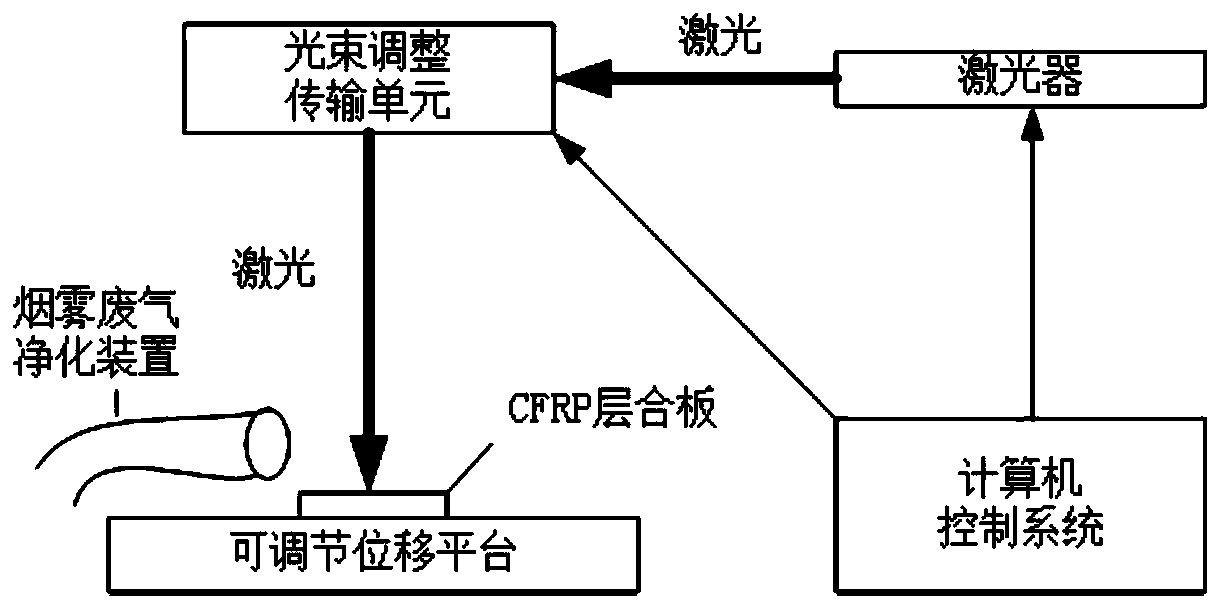

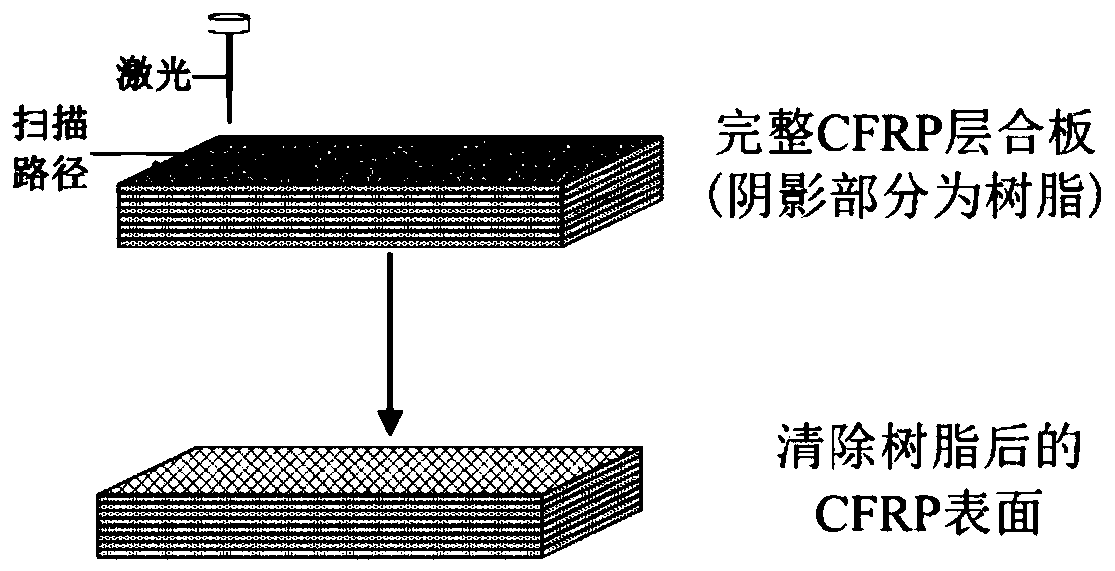

Carbon fiber composite material infrared laser surface treatment process

An infrared laser and surface treatment technology, used in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient comprehensive mechanical properties of composite materials, damage to substrates, high plant and environmental requirements, etc. Excellent controllability and stability, reduced manufacturing costs, and reduced maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

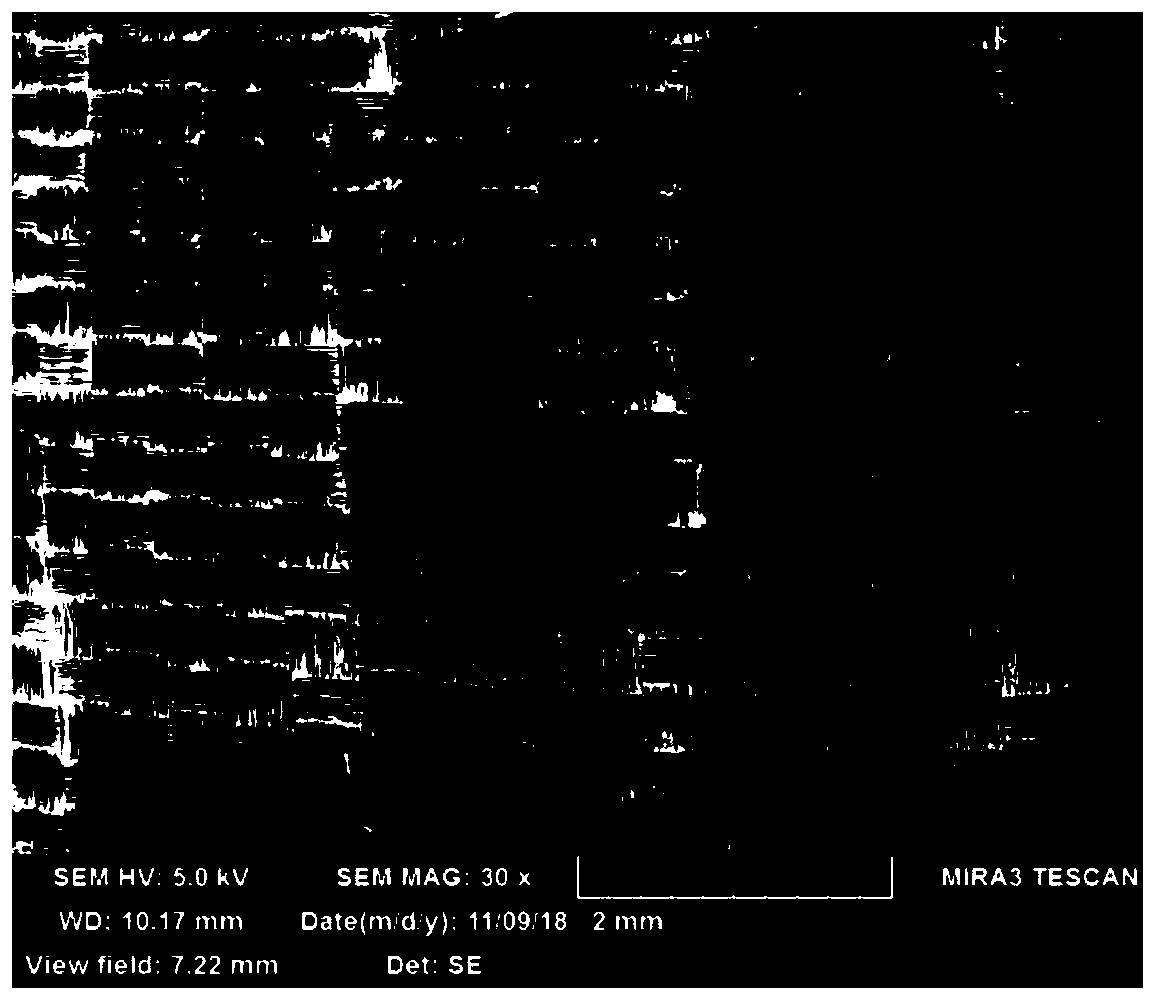

[0092] An infrared laser surface treatment process for carbon fiber composite materials, using an energy density of 1.07J / cm 2 , 1.25J / cm 2 and 1.43J / cm 2 Infrared laser for surface treatment of carbon fiber composite materials;

[0093] In Examples 1-3, the power of the laser is 12W, 14W and 16W respectively, the frequency of the laser is 100kHz, the spot diameter is 119μm, the wavelength of the laser is 1064nm, the pulse width of the laser is 200ns, and the scanning speed of the laser is 800mm / s , the scanning times of the laser is 5 times, and the defocusing amount of the laser is 4mm.

Embodiment 4-5

[0095] A carbon fiber composite material infrared laser surface treatment process, different from Example 2, the energy density is 1.25J / cm 2 The scanning speeds of the laser are 700mm / s and 900mm / s respectively, and the scanning times are 5 times.

Embodiment 6-7

[0097] An infrared laser surface treatment process for carbon fiber composite materials is different from Example 2 in that the number of laser scans is 3 and 7 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com