Preparation method for active aluminosilicate

An aluminosilicate, active technology, applied in the field of comprehensive utilization of natural minerals, can solve the problems of high activation cost of natural minerals, single input product, material consumption, etc., and achieve the effects of easy promotion and implementation, wide source of raw materials and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention provides a preparation method of active aluminosilicate, which comprises the step of reacting natural silicon-aluminum minerals in an aqueous alkali metal hydroxide solution with a concentration of more than 350g / L at 150°C to 300°C.

[0015] In the method of the present invention, the reaction can be carried out in an open system under normal pressure, and the solid-liquid mass ratio at the beginning of the reaction is greater than 40%.

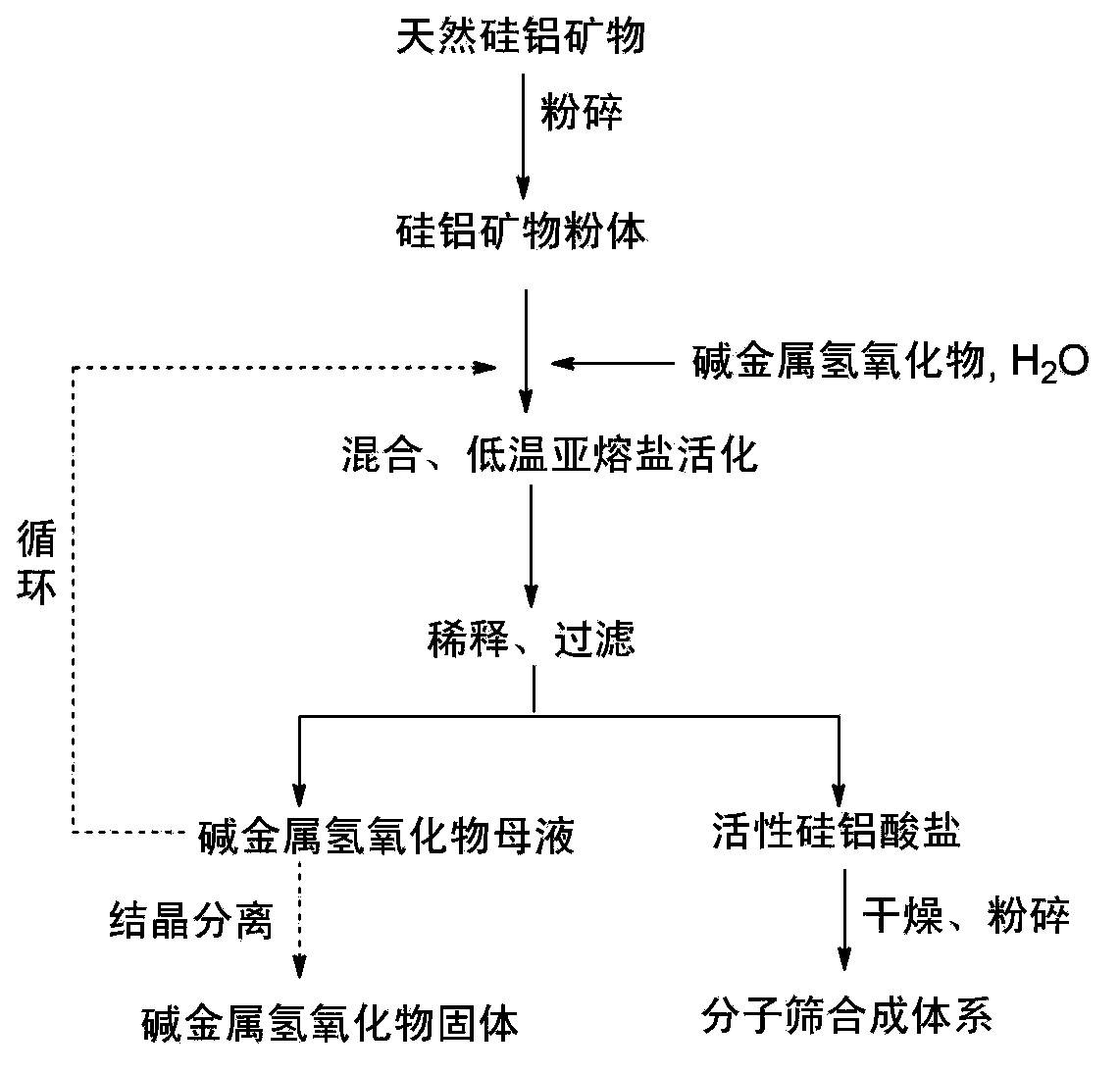

[0016] Specifically, the activation method of the natural silicon-aluminum mineral based on the sub-molten salt system provided by the present invention comprises the following steps:

[0017] (1) Material preparation: Weigh alkali metal hydroxide and natural mineral raw materials according to the molar ratio of alkali metal hydroxide to the total molar ratio of silicon and aluminum in natural minerals (n(Si)+n(Al)) of 0.5 to 3:1 .

[0018] (2) sub-molten salt activation: the alkali metal hydroxide solution prepared by ...

Embodiment 1

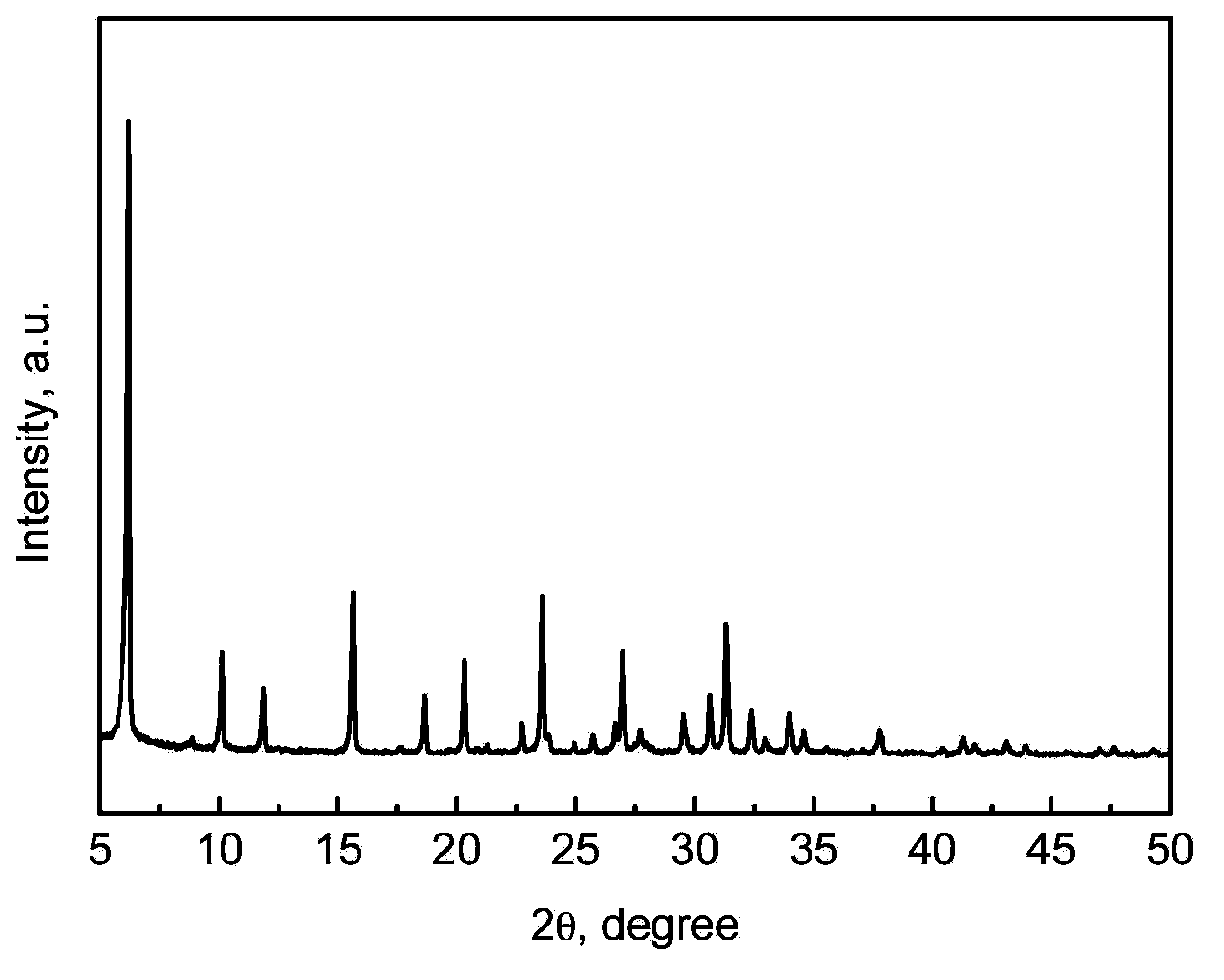

[0031] Preparation of active sodium aluminosilicate

[0032] The natural silica-alumina mineral used in this embodiment is natural kaolin (produced by China Kaolin Company, particle size is less than 300 mesh). The mineral contains 44.6wt% of alumina and 50.5wt% of silicon oxide.

[0033] (1) Weighing materials: According to the ratio of the number of moles of sodium hydroxide to the total number of moles of silicon and aluminum in natural minerals is 2:1, a certain amount of NaOH and natural silicon and aluminum minerals are weighed, that is, 80g of NaOH and 78.2 grams of kaolin are weighed. g.

[0034](2) Sub-molten salt activation reaction: Dissolve the NaOH weighed in step (1) in 200mL deionized water, mix the kaolin powder weighed in (1) with the NaOH solution, and place it in polytetrafluoroethylene to react React in an open system under normal pressure at 200°C for 5 hours in the still, and obtain a reaction product after the reaction is completed.

[0035] (3) Separ...

Embodiment 2

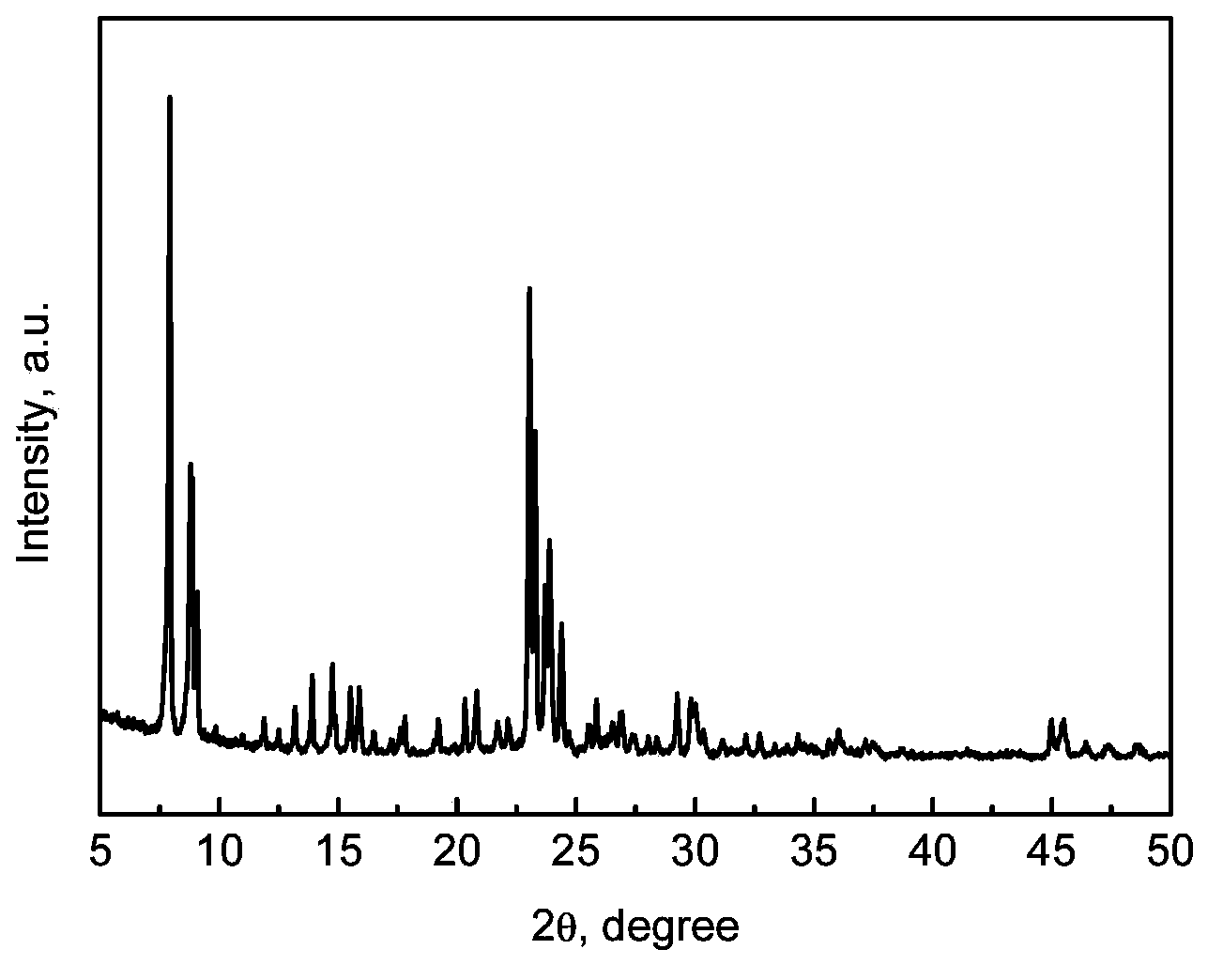

[0042] Preparation of active sodium aluminosilicate

[0043] The natural silica-alumina mineral used in this embodiment is natural rectorite (produced by Hubei Mingliu Rectorite Co., Ltd., with a particle size of less than 100 mesh). The mineral contains 38.2wt% of alumina and 41.3wt% of silicon oxide.

[0044] (1) Weighing materials: According to the ratio of the number of moles of sodium hydroxide to the total number of moles of silicon and aluminum in natural minerals is 3:1, a certain amount of NaOH and natural silicon and aluminum minerals are weighed, that is, 120g of NaOH is weighed, and the retort Soil 94.1g.

[0045] (2) Sub-molten salt activation reaction: Dissolve the NaOH weighed in step (1) in 250mL deionized water, mix the retort earth powder weighed in (1) with the NaOH solution, and place In an ethylene reactor, react in an open system under normal pressure at 220°C for 6 hours, and obtain a reaction product after the reaction is completed.

[0046] (3) Sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com