Negative lead paste for lead-acid storage battery and preparation method thereof

A lead-acid battery and negative electrode paste technology, which is applied in the direction of lead-acid battery electrodes, battery electrodes, negative electrodes, etc., can solve the problems of easy dissolution of lignin, battery performance degradation, etc., to reduce the shrinkage of negative active materials and improve the rate performance , the effect of good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

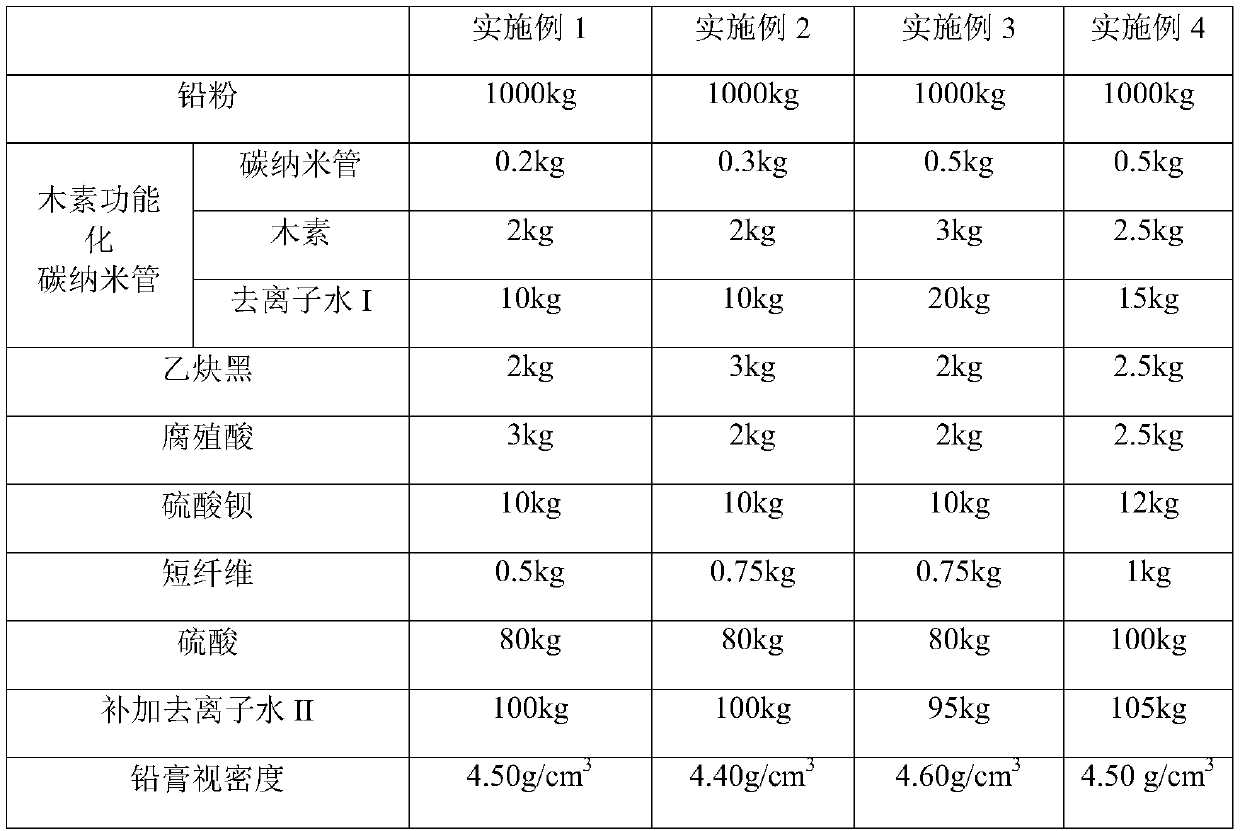

Examples

Embodiment 1

[0034] (1) according to the formula table of table 1, add deionized water I 10kg, outer diameter to be 5nm, interlayer spacing be 0.2kg and lignin 2kg in the high-energy nanoscale dispersion ball mill respectively;

[0035] (2) Add zirconia grinding beads for grinding, ball mill and mix for 30min at a speed of 300r / min, filter the grinding beads to obtain lignin-functionalized carbon nanotubes, and set aside;

[0036] (3) Add 1000kg of lead powder, 3kg of humic acid, 2kg of acetylene black, 10kg of barium sulfate and 0.5kg of polyacrylonitrile fiber into the paste mixing machine, and dry mix for 7 minutes;

[0037] (4) The lignin-functionalized carbon nanotube dispersion obtained in step (2) is quickly added to the paste mixer at one time, and 100 kg of deionized water II is added, and wet mixed for 5 minutes;

[0038] (5) Slowly add a sulfuric acid solution with a density of 1.4g / ml to the pasting machine, stir while adding, and control the addition within 15 minutes. After a...

Embodiment 2

[0040] (1) according to the formula table of table 1, add deionized water I 10kg, outer diameter to be 50nm, layer spacing be 0.3kg and lignin 2kg of multi-walled carbon nanotubes of 0.5nm respectively in high-energy nanoscale dispersion ball mill;

[0041] (2) Add silicon oxide grinding beads for grinding, ball mill and mix for 20 minutes at a speed of 500r / min, filter the grinding beads to obtain lignin-functionalized carbon nanotubes, and set aside;

[0042](3) Add 1000kg of lead powder, 2kg of humic acid, 3kg of acetylene black, 10kg of barium sulfate and 0.75kg of polypropylene fiber to the paste mixing machine, and dry mix for 5 minutes;

[0043] (4) The lignin-functionalized carbon nanotube dispersion obtained in step (2) is quickly added to the paste mixer at one time, and 100 kg of deionized water II is added, and wet mixed for 3 minutes;

[0044] (5) Slowly add a sulfuric acid solution with a density of 1.3g / ml into the pasting machine, stir while adding, and control...

Embodiment 3

[0046] (1) according to the formula table of table 1, add deionized water 1 20kg, carbon outer diameter respectively in the high-energy nanoscale dispersion ball mill that 25nm, interlayer spacing are 0.5kg and lignin 3kg for multi-walled carbon nanotubes of 0.4nm;

[0047] (2) Add agate beads for grinding, ball mill and mix for 10 min at a speed of 800r / min, filter out the grinding beads to obtain lignin-functionalized carbon nanotubes, and set aside;

[0048] (3) Add 1000kg of lead powder, 2kg of humic acid, 2kg of acetylene black, 10kg of barium sulfate, 0.25kg of polypropylene fiber and 0.5kg of polyester fiber into the paste mixing machine, and dry mix for 3 minutes;

[0049] (4) The lignin-functionalized carbon nanotubes obtained in step (2) are quickly added to the paste mixer at one time, and 95 kg of deionized water II is added, and wet mixed for 7 minutes;

[0050] (5) Slowly add a sulfuric acid solution with a density of 1.4g / ml to the pasting machine, stir while ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com