A boron doping modified soft carbon coating negative electrode material with high stability under high and low temperature environment and a preparation method thereof

A high-stability, negative-electrode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of high modification cost, high-pollution and high-risk type gases, difficult to apply on a large scale, and reduce surface Defects, simple preparation process, economical effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of above-mentioned negative electrode material, comprises the following steps:

[0042] 1) Take the powder of the negative electrode base material, add soft carbon carbon source and boron compound to the powder, then add it to the high-speed mixer, stir evenly, and obtain the mixed powder;

[0043] 2) Transfer the mixed powder into the low-temperature thermal composite reaction equipment, and heat it to 400-700°C under a protective atmosphere, preferably at a temperature of 500-650°C, keep it warm, and take it out after natural cooling;

[0044] 3) transfer the cooled mixed powder into a carbonization equipment, and heat it to 800-1350°C under a protective atmosphere, wherein the preferred temperature is 950-1150°C, keep it warm, take it out after natural cooling, and obtain the negative electrode material;

[0045] 4) Sieving to obtain a finished negative electrode material.

[0046] As preferably, in step 1), the stirring time is 1-12h, wherein...

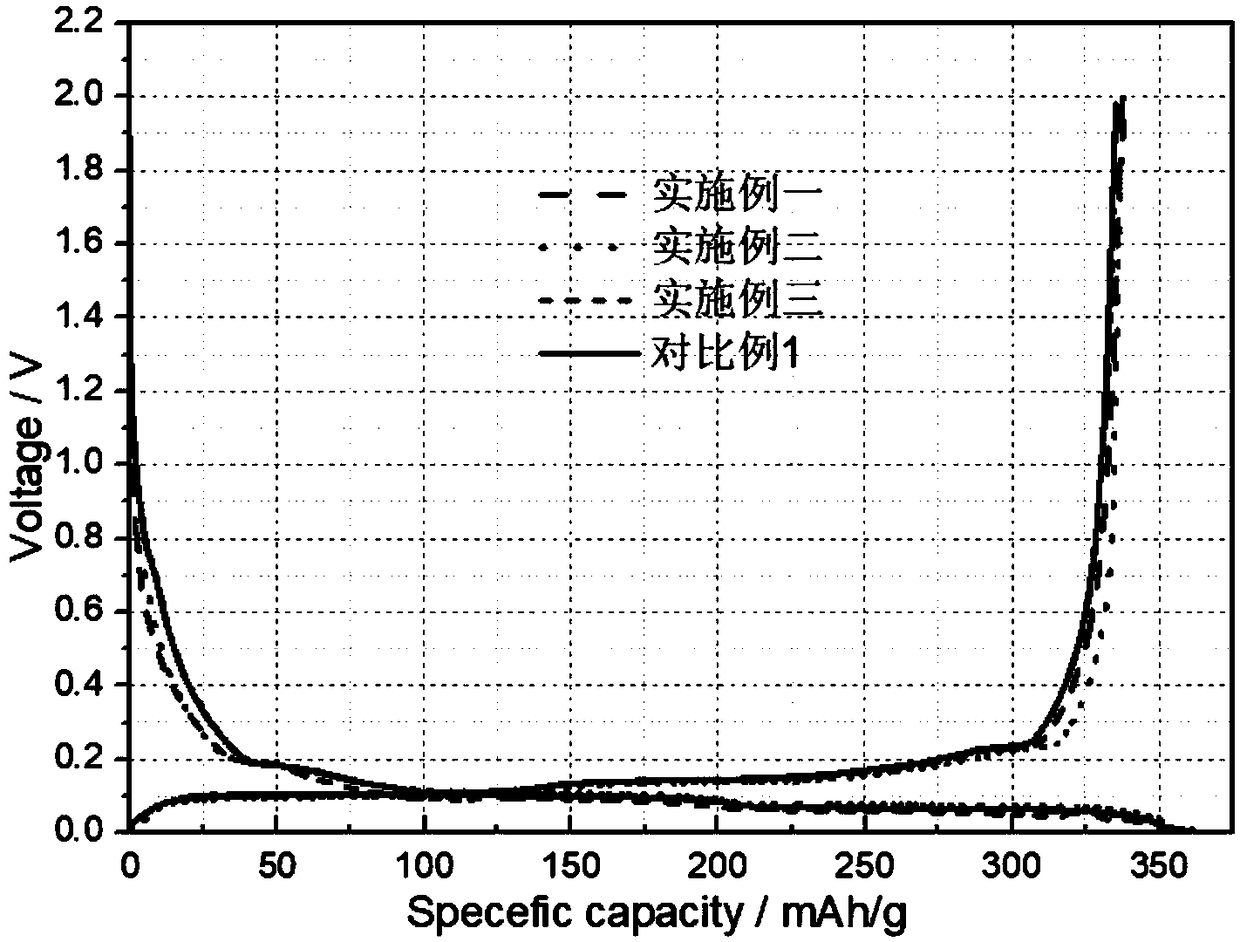

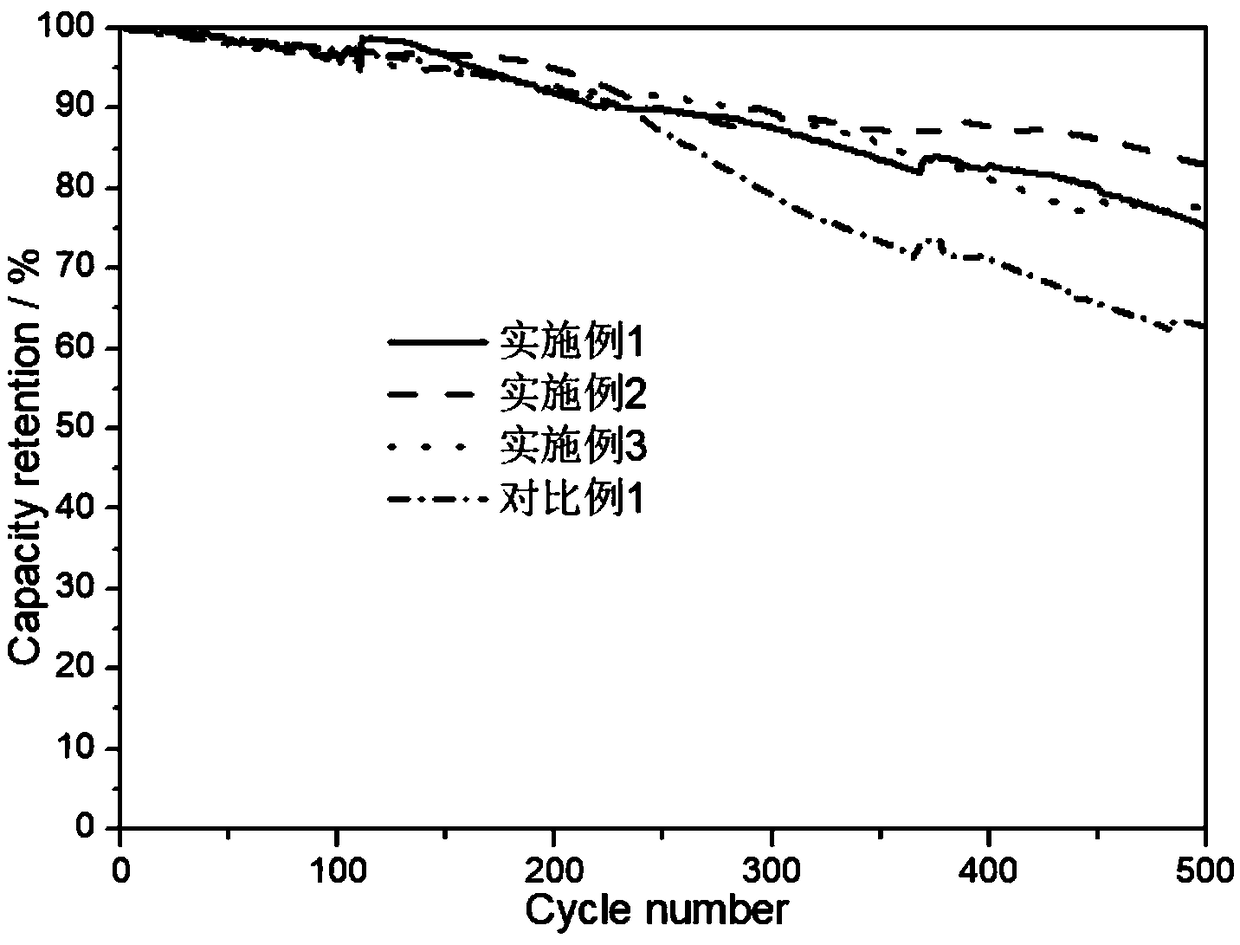

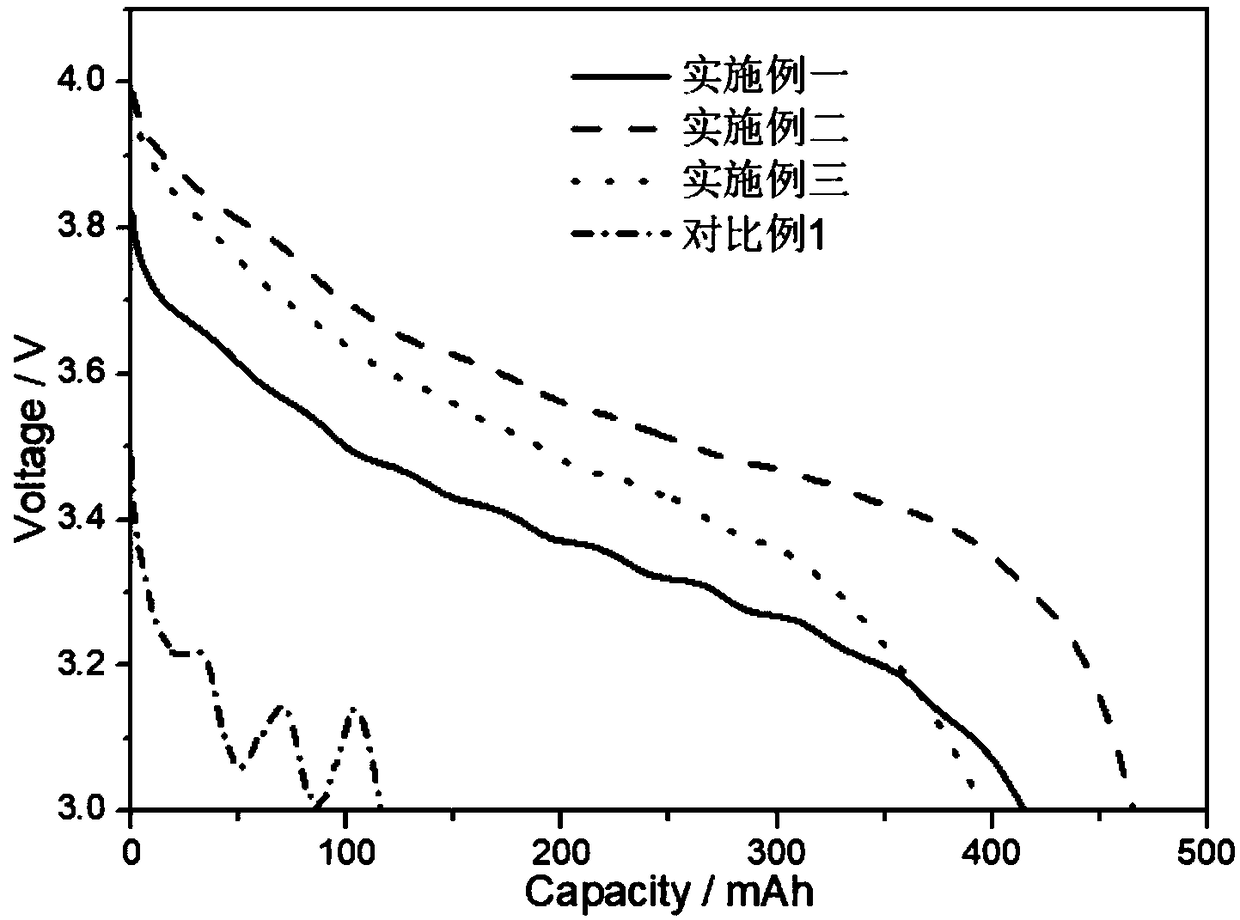

Embodiment 1

[0050] Example 1: 0.5% boric acid doping modification, 2% high softening point pitch carbon source coated boron doped modified soft carbon coated high and low temperature negative electrode material

[0051] Get 4g of high softening point pitch (5 microns in median particle size) and 1g boric acid (3 microns in median particle size) and add 200g of graphite negative electrode material (6.60 μm in median particle size), then add to the high-speed mixer, Stir rapidly for 1 hour. After mixing evenly, transfer to a small vertical kettle. Under a nitrogen atmosphere, heat up to 550°C and heat for 6 hours. After cooling, transfer the compounded materials into a tubular carbonization furnace. Under a nitrogen atmosphere, heat up to 1000°C, heat for 10 hours, cool naturally and sieve with a 325-mesh sieve. A high and low temperature negative electrode material coated with 0.5% non-metallic boron doped and modified with 2% soft carbon is obtained. The prepared product was uniformly mi...

Embodiment 2

[0053] Example 2: 2% boric acid doping modification, 6% high softening point pitch carbon source coating boron doping modified soft carbon coating high and low temperature negative electrode material.

[0054] Get 12g of high softening point pitch (5 microns in median particle diameter) and 4g boric acid (8 microns in median particle diameter) and add 200g graphite negative electrode material (6.60 μm in median particle diameter), then join in the high-speed mixer, Stir rapidly for 1 hour. After mixing evenly, transfer to a small vertical kettle. Under a nitrogen atmosphere, heat up to 550°C and heat for 6 hours. After cooling, transfer the compounded materials into a tubular carbonization furnace. Under a nitrogen atmosphere, the temperature was raised to 1000° C., heated for 10 hours, and cooled naturally to obtain a negative electrode material. Pass the fluorine gas through the cooling medium containing calcium chloride and ice and the filter layer of sodium fluoride at 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com