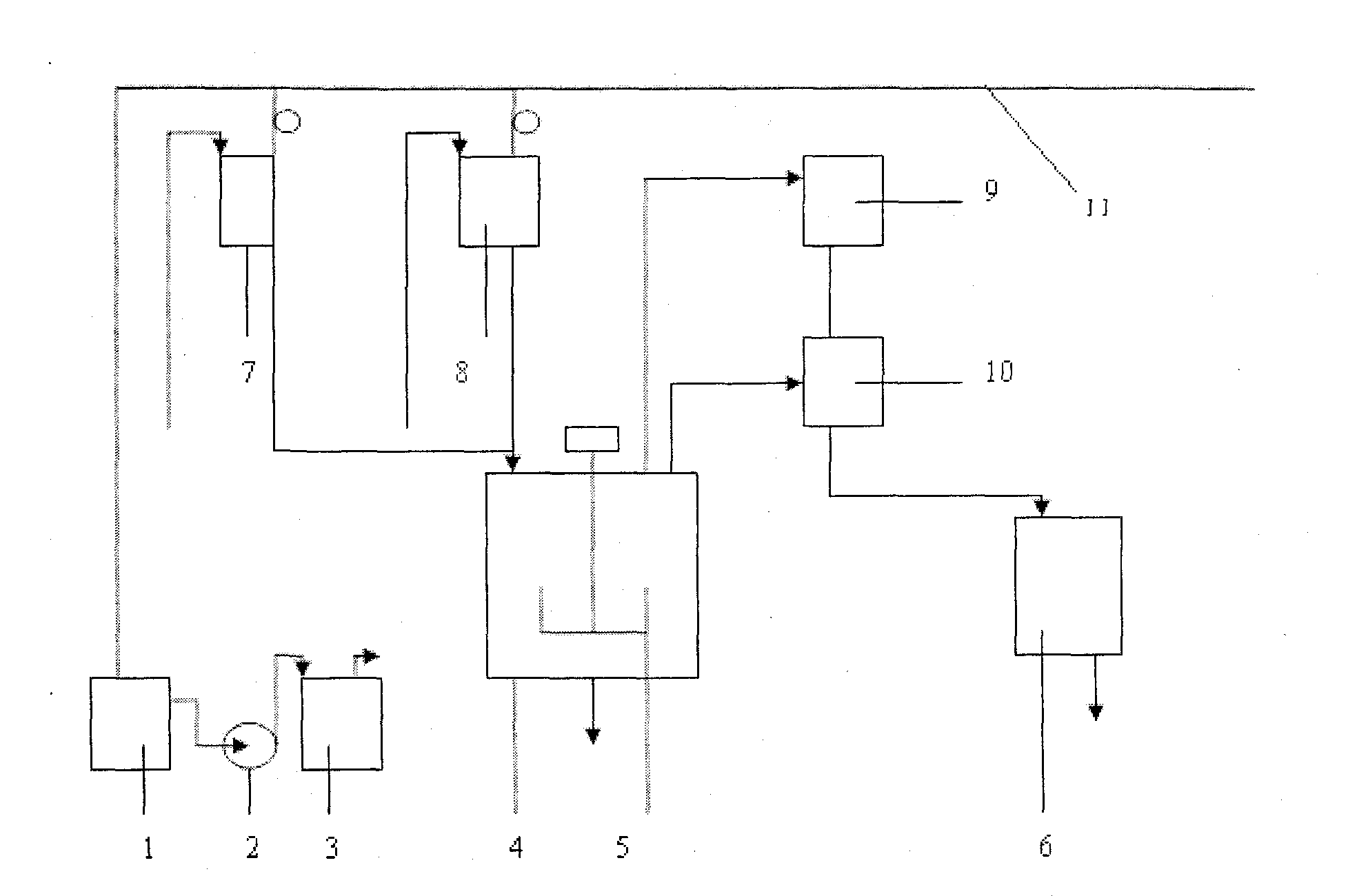

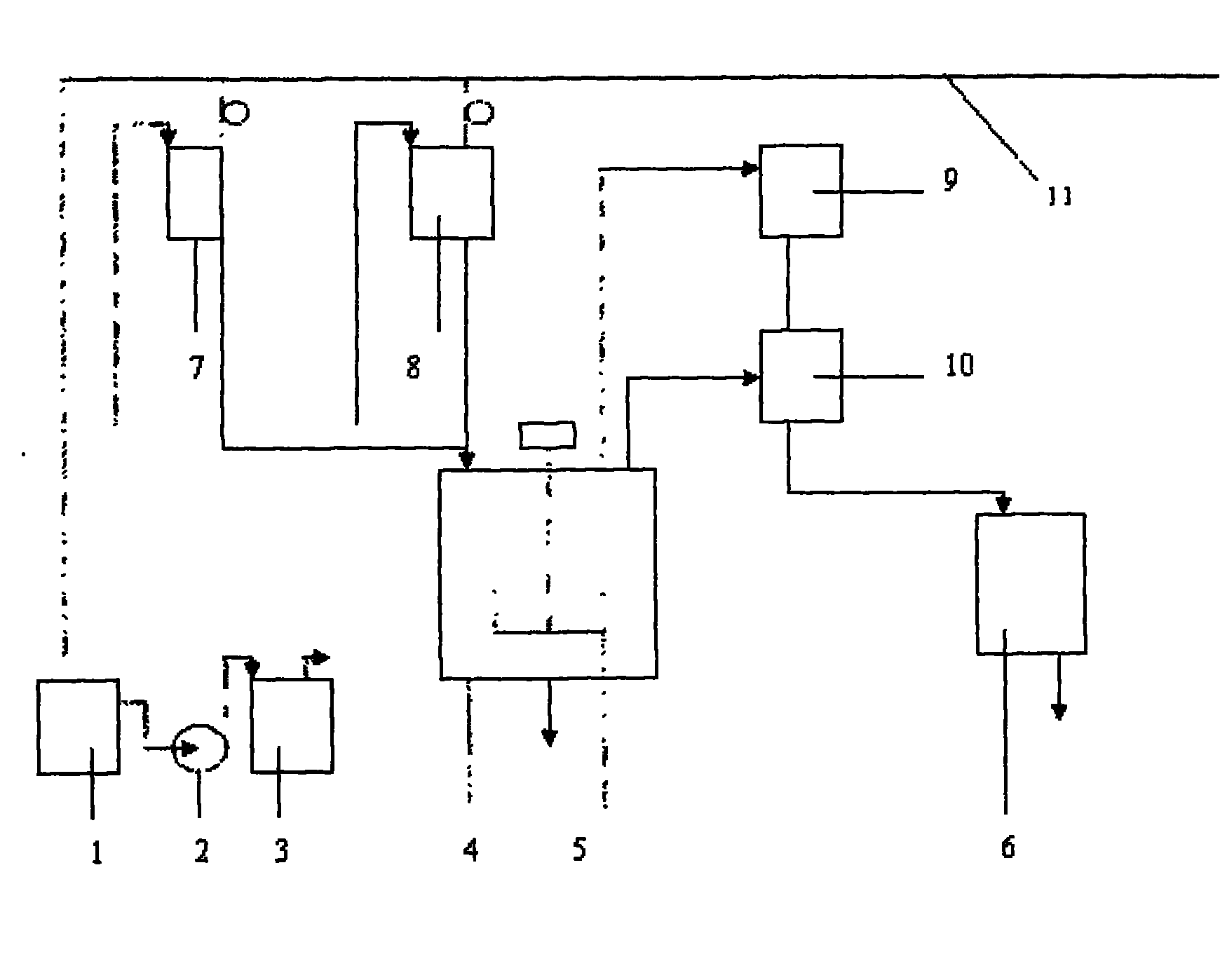

Preparation method and device of methanol fuel finished gasoline for vehicles

InactiveCN101987977ASave energySimple processCatalyst activation/preparationLiquid carbonaceous fuelsMethanol fuelGasoline

The invention relates to a preparation method and device of methanol fuel finished gasoline for vehicles. The method provided by the invention comprises two steps of preparation of modified methanol and preparation of the methanol fuel finished gasoline for vehicles, wherein the preparation of the modified methanol is realized by the processes of proportioning, preheating, catalytic reaction and heat exchange of methanol and auxiliary materials; and the preparation of the methanol fuel finished gasoline for vehicles is finished by modulation of the modified methanol and modulation of the methanol fuel finished gasoline. The device provided by the invention sequentially comprises a mixer 2, a mixer 4, a catalytic reactor 5, a condensing, cooling and preheating device I1, a preheating and cooling device II3, a low-temperature cooler 6 and a receiving tank 7. Because an integrated device is designed for condensing, cooling and preheating raw materials, the invention ensures that the residual heat of reaction products is recycled, the process is simple and no emission of 'the three wastes' is realized; and simultaneously, the catalytic reactor is heated in a far-infrared radiation explosion-proof type, thus the invention has the advantages of obvious effects of energy saving, environmental protection and safety.

Owner:艾长江 +1

Preparation method and use method of modified bentonite environment-friendly formaldehyde removing agent

ActiveCN103007898AImprove adsorption efficiencyLow release rateOther chemical processesAldehyde/ketone condensation polymer adhesivesCalcium in biologySodium Bentonite

The invention relates to a modified bentonite environment-friendly formaldehyde removing agent for removing free formaldehyde in urea-formaldehyde glue. A preparation method of the formaldehyde removing agent comprises the following steps of: in parts by weight, crushing 100 parts of calcium bentonite, screening the crushed calcium bentonite through a 200-mesh sieve, adding 2 to 3.5 parts of sodium carbonate into the screened calcium bentonite, mixing uniformly, spraying water of which the weight accounts for 10 percent of that of the calcium bentonite, fully mixing uniformly, sealing the mixture for 24 hours for sodication reaction, and air-drying naturally; and adding 0.5 to 2.5 parts of hydroxyethyl cellulose, 1.5 to 2.5 parts of ammonia chloride and 2.5 to 5 parts of sodium nitrite into 100 parts of a raw material subjected to sodication, crushing the mixture and stirring for 3 hours to obtain powder, and screening the powder through a 300-mesh sieve to obtain formaldehyde removing powder. A use method of the modified bentonite environment-friendly formaldehyde removing agent comprises the following steps of: in parts by weight, adding 10 parts of water into 10 parts of the formaldehyde removing agent, stirring at a high speed for 40 minutes, adding 10 parts of a suspension of the mixture into 90 parts of the urea-formaldehyde glue, raising the temperature to 50 DEG C, fully stirring for 30 minutes, standing for more than 24 hours, and thus fully adsorbing the formaldehyde in the urea-formaldehyde glue. The modified bentonite environment-friendly formaldehyde removing agent has good adsorption effect on the formaldehyde, and cannot influence the performance of the urea-formaldehyde glue.

Owner:吕新民

Clay solidification intensifier for express highway pavement foundation and uses thereof

InactiveCN101041569AReduce construction costsNo "three wastes" dischargeRoadwaysSolid waste managementMass ratioPotassium hydroxide

The invention discloses a clay solidifying and reinforcing agent used to highway paving basal layer and its application, which comprises the following steps: allocating the mother powder with component and mass ratio at 10-50 amorphous silica powder (active silica powder), 5-40 cement plumping agent, 5-35 alum, 5-45 burnt lime or burned lime, 0-20 caustic soda or caustic potash, 0-20 calcium sulfate, 0-5 cement hardener and 0-2 cement set retarder; mixing mother powder and silicate cement with mass ratio at 10-50:90-50; getting the product; blending clay solidifying and reinforcing agent and clay or clay with sand rock according to intended mass ratio; adding 10-30% water; stirring evenly; rolling; shaping; protecting 7-14 days under normal temperature; becoming clay composite material of highway paving basal layer.

Owner:刘文伟 +3

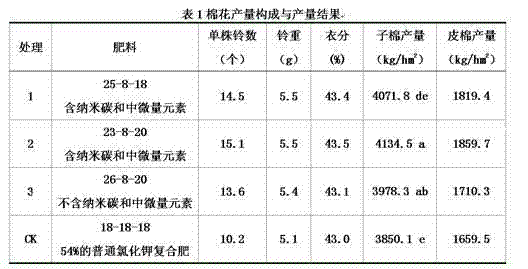

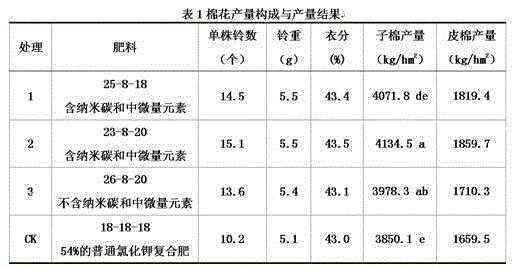

High-concentration nano-carbon cotton special fertilizer and preparation method thereof

The invention discloses high-concentration nano-carbon cotton special fertilizer and a preparation method thereof, and belongs to the technical field of fertilizer. The high-concentration nano-carbon cotton special fertilizer obeys a cotton nutrient absorption rule and is prepared form raw materials of urea, potassium dihydrogen phosphate, potassium chloride, calcium-magnesium-phosphate fertilizer, monoammonium phosphate, ferrous sulphate, zinc sulfate, ethylene diamine tetraacetic acid (EDTA)-manganese chelate, borax, ammonium molybdate and nano-carbon according to certain ratios. The preparation method comprises the following steps of melting urea at a high temperature, carrying out pressurization, mixing the melted urea and other raw materials well, carrying out crushing and sieving, heating, preparing paste, carrying out vibration filtration, carrying out sprinkling and forming, cooling, sieving, carrying out anti-caking treatment and carrying out packaging. The high-concentrationnano-carbon cotton special fertilizer has comprehensive nutrition, balanced fertilizer components and a high fertilizer utilization rate, and can improve a cotton yield and cotton quality.

Owner:STANLEY AGRI GRP CO LTD

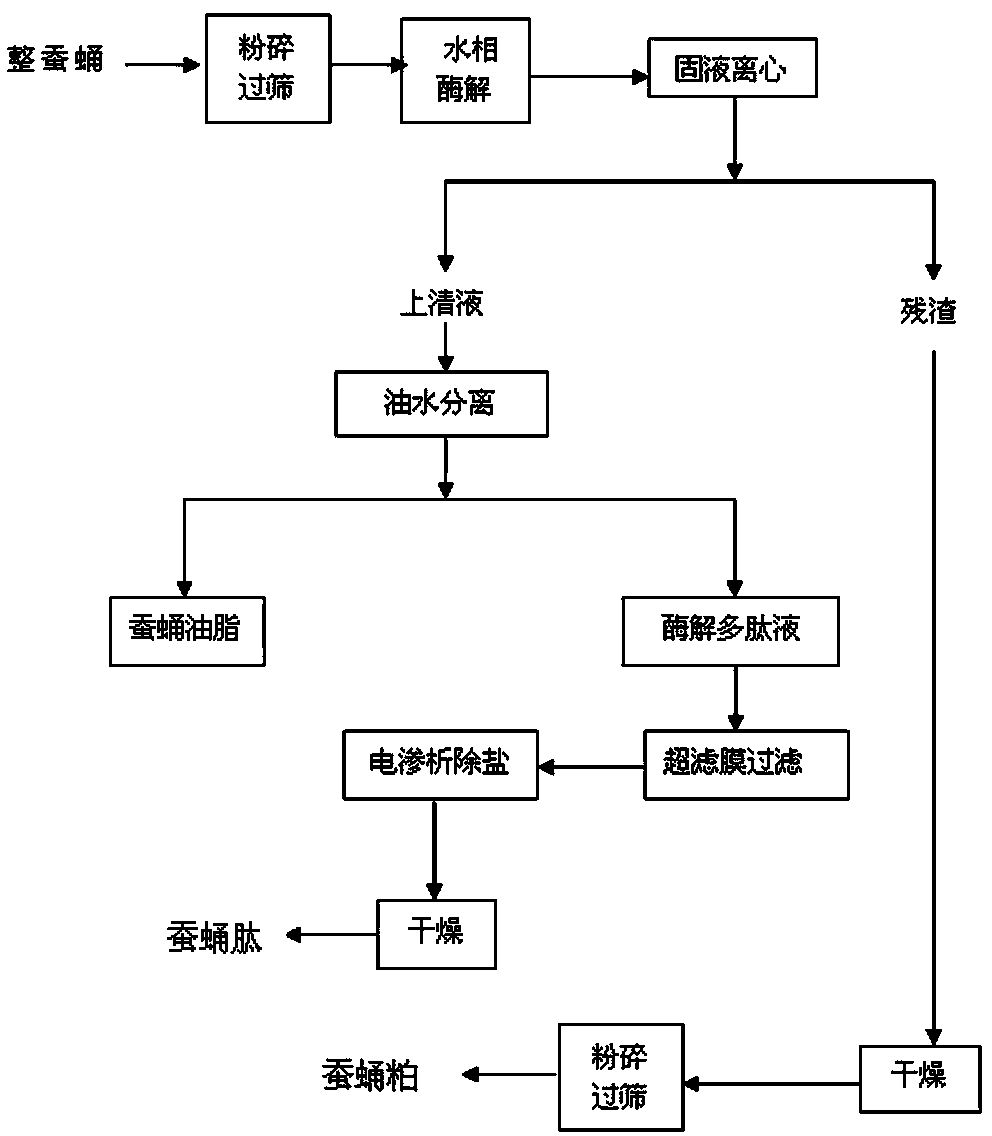

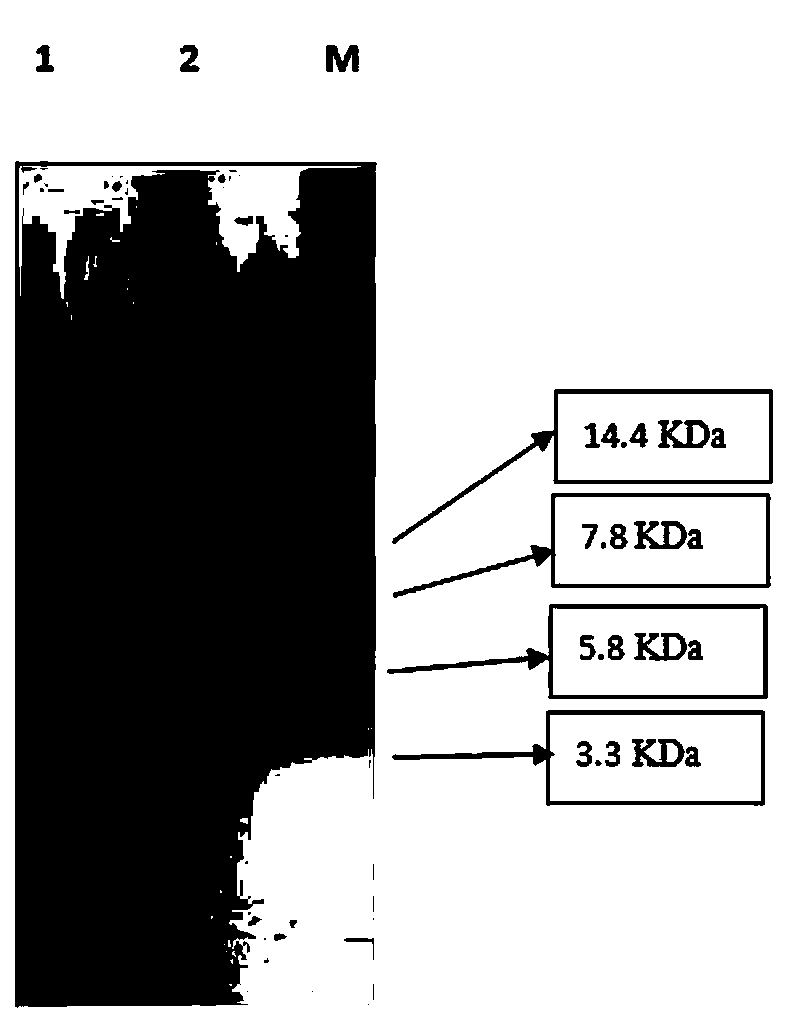

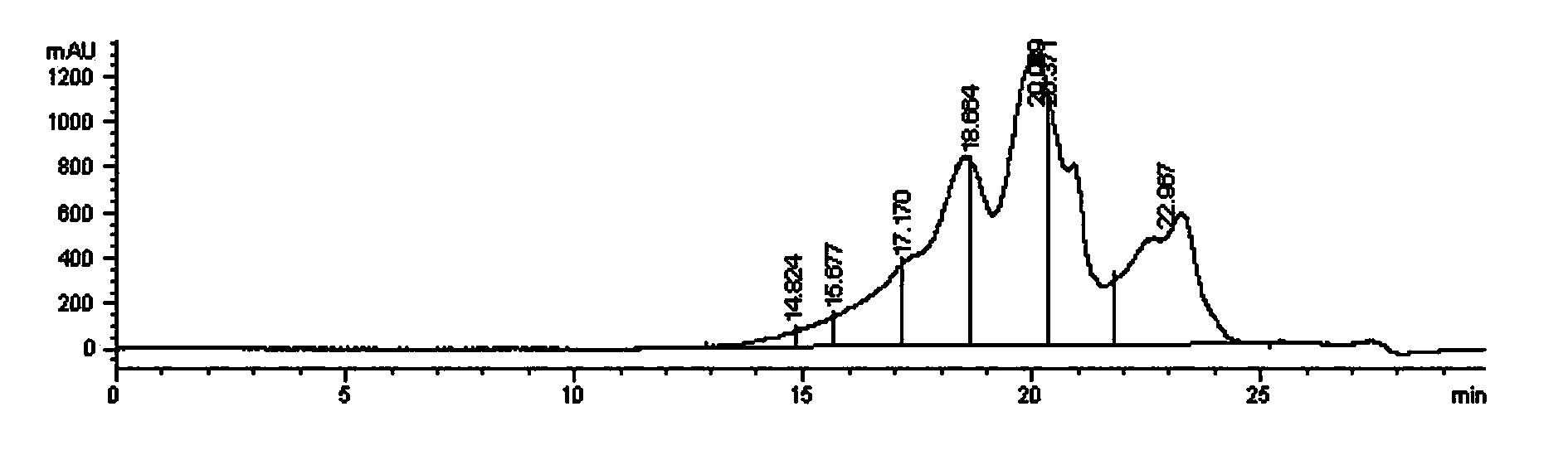

Method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by aqueous biological enzyme method

ActiveCN103540639AImprove qualityGood effectAnimal feeding stuffPeptide preparation methodsBiotechnologyUltrafiltration

The invention relates to a method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by an aqueous biological enzyme method. According to the method, silkworm chrysalises serve as raw materials, an enzymolysis solution is obtained through drying, crushing and carrying out aqueous-phase enzymolysis, a supernatant and residues are obtained through carrying out centrifugation on the enzymolysis solution, the silkworm chrysalis meal is obtained through drying and crushing the residues, and the silkworm chrysalis peptide powder is obtained through carrying out oil-water separation, ultrafiltration-membrane ultrafiltration and desalination on the supernatant and then drying and crushing. The method specifically comprises the following steps of (1) drying and crushing; (2) carrying out aqueous-phase enzymolysis; (3) carrying out centrifugation and oil-water separation; (4) carrying out ultrafiltration-membrane filtration; (5) carrying out desalination; (6) drying and crushing, thereby obtaining the silkworm chrysalis peptide powder. According to the method, the aqueous biological enzyme method is applied to insect cells-silkworm chrysalis cells for the first time; the method has the advantages that the process is simple, safe and environmental-friendly, the cost is low, the quality of the obtained silkworm chrysalis peptide powder and silkworm chrysalis meal is high, and the like; the method disclosed by the invention has the characteristics that the oil and fat removal efficiency is high, the residual fat content of the obtained silkworm chrysalis peptide powder and silkworm chrysalis meal is low, the oligopeptide content of the obtained silkworm chrysalis peptide powder and silkworm chrysalis meal is high, and the like.

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD +1

Preparation method of methyl anthranilate

ActiveCN101948400AHigh methyl ester contentIncrease contentOrganic compound preparationAmino-carboxyl compound preparationSynthesis methodsDisplacement reactions

The invention relates to the synthesis method of an organic compound, in particular to a preparation method of methyl anthranilate. The preparation method comprises the following steps: firstly using phthalic anhydride and ammonia water as raw materials to perform an amidation reaction and generate ammonium phthalamate; secondly adding sodium hydroxide solution to perform a displacement reaction and generate sodium phthalamate, removing ammonia molecules in the reaction solution, then adding methanol solution and sodium hypochlorite solution in the reaction solution to react and obtain paste methyl anthranilate, heating the paste methyl anthranilate to dissolve in water; and finally distilling the mixed liquid of methyl anthranilate and water to obtain methyl anthranilate. The methyl anthranilate prepared by the method of the invention has high content which is up to 98.4%; the appearance is good, the light transmittance of the product is 58.6%; the yield is high, which is increased by 0.4%-0.5% compared with the original technology; and the technology is advanced, the secondary recovery of ammonia water and methanol can be performed, and three wastes are not discharged in the production process.

Owner:濮阳市佳华化工有限公司

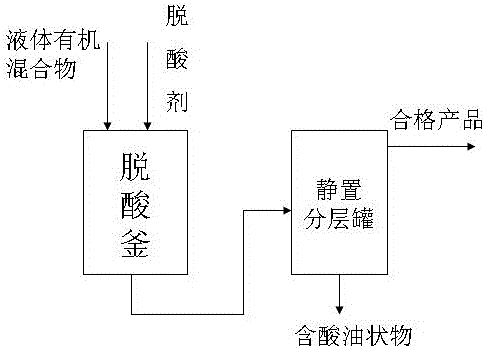

Deacidifying agent decreasing acid value of liquid organic mixtures and preparation technology

ActiveCN105368574AReduce volume ratioNo emissionsBiofuelsFatty-oils/fats refiningOrganic acidOrganic solvent

The invention discloses a deacidifying agent decreasing the acid value of liquid organic mixtures and a preparation technology. Organic acid in the liquid organic mixtures like fuel oil products is removed through the method of deacidifying agent complexation. According to the preparation technology of the deacidifying agent, inorganic base, organic base and an organic solvent are mixed and stirred at certain temperature to form a high-boiling-point transparent solution with good fluidity. According to the deacidifying technology, deacidifying conditions are mild, operation is easy, production cost is low, safety is high, and the problems that in an existing deacidifying technology, emulsification is likely to occur, high energy consumption and high solvent consumption are caused in solvent evaporation, and the recovery rate is low because separation is not thorough are solved. The new deacidifying technology has the advantages that complexation extraction is thorough, the two-phase settling and layering speed is high, the solvent-oil volume ratio is small, the solvent does not need to be evaporated and can be recycled, energy consumption is low, and three waste discharge is avoided.

Owner:石家庄搏澳增塑材料科技有限公司

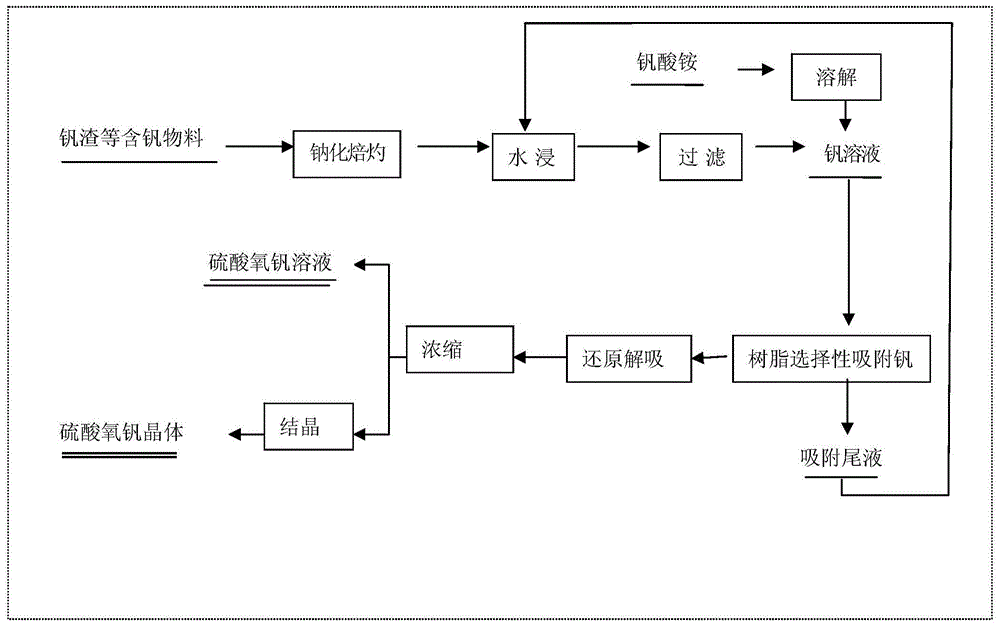

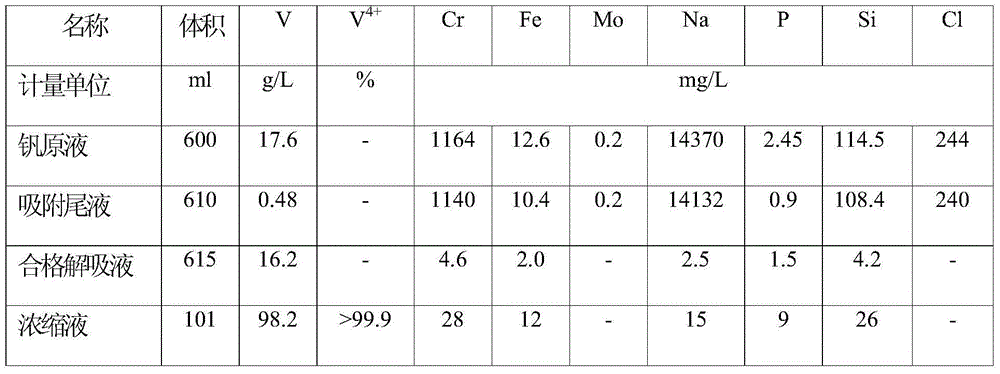

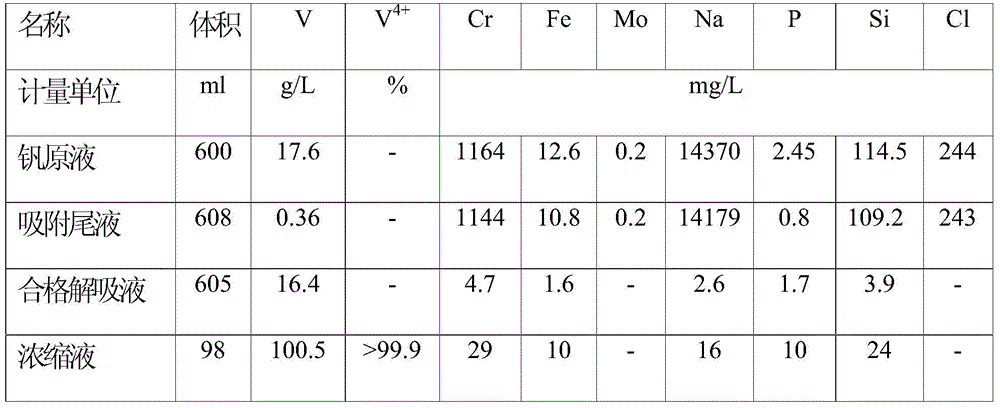

Method for preparing vanadyl sulfate

ActiveCN104310476ATo achieve the purpose of purificationProcess energy saving and environmental protectionVanadium compoundsVanadyl sulfatePhysical chemistry

The invention provides a method for preparing vanadyl sulfate. According to the method, a technical process that ion exchange resin is adopted to selectively adsorb vanadium and reduce and desorb vanadium so as to directly prepare vanadyl sulfate is adopted, so that a middle process in which powder high-purity vanadium pentoxide is prepared is canceled. In addition, as the decontamination process is evolved into direct selective pure vanadium extraction, contamination and the labor and material consumption in the decontamination process are avoided, the operation procedure is greatly simplified. Compared with a conventional vanadyl sulfate preparation process, the method has the advantages of short procedure, high vanadium yield, low cost, no waste discharge and the like.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY +2

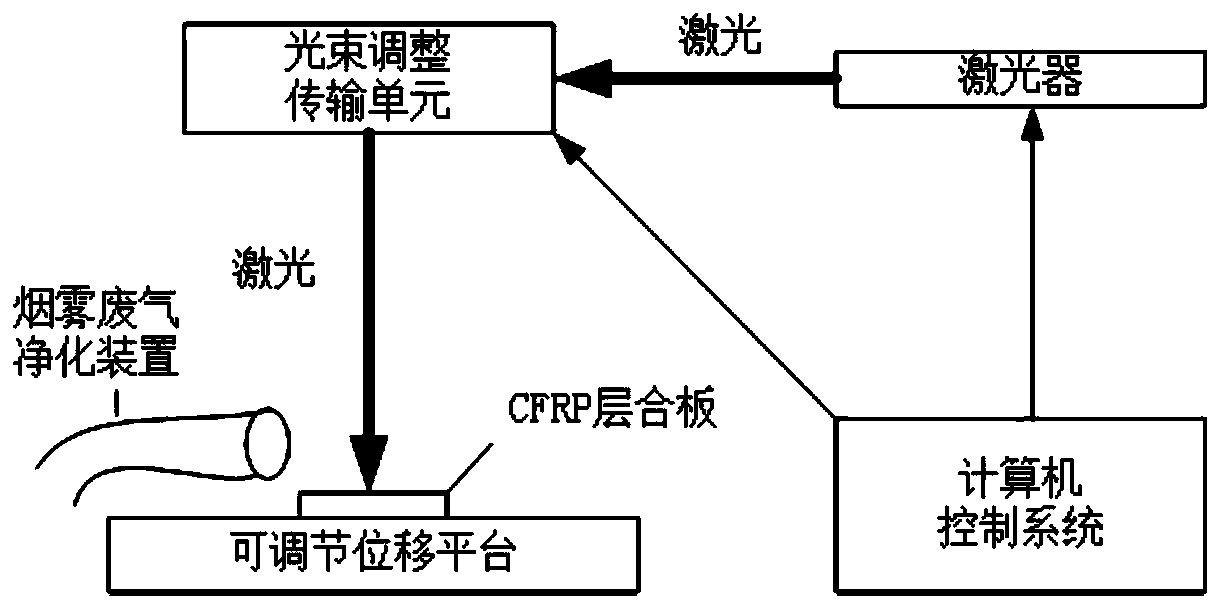

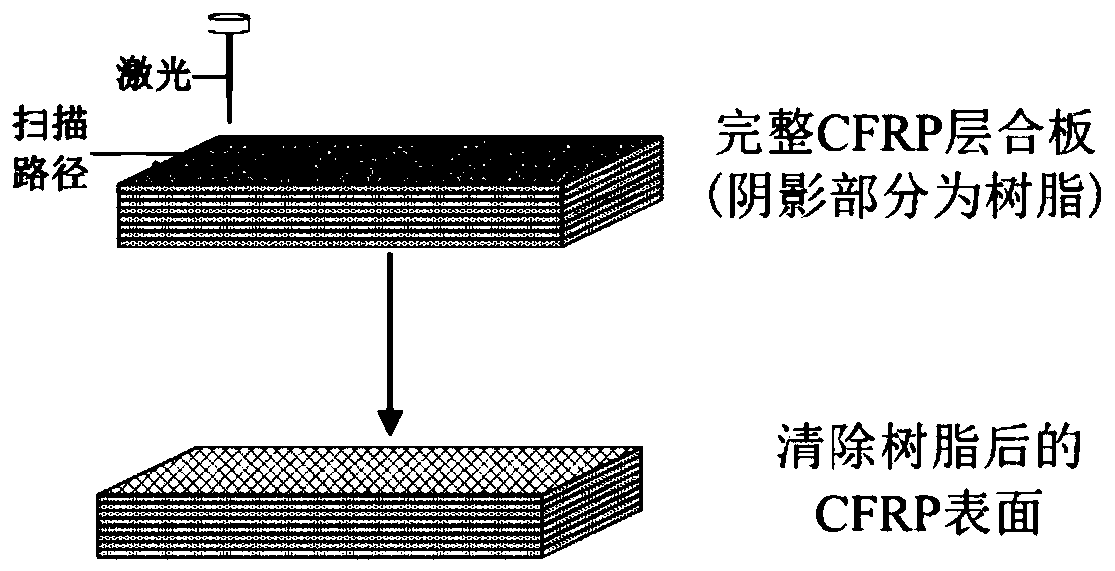

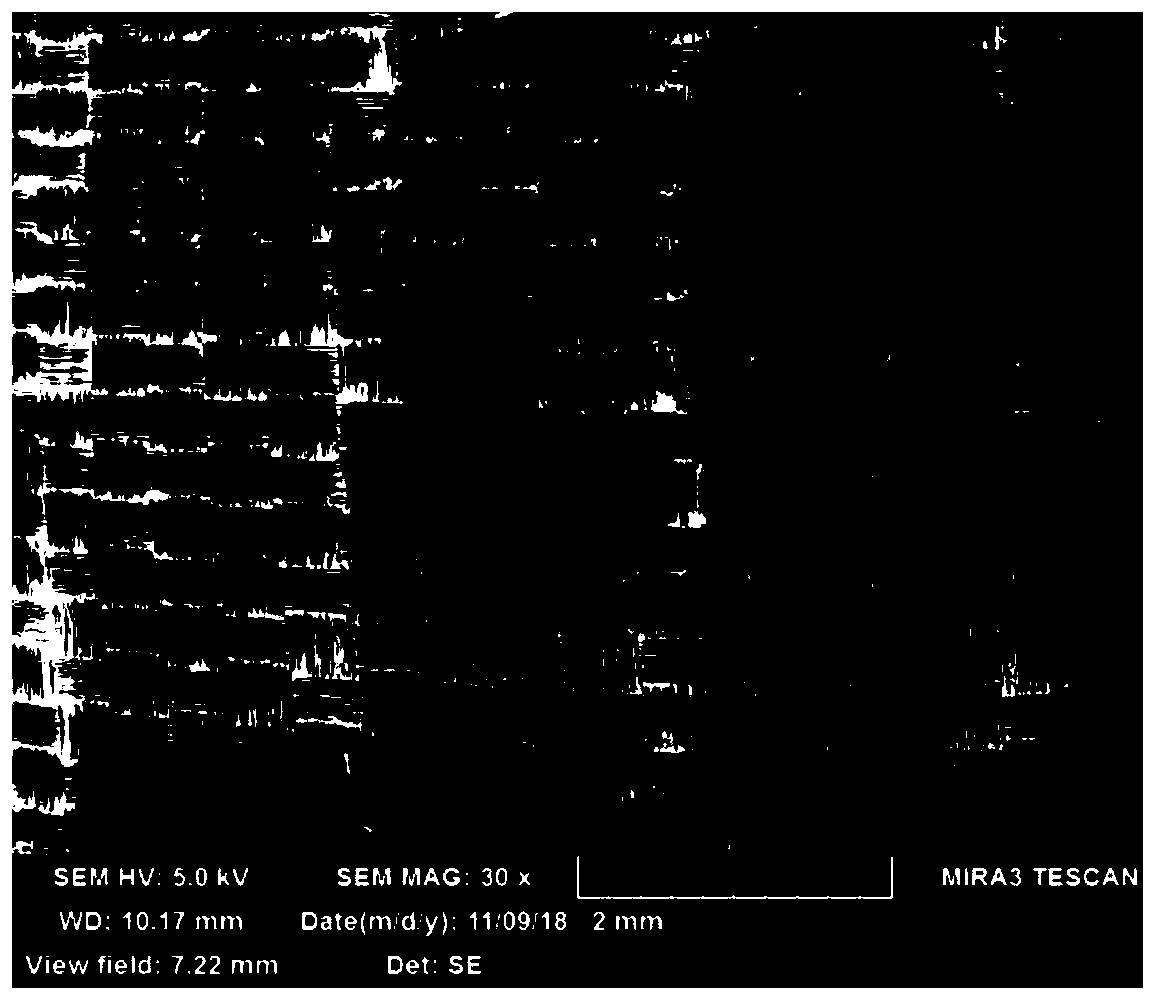

Carbon fiber composite material infrared laser surface treatment process

InactiveCN110560907ASo as not to damageGuaranteed mechanical propertiesWelding/soldering/cutting articlesCleaning using liquidsChemical reactionHigh energy

The invention relates to the field of composite material processing and treatment, and particularly provides a carbon fiber composite material infrared laser surface treatment process. According to the surface treatment process, an infrared laser with the energy density of 0.9-1.5 J / cm<2> is adopted for the surface treatment of the carbon fiber composite material; the high-energy pulse of a laseris utilized to make the complex physical and chemical reactions such as instant evaporation, peeling or cracking conduct on dirt or resin on the surface of the composite material, and the purpose of cleaning the surface of the composite material efficiently is achieved. The laser with the specific energy density is adopted for surface treatment of the carbon fiber composite, the resin or dirt on the surface of the composite material can be completely removed, residual resin or dirt is avoided on the surface, it can be guaranteed that the carbon fiber is not damaged, and thus the mechanical property of the composite material can be guaranteed.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

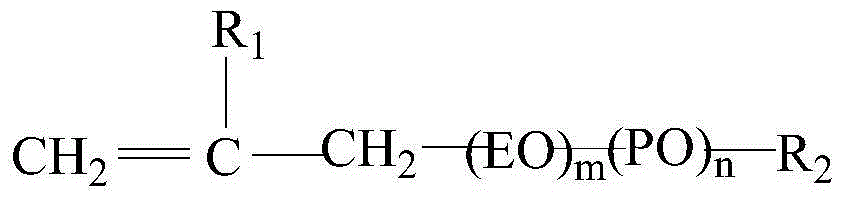

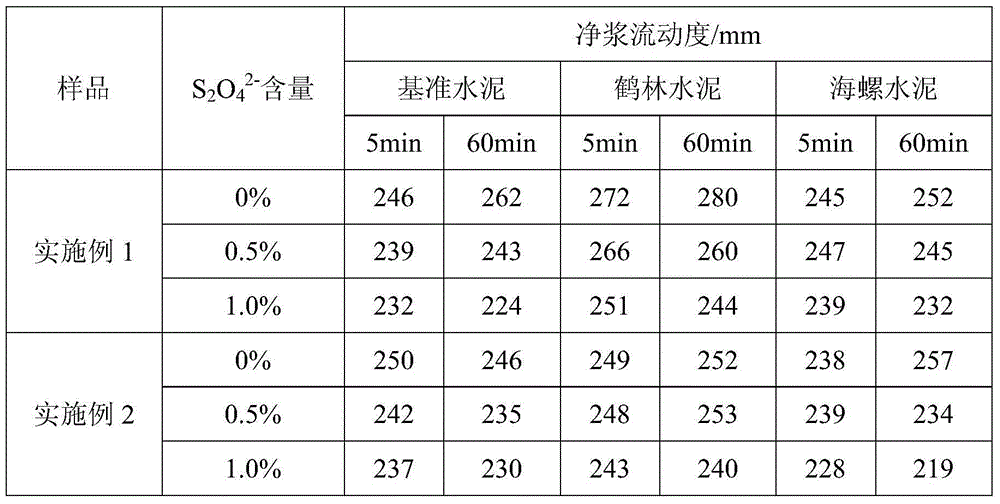

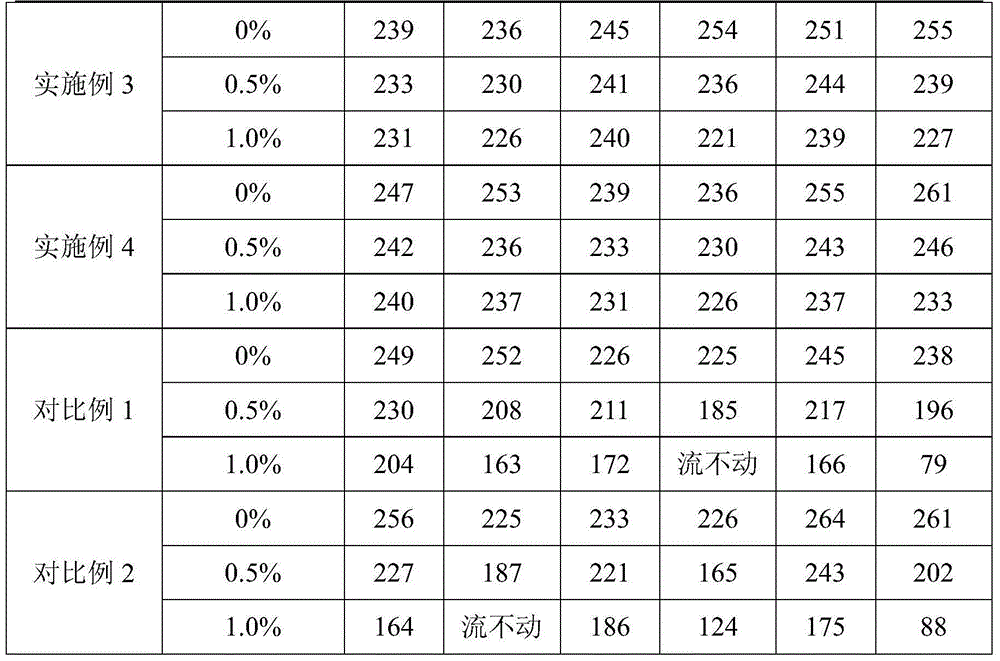

Preparation method for sulfate-compatible polycarboxylic water reducer

The invention relates to a preparation method for a sulfate-compatible polycarboxylic water reducer, and belongs to the field of cement concrete water reducers. The preparation method comprises the following specific steps: firstly, under the action of lauryl sodium sulfate and an initiator, preparing terpolymer from 2-acrylamide-2-methyl propane sulfonic acid, a vinyl aromatic compound monomer A and an unsaturated amide monomer B; secondly, under the action of a redox system initiator and a chain transfer agent, producing an aqueous-phase free radical polymerization reaction of the terpolymer, a polyoxyethylene-polyoxypropylene copolymer monomer C, an unsaturated carboxylic monomer D and a silane coupling agent monomer E, and after finishing the reaction, regulating the pH (potential of hydrogen) value to prepare the sulfate-compatible polycarboxylic water reducer. The sulfate-compatible polycarboxylic water reducer prepared with the method has the advantages of high cost performance, simplicity for reaction, easiness for control, strong cement adaptability and the like, and is polymerized in an aqueous solution and free of 'three-waste' emission, thereby belonging to clean production.

Owner:NANJING HYDRAULIC RES INST

Novel scale inhibition and dispersion agent

InactiveCN102146149AExcellent anti-calcium carbonate scale performanceReliable workmanshipScale removal and water softeningCalcium biphosphateSulfamic acid

The invention discloses a novel scale inhibition and dispersion agent. The novel scale inhibition and dispersion agent with excellent calcium carbonate scale inhibition performance and a certain calcium phosphate scale dispersion performance is prepared from maleic anhydride monomers and sulfamic acid monomers under the action of a catalyst in a peroxide and sodium hypophosphite initiation system. The scale inhibition and dispersion agent product has simple reaction process and stable and reliable technique. No three wastes are discharged, and environment pollution is not caused.

Owner:TIANJIN TELONG BIOCHEM

Anti-stress agent for piglet and preparation method of anti-stress agent

InactiveCN104186971AOxygen consumption in timeGuaranteed stabilityBacteriaBacteria material medical ingredientsAnti stressOrganic acid

The invention discloses an anti-stress agent for a piglet and a preparation method of the anti-stress agent. The preparation method comprises the following steps: mixing butyrate clostridium powder, lactic acid bacteria powder, bacillus natto powder, vitamin C and / or vitamin E phosphate, organic acid and sylvite, and uniformly stirring. The butyrate clostridium powder, the lactic acid bacteria powder and the bacillus natto powder are prepared by adopting the steps of inoculating various strain liquid seeds in a solid culture medium, fermenting, drying and crushing. The anti-stress agent disclosed by the invention is capable of helping intestinal tracts of the piglet rapidly establish microecological balance, and capable of improving the immunity of the piglet at delactation stage and preventing the stress syndromes of the piglet occurring in ablactation, crowd transferring, transporting and the like, and has the characteristics of good stress resisting effect, wide raw material source, simple production process, low cost, no three-waste (waste gas, waste water and industrial residue) emission and the like.

Owner:HUNAN DANWEI BILOGICALTECH

High-tower slow-release compound fertilizer and preparation method thereof

ActiveCN101759481ASimple production processLow investment costMagnesium fertilisersAlkali orthophosphate fertiliserIsobutylidene diureaChemistry

The invention discloses a high-tower slow-release compound fertilizer. The fertilizer contains the following raw materials in parts by weight: 28-32.5 parts of urine, 15-19 parts of isobutylidene diurea, 23-30 parts of monoammonium phosphate, 17-25 parts of potassium sulfate or potassium chloride and 4-6 parts of magnesium sulfate. Since the isobutylidene diurea is taken as slow-release matrix and the fertilizer core internal slow-release technology is adopted, the invention has the advantages that the nutrition slow-release performance is good, the nitrogen loss is reduced, the protection of the ecological environment is facilitated, no production line is required to be newly constructed for the production, the production technology is simple, the investment is saved, the production cost is low, and the popularization and the application of the high-tower slow-release compound fertilizer in the agricultural production are facilitated.

Owner:KINGENTA ECOLOGICAL ENG GRP

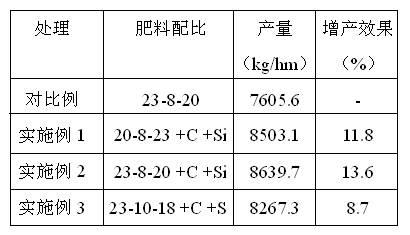

Nano-carbon type special silicon fertilizer for rice and production process of fertilizer

ActiveCN102674936AUnique preparation processComprehensive nutritionFertilizer mixturesFertilizerAgricultural crops

The invention discloses a nano-carbon type special silicon fertilizer for rice and a production process of the fertilizer and relates to the technical field of special formula fertilizers for crops. The process comprises the steps of taking 400-500 parts of urea, 260-400 parts of potassium chloride, 100-220 parts of monoammonium phosphate, 1-5 parts of nano-carbon and 1-50 parts of sodium silicate as raw materials, and obtaining the fertilizer after melting the urea under the high-temperature, crushing, screening and heating a mixing material, mixing, stirring, spraying, pelleting, cooling, screening, metering and packing. The process is unique in production technology, energy-saving and capable of reducing consumption, and the special fertilizer is complete in nutrient, balanced, high in use ratio and low in environment pollution.

Owner:STANLEY AGRI GRP CO LTD

Method for synthesizing grafted lysine viscose fibers

InactiveCN107829300AMild reaction conditionsStrong response specificityBiochemical treatment with enzymes/microorganismsVegetal fibresChemistryDyeing

The invention provides a method for synthesizing grafted lysine viscose fibers and belongs to the technical field of modification of fiber materials. According to the method, commercially available viscose fibers and lysine are taken as raw materials, and the grafted lysine viscose fibers with good skin-friendly property, antibacterial property and dyeing property can be prepared stably through steps as follows: preparation of purified viscose fibers, preparation of carboxylated viscose fibers, preparation of ethylene glycol non-aqueous reaction media, preparation of the grafted lysine viscosefibers and preparation of purified ethylene glycol. The carboxylated viscose fibers and the grafted lysine viscose fibers are produced under catalysis of glucose oxidase and protease in sequence, thegrafted lysine viscose fibers are prepared in the ethylene glycol non-aqueous reaction media, reaction conditions are mild, reaction specificity and reaction efficiency are high, no by-products or three wastes are produced, and the method is a typical green production technology; the grafted lysine viscose fibers synthesized with the method are covered with amino acid, can be widely applied to the fields such as textiles, clothes, food and the like and have great social value and economic benefits.

Owner:CHONGQING UNIV

Preparation method of anhydrous hydrofluoric acid

InactiveCN108439340ASimple processReduce energy consumptionSilicaCalcium/strontium/barium sulfatesHydrogen fluorideHydrofluoric acid

The invention discloses a preparation method of anhydrous hydrofluoric acid. The preparation method comprises the following steps of: adopting a sulfuric-acid method to mix sodium fluorosilicate and concentrated sulfuric acid uniformly, after reaction, obtaining sodium sulfate for reaction with fluosilicic acid to prepare sodium fluorosilicate; freezing to obtain liquid hydrofluoric acid, and after distillation, obtaining an anhydrous hydrogen fluoride product; absorbing the remaining gas by water to obtain fluosilicic acid solution and silicon dioxide, adding solid sodium sulfate into the fluosilicic acid solution, and separating to obtain anhydrous hydrofluoric acid. The preparation method disclosed by the invention has the beneficial effects that the fluorine utilization rate in sodiumfluorosilicate is high, so that not only can the technical process be simplified, but also the production cost can be reduced; the new method is simple in operation and high in safety, and is especially suitable for large-scale industrial production.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

Special corrosion and scale inhibitor for water reuse in power plant and preparation method thereof

InactiveCN104843879ANo pollution in the processIncreased slow-release scale inhibition effectScale removal and water softeningEpoxySolubility

The invention relates to a special corrosion and scale inhibitor for water reuse in a power plant and a preparation method thereof. The special corrosion and scale inhibitor comprises the following components by weight percentage content: 25 to 40% of sulfonic methane amino poly epoxy succinic acid, 20 to 30% of N, N-diacetyl adipic dihydrazide, 12 to 30% of maleic acid-acrylic copolymer, 3 to 5% of graphene oxide aqueous dispersion, 3 to 6% of fatty alcohol-polyoxyethylene ether and 15 to 40% of zinc sulfate aqueous solution. The components of the corrosion and scale inhibitor achieve a synergistic effect, and can realize trace removal of pollutants, after the corrosion and scale inhibitor is compounded, the corrosion and scale inhibition properties are greatly improved, the synergistic effect of physical adsorption and chemical adsorption of the pollutants can be effectively realized, and the special corrosion and scale inhibitor can be used in a wider water pH scope and temperature, and has an excellent sterilizing effect. The production process is simple, three-waste emission is avoided, the stability and water solubility are good, and the main components are biodegradable, free of toxic, phosphorus, pollution and corrosivity, less in adding rate, and environment-friendly.

Owner:山东应天环保能源有限公司

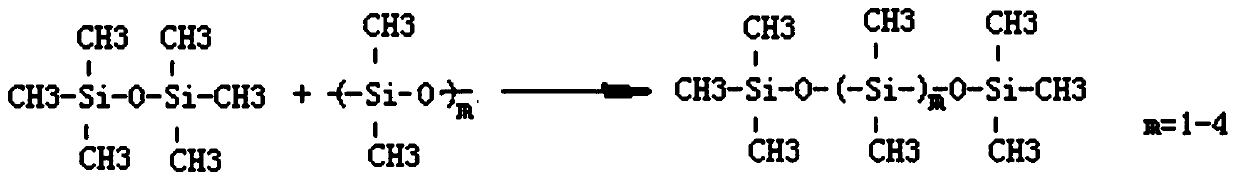

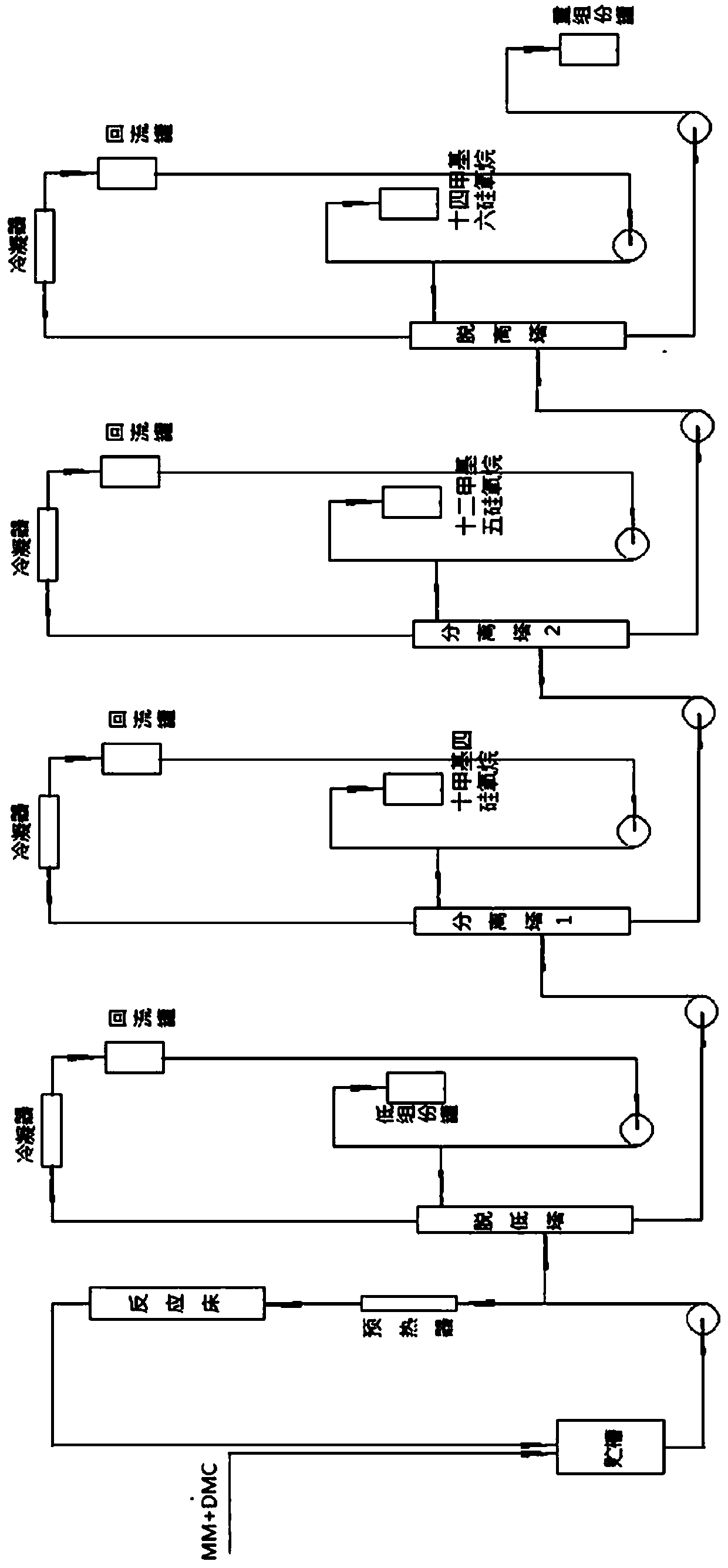

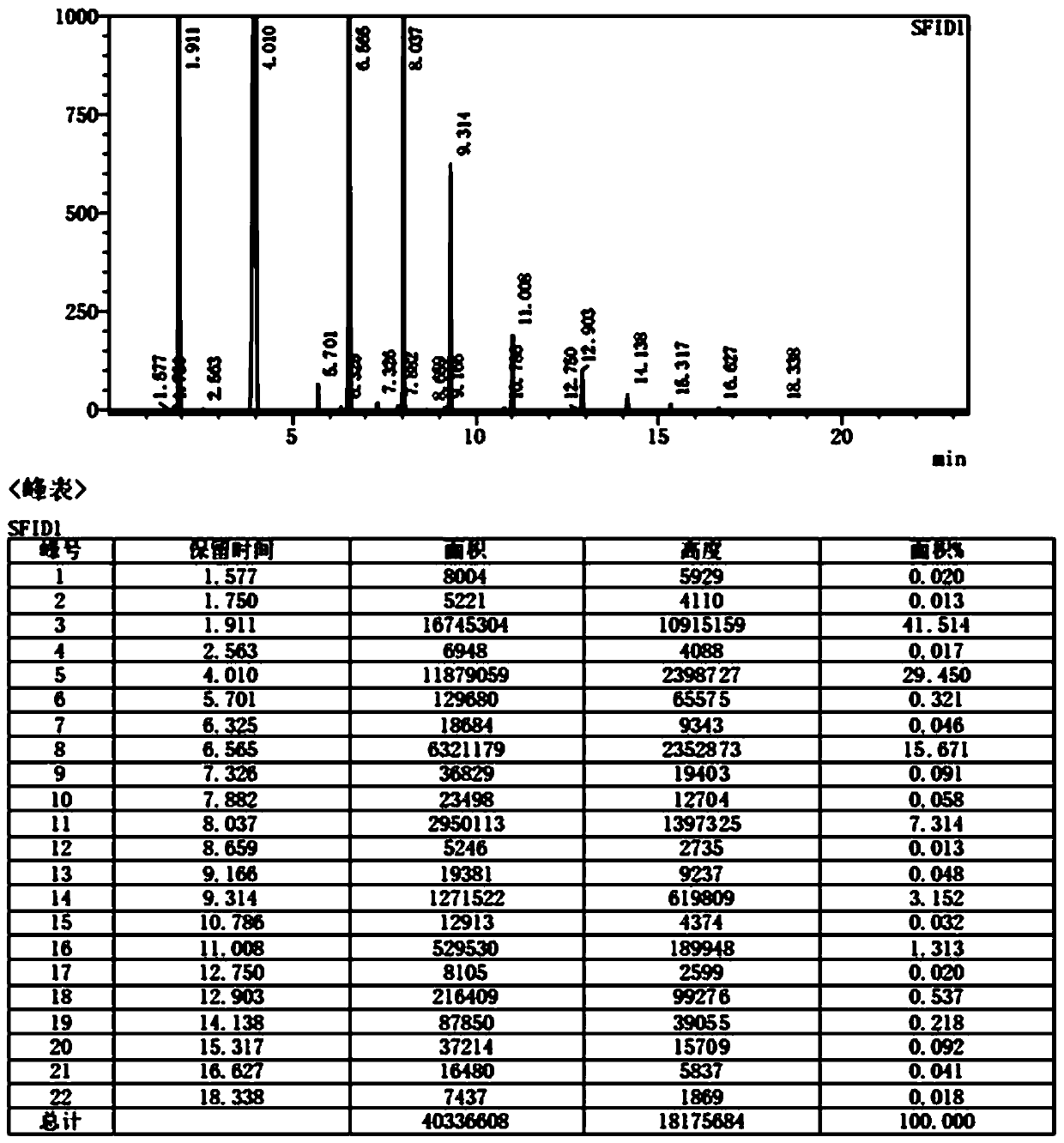

Method and production system for continuous catalytic synthesis and separation of high-purity low-viscosity dimethyl silicone oil

ActiveCN110818900AImprove automation control levelImprove securityGroup 4/14 element organic compoundsProcess engineeringTower

The invention relates to a production method of cosmetic silicone oil, and in particular, relates to a method and production system for continuous catalytic synthesis and separation of high-purity low-viscosity dimethyl silicone oil. The method comprises the following steps: 1) a synthesis step; and 2) a separation step. The separation step comprises the steps: (1) discharging light components hexamethyldisiloxane and octamethyltrisiloxane from the tower top of a light component removal tower, condensing, enabling the condensed liquid to automatically flow to a low-boiling-point receiving tankof the light component removal tower, and conveying to an external low-boiling-point substance storage tank; and pumping heavy components at the bottom of the light component removal tower to a firstseparation tower; (2) discharging a component decamethyltetrasiloxane from the tower top of the first separation tower, and pumping a heavy component at the tower bottom to a second separation tower;(3) discharging a component dodecylmethylpentasiloxane from the tower top of the second separation tower, and pumping a heavy component at the tower bottom to a heavy component removal tower; and (4)discharging tetradecylmethylhexasiloxane from the tower top of the heavy component removal tower, and discharging a heavy component from the tower bottom of the heavy component removal tower. According to the method, continuous operation is carried out, and high-purity decamethyltetrasiloxane, dodecylmethylpentasiloxane and tetradecylmethylhexasiloxane can be prepared by continuously separating amixture through a separation tower.

Owner:RUNHE ORGANICSILICONE NEW MATERIAL

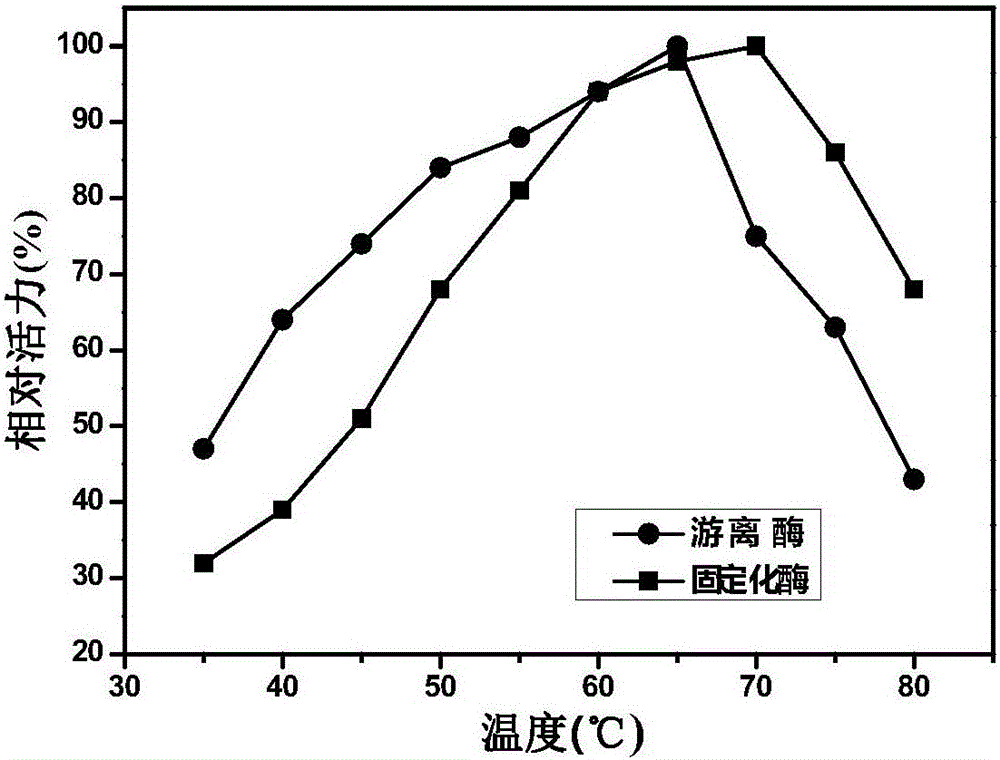

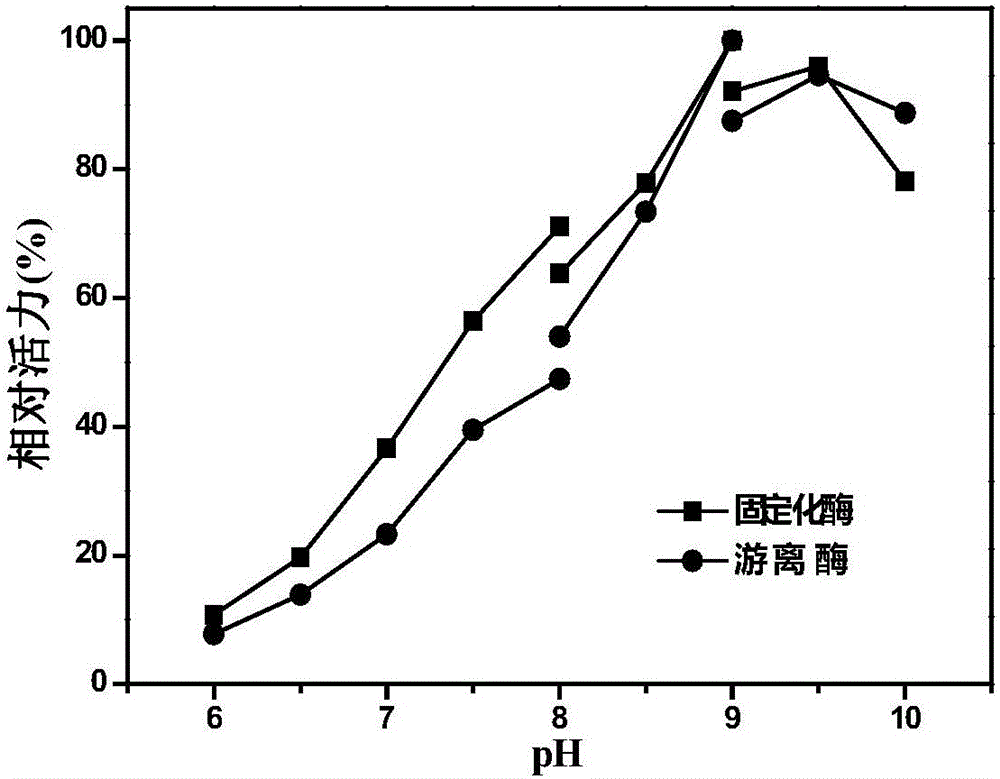

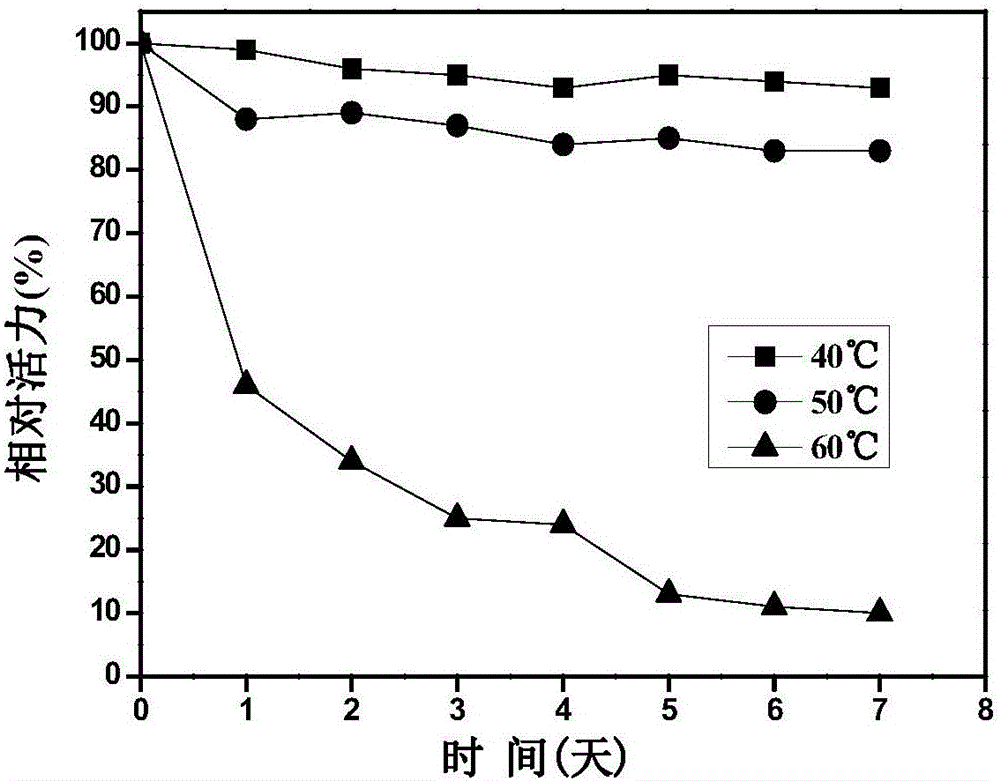

Immobilized halohydrin dehalogenase and application thereof

InactiveCN105838700AWide variety of sourcesReduce fermentation costsCarbon-halide lyasesOn/in organic carrierEpoxyAlcohol

The invention discloses immobilized halohydrin dehalogenase and an application thereof. The immobilized halohydrin dehalogenase has high conversion efficiency on a halohydrin substrate, is strong in substrate tolerance, and has excellent catalysis selectivity on the substrate and structural analogues thereof. In the invention, recombinant halohydrin dehalogenase is successfully fixed on the surface of an epoxy resin carrier through multipoint covalence, and through low-salt adsorption and addition of glycerol as a protection agent of an enzyme activity center, enzyme activity loss during immobilization is effectively reduced. The immobilization method is simple in operation, is low in raw materials cost, and is suitable for large-scale operation. The immobilized halohydrin dehalogenase has homogeneous property, high stability and good repeatability. With the immobilized halohydrin dehalogenase,epoxy chloropropane, (R)-4-cyano-3-hydroxylethyl butyrate, (S)-2,3-dichloro-1-propyl alcohol and the like can be synthesized. The immobilized halohydrin dehalogenase can be continuously used for more than 50 batches before significant reduction of activity of the immobilized halohydrin dehalogenase and also has good industrial application prospect.

Owner:ZHEJIANG UNIV OF TECH

High-concentration nano-carbon cotton special fertilizer and preparation method thereof

The invention discloses high-concentration nano-carbon cotton special fertilizer and a preparation method thereof, and belongs to the technical field of fertilizer. The high-concentration nano-carbon cotton special fertilizer obeys a cotton nutrient absorption rule and is prepared form raw materials of urea, potassium dihydrogen phosphate, potassium chloride, calcium-magnesium-phosphate fertilizer, monoammonium phosphate, ferrous sulphate, zinc sulfate, ethylene diamine tetraacetic acid (EDTA)-manganese chelate, borax, ammonium molybdate and nano-carbon according to certain ratios. The preparation method comprises the following steps of melting urea at a high temperature, carrying out pressurization, mixing the melted urea and other raw materials well, carrying out crushing and sieving, heating, preparing paste, carrying out vibration filtration, carrying out sprinkling and forming, cooling, sieving, carrying out anti-caking treatment and carrying out packaging. The high-concentration nano-carbon cotton special fertilizer has comprehensive nutrition, balanced fertilizer components and a high fertilizer utilization rate, and can improve a cotton yield and cotton quality.

Owner:STANLEY AGRI GRP CO LTD

Method for preparing oligomeric proanthocyanidins by utilizing grape seed extract

ActiveCN106045959AIncrease profitHigh separation precisionOrganic chemistryWine preparationBetacyaninsFreeze-drying

The invention provides a method for preparing oligomeric proanthocyanidins by utilizing a grape seed extract, belonging to the technical field of separation and preparation of the oligomeric proanthocyanidins. According to the invention, oligomeric proanthocyanidins freeze-dried powder and polymeric proanthocyanidins freeze-dried powder are prepared through dissolving, filtering, vacuum concentration, ultrafiltration, column filling, elution, nanofiltration and freeze-drying by using the grape seed extract as a raw material. The method provided by the invention has high raw material utilization rate, high separation accuracy, good separation effect, high product purity and clear product use, realizes complete utilization of raw materials and complete recycling of the solvent, is free of three-wastes discharge, and is a typical high-tech green process. The oligomeric proanthocyanidins prepared by using the method provided by the invention can be extensively applied in the fields of medicines, health-care products, etc.

Owner:HUNAN XINLI BIOLOGICAL SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com