Low-temperature-resistant sponge sealing strip and preparation method thereof

A technology of low temperature resistant and sealing strips, which is applied in the field of low temperature resistant sponge sealing strips and its preparation, can solve the problems of hardening of seals, weakening of resilience, difficulty in sealing and opening and closing doors, etc., reducing the possibility of achieving, improving cold resistance, increasing Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

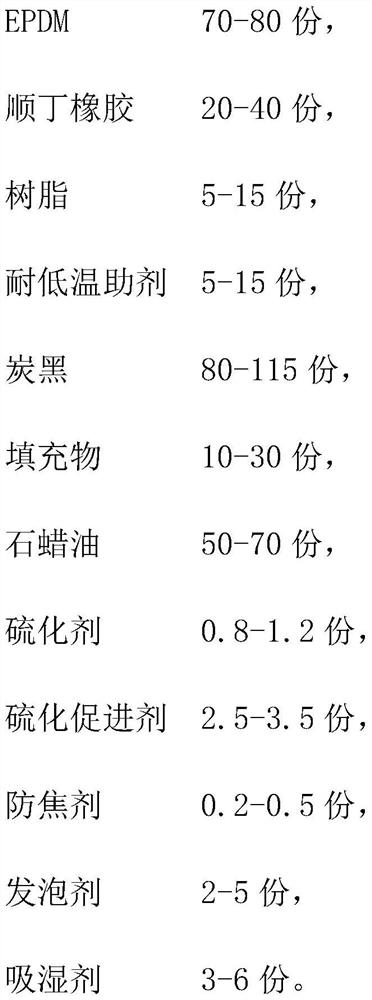

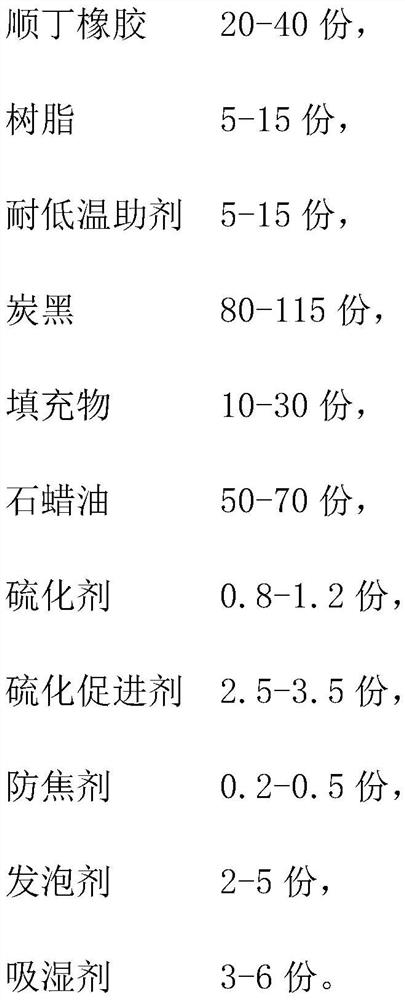

Method used

Image

Examples

Embodiment 1

[0034] A low temperature resistant sponge sealing strip, raw materials include: 70 parts of EPDM, 30 parts of BR, 10 parts of resin, 5 parts of low temperature resistance additive, 5 parts of active zinc oxide, 1 part of stearic acid, 1 part of PEG-4000, quick pressing 50 parts of carbon black, 30 parts of high-structure semi-reinforcing carbon black, 20 parts of light calcium carbonate, 70 parts of high flash point and low pour point paraffin oil; 1.2 parts of sulfur, 2.8 parts of vulcanization accelerator, 2.5 parts of foaming agent, 0.4 parts of anti-scorch agent, 5 parts of KEZADOL GR;

[0035] Among them, in EPDM, ENB content is 9%, ethylene content is 44%, Mooney viscosity ML 1+8 150°C is 60; Mooney viscosity ML of BR 1+4 100°C is 45; the resin is p-tert-octylphenol formaldehyde resin; the low-temperature resistance additive is anti-cold agent A of Anhui Weide Rubber and Plastic Technology, and the composition is diene polymer; the model of quick-pressed carbon black ...

Embodiment 2

[0045] A low-temperature-resistant sponge sealing strip, the difference from Example 1 is that the amount of raw materials is different, and the raw materials include: 70 parts of EPDM, 30 parts of BR, 10 parts of resin, 15 parts of low-temperature resistant additives, 5 parts of active zinc oxide, stearic acid 1 part, 1 part of polyethylene glycol, 50 parts of fast extruded carbon black, 30 parts of high-structure semi-reinforcing carbon black, 20 parts of light calcium carbonate, 70 parts of paraffin oil with high flash point and low pour point; 1.2 parts of sulfur, 2.8 parts of vulcanization accelerator, 2.5 parts of foaming agent, 0.4 parts of anti-scorch agent, 5 parts of GR.

Embodiment 3

[0047] A low-temperature-resistant sponge sealing strip, the difference from Example 1 is that the amount of raw materials is different, and the raw materials include: 70 parts of EPDM, 40 parts of BR, 10 parts of resin, 15 parts of low-temperature resistant additives, 5 parts of active zinc oxide, stearic acid 1 part, 1 part of polyethylene glycol, 50 parts of fast extruded carbon black, 30 parts of high-structure semi-reinforcing carbon black, 20 parts of light calcium carbonate, 70 parts of paraffin oil with high flash point and low pour point; 1.2 parts of sulfur, 2.8 parts of vulcanization accelerator, 2.5 parts of foaming agent, 0.3 parts of anti-scorch agent, 5 parts of GR.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com