Preparation method of artificial graphite and lithium ion battery

A technology of artificial graphite and graphitization treatment, which is applied in the direction of secondary batteries, battery electrodes, chemical instruments and methods, etc., can solve the problems of poor fast charging performance and safety performance of lithium-ion batteries, irregular shape of single-particle artificial graphite powder, lithium Ion transport slow kinetics and poor performance, to achieve the effect of favorable internal resistance, reduced internal resistance, and good liquid absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

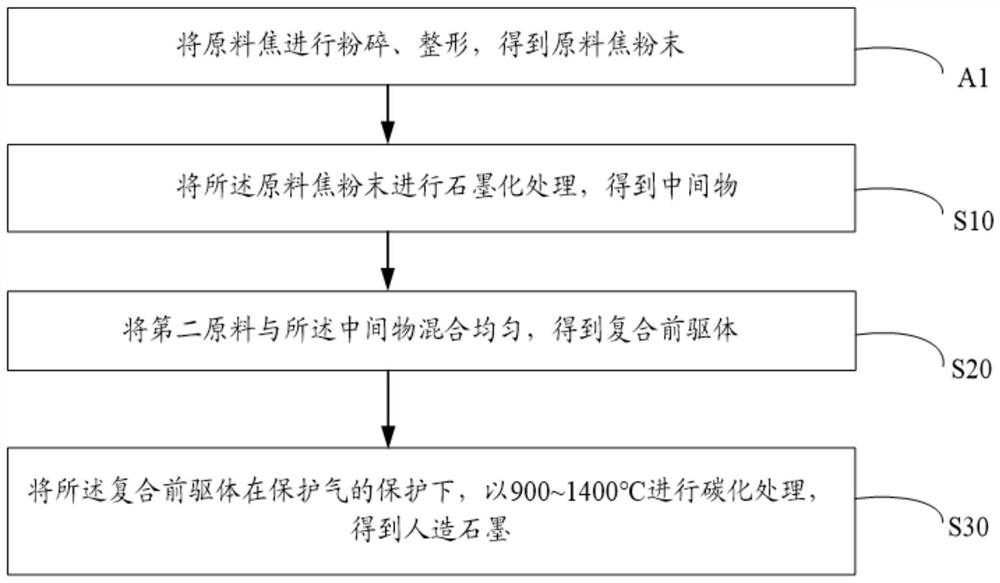

[0030] In view of this, the present invention proposes a kind of preparation method of artificial graphite, in one embodiment, described preparation method comprises the following steps:

[0031] Step S10, subjecting the raw coke powder to graphitization treatment to obtain an intermediate;

[0032] Step S20, uniformly mixing the second raw material and the intermediate to obtain a composite precursor;

[0033] Step S30 , carbonizing the composite precursor at 900-1400° C. under the protection of protective gas to obtain artificial graphite.

[0034] In this embodiment, the particle size of the raw coke powder is 4-15 μm. By selecting raw coke with a small particle size, the channel resistance for lithium ions to enter the graphite layer can be shortened, so that the obtained artificial graphite exhibits more excellent performance. rate performance and low temperature performance. Wherein, the temperature of the graphitization treatment is 2800-3200°C.

[0035] In one embod...

Embodiment 1

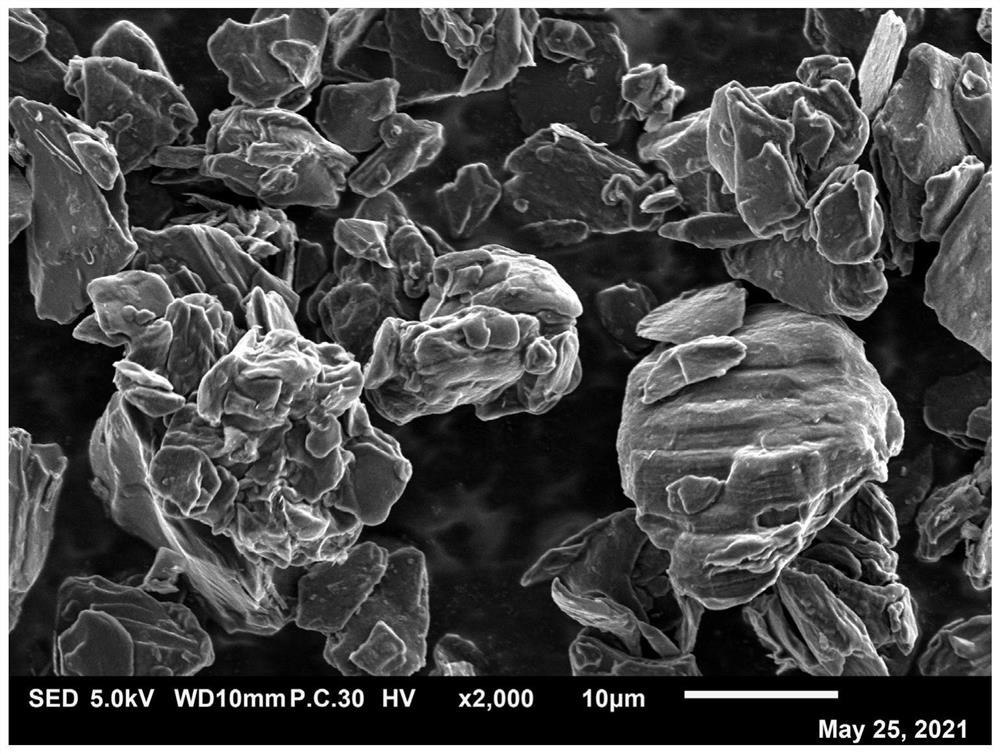

[0052] (1) Putting the needle coke into a mechanical crushing and shaping machine for crushing and shaping to obtain needle coke powder, the particle size D50 of the needle coke powder is 6 μm.

[0053] (2) The needle coke powder is graphitized at a high temperature in an Acheson furnace to obtain an intermediate product, wherein the graphitization temperature is 3000°C.

[0054] (3) The liquid-phase coating agent (a mixture of coal tar and pitch oil) and the conductive agent (carbon nanotubes) are stirred and mixed at high speed in a container, wherein the mass ratio of the liquid-phase coating agent to the conductive agent is 1 : 1 (that is, the mass fraction of the conductive agent is 50%), after compounding, the second raw material is obtained.

[0055] (4) Under a nitrogen atmosphere, mix the intermediate and the above-mentioned second raw material in a mixer at high speed, wherein the mass ratio of the second raw material to the intermediate is 5:95 to obtain a composite...

Embodiment 2

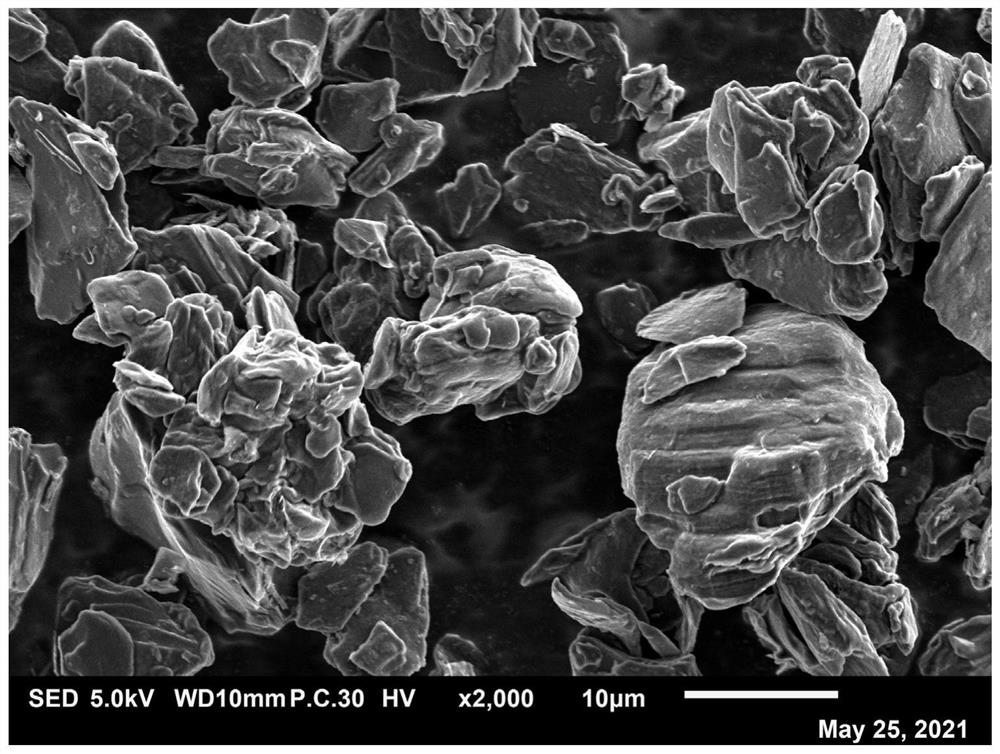

[0058] (1) Putting the needle coke into a mechanical crushing and shaping machine for crushing and shaping to obtain needle coke powder, the particle size D50 of the needle coke powder is 10 μm.

[0059] (2) The needle coke powder is graphitized at a high temperature in an Acheson furnace to obtain an intermediate product, wherein the graphitization temperature is 3000°C.

[0060] (3) Stir and mix the liquid-phase coating agent (liquid pitch) and the conductive agent (carbon black) in a container at high speed, wherein the mass ratio of the liquid-phase coating agent to the conductive agent is 6:4 (that is, the conductive agent The mass fraction of is 40%), compound and obtain the second raw material.

[0061] (4) Under a nitrogen atmosphere, mix the intermediate and the above-mentioned second raw material in a mixer at high speed, wherein the mass ratio of the second raw material to the intermediate is 8:92 to obtain a composite precursor.

[0062] (5) The composite precurso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com