Hydrocracking method

A hydrocracking and hydropretreatment technology, applied in hydrotreating process, treatment of hydrocarbon oil, petroleum industry, etc., can solve problems such as poor product quality and inability to operate for a long time, reduce low temperature performance and reduce equipment investment and operational risk, the effect of increased temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

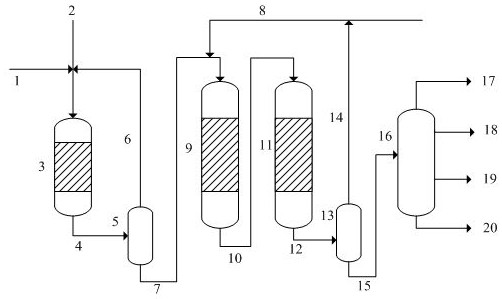

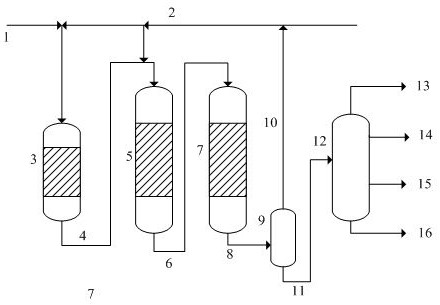

Method used

Image

Examples

Embodiment Construction

[0035] The action and effect of the present invention are further illustrated below through the examples, but the following examples do not constitute a limitation to the method of the present invention, and % are mass percentages in the application unless otherwise specified.

[0036] The protective agent used in the hydrocracking pretreatment reaction zone in the embodiments of the present invention and comparative examples is FDM-21, the hydrofinishing catalyst is FF-33, the protective agent used in the hydrofinishing reaction zone is FDM-21, and the hydrofinishing catalyst is FF-33. The catalyst is FF-46, and the hydrocracking catalyst used in the hydrocracking reaction zone is FC-14, and the manufacturers of the catalysts are Sinopec Catalyst Co., Ltd.

[0037] Table 1 Catalyst Physicochemical Properties

[0038]

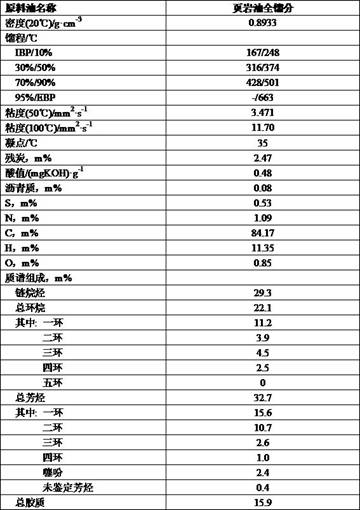

[0039] Table 2 Main properties of raw oil

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com