Nano-carbon type special silicon fertilizer for rice and production process of fertilizer

A nano-carbon and special-purpose fertilizer technology, which is applied in the direction of application, fertilization device, fertilizer mixture, etc., to reduce environmental pollution, improve the utilization rate of fertilizer, and promote the effect of enriching nutrients and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

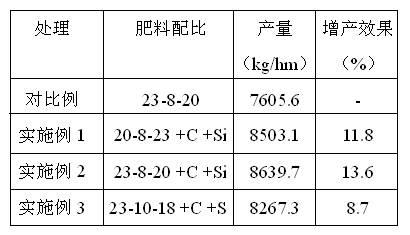

Embodiment 1

[0042] Example 1: Preparation of nano-carbon silicon-containing special fertilizer for rice

[0043] The mass parts of raw material components are as follows: 407 parts of urea, 380 parts of potassium chloride (60% potassium oxide content), 160 parts of monoammonium phosphate, 3 parts of nano-carbon, and 50 parts of sodium silicate.

[0044] The production process is as follows:

[0045] 1. Melt urea at a high temperature of 135°C, enter the buffer tank, pressurize it through a delivery pump, and pump it into the top mixer;

[0046] 2. Put potassium chloride, monoammonium phosphate, sodium silicate, and nano-carbon into the agitator to mix well, and after crushing and screening, send it to the mixing heater to heat to 90°C, and send it to the mixer with a bucket elevator. To the tower top silo;

[0047] 3. Put the hot mixture in the tower top silo in step 2 into the mixer described in the above step 1 after being evenly measured by a spiral meter, and mix it with a high-sp...

Embodiment 2

[0049] Example 2: Preparation of nano-carbon silicon-containing special fertilizer for rice

[0050] The mass parts of raw material components are as follows: 460 parts of urea, 327 parts of potassium chloride (62% potassium oxide content), 160 parts of monoammonium phosphate, 3 parts of nano-carbon, and 50 parts of sodium silicate.

[0051] The production process is the same as implementation example 1.

[0052] The obtained product contains nano-carbon and silicon elements, and the contents of nitrogen, phosphorus pentoxide and potassium oxide are respectively 23%, 8% and 20%, all of which are percentages by mass.

Embodiment 3

[0053] Example 3: Preparation of nano-carbon silicon-containing special fertilizer for rice

[0054] The raw material components are as follows: 457 parts of urea, 290 parts of potassium chloride (62% potassium oxide content), 200 parts of monoammonium phosphate, 3 parts of nano-carbon, and 50 parts of sodium silicate.

[0055] The production process is the same as implementation example 1.

[0056] The obtained product contains nano-carbon and silicon elements, and the contents of nitrogen, phosphorus pentoxide and potassium oxide are respectively 23%, 10% and 18%, all of which are percentages by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com