Sodium ion battery electrolyte additive, electrolyte and sodium ion battery

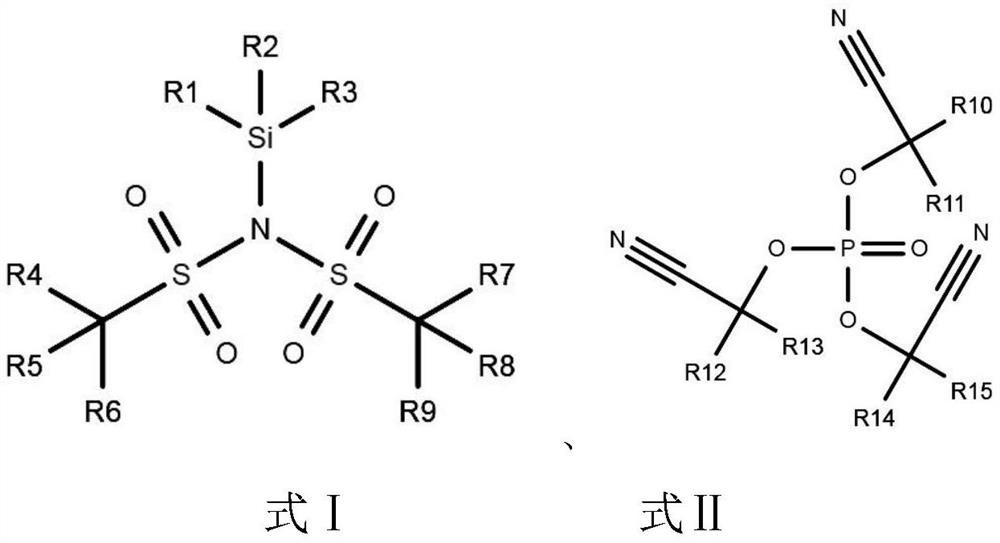

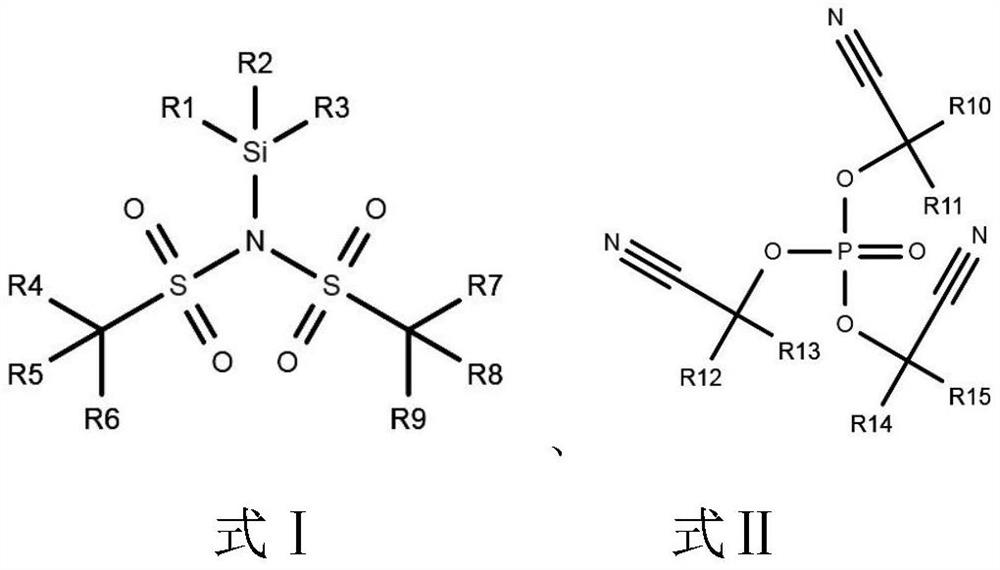

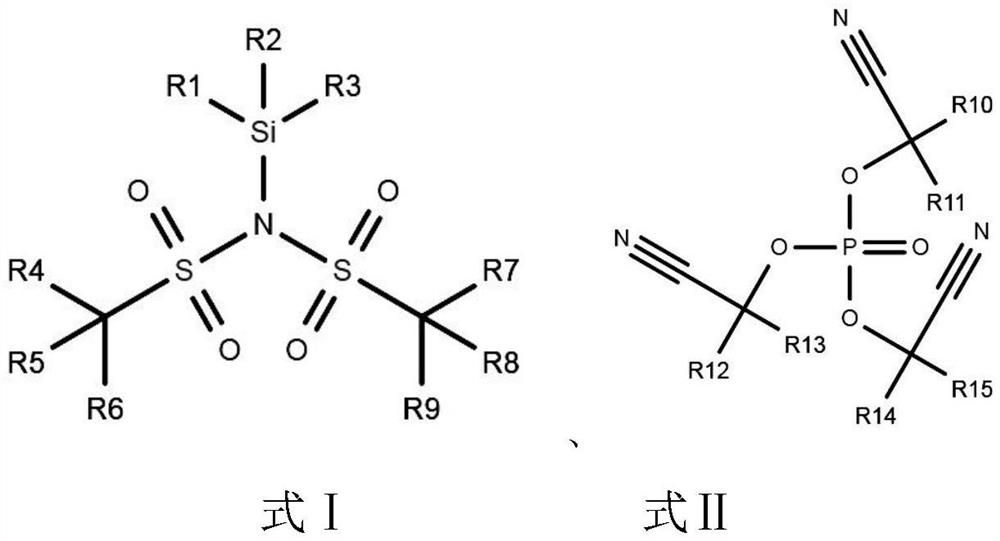

An electrolyte additive, sodium ion battery technology, applied in electrolytes, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of restricted application, low initial efficiency, poor cycle performance of sodium ion batteries, etc. The effect of low internal resistance, film formation resistance, and improved battery cycle and high temperature storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Positive electrode preparation: the positive electrode material Na 1.72 MnFe(CN) 6 , binder PVDF, and conductive agent Super-P are dispersed in NMP organic solvent at a mass ratio of 90:4:6, stirred until stable and uniform under the action of a vacuum mixer, and evenly coated on an aluminum foil with a thickness of 12 μm. After the aluminum foil was dried at room temperature, it was transferred to a blast oven at 120° C. to dry for 1 hour, and then cold pressed and die-cut to form a positive electrode sheet.

[0042] Negative electrode preparation: According to the mass ratio of 97:2:1, spherical hard carbon, binder PVDF, and conductive agent Super-P are mixed together, dispersed in NMP organic solvent, and evenly coated on aluminum foil with a thickness of 15 μm. After the aluminum foil was dried at room temperature, it was transferred to a blast oven at 120°C to dry for 1 hour, and then cold pressed and die-cut to form a negative electrode sheet.

[0043] Electroly...

Embodiment 2

[0051] The difference from Example 1 is that the sodium salt solution, organic solvent, additive a and additive b are 14 parts, 82 parts, 2 parts and 2 parts by weight.

[0052] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] The difference from Example 1 is that the sodium salt solution, organic solvent, additive a and additive b are 14 parts, 79 parts, 5 parts and 2 parts by weight.

[0055] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com