Low-temperature lithium iron phosphate lithium ion power battery and low-temperature discharging method thereof

A power battery, lithium iron phosphate technology, applied in the direction of secondary battery charging/discharging, battery electrodes, secondary batteries, etc., can solve the problem of electrochemical performance to be improved, reduce the growth activation energy, improve the discharge capacity, improve the Effects of Diffusion Rate and Growth Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

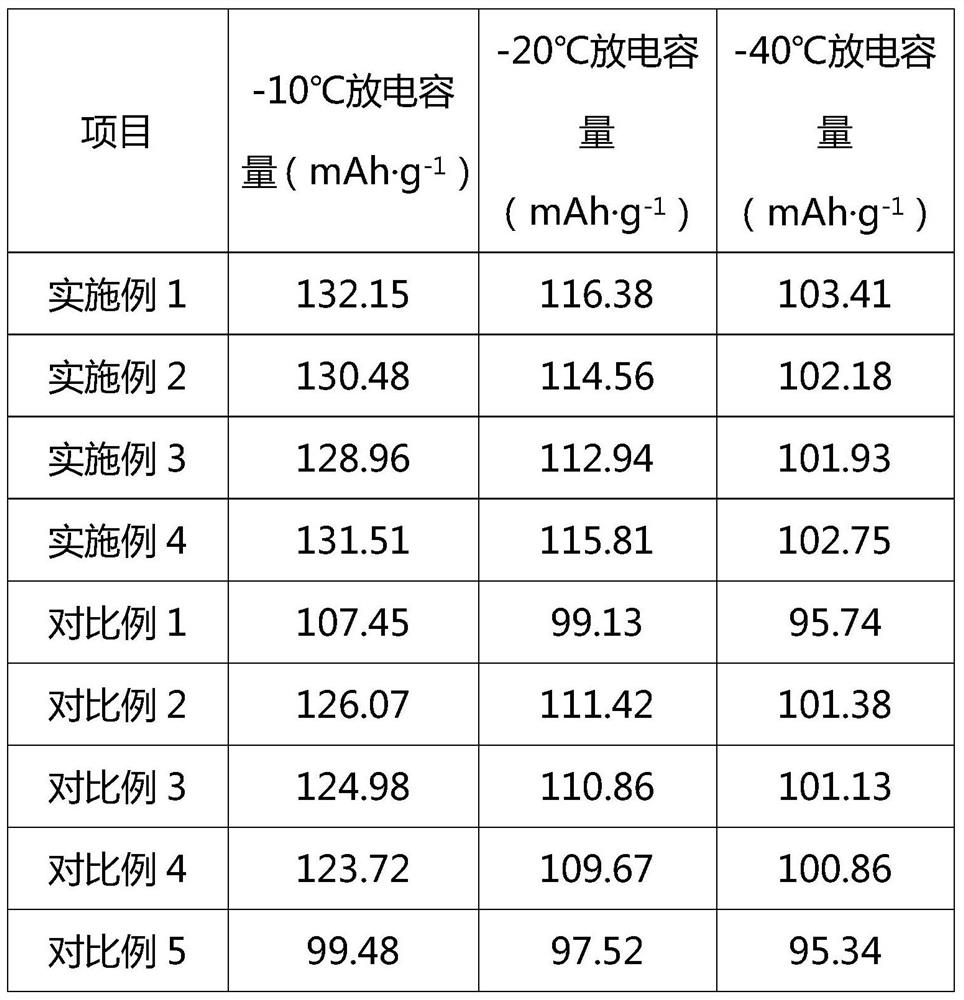

Examples

preparation example Construction

[0032] The preparation method of the power battery is as follows: adding N-methylpyrrolidone to the mixed solution of positive electrode active material, binder and conductive agent, stirring in vacuum for 4-6 hours under the condition of circulating water cooling, and passing through a 150-mesh sieve Make a slurry 1-2 times, coat the slurry on an aluminum sheet, and dry it in vacuum at 50°C-60°C for 6-8h to make the positive electrode sheet of the battery;

[0033] Stir the negative electrode active material in deionized water for 3-5 hours, add binder, thickener, and conductive agent and stir for 2-3 hours, pass the slurry through a colloid mill to completely disperse the conductive agent, and pass through a 150-mesh sieve for 1- The slurry is made twice, the slurry is coated on the aluminum sheet, and vacuum-dried at 50°C-60°C for 6-8h to make the negative electrode sheet of the battery; the compacted density of the positive electrode is 2.5-3.5g / cm 3 , the compacted densit...

Embodiment 1

[0038] A low-temperature lithium iron phosphate lithium-ion power battery, comprising a positive electrode sheet, a negative electrode sheet, a diaphragm, an electrolyte, and a battery case column, and the positive electrode material in the positive electrode sheet is composed of a positive electrode active material, a binder, a conductive agent and a positive electrode The composition of the current collector, the dosage ratio of the positive electrode active material, the binder, and the conductive agent is 90:5:8; the positive electrode active material is made of carbon-coated lithium iron phosphate material, and the thickness of the nano-carbon layer in the carbon-coated lithium iron phosphate is It is 2-5nm thick, and the preparation method of carbon-coated lithium iron phosphate is to weigh bis-1,6-hexamethylene triamine pentamethylene with a molar ratio of P:Fe:Li of 1.2:1.5:3.2 Dissolve phosphonic acid, ferrous carbonate, and lithium hydroxide in deionized water, then a...

Embodiment 2

[0047] A low-temperature lithium iron phosphate lithium-ion power battery, comprising a positive electrode sheet, a negative electrode sheet, a diaphragm, an electrolyte, and a battery case column, and the positive electrode material in the positive electrode sheet is composed of a positive electrode active material, a binder, a conductive agent and a positive electrode The composition of the current collector, the dosage ratio of the positive electrode active material, the binder, and the conductive agent is 93:8:12; the positive electrode active material is made of carbon-coated lithium iron phosphate material, and the thickness of the nano-carbon layer in the carbon-coated lithium iron phosphate is It is 2-5nm thick, and the preparation method of carbon-coated lithium iron phosphate is to weigh bis-1,6-hexamethylene triamine pentamethylene with a molar ratio of P:Fe:Li of 1.2:1.5:3.2 Dissolve phosphonic acid, ferrous carbonate, and lithium hydroxide in deionized water, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com