Preparation method and device of methanol fuel finished gasoline for vehicles

A vehicle-used methanol and finished product technology, which is applied to fuels, liquid carbon-containing fuels, chemical instruments and methods, etc., can solve problems such as high construction investment and operation costs, and large safety hazards, and achieve compact equipment structure and high-performance response life , high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

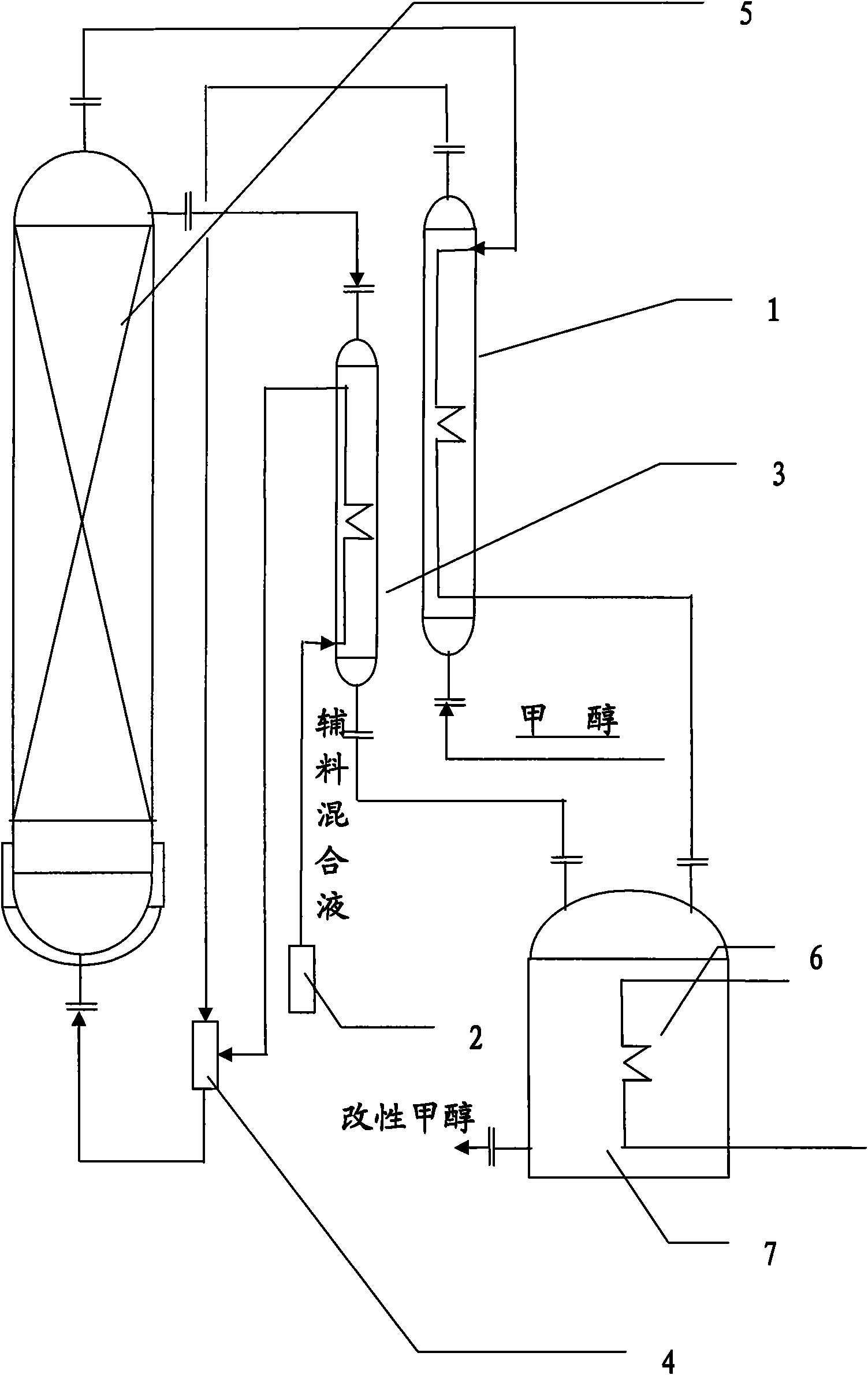

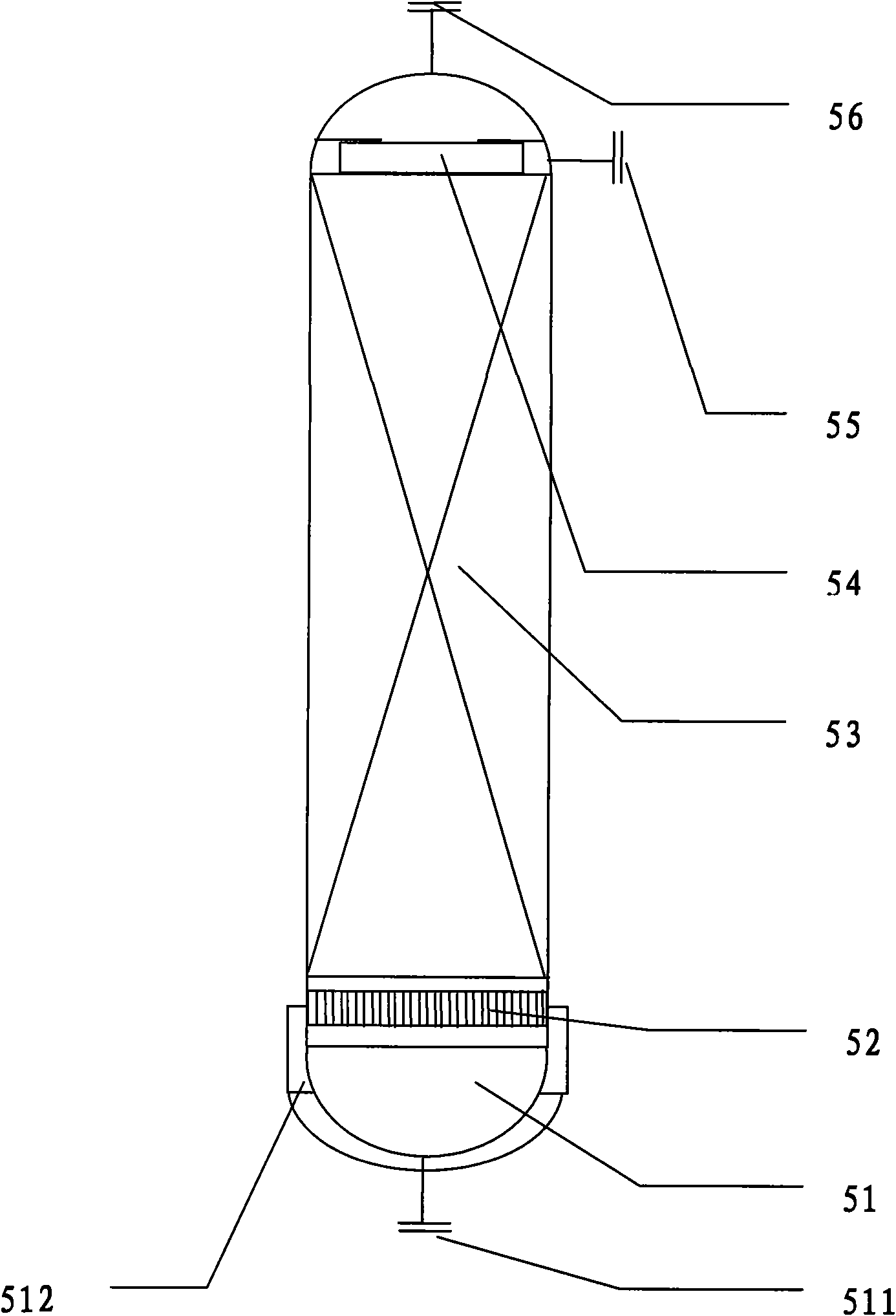

Method used

Image

Examples

Embodiment 1

[0066] Raw material: commercially available industrial methanol 85kg

[0067] Excipients: naphtha 5%; petroleum benzene 3%; isobutene 3%; isopropanol 1%; isobutyraldehyde 1%; sec-octanol 0.5%; %; Butyrophenone 0.2%, a total of 15kg

[0068] Mixture of methanol and auxiliary materials: (1) density: 0.816, (2) pH value: 7.0, (3) sulfonic acid to adjust the pH value: 5.5.

[0069] Modified methanol: (1) Density: 0.794, (2) PH value: 6.0.

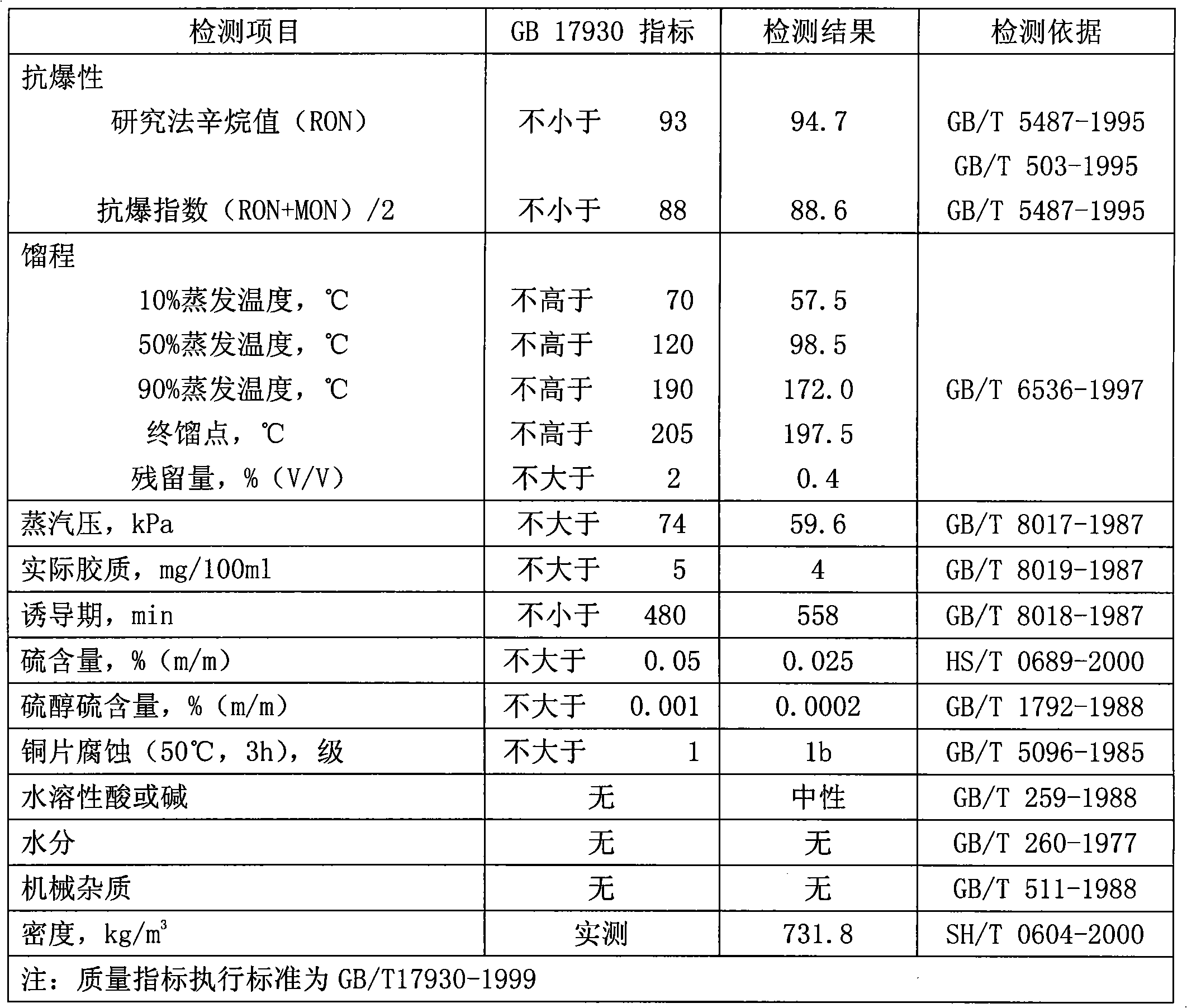

[0070] The distillation range test result of modified methanol is shown in Table 1:

[0071] Table 1 Modified Methanol Distillation Range Test Table

[0072] initial boiling point

10%

20%

30%

40%

50%

52℃

56℃

58℃

59℃

60℃

63℃

60%

70%

80%

90%

95%

do it

65℃

68℃

69℃

71℃

76℃

80℃

[0073] Miscibility test: It is infinitely miscible with commercially available gasoline in any proportion.

[0074] The obvious ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com