Patents

Literature

40results about How to "Reduced low temperature performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer modified asphalt and producing method thereof

InactiveCN101104740AGood compatibilityImprove performanceBuilding insulationsPolymer sciencePolyolefin

The invention discloses a polymer modified asphalt and a product method of the polymer modified asphalt. The polymer modified asphalt of the invention comprises the components of basic asphalt and maleic anhydride modified polyolefin, wherein, the amount of the maleic anhydride modified polyolefin is 1 to 6 percent of the weight of the basic asphalt. The maleic anhydride is grafted on the chain of polyethylene or polypropylene, so that maleic anhydride grafted modified polyethylene and polypropylene are formed. Because the groups of anhydride are easy to have reaction with the functional groups of the asphalt, the compatibility of the polyethylene and / or polypropylene with the asphalt is enhanced, various performances of the modified asphalt are increased. The modified asphalt prepared by the maleic anhydride modified polyolefin being modified has excellent high temperature performance, meanwhile does not decrease or decreases little low temperature performance. Moreover, no rut will be formed when the modified asphalt is used on the surface of the expressway.

Owner:CHINA NAT OFFSHORE OIL CORP +1

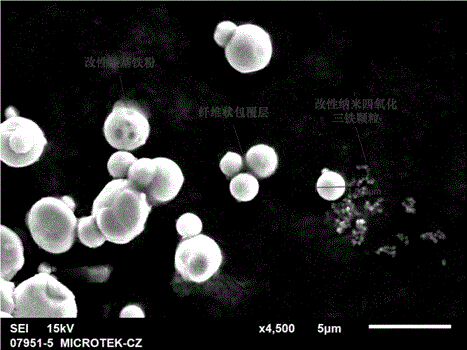

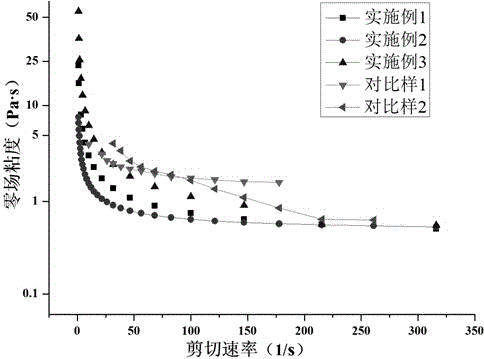

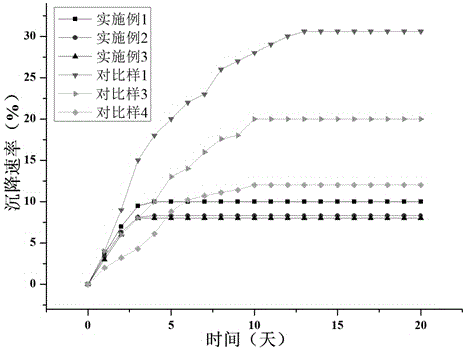

Mineral oil based magnetorheological fluid for high power transmission and preparation method thereof

The invention discloses mineral oil based magnetorheological fluid for high power transmission. The mineral oil based magnetorheological fluid comprises the following components by mass percent: 60-80% of magnetic particles, 15-40% of carrier liquid and 2-5% of additives, wherein the magnetic particles are carbonyl iron powder particles and nano ferriferrous oxide particles; the carrier liquid is mineral oil; the additives comprise a surface active agent, a thixotropic agent, an antioxidant and an antiwear agent, meanwhile, the invention further provides a preparation method of the magnetorheological fluid, and the prepared magnetorheological fluid has excellent sedimentation stability, lower zero field viscosity, higher shear yield stress and long service life, and can meet the application requirements of high power transmission devices.

Owner:CHINA UNIV OF MINING & TECH

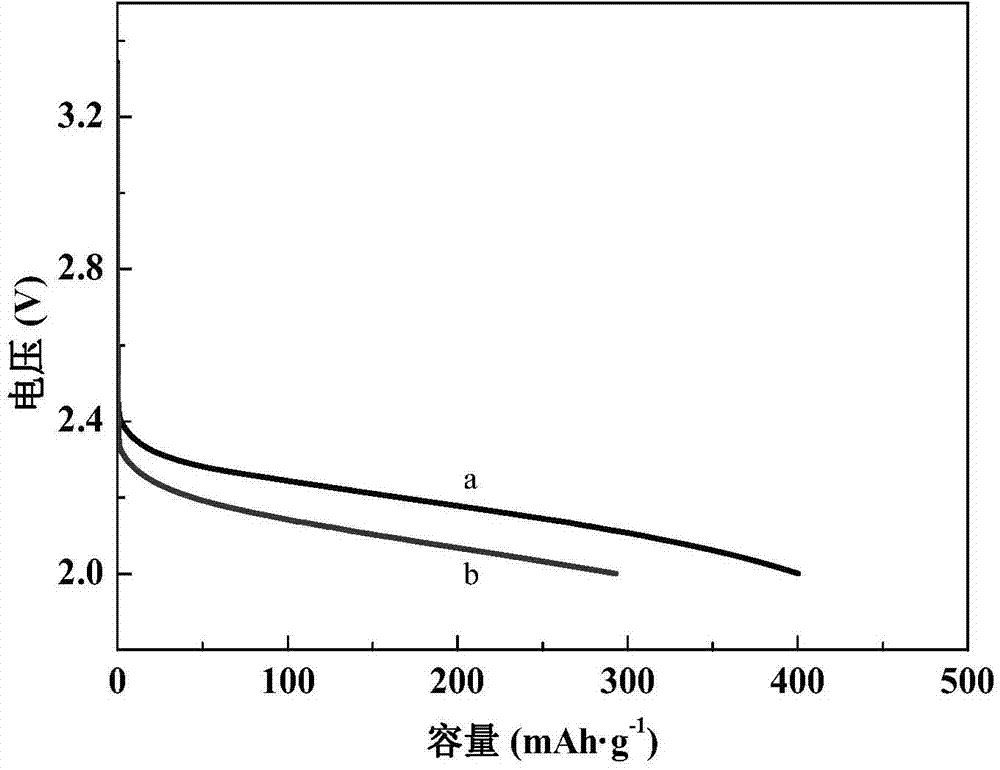

Lithium-ion battery electrolyte

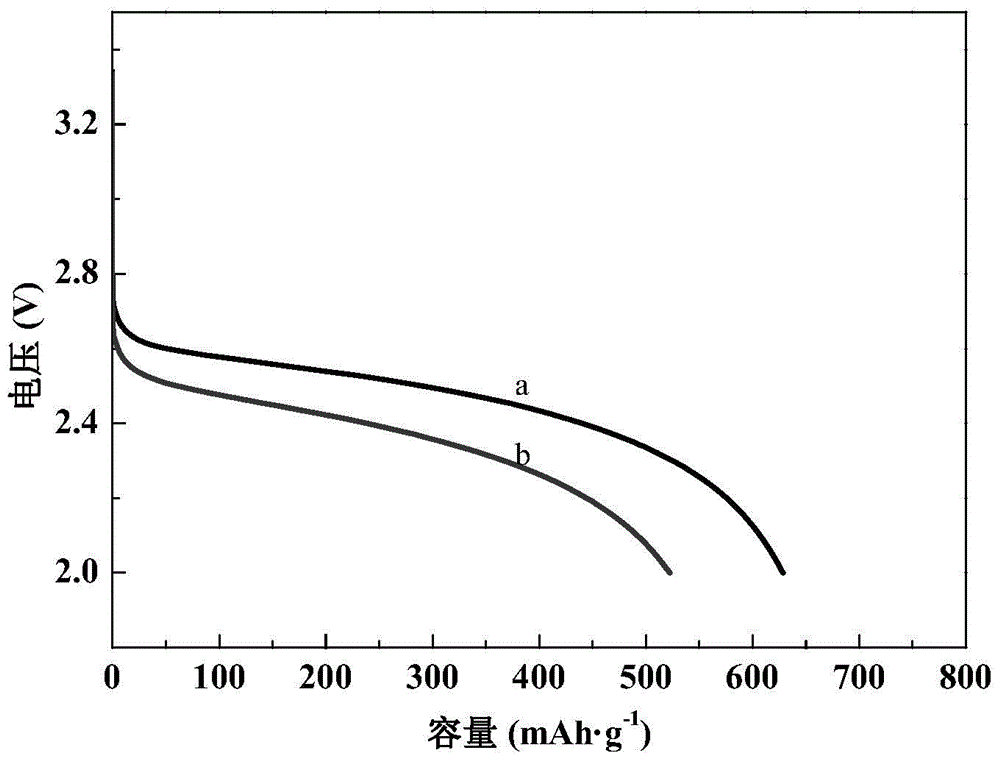

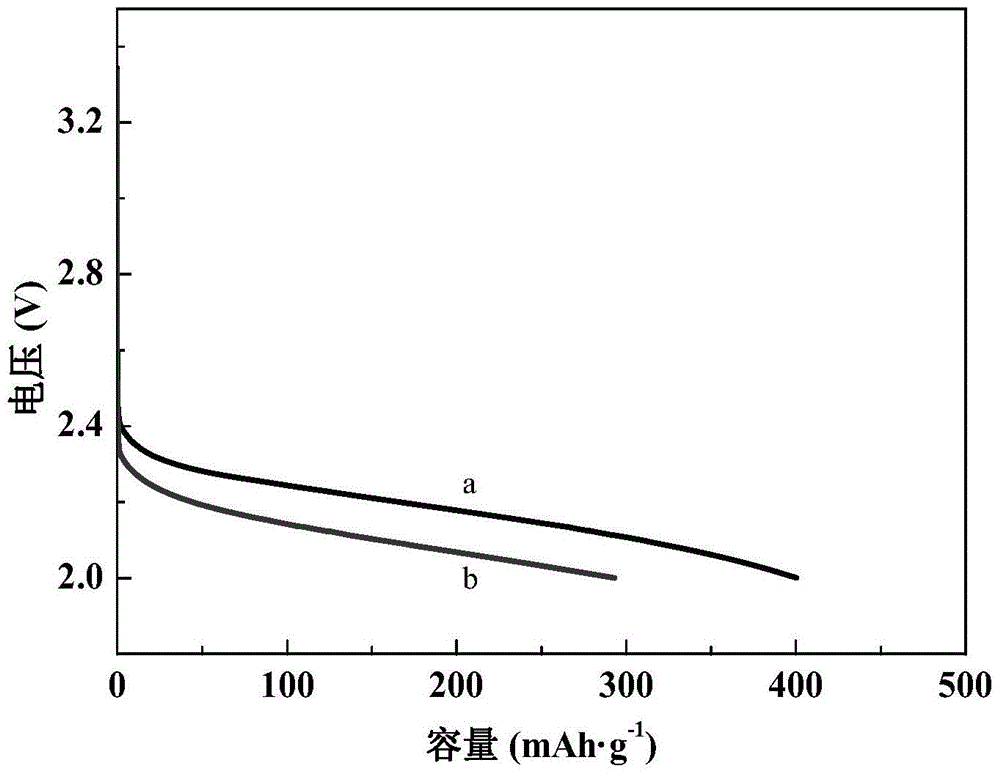

ActiveCN104124469AWide temperature windowLow freezing pointSecondary cellsHigh temperature storageLithium-ion battery

The invention discloses a lithium-ion battery electrolyte relating to a lithium ion battery. The lithium-ion battery electrolyte comprises an organic solvent, a lithium salt and an additive, wherein the organic solvent comprises propylene carbonate, chain carboxylic ester and chain carbonic ester, wherein the content of propylene carbonate is 24-58 percent, the content of chain carboxylic ester is 9-58 percent, the content of chain carbonic ester is 0-26 percent, the content of the lithium salt is 9-16 percent, and the content of the additive is 2-10 percent; and the additive is selected from vinylene carbonate, fluoroethylene carbonate, vinyl vinylene carbonate, glycol sulfite, vinyl glycol sulfite, propylene sulfite, dimethyl sulfate or trimethylene sulfate. Propylene carbonate is used for completely replacing ethylene carbonate, and is low in melting point and high in boiling point, thus a temperature window of the electrolyte can be enlarged; and chain carboxylic ester is low in melting point and low in viscosity, thus the solidifying point and the viscosity of the electrode can be reduced, and the conductivity of the electrode is increased. PC (Poly Carbonate) co-block is inhibited by using the additive in the electrolyte, thus the film-forming property for the surface of a negative electrode can be improved, and the high-temperature storage property is improved.

Owner:XIAMEN UNIV

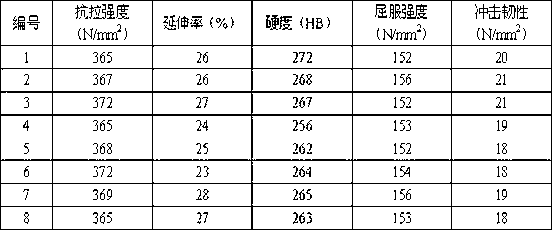

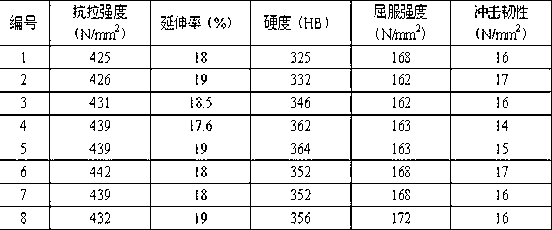

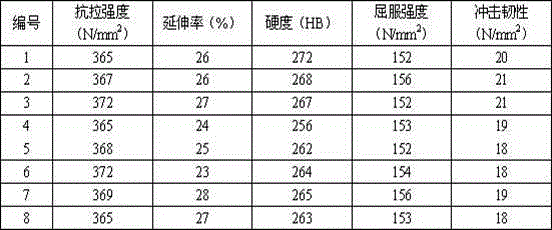

Casting method of low temperature resistant iron cushion plate for high speed railway buckling part

The invention discloses a casting method of a low temperature resistant iron cushion plate for a high speed railway buckling part. The method comprises smelting, spheroidizing inoculation and casting, a smelting material is made of cast iron and low-carbon steel which meets requirements that P: <=0.04% and S: <=0.03%, smelted iron water is subjected to nodulizing and inoculation and then is subjected to casting molding, and hot processing is conducted to obtain the required iron cushion plate. According to the casting method, the quantity of ferrites can be increased, the low-temperature toughness is improved, and the anti-impact performance of the iron cushion plate can be improved further.

Owner:中原利达铁路轨道技术发展有限公司

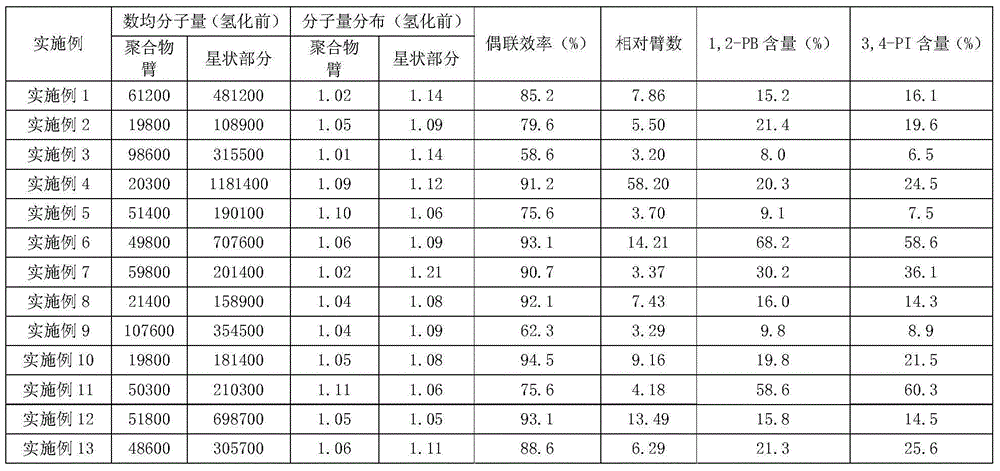

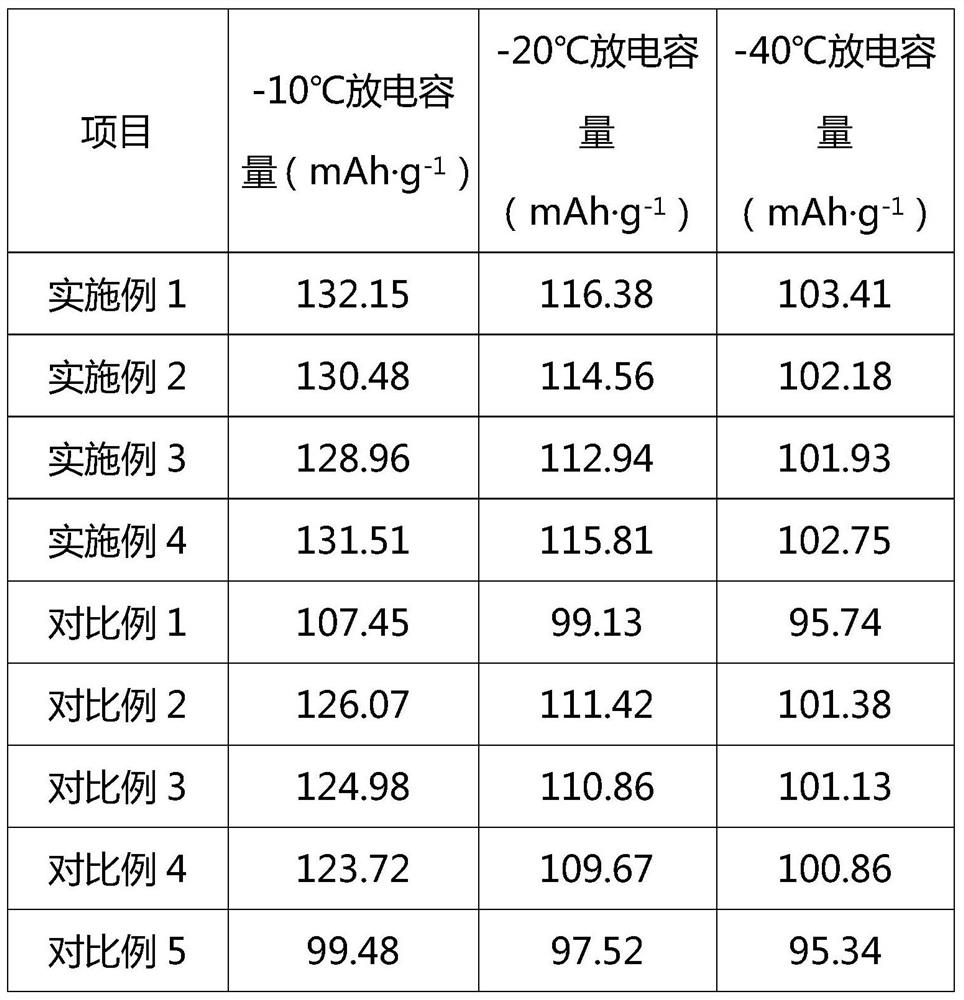

Star-shaped hydrogenated styrene diene copolymer and preparation method thereof

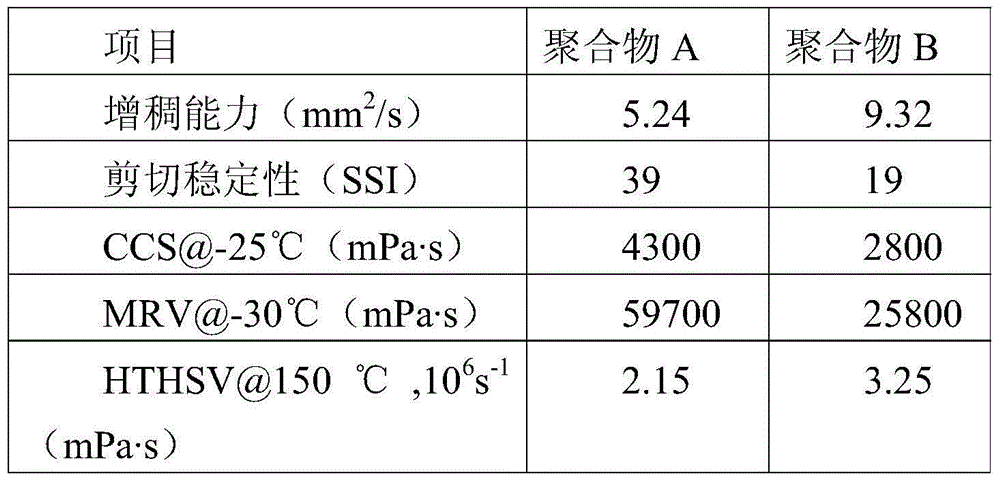

The invention relates to a star-shaped hydrogenated styrene diene copolymer which is used as a lubricating oil viscosity index improver. Each arm of the star-shaped hydrogenated styrene diene copolymer is a diblock copolymer including a block I being hydrogenated polyisoprene (EP) and a block II being and a block II being hydrogenated styrene-butadiene copolymer (SEB), and has a structural formula being (EP-SEB)n-C, wherein C is a core of a coupling agent, and n is the arm number of the copolymer and is no less than 3. The star-shaped hydrogenated styrene diene copolymer is finally prepared through polymerization, coupling, and hydrogenation. A novel copolymer is prepared through adjustment of numbers, ratio, and addition sequence of monomers in the arms of the copolymer and a microstructure. The copolymer is applied to a lubricating oil composition, and the thickening capacity, shear stability, low-temperature performance, and processing ability of lubricating oil are obviously improved. Meanwhile, the preparation method is simple and low in production cost.

Owner:PETROCHINA CO LTD

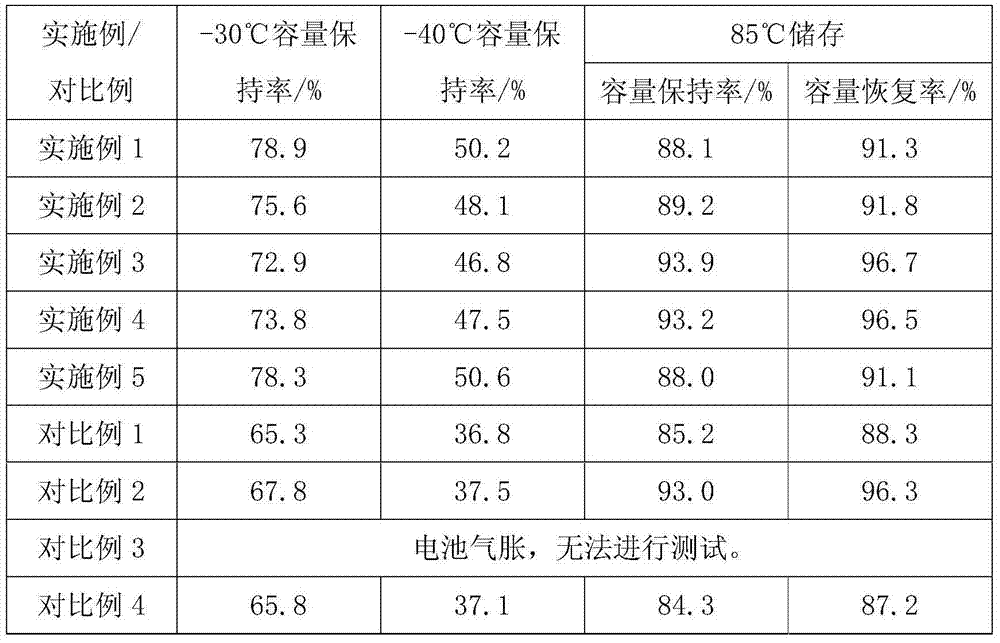

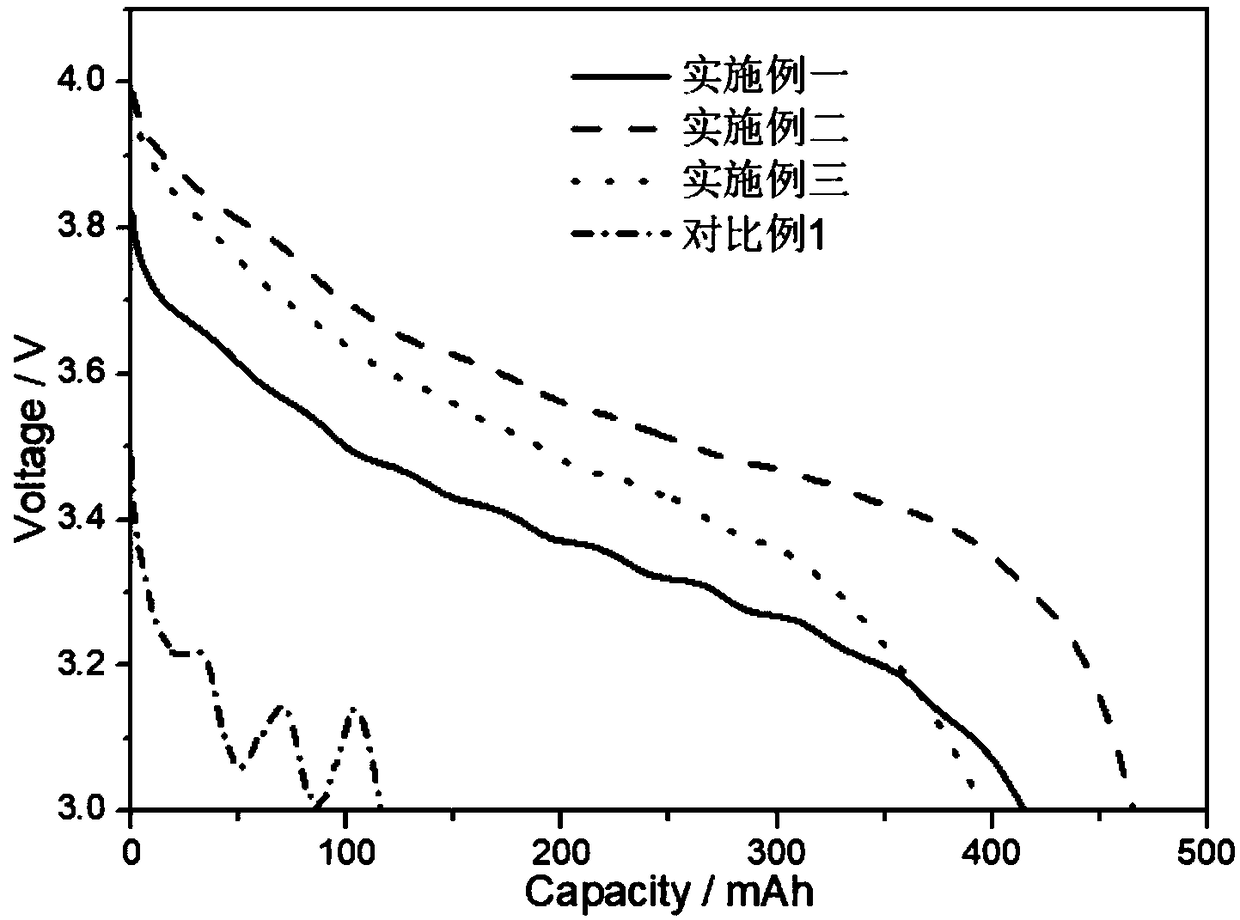

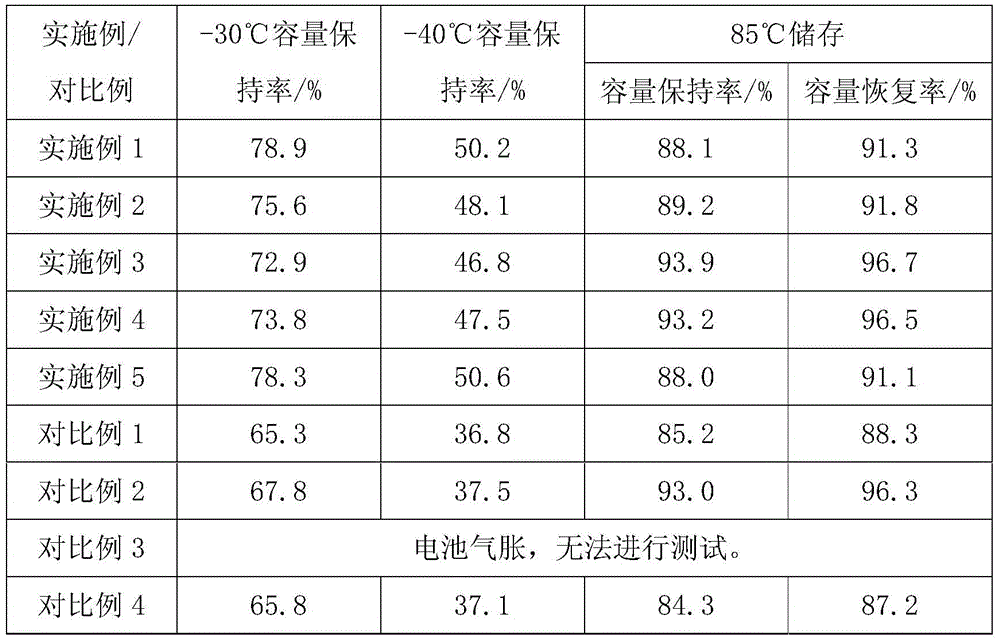

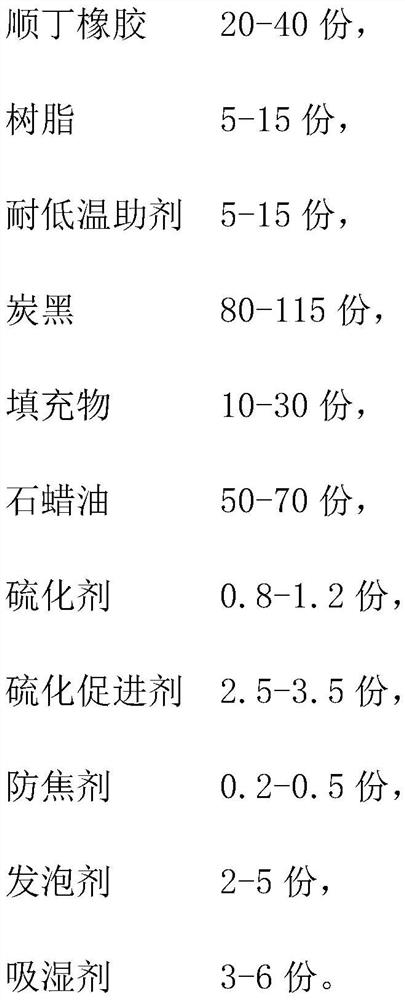

Ternary high-nickel electrolyte and high-nickel anode lithium ion battery containing same

InactiveCN109687010AReduced low temperature performanceGood low temperature performance, lowCell electrodesSecondary cellsHigh temperature storageSlurry

The invention provides ternary high-nickel electrolyte and a high-nickel anode lithium ion battery containing the electrolyte. The ternary high-nickel electrolyte is characterized by comprising, by weight, 13-15% of lithium salt, 80-85% of a non-aqueous organic solvent and 0.1-5% of an additive; wherein the additive comprises vinylene sulfate, vinylene carbonate, succinonitrile, tris (trimethyl silicon-based) phosphorus, lithium bifluroflavin imide and lithium dioxalate borate; the lithium salt is lithium hexafluorophosphate; the non-aqueous organic solvent comprises a cyclic carbonate compound, dimethyl carbonate and ethoxy pentafluoro tripolyphosphate; the high-nickel anode lithium ion battery containing the ternary high-nickel electrolyte adopts anode slurry prepared from high-nickel ternary anode powder, a conductive agent, a functional composite binder, a solvent N-methyl pyrrolidone to prepare the anode membrane, the high-nickel anode lithium ion battery has excellent normal-temperature cycle performance, high-temperature cycle performance and high-temperature storage service life, and can obviously reduce the gas yield in the high-temperature storage process.

Owner:湖北诺邦科技股份有限公司

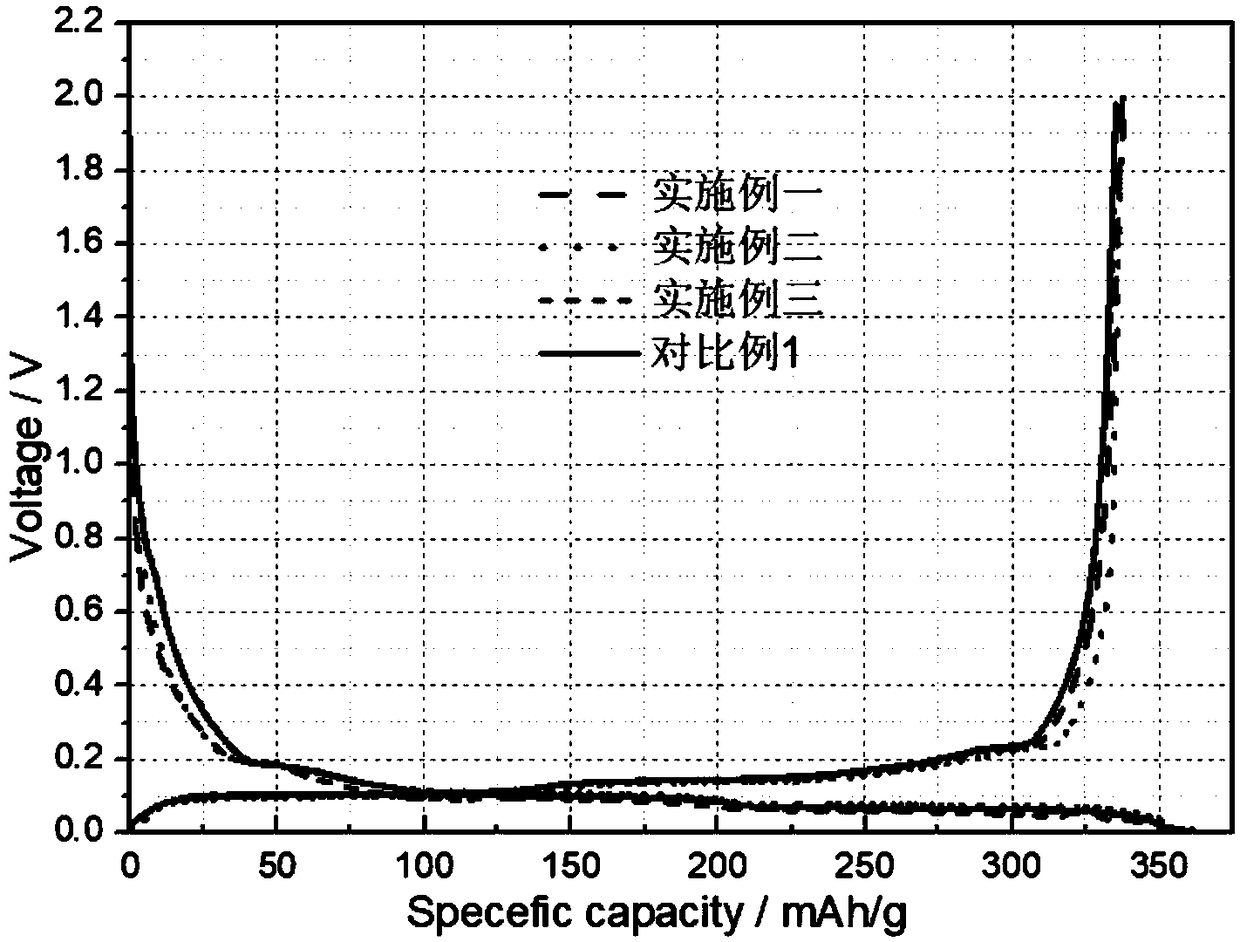

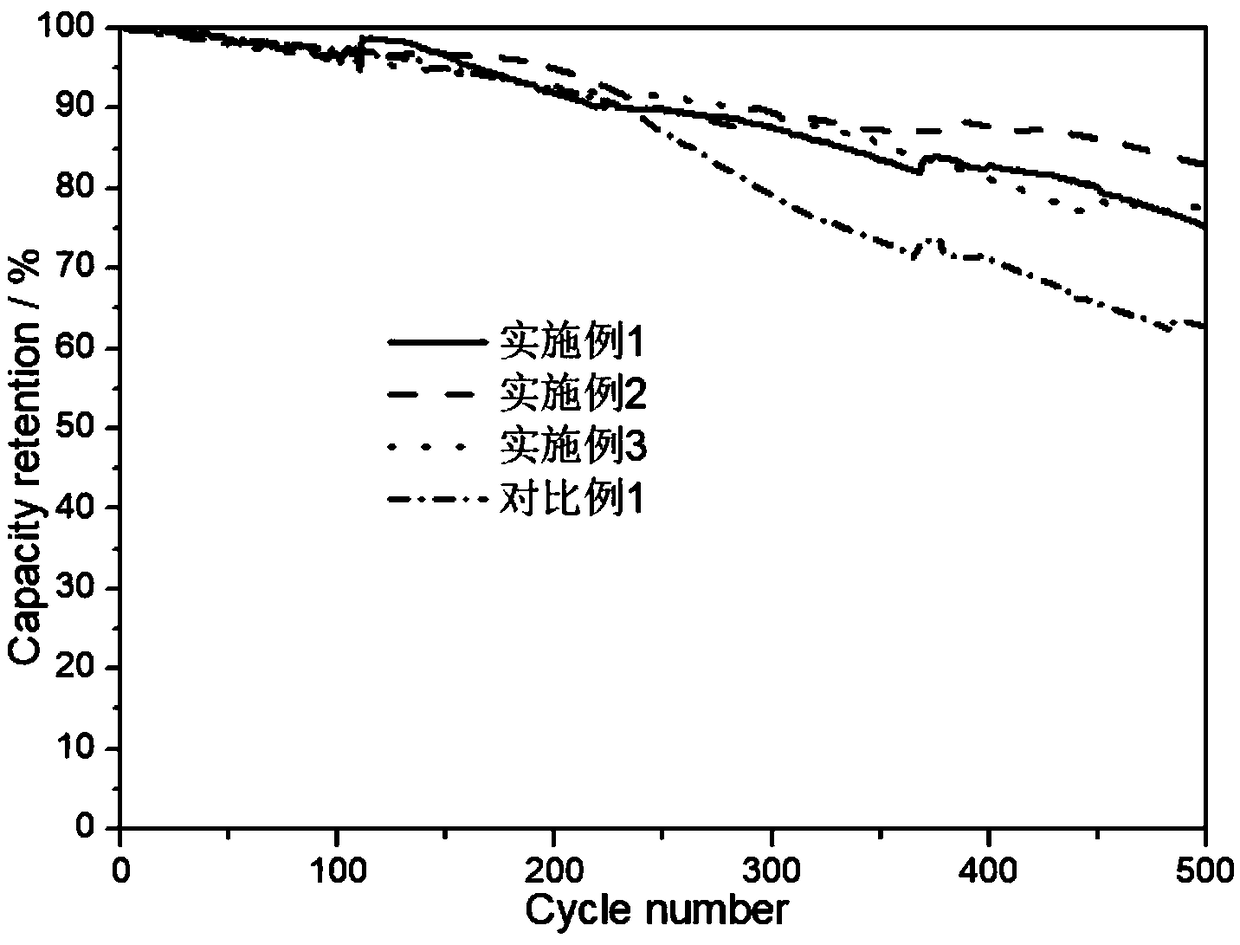

A boron doping modified soft carbon coating negative electrode material with high stability under high and low temperature environment and a preparation method thereof

ActiveCN109167025AEasy to operateUnique preparation processCell electrodesSecondary cellsCarbon–oxygen bondCarbonization

The invention relates to the field of lithium batteries, and discloses a boron doped modified soft carbon coating negative electrode material with high stability under a high-low temperature environment and a preparation method thereof. An amorphous carbon-carbon lay is formed on that surface of a negative electrode substrate aft carbonization by a soft carbon source, boron oxide is generated by decomposing a boron compound at a high temperature, the reaction of the boron oxide with the amorphous carbon and the surface of the negative electrode substrate is controlled, and a composite structure such as a boron-carbon bond and a boron-carbon-oxygen bond is for on the surface of the negative electrode material at a high temperature. 1, that soft carbon coat can reduce the impedance of the material under the low temperature, improve the liquid absorption performance, increase the low-temperature discharge voltage platform and greatly improve the low-temperature performance of the material; 2. By the catalysis of boron, the degree of graphitization of the cathode material is increased by reducing the surface defects, so that the specific surface area is greatly reduced, and the side reaction of the cathode material with the electrolyte at high temperature is reduced by the smaller specific surface area, and the performance at high temperature is obviously improved.

Owner:HUZHOU CHUANGYA POWER BATTERY MATERIALS

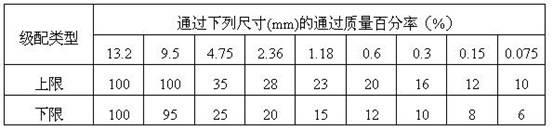

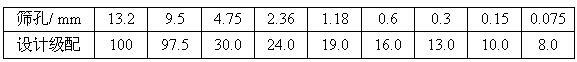

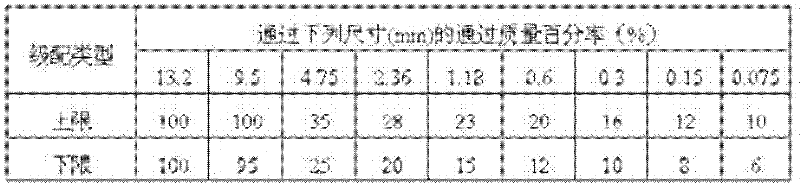

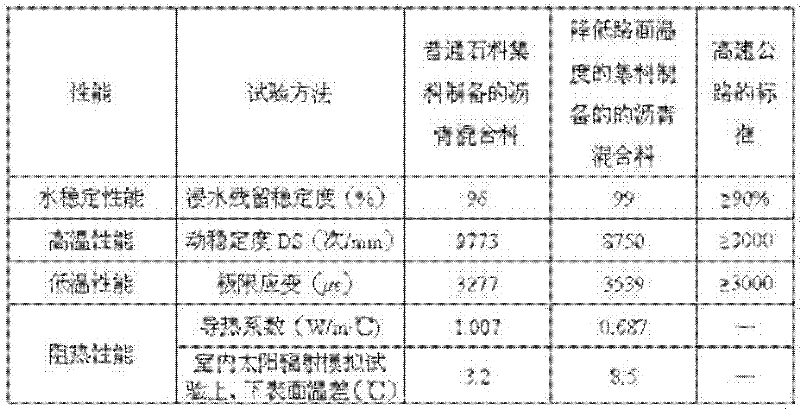

Aggregate for lowering pavement temperature and method for preparing bitumen mixture by utilizing same

InactiveCN101830658AWell mixedImprove road performanceSolid waste managementClimate change adaptationThermal coefficientRoad surface

The invention discloses an aggregate for lowering pavement temperature and a method for preparing a bitumen mixture by utilizing the same, which relates to an aggregate and a method for preparing a bitumen mixture by utilizing the aggregate, and solves the problems that the existing stone serving as the aggregate for paving a highway wearing layer has large thermal coefficient and high cost. The aggregate for lowering the pavement temperature of the invention is wasted ceramic particles with the grain diameter of 4.75mm-9.5mm. The method for preparing the bitumen mixture by utilizing the aggregate comprises the following steps: 1), computing needed stones with various grain diameters according to the grading mode of the wearing layer; 2), utilizing the aggregate to substitute for 18%-22% of the volume of the stone with the grain diameter of 4.75mm-9.5mm, weighting, and evenly mixing; and 3), preparing the mixed aggregate, mineral powder, slaked lime and bitumen into the bitumen mixture by the conventional method. The invention has low cost, and the thermal coefficient of the prepared wearing layer is 0.680W / m.DEG C-0.690W / m.DEG C, thus track diseases and the urban heat land effect are reduced, and the aggregate can be used for paving highways.

Owner:HARBIN INST OF TECH

NEPE (nitrate ester plasticized polyether) propellant with good low-temperature mechanical property

ActiveCN106748601AActiveReduced low temperature performanceNon-explosive/non-thermic compositionsPressure gas generationAdhesiveTriethylene glycol dinitrate

The invention relates to a NEPE (nitrate ester plasticized polyether) propellant with good low-temperature mechanical property. The NEPE propellant is prepared from the following components in percentage by mass: 5 to 10% of adhesive, 6 to 16% of energetic plasticizer, 0 to 3% of cold-resistant plasticizer, 15 to 40% of oxidant, 20 to 41% of energetic oxidant, 0.3 to 1.0% of curing agent, and 15 to 19% of fuel, wherein the cold-resistant plasticizer is triglyceride ethyl carbonate, and the adhesive is ethylene oxide-tetrahydrofuran copolymer; the plasticizer is a nitroglycerin and triethylene glycol dinitrate mixture, and singly uses triethylene glycol dinitrate; the oxidant is ammonium perchlorate, and the energetic oxidant is octogen or hexogen; the curing agent is hexamethylene diisocyanate; the fuel is Al (aluminum). The NEPE propellant has the characteristics that the low-temperature mechanical property is good, the energy is higher, and the like; the NEPE propellant is suitable for tactical missiles with low use environment temperature, high charge ratio and large thrust.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

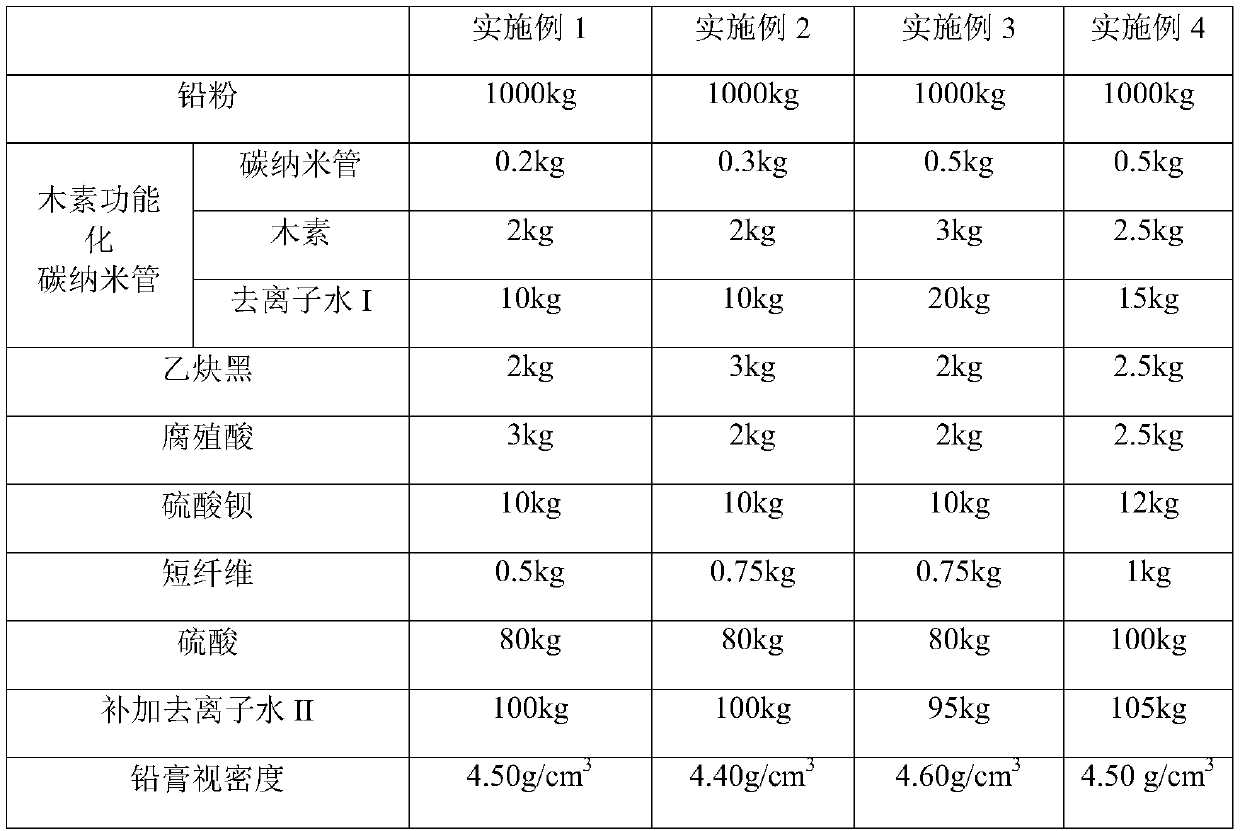

Negative lead paste for lead-acid storage battery and preparation method thereof

ActiveCN110729461AImprove low temperature performanceImprove cycle lifeNegative electrodesLead-acid accumulator electrodesElectrical batteryPhysical chemistry

The invention relates to the technical field of storage batteries, aims to solve the problem that lignin in the negative lead paste for the traditional lead-acid storage battery is liable to dissolveand reduce in the battery formation and subsequent use process to cause battery performance degradation, and provides a negative lead paste for a lead-acid storage battery and a preparation method thereof. The negative lead paste for the lead-acid storage battery is prepared from the following components in parts by weight: 1000 parts of lead powder, 12-25 parts of lignin functionalized carbon nanotube dispersion liquid, 2-3 parts of humic acid, 2-3 parts of acetylene black, 10-12 parts of barium sulfate, 100-120 parts of deionized water, 80-100 parts of sulfuric acid and 0.5-1 part of short fibers. The lignin used in the negative lead paste for the lead-acid storage battery is beneficial to the battery having better low-temperature performance and cycle life after being anchored by the carbon nanotubes, and the carbon nanotubes can be more uniformly distributed in the negative lead paste after being functionalized by the lignin so as to improve the rate performance of the battery.

Owner:CHAOWEI POWER CO LTD

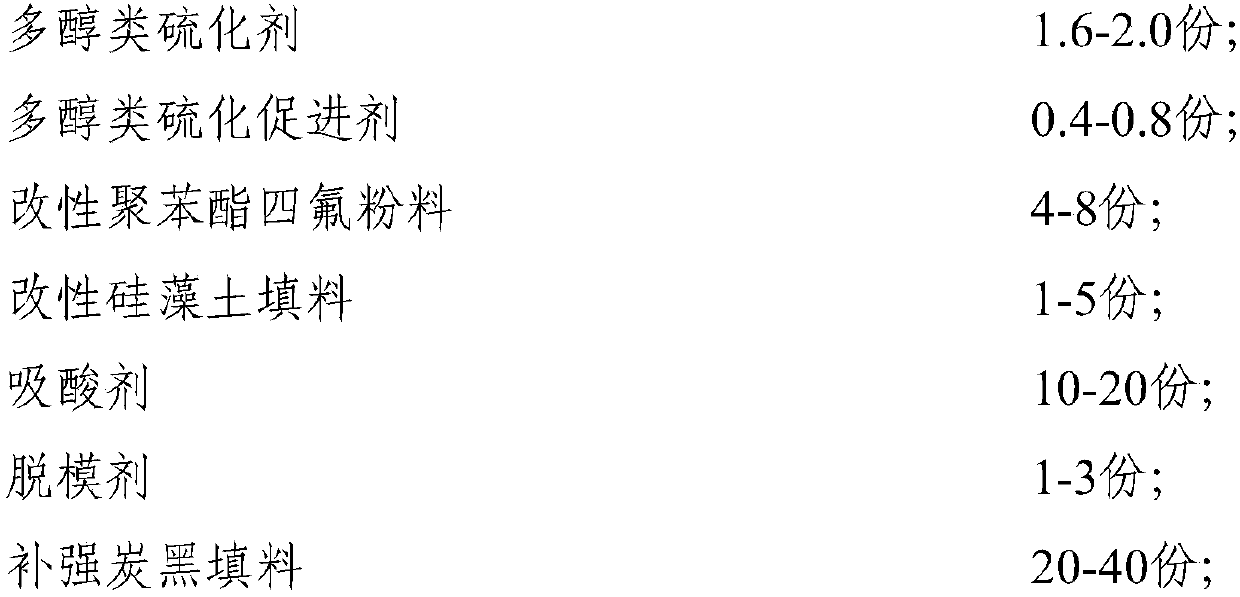

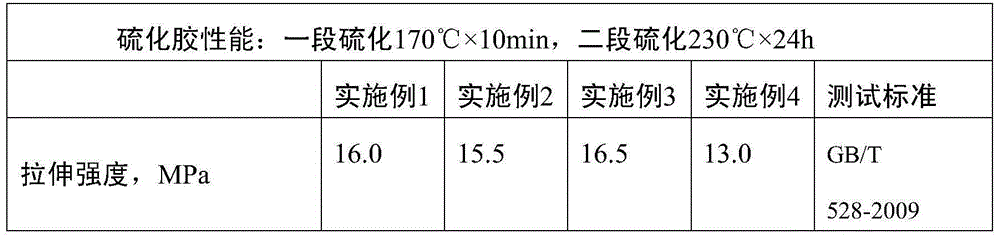

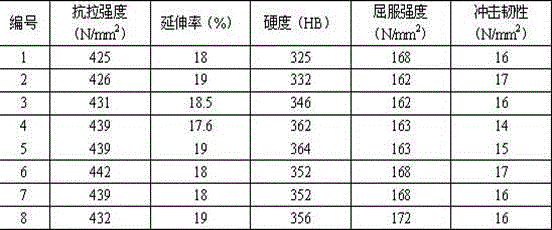

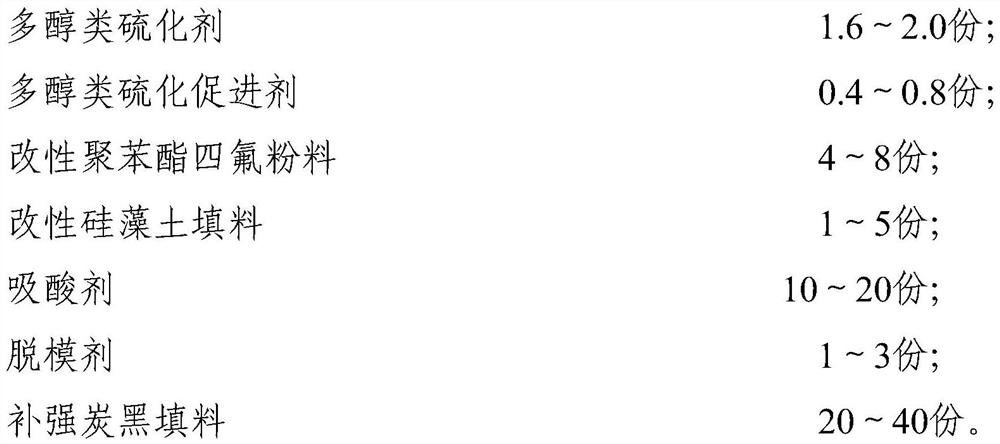

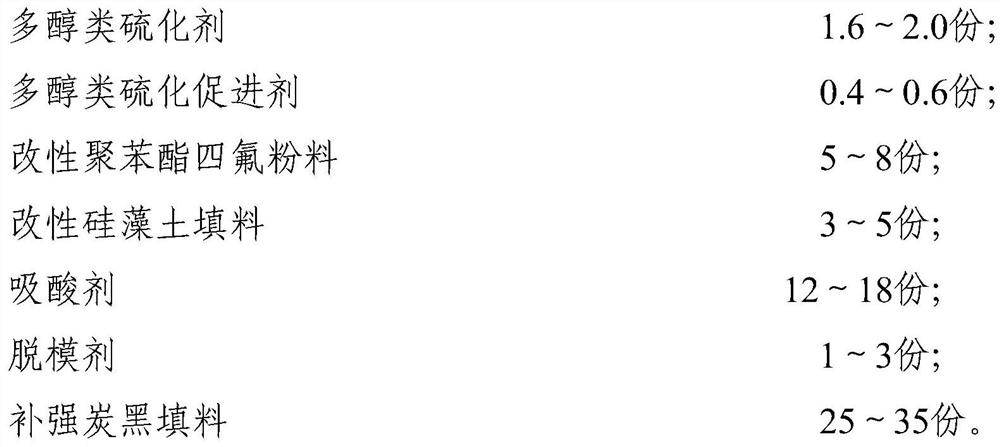

Fluororubber compound with low-temperature flexibility and high wear resistance, and preparation method thereof

ActiveCN110835446AImprove mechanical propertiesImprove low temperature performanceRubber materialPolymer science

The invention relates to a fluororubber compound with low-temperature flexibility and high wear resistance, and a preparation method thereof, wherein the preparation raw materials of the compound comprise a main material and an auxiliary material, wherein the main material comprises a fluororubber modified low-temperature raw rubber, a fluororubber raw rubber and graphene master batch, the auxiliary agent is modified polyphenyl ester tetrafluoro powder, the fluororubber modified low-temperature raw rubber is a low-temperature raw rubber with a vulcanization point monomer, the modified polyphenyl ester tetrafluoro powder is obtained by modifying polyphenyl ester and tetrafluoro micro-powder in the presence of a silane coupling agent, and the graphene master batch is a graphene master batchtaking a ternary raw rubber as a basic raw rubber. According to the invention, the fluororubber compound rubber prepared by mixing and adding the modified raw rubber and the novel auxiliary agent according to a certain ratio through the special mixing method and the vulcanization process, so the low-temperature performance of the rubber material is improved, the wear resistance and the mechanicalproperty of the rubber material at a low temperature are improved, and the fluororubber compound rubber can be used as a low-temperature sealing material and can replace foreign products.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Novel lead-acid storage battery grid

InactiveCN103427089AReduce weightReduce pollutionElectrode carriers/collectorsProduction lineInternal resistance

The invention discloses a novel lead-acid storage battery grid. A base body of the battery grid is made of conductive polymeric materials with a lead plating layer prepared on the surface thereof. The novel lead-acid storage battery grid has the advantages that the battery is greatly reduced in weight, output power is improved, and mass specific capacity of the battery is improved; internal resistance of the battery is reduced, conductivity is excellent, flow conductivity of a current collector is improved, distribution of electric current in polar plates is improved, so that utilization rate of electrode active materials is improved; mechanical strength is good, low-temperature performance of the battery is improved, and charge and discharge performance is better; passivation of a negative electrode can be effectively inhibited, so that the assembled battery is good in performance and long in service life; consumption of lead metal is greatly reduced, and environmental pollution and damage to human bodies are greatly reduced. In addition, an original production line is slightly modified, so that cost of investment is low.

Owner:JIANGSU OLITER ENERGY TECH

A kind of lithium ion battery electrolyte

ActiveCN104124469BWide temperature windowLow freezing pointSecondary cellsHigh temperature storageElectrolytic agent

The invention discloses a lithium-ion battery electrolyte relating to a lithium ion battery. The lithium-ion battery electrolyte comprises an organic solvent, a lithium salt and an additive, wherein the organic solvent comprises propylene carbonate, chain carboxylic ester and chain carbonic ester, wherein the content of propylene carbonate is 24-58 percent, the content of chain carboxylic ester is 9-58 percent, the content of chain carbonic ester is 0-26 percent, the content of the lithium salt is 9-16 percent, and the content of the additive is 2-10 percent; and the additive is selected from vinylene carbonate, fluoroethylene carbonate, vinyl vinylene carbonate, glycol sulfite, vinyl glycol sulfite, propylene sulfite, dimethyl sulfate or trimethylene sulfate. Propylene carbonate is used for completely replacing ethylene carbonate, and is low in melting point and high in boiling point, thus a temperature window of the electrolyte can be enlarged; and chain carboxylic ester is low in melting point and low in viscosity, thus the solidifying point and the viscosity of the electrode can be reduced, and the conductivity of the electrode is increased. PC (Poly Carbonate) co-block is inhibited by using the additive in the electrolyte, thus the film-forming property for the surface of a negative electrode can be improved, and the high-temperature storage property is improved.

Owner:XIAMEN UNIV

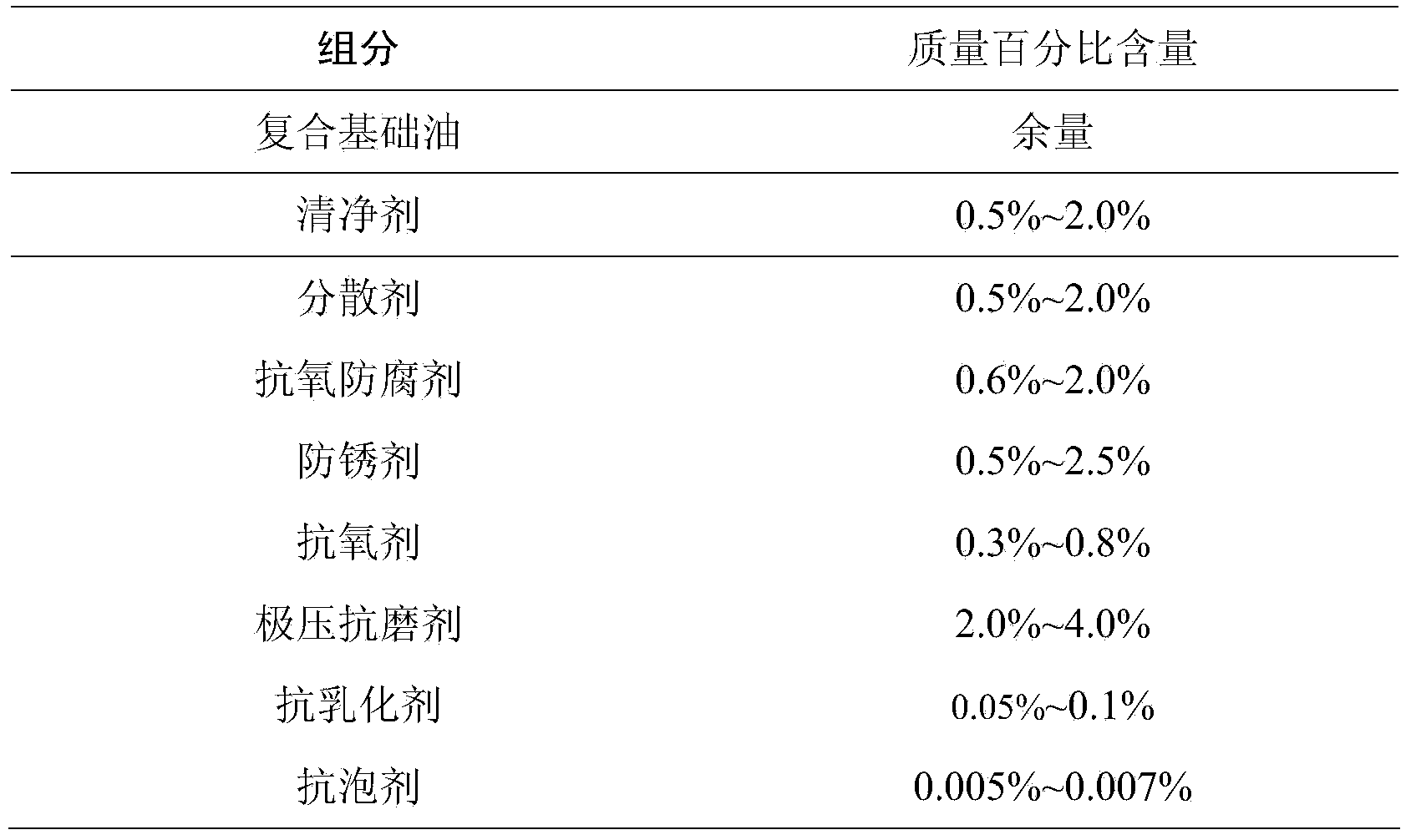

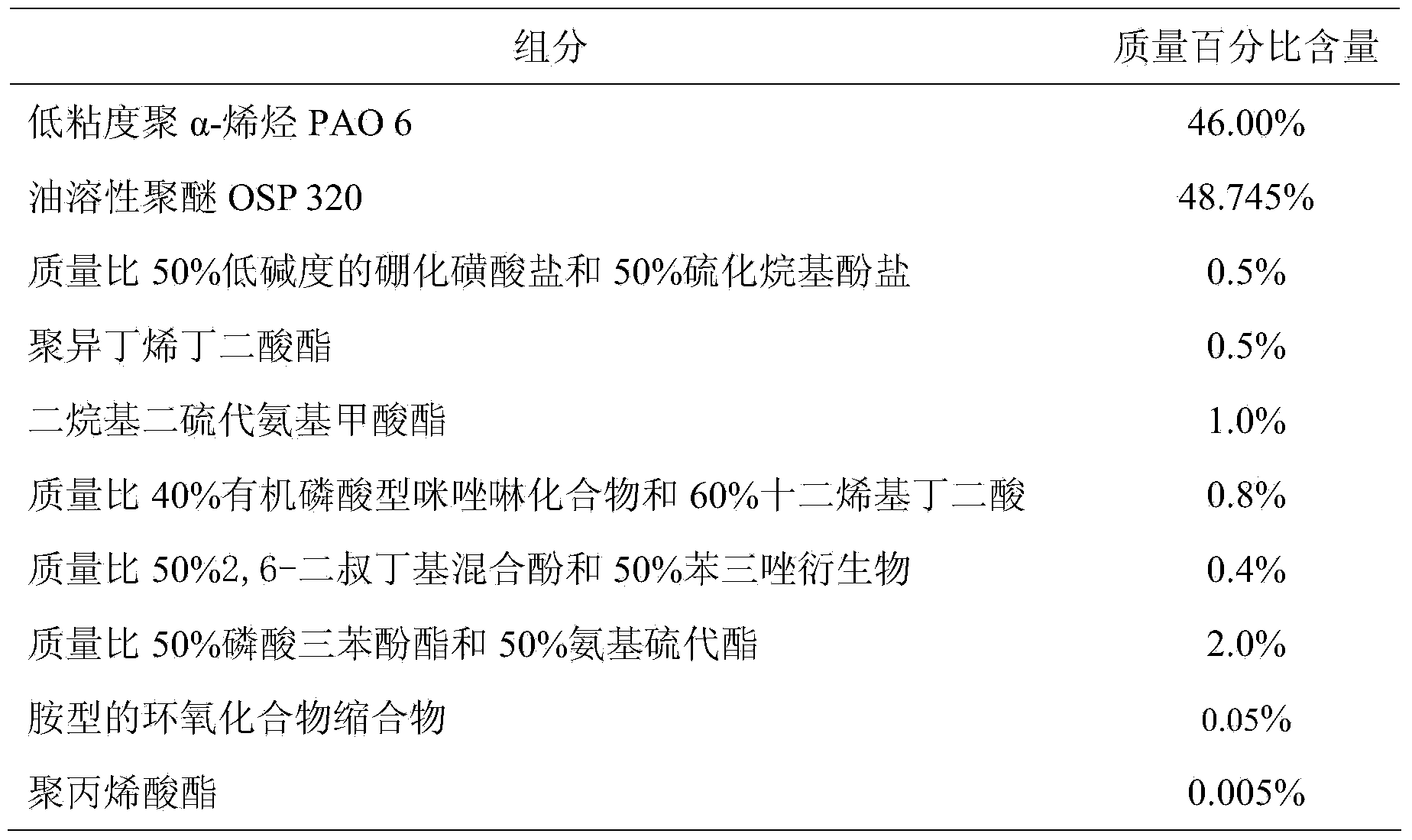

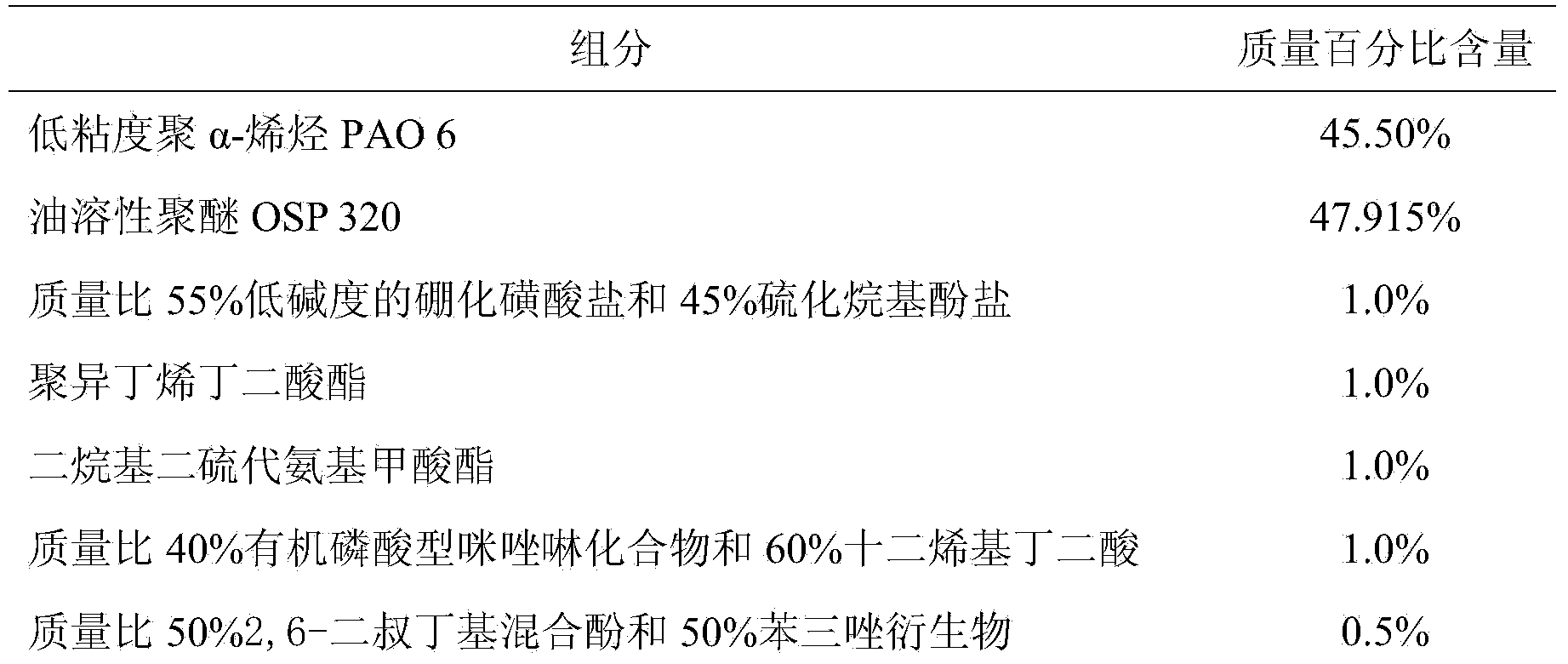

Lubricating agent of sulfur dioxide compressor

ActiveCN103525520AMeet the requirements of harsh working conditionsReduce dilutionBase-materialsOil sludgeAlpha-olefin

The invention relates to a lubricating agent of a sulfur dioxide compressor. The lubricating agent is prepared by compounding oil-soluble polyether and low-viscosity poly alpha-olefin to be base oil and mixing with various additives. The lubricating agent effectively alleviates the dilution degree on oil products caused by sulfur dioxide and avoids frictional wear due to insufficient oil film thickness caused by ultralow viscosity of the oil products, has excellent sediment controllability, does not generate carbon deposit and oil sludge, increases safety coefficient, has excellent viscosity-temperature property, low-temperature property, volatility, cooling property, high anti-shearing stability, hydrolytic stability and thermal oxidation stability, can reduce the friction coefficient of the surface of metal, and can meet the using requirement of the sulfur dioxide compressor under the harsh working condition.

Owner:GUANGXI UNIV

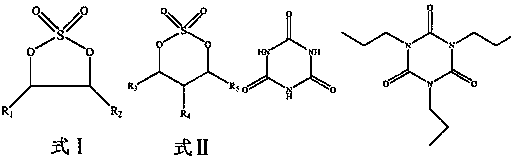

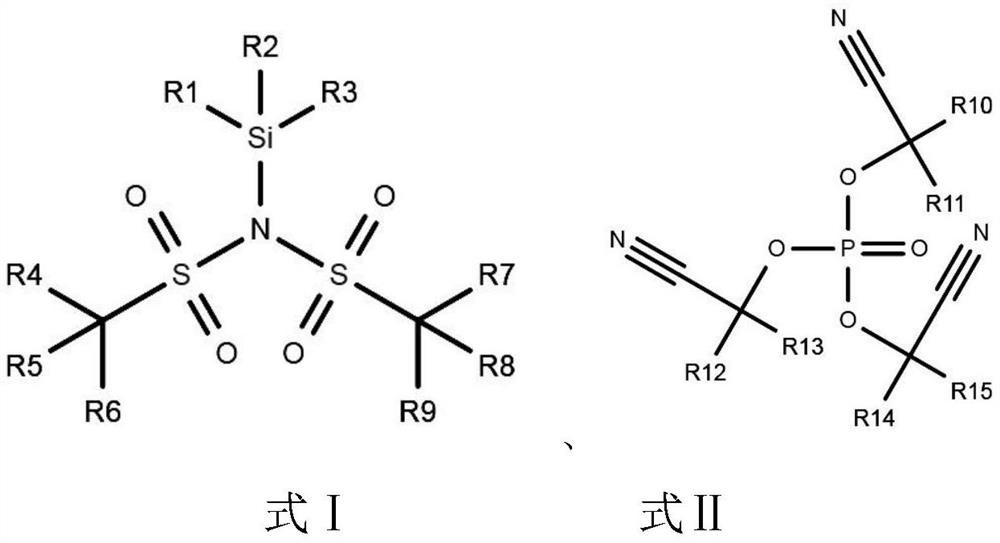

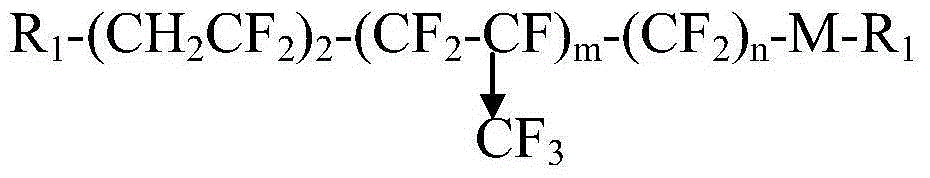

Sodium ion battery electrolyte additive, electrolyte and sodium ion battery

PendingCN113488697ALower internal resistanceRaise the temperatureElectrolytesSecondary cells servicing/maintenanceElectrolytic agentAlkane

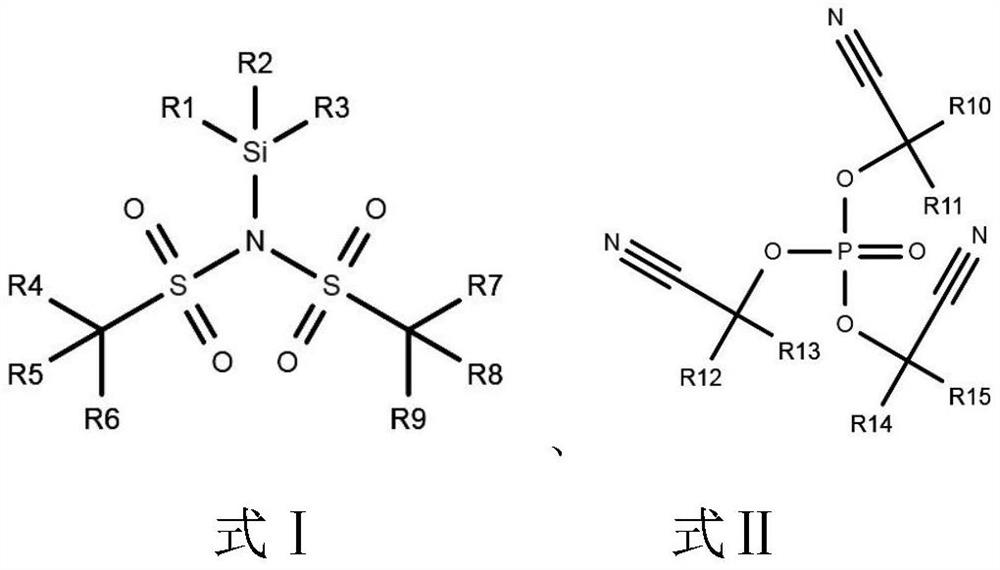

The invention belongs to the technical field of sodium ion batteries, and particularly relates to a sodium ion battery electrolyte additive, an electrolyte and a sodium ion battery. The additive a comprises at least one of compounds shown in a formula I and a formula II; in the formula I and the formula II, R1-R15 are independently selected from one of H, halogen atoms, alkane groups, unsaturated alkyl groups, alkoxy groups and alkanoyl groups respectively; H in the alkane group, the unsaturated alkyl group, the alkoxy group and the alkanoyl group can be partially or completely substituted by one or more of halogen atoms, cyano groups, carboxyl groups and sulfonic acid groups; the additive b is one or more of ethylene carbonate, fluoroethylene carbonate, vinylethylene carbonate, ethylene sulfate and allyl sultone. The electrolyte additive can form a stable and compact interface film on the surfaces of a positive electrode and a negative electrode, reduces side reaction with an electrolyte, reduces gas generation, and enables the cycle performance and the high-temperature performance of a battery to be better.

Owner:SO-FUN TECH CORP LTD

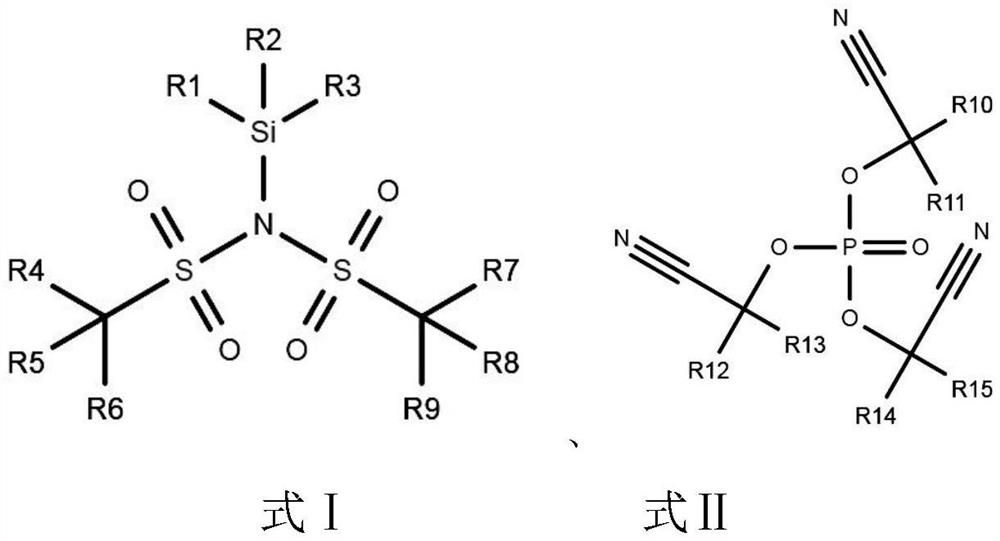

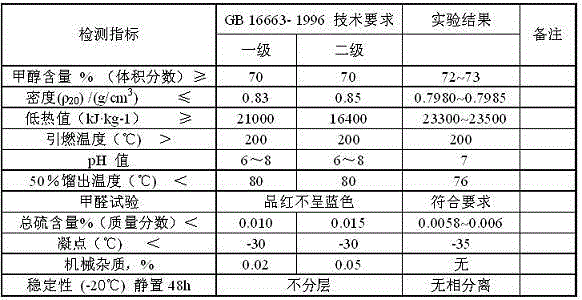

Methanol fuel additive for cold plateau region and methanol fuel containing the additive

The invention relates to a methanol fuel additive for cold plateau region. The additive is prepped by adding 3-20 wt.% of an oxidant hydrogen peroxide with mass concentration of 30%, 1-6% of an antifreeze, 0.2-3% of an antioxidant antigum agent 2,6-butylated hydroxytoluene, 0.05-0.6% of a metal passivator N,N-bis(salicylidene)-1,2-propanediamine, 0.008-0.06% of a detergent dispersant, 1-6% of a preservative and 1-20% of a emulsifier into 10-83.742% of aqueous solution, mixing evenly by pump circulation, then successively adding 3-20% of naphtha, 3-10% of toluene, 2-10% of xylene, 2-10% of C5H12-C7H16 in weight ratio of 1:1, and mixing homogeneously by pump circulation. At the same time, the invention also discloses a ratio and a preparation method of a methanol fuel containing the methanol fuel additive for cold plateau region. The methanol fuel additive for cold plateau region provided by the invention has good and stable performance, and solves the problems of low temperature fluidity, high altitude hypoxia burning property, low sulfur, low nitrogen and dynamic stability.

Owner:GANSU ZHONGAO PETROCHEM CO LTD

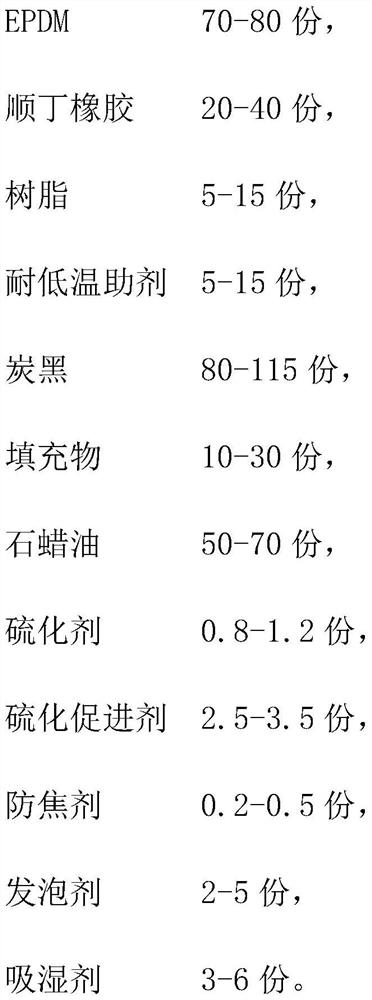

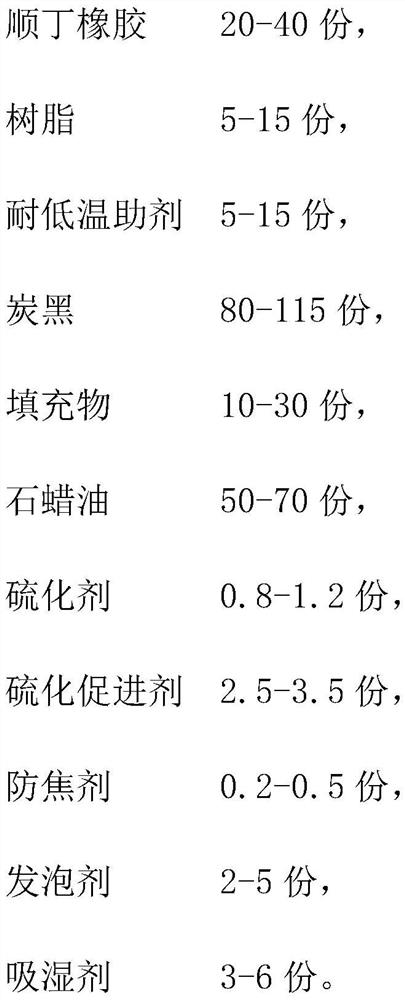

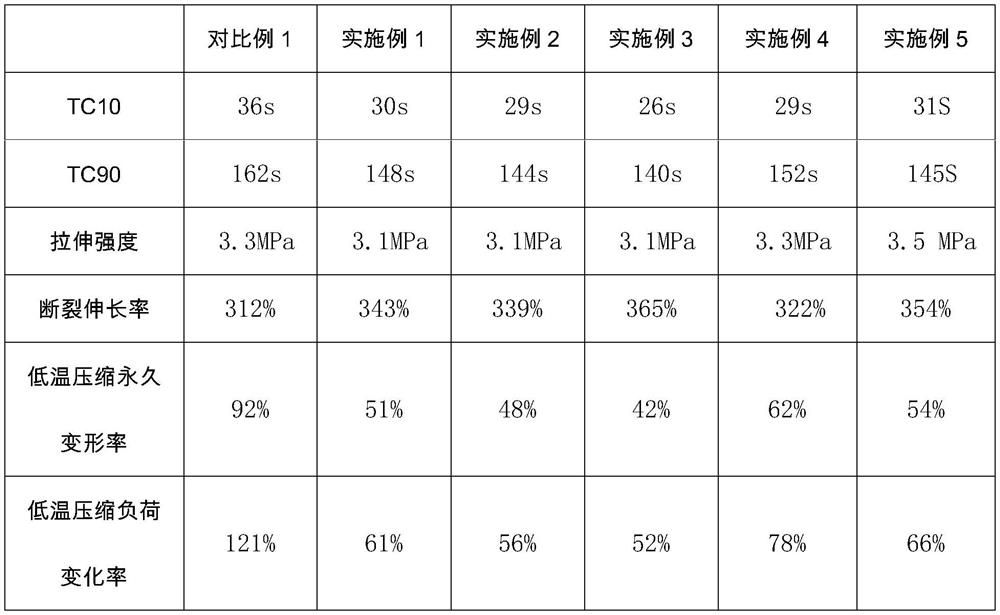

Low-temperature-resistant sponge sealing strip and preparation method thereof

The invention discloses a low-temperature-resistant sponge sealing strip and a preparation method thereof. The defects that in the prior art, EPDM rubber is hardened in sealing and weakened in rebound resilience in alpine regions are overcome. The low-temperature-resistant sponge sealing strip comprises the following raw materials in parts by weight: 70 to 80 parts of EPDM, 20 to 40 parts of butadiene rubber, 5 to 15 parts of resin, 5 to 15 parts of a low-temperature-resistant aid, 80 to 115 parts of carbon black, 10 to 30 parts of a filler, 50 to 70 parts of paraffin oil, 0.8 to 1.2 parts of a vulcanizing agent, 2.5 to 3.5 parts of a vulcanization accelerator, 0.2 to 0.5 part of a scorch retarder, 2 to 5 parts of a foaming agent and 3 to 6 parts of a moisture absorbent. By compounding the resin, the butadiene rubber, the low-temperature-resistant aid and the EPDM, the cold resistance, the low-temperature resilience and the like of the product can be effectively improved.

Owner:瀚德(中国)汽车密封系统有限公司 +2

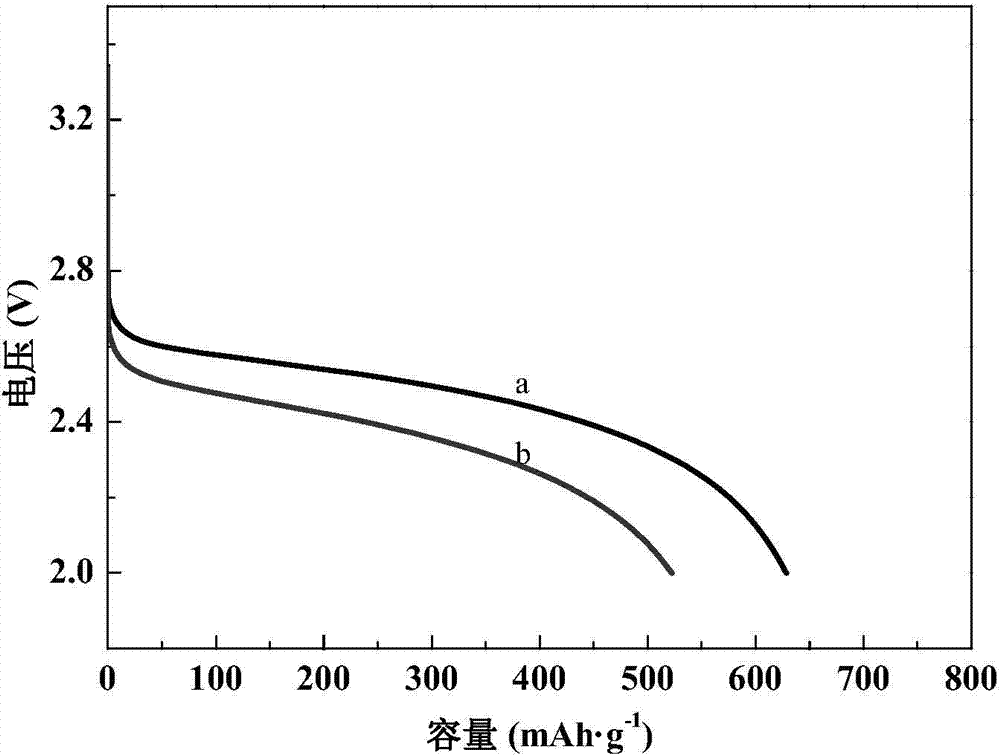

Low-temperature lithium iron phosphate lithium ion power battery and low-temperature discharging method thereof

PendingCN113707882AIncreased diffusion rateImprove growth efficiencyCell electrodesSecondary cells charging/dischargingElectrolytic agentCarbon layer

The invention discloses a low-temperature lithium iron phosphate lithium ion power battery and a low-temperature discharging method, and belongs to the technical field of batteries. The low-temperature lithium iron phosphate lithium ion power battery comprises a positive plate, a negative plate, a diaphragm, an electrolyte and a battery shell column. A positive material in the positive plate consists of a positive active material, a binder, a conductive agent and a positive current collector, the positive active material adopts a carbon-coated lithium iron phosphate material, and the thickness of a nano carbon layer in the carbon-coated lithium iron phosphate is 2-5nm. Polyvinylidene fluoride is adopted as the binder, one or more of conductive carbon black, conductive graphite, crystalline flake graphite and carbon nanotubes are adopted as the conductive agent, and aluminum foil is adopted as the current collector. According to the invention, through chelating of bis-1, 6-hexylidene triamine penta (methylene phosphonic acid) and Fe<2+> ions, a carbon layer is formed in situ, so that the growth activation energy of lithium phosphonate crystal grains can be remarkably reduced, a single crystal carbon-coated lithium phosphonate composite material is obtained, and the electrochemical performance of a battery in a low-temperature environment is improved.

Owner:江苏久泰电池科技有限公司

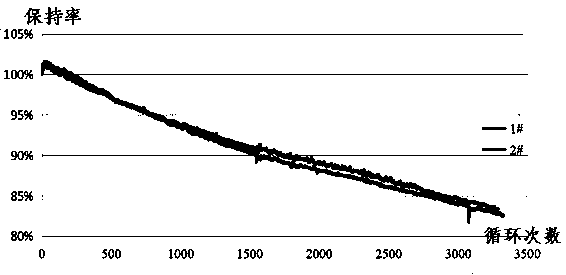

Star polymer used as lubricating oil viscosity index improver, preparation method and application thereof

The invention discloses a star polymer used as a lubricating oil viscosity index improver, a preparation method of the star polymer and application of the star polymer. The star polymer has asymmetrical arms and consists of two different types of polymer arms, wherein the first type of polymer arm is a hydrogenation polyisoprene homopolymer, and the second type of polymer arm is a copolymer in a hydrogenation polyisoprene-hydrogenation polybutadiene-polystyrene block structure; and in the copolymer arm, the polystyrene section is close to the core of the star polymer, the hydrogenation polybutadiene section is in the middle of the arm, and the hydrogenation isoprene section is outside the arm. The structure of the star polymer contains 2-15% of polybutadiene block by weight, and at least a part of the polyisoprene block and the polybutadiene block in the structure of the start polymer is hydrogenated. The star polymer has an excellent tackifying effect and excellent shear resistance stability, and is lower in pumping viscosity and low-temperature start viscosity during blending of thickened engine oil, and crystal or gel cannot be formed in the engine oil by the star polymer.

Owner:FUYANG JINGLUE CHEM TECH

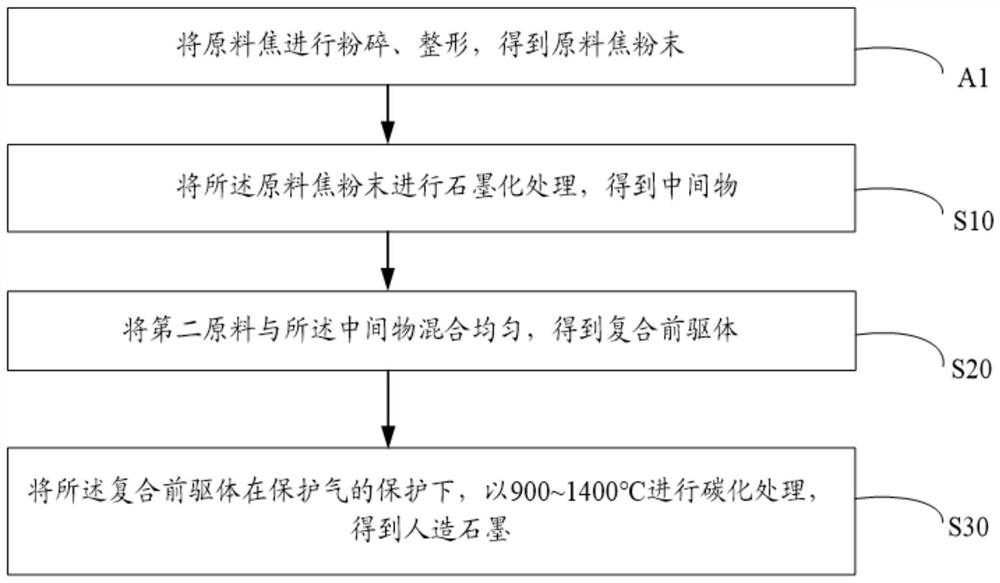

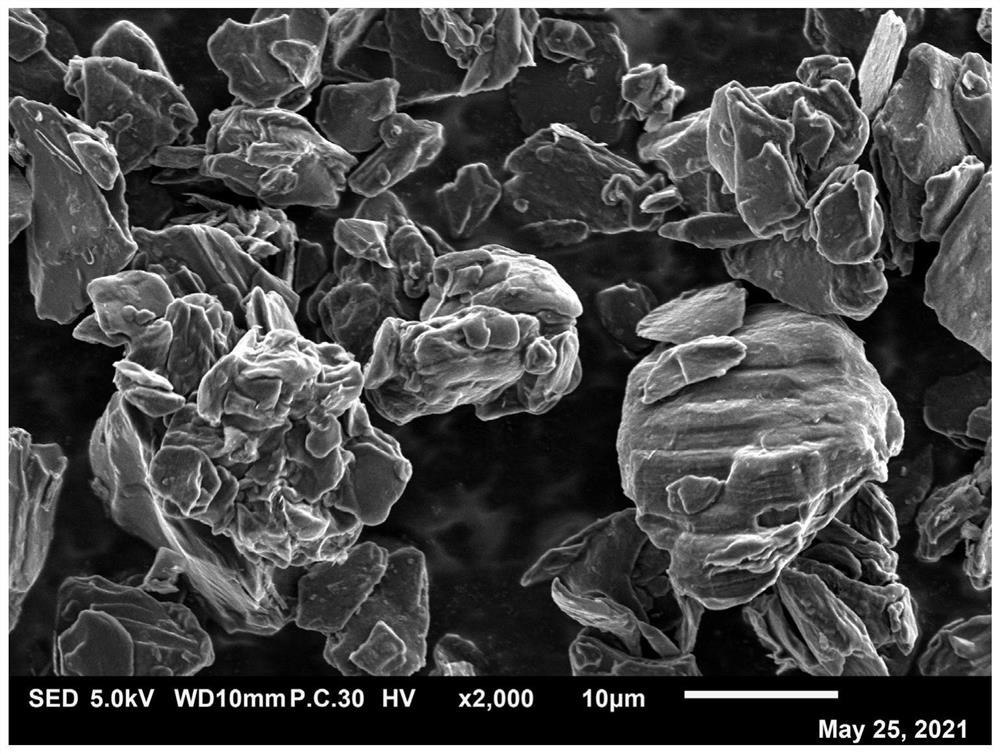

Preparation method of artificial graphite and lithium ion battery

PendingCN113955750AGood lookingImprove the problem of gas productionCarbon compoundsSecondary cellsInternal resistancePhysical chemistry

The invention discloses a preparation method of artificial graphite and a lithium ion battery. The preparation method of the artificial graphite comprises the following steps: S10, carrying out graphitization treatment on raw material coke powder to obtain an intermediate; s20, uniformly mixing a second raw material with the intermediate to obtain a composite precursor; amd s30, carrying out carbonization treatment on the composite precursor at 900-1400 DEG C under the protection of protective gas to obtain artificial graphite; wherein the second raw material comprises a liquid-phase coating agent. Through liquid phase coating, the surface morphology of the artificial graphite can be effectively improved, the specific surface area is reduced, active sites of side reactions are reduced, gas production of the lithium ion battery is reduced, volume expansion is reduced, and the safety performance of the lithium ion battery is improved; in addition, graphitization treatment is performed firstly and then coating is performed, so that the prepared artificial graphite has relatively good liquid absorption performance, the internal resistance is reduced, the low-temperature performance is improved, the reduction of the internal resistance is beneficial to the movement of lithium ions, and the prepared lithium ion battery has relatively good fast charging performance.

Owner:内蒙古斯诺新材料科技有限公司

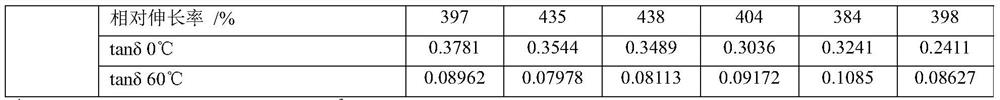

Rubber composition for tire tread and pneumatic tire

InactiveUS20190264011A1Reduced low temperature performanceImprove performanceSpecial tyresTyre tread bands/patternsVitrificationPolymer science

While suppressing a decrease in low-temperature performance, performance at ambient temperature, such as wet performance and dry performance, is improved. A rubber composition for a tire tread according to an embodiment includes, per 100 parts by mass of a rubber component containing a styrene-butadiene rubber having a glass transition temperature of −60° C. or less, 70 parts by mass or more of a reinforcing filler containing silica. The rubber composition has, when vulcanized, a storage modulus E′(−20° C.) at a temperature of −20° C. and a storage modulus E′(30° C.) at a temperature of 30° C. such that the ratio between E′(−20° C.) and E′(30° C.) measured under conditions of a frequency of 10 Hz, an initial strain of 10%, and a dynamic strain of ±0.25% satisfies 2.0≤E′(−20° C.) / E′(30° C.)≤3.0.

Owner:TOYO TIRE & RUBBER CO LTD

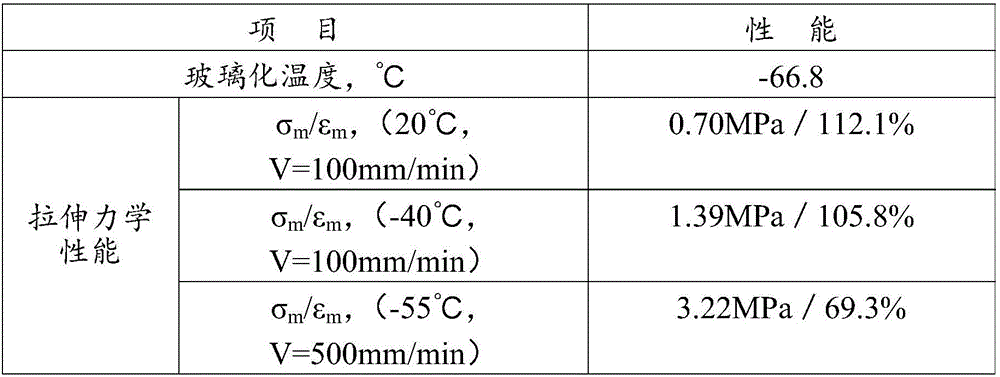

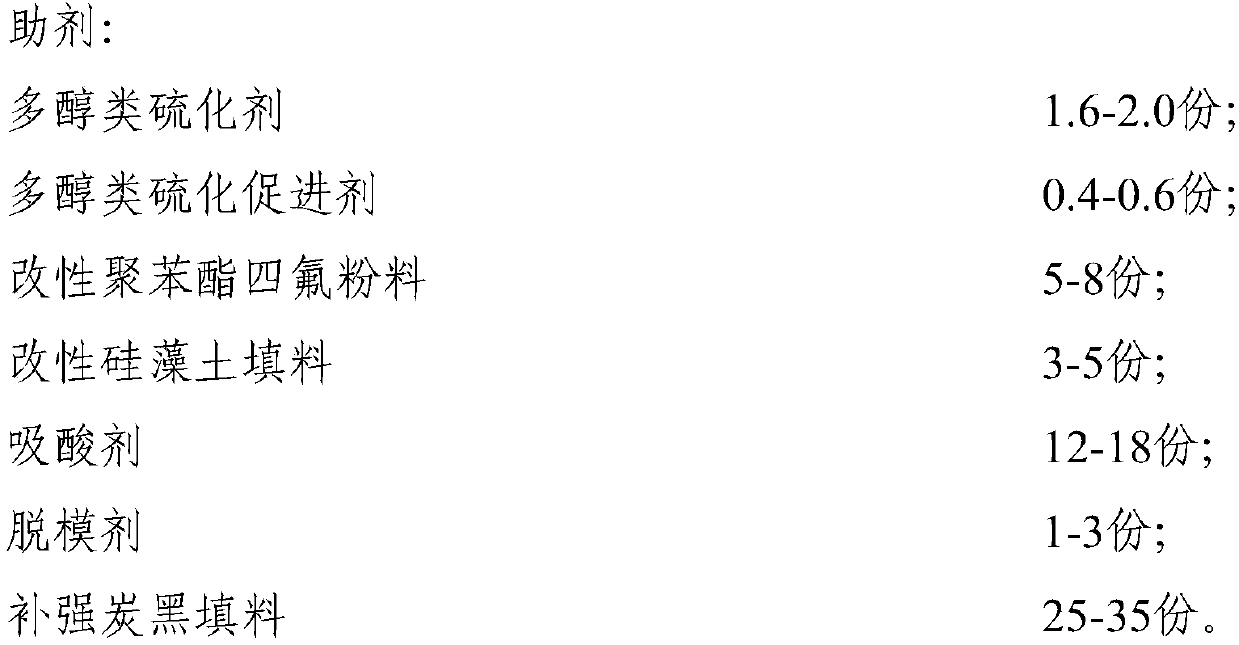

A kind of modified fluorine rubber compound and preparation method thereof

ActiveCN103772859BImprove physical performanceReduced low temperature performanceAviationVulcanization

The invention provides a modified fluororubber rubber compound and a preparation method thereof. The fluororubber takes modified binary fluororubber as a raw material; meanwhile, two vulcanization agent manners including a bisphenol vulcanization system and a peroxide vulcanization system are combined to carry out vulcanization; an auxiliary agent is increased and matched, and is mixed with the material to prepare the modified fluororubber rubber compound. The modified fluororubber rubber compound has excellent high heat resistance, cold resistance, low permeability and fuel oil resistance, and is applicable to industries including aerospace, aviation, cars, metallurgy, petrochemical engineering, electronics and the like; the performance on a sealing application is not too low and a problem caused by that an application environment is changed is not caused; the modified fluororubber rubber compound can be used as the first choice of a sealing material.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

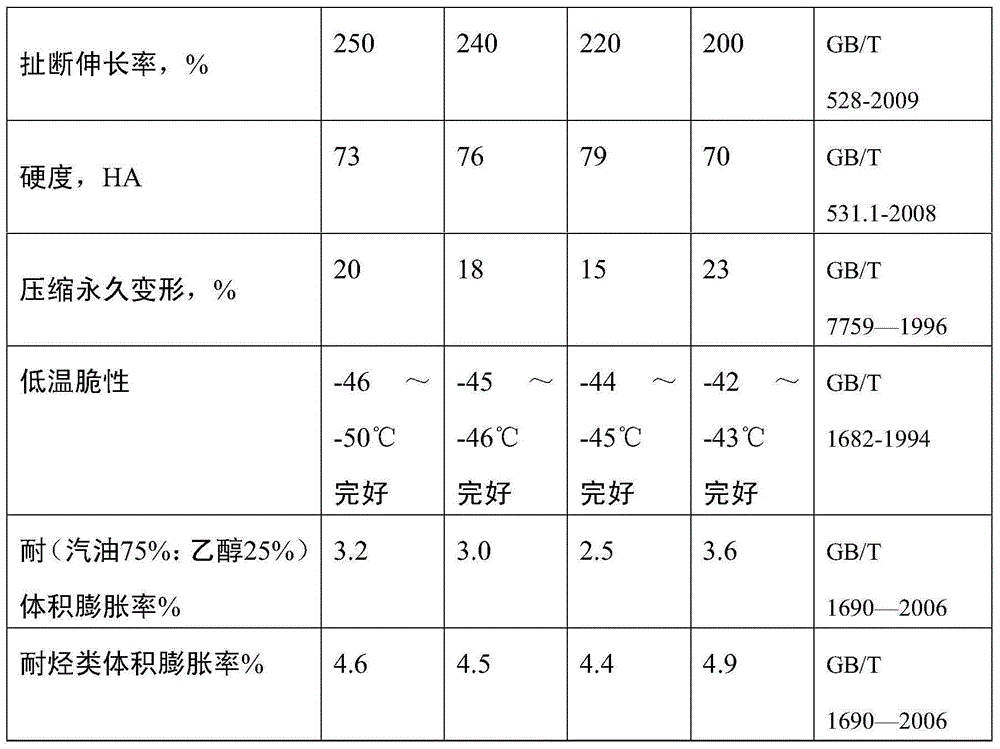

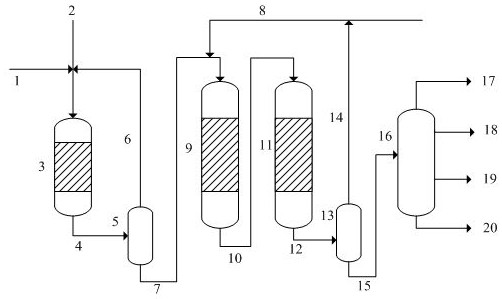

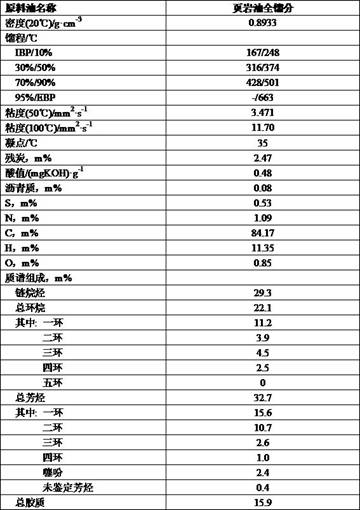

Hydrocracking method

ActiveCN114437799ASimple processEasy to operateTreatment with hydrotreatment processesFluid phasePhysical chemistry

The invention discloses a hydrocracking method. The method comprises the following steps: (1) high-nitrogen raw oil and hydrogen are mixed and enter a hydrogenation pretreatment reaction zone for reaction; (2) carrying out heat exchange on the reaction effluent in the step (1) or a liquid phase separated from the reaction flow in the step (1), and then, carrying out reaction in a hydrofining reaction zone; (3) effluent of the hydrofining reaction zone in the step (2) enters a hydrocracking reaction zone for hydrocracking reaction, the outlet temperature of the hydrofining reaction zone is T1, the inlet temperature of the hydrocracking reaction zone is T2, T1-T2 = T, and T is controlled to be greater than 5 DEG C; and (4) treating the reaction effluent in the step (3) through a separator to obtain different products. The method can be used for directly processing the full-fraction shale oil, and can run for a long period to produce high-quality diesel oil and gasoline by adopting a once-through process flow.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aggregate for lowering pavement temperature and method for preparing bitumen mixture by utilizing same

InactiveCN101830658BImprove road performanceImprove water stabilitySolid waste managementClimate change adaptationThermal coefficientRoad surface

The invention discloses an aggregate for lowering pavement temperature and a method for preparing a bitumen mixture by utilizing the same, which relates to an aggregate and a method for preparing a bitumen mixture by utilizing the aggregate, and solves the problems that the existing stone serving as the aggregate for paving a highway wearing layer has large thermal coefficient and high cost. The aggregate for lowering the pavement temperature of the invention is wasted ceramic particles with the grain diameter of 4.75mm-9.5mm. The method for preparing the bitumen mixture by utilizing the aggregate comprises the following steps: 1), computing needed stones with various grain diameters according to the grading mode of the wearing layer; 2), utilizing the aggregate to substitute for 18%-22% of the volume of the stone with the grain diameter of 4.75mm-9.5mm, weighting, and evenly mixing; and 3), preparing the mixed aggregate, mineral powder, slaked lime and bitumen into the bitumen mixture by the conventional method. The invention has low cost, and the thermal coefficient of the prepared wearing layer is 0.680W / m.DEG C-0.690W / m.DEG C, thus track diseases and the urban heat land effectare reduced, and the aggregate can be used for paving highways.

Owner:HARBIN INST OF TECH

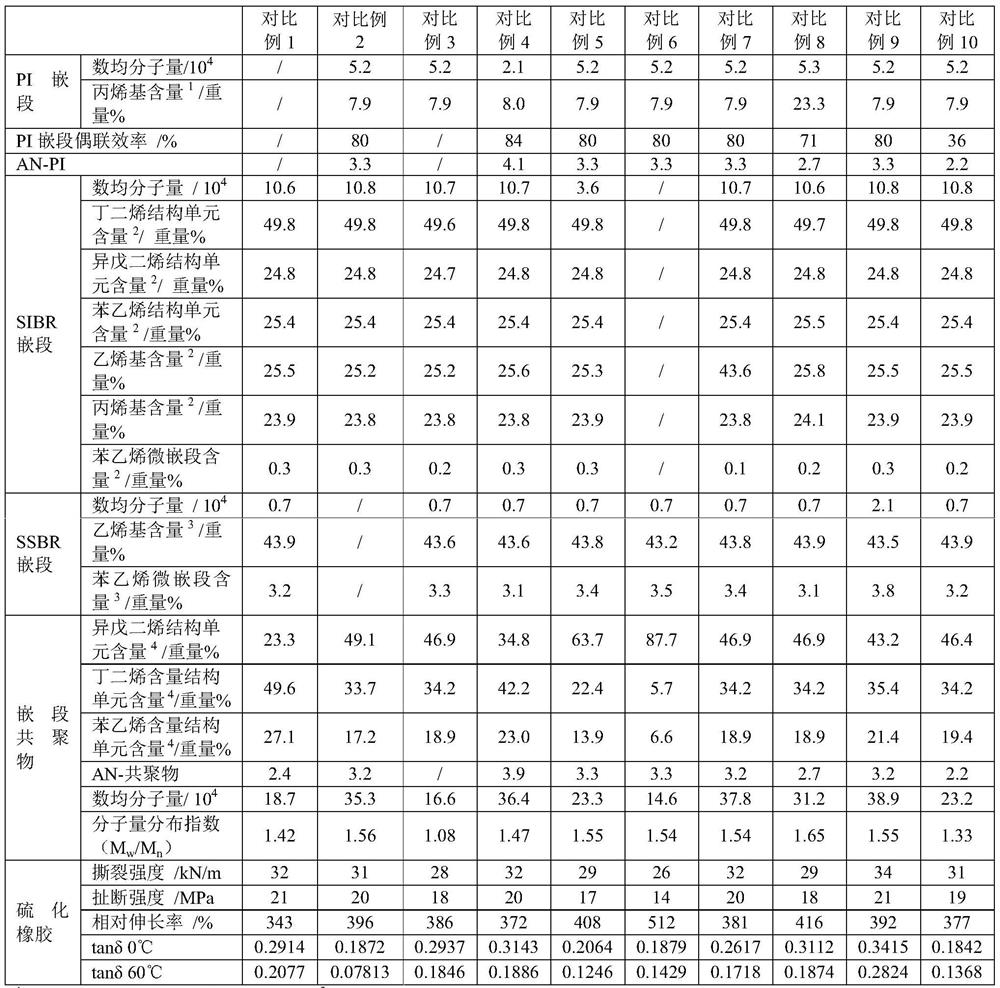

Block copolymer and block copolymer composition and its preparation method and vulcanized rubber and application and tire tread and tire

ActiveCN111217969BUniform performanceReduce rolling resistanceSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

The invention discloses a block copolymer and composition, its preparation method, vulcanized rubber and application, tread rubber and tire. The block copolymer according to the present invention contains PI block, SIBR block and SSBR block, and the vinyl content of PI block is relatively low, and the vinyl content, propenyl content and styrene content in SIBR block are moderate, and SSBR block The vinyl content and styrene content in the medium are relatively high, and the block copolymer also contains linking units derived from compounds shown in formula I, part of the SIBR block is connected to the PI block through the linking unit, and the remaining part of the SIBR block is directly connected to the The PI blocks are connected, and at least part of the SSBR blocks are directly connected to the SIBR blocks. While the copolymer rubber can obtain good wet skid resistance, the rolling resistance is also significantly reduced, and has better comprehensive physical and mechanical properties, and is particularly suitable as a tire tread rubber. CH 2 =CH‑R 1 -CH=CH 2 (Formula I).

Owner:CHINA PETROLEUM & CHEM CORP +1

Casting method of low temperature resistant iron cushion plate for high speed railway buckling part

The invention discloses a casting method of a low temperature resistant iron cushion plate for a high speed railway buckling part. The method comprises smelting, spheroidizing inoculation and casting, a smelting material is made of cast iron and low-carbon steel which meets requirements that P: <=0.04% and S: <=0.03%, smelted iron water is subjected to nodulizing and inoculation and then is subjected to casting molding, and hot processing is conducted to obtain the required iron cushion plate. According to the casting method, the quantity of ferrites can be increased, the low-temperature toughness is improved, and the anti-impact performance of the iron cushion plate can be improved further.

Owner:中原利达铁路轨道技术发展有限公司

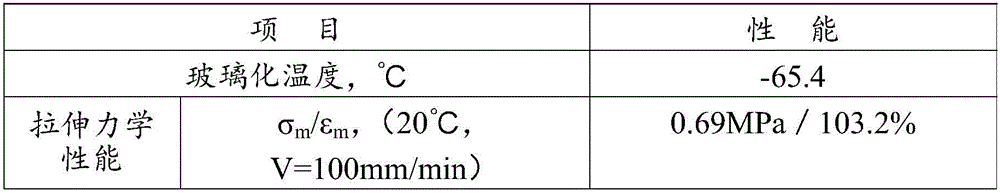

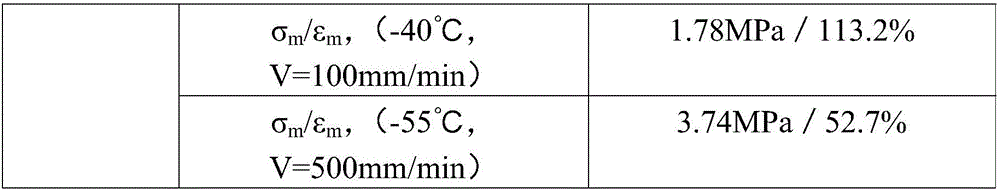

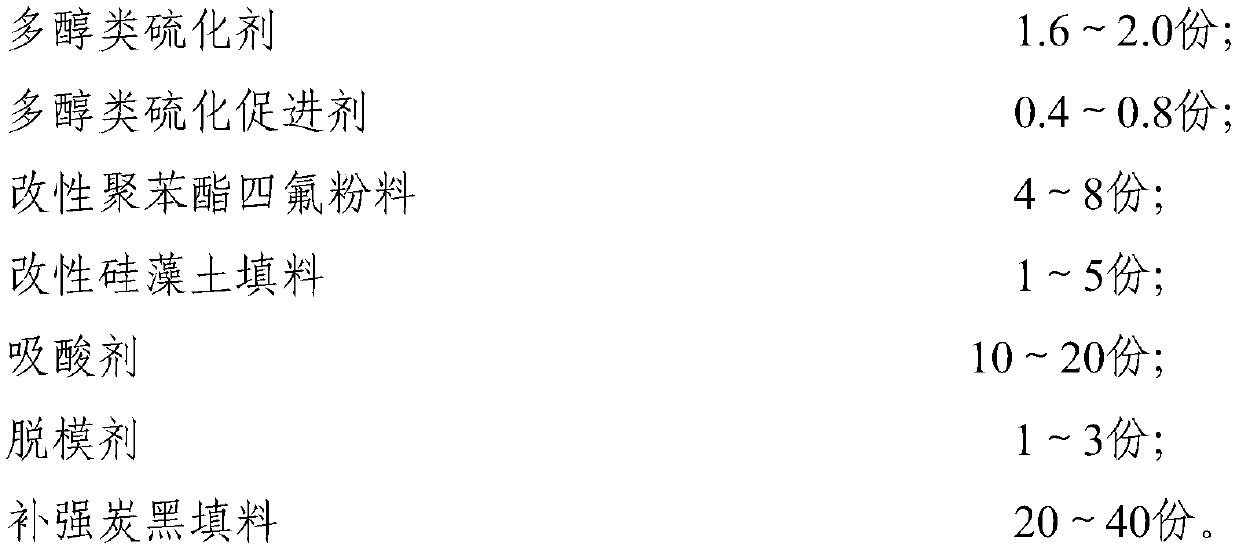

A kind of fluorine rubber compound with low temperature flexibility and high wear resistance and preparation method

ActiveCN110835446BGood physical and mechanical propertiesReduced low temperature performanceMasterbatchHigh wear resistance

The invention relates to a fluororubber compound rubber with low temperature flexibility and high wear resistance and a preparation method thereof. The raw materials for preparing the compound rubber include: main ingredients: fluororubber modified low temperature raw rubber, fluororubber raw rubber, graphene master material; auxiliary agent: modified polyphenylene tetrafluoro powder; wherein, the fluororubber modified low-temperature raw rubber is a low-temperature raw rubber with a vulcanization point monomer; the modified polyphenylene tetrafluoro powder is The polyphenylene ester and the tetrafluoro micropowder are obtained through modification in the presence of a silane coupling agent; the graphene master batch is a graphene master batch of raw rubber based on ternary rubber. By adding modified raw rubber and new additives in a mixing ratio, the fluorine rubber compound obtained by using a special mixing method and vulcanization process improves the low-temperature performance of the rubber compound and improves the wear resistance of the rubber compound at low temperatures. Performance and mechanical properties, while meeting the application as a low-temperature sealing material, it can replace foreign products.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

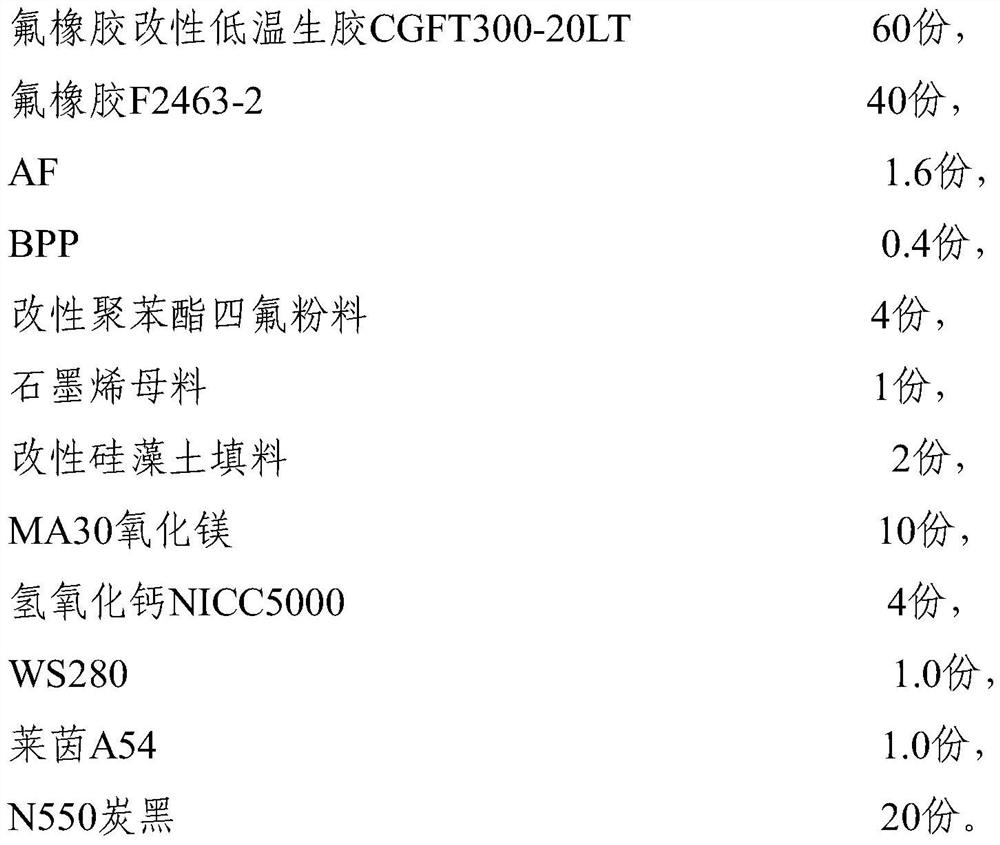

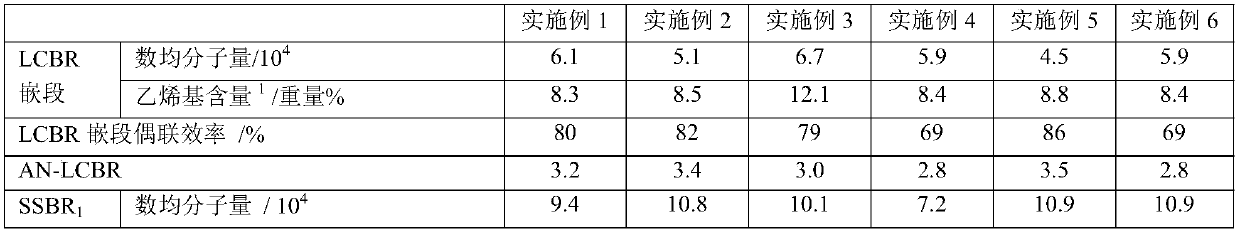

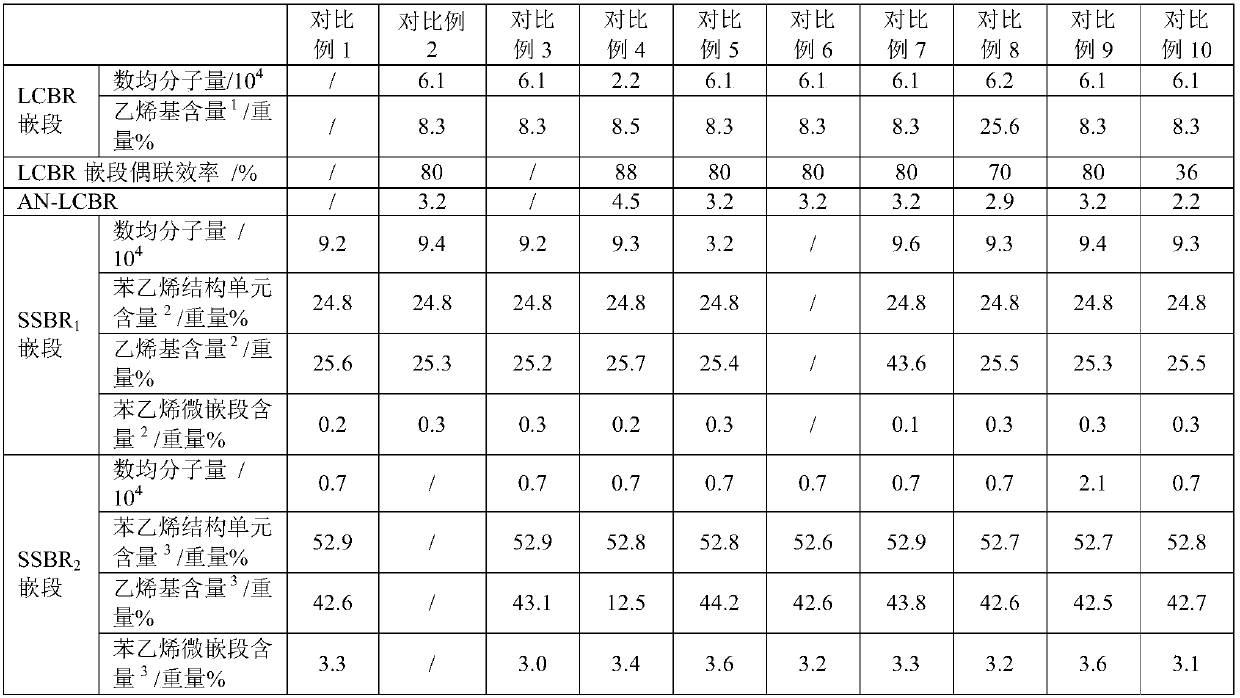

Block copolymer, block copolymer composition, preparation method of block copolymer, vulcanized rubber, application of vulcanized rubber, tire tread and tire

ActiveCN111072879AReduce rolling resistanceImprove wet skid resistanceSpecial tyresRolling resistance optimizationPolymer chemistryStyrene

The invention discloses a block copolymer, a composition and a preparation method thereof, a vulcanized rubber and applications thereof, a tread rubber and a tire. According to the invention, the block copolymer contains an LCBR block, an SSBR1 block and an SSBR2 block, wherein the content of vinyl in the LCBR block is low, the content of vinyl and the content of styrene in the SSBR1 block are moderate, and the content of vinyl and the content of styrene in the SSBR2 block are high; the block copolymer further comprises a connecting unit derived from a compound represented by a formula I, wherein part of the SSBR1 block is connected with the LCBR block through the connecting unit, the rest SSBR1 block is directly connected with the LCBR block, and at least part of the SSBR2 block is directly connected with the SSBR1 block; the copolymer rubber can obtain favorable wet skid resistance, obviously lowers the rolling resistance, has favorable comprehensive physical and mechanical properties, and is especially suitable to be used as tread rubber of tires; and the formula I is CH2=CH-R1-CH=CH2.

Owner:CHINA PETROLEUM & CHEM CORP +1

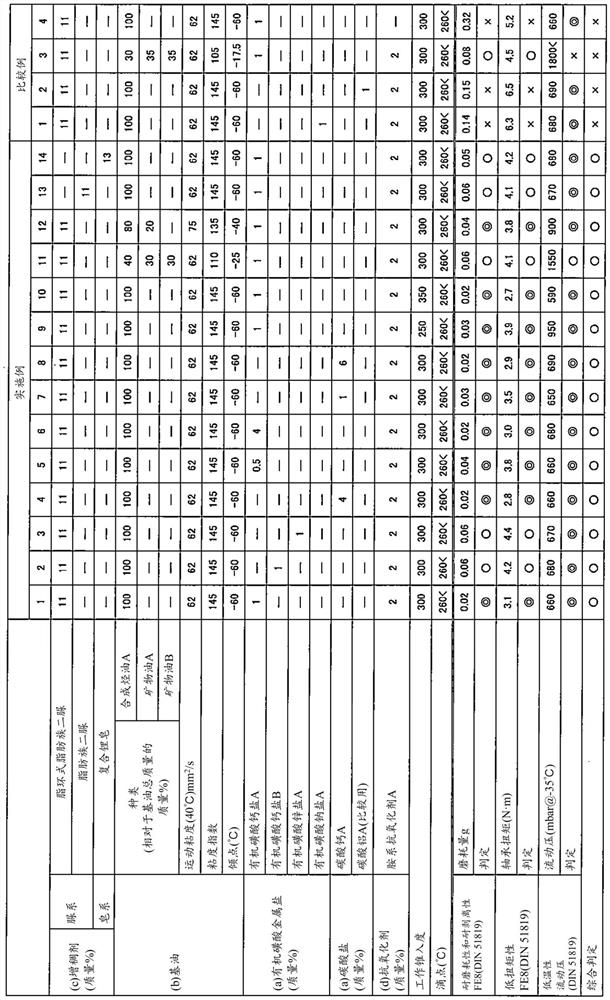

Grease composition for tapered roller bearing

PendingCN113166673AExcellent abrasion resistanceEnhanced resistance to peelingRoller bearingsShaftsEngineeringAnti oxidant

Owner:KYODO YUSHI CO LTD

A kind of low temperature resistant sponge sealing strip and preparation method thereof

The invention discloses a low-temperature-resistant sponge sealing strip and a preparation method thereof, which overcomes the defects of EPDM rubber in the prior art that the seal becomes hard and the rebound elasticity is weakened in the alpine region. A low-temperature-resistant sponge sealing strip in the present invention comprises the following raw materials in parts by weight: 70-80 parts of EPDM, 20-40 parts of butadiene rubber, 5-15 parts of resin, 5-15 parts of low-temperature resistant additive, and carbon black 80-115 parts, 10-30 parts of filler, 50-70 parts of paraffin oil, 0.8-1.2 parts of vulcanizing agent, 2.5-3.5 parts of vulcanization accelerator, 0.2-0.5 parts of anti-scorch agent, 2-5 parts of foaming agent, Hygroscopic agent 3-6 parts. The invention adopts resin, butadiene rubber, low-temperature resistance additive and EPDM to compound, which can effectively improve the cold resistance and low-temperature rebound performance of the product.

Owner:HENNIGES (CHINA) AUTOMOTIVE SEALING SYST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com