Patents

Literature

156results about How to "High cracking activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the conversion of ethane to aromatic hydrocarbons

ActiveUS20090209794A1Limit initial cracking activitySacrificing activityMolecular sieve catalystsMolecular sieve catalystBenzenePlatinum

A process for producing aromatic hydrocarbons which comprises (a) contacting ethane with a dehyroaromatization aromatic catalyst which is comprised of about 0.005 to about 0.1 wt % platinum, an amount of gallium which is equal to or greater than the amount of the platinum, from about 10 to about 99.9 wt % of an aluminosilicate, and a binder, and (b) separating methane, hydrogen, and C2-5 hydrocarbons from the reaction products of step (a) to produce aromatic reaction products including benzene.

Owner:SHELL USA INC

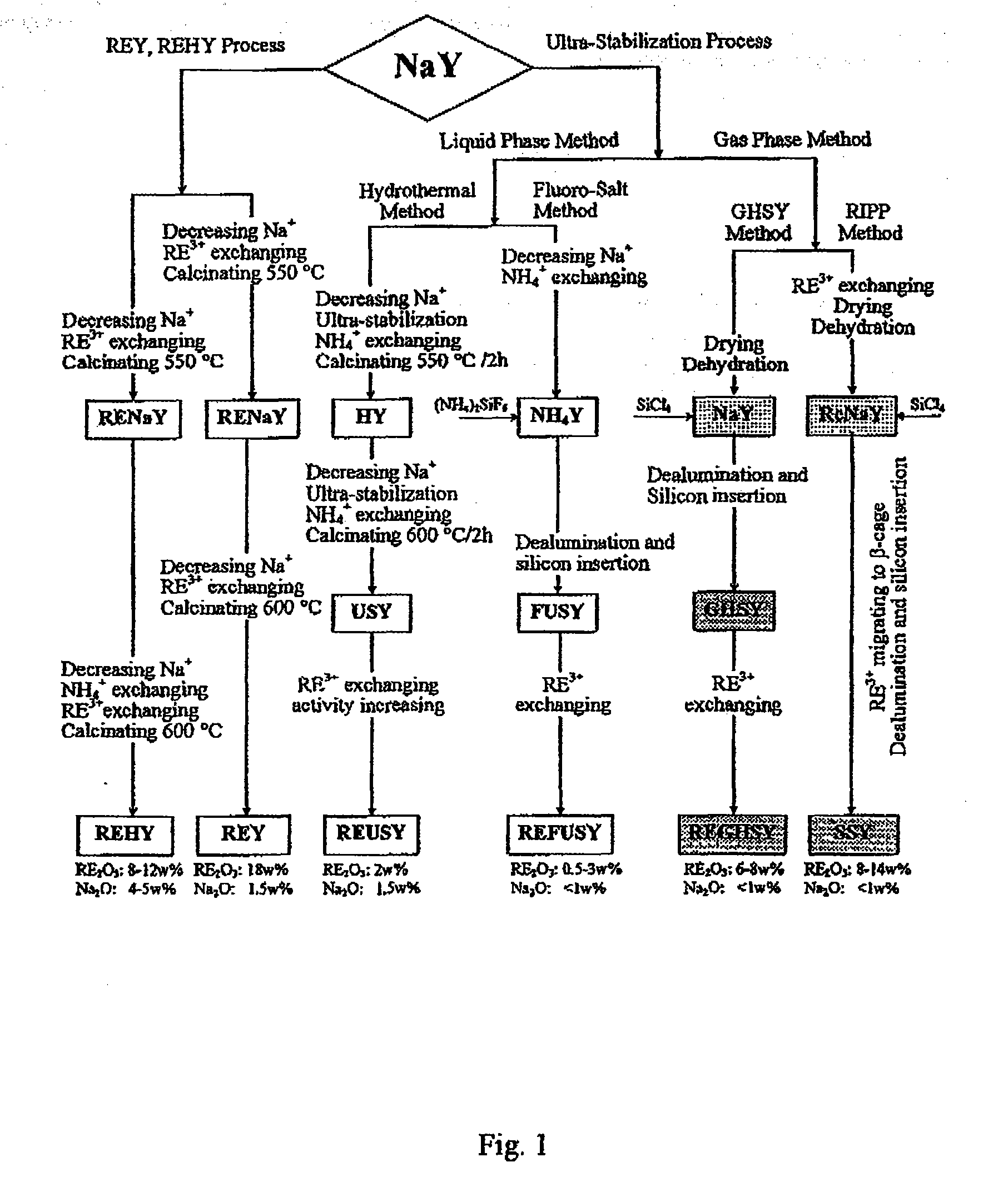

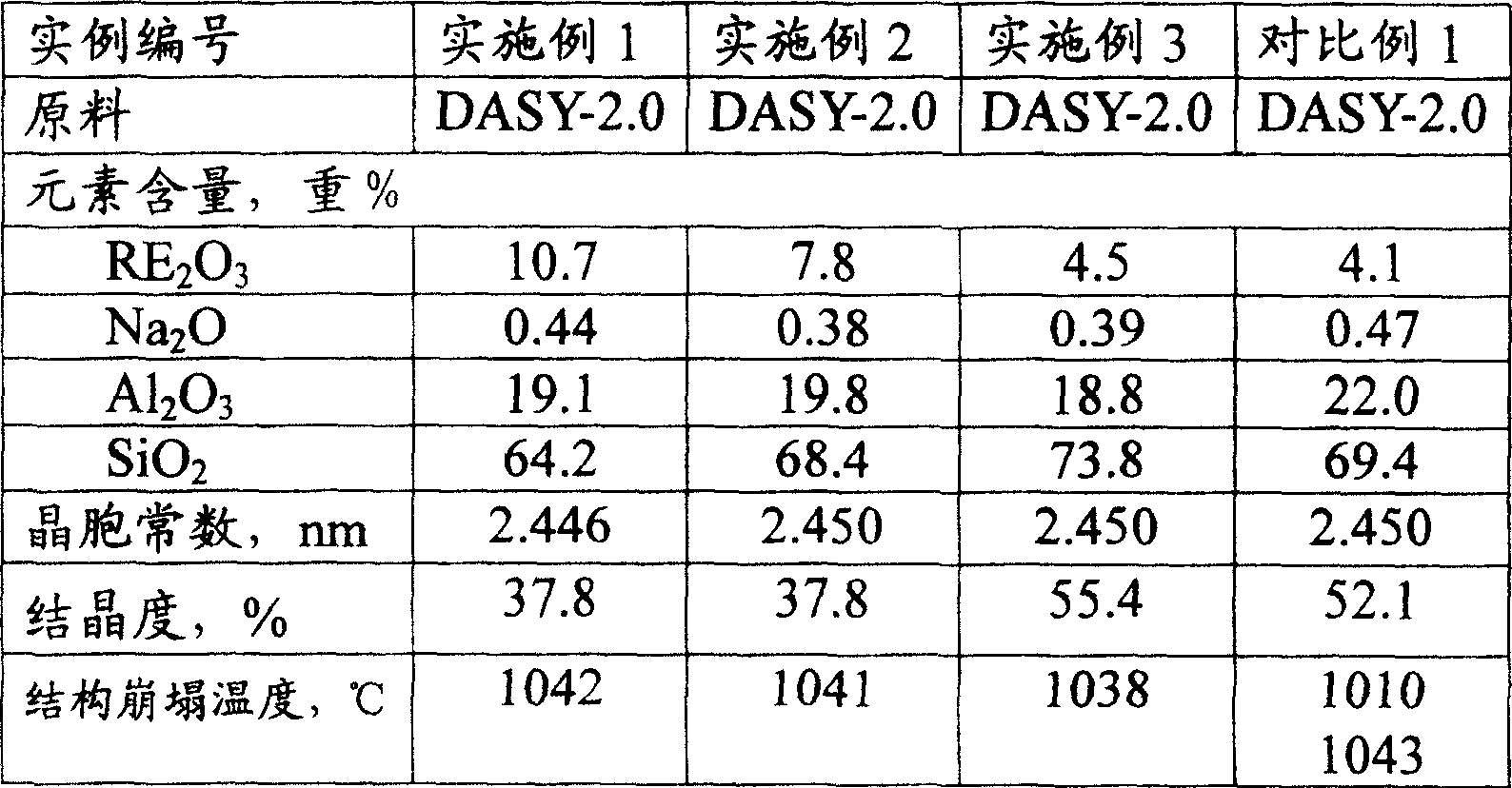

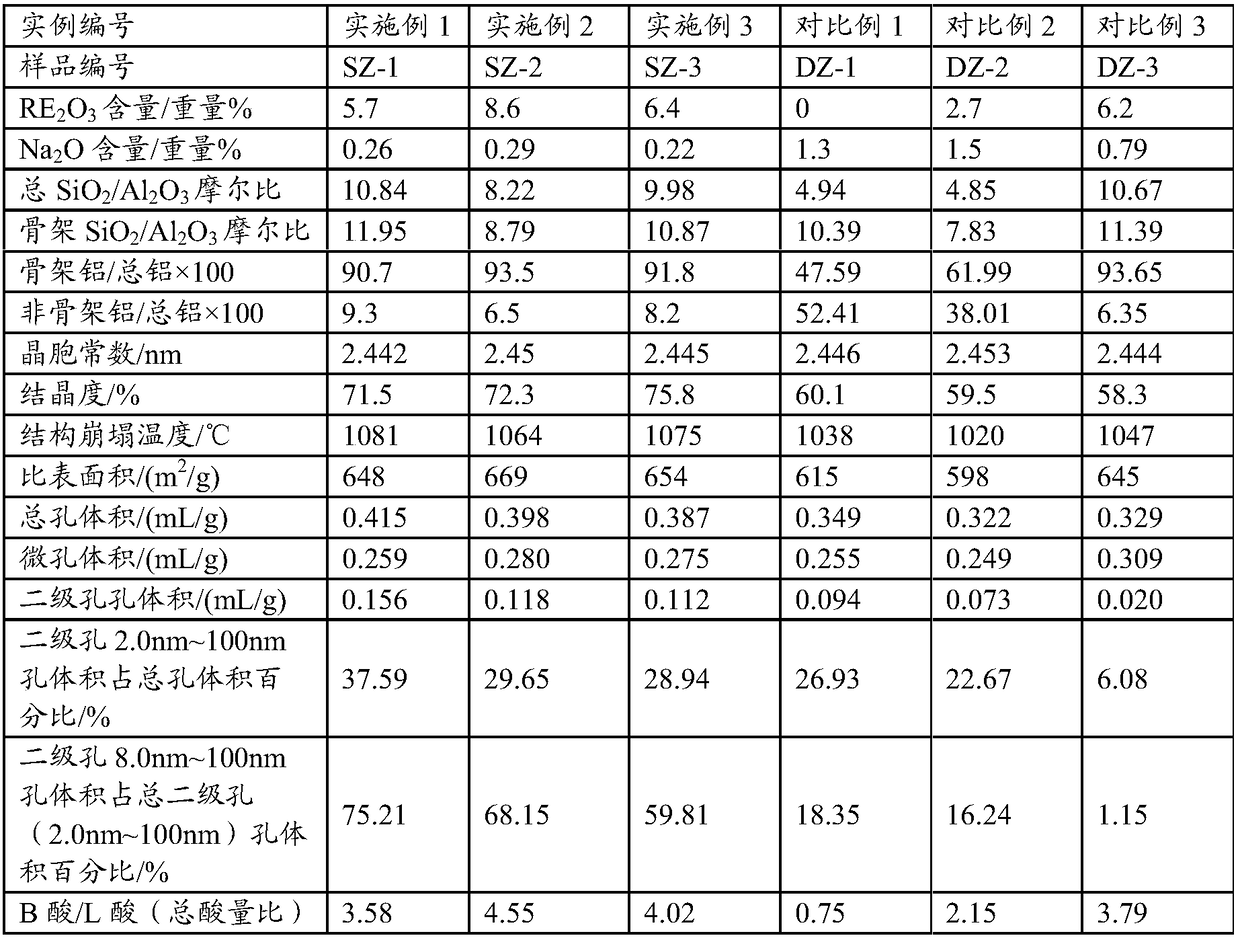

Method for raising content of rare earth of ultra stable Y type zeolite

ActiveCN1958452AHigh cracking activityStrong ability to convert heavy oilFaujasite aluminosilicate zeoliteRare earth ionsActive component

This invention discloses a method for raising rare earth content in super-stable Y-type zeolite. The method comprises: mixing super-stable Y-type zeolite and 0.01-2 N acid solution at a liquid / solid ratio of 4-20 at 20-100 deg.C, treating for 10-300 min, washing, filtering, adding rare earth salt solution for rare earth ion exchange, washing, filtering, and drying to obtain rare earth reinforced super-stable Y-type zeolite. The obtained rare earth reinforced super-stable Y-type zeolite has through pores without any blockage, and has obviously raised rare earth content. Cracking catalyst containing the rare earth reinforced super-stable Y-type zeolite as the active component has high heavy oil conversion ability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst containing mesoporous silica-alumina materials

ActiveCN102078821AIncrease productivityHigh solid contentCatalytic crackingMolecular sieve catalystsAdhesiveActive component

The invention discloses a cracking catalyst containing mesoporous silica-alumina material, wherein the cracking catalyst is composed of cracking active components: clay, adhesive and mesoporous silica-alumina material. The mesoporous silica-alumina material is of a pseudo-boehmite crystal phase structure. In case of the weight of oxide, the anhydrous chemical expression formula is: (0-0.3) Na2O (40-90) Al2O3 (10-60) SiO2, the specific surface area is 200-400m<2> / g, pore volume is 0.5-2.0ml / g, the average pore size is 8-20nm, and the most probable pore size is 5-15nm. The adhesive is selected from one or two mixtures of silica sol or aluminum sol. Compared with the conventional catalyst with pseudo-boehmite, the cracking catalyst has the advantages of low production cost and better crude oil conversion capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of kaolin type fluid catalytic cracking catalyst

InactiveCN1429882AHigh zeolite contentStrong resistance to heavy metalsCatalytic crackingHigh resistanceMicrosphere

A catalyst for catalytic cracking process is prepared from kaolinite, solid crystal seed, assistant, organic disperser and / or adhesive through spray drying, shaping microspheres, high-temp calcining,crystallizing reaction on sodium silicate and sodium hydroxide to obtain crystallized microspheres (content of NaY zeolite is 20-70%, ratio of zeolite silica-alumina is 4.0-6.0), calcining, and exchanging with NH4 and Re3 three times. Its advantages are high resistance to heavy metal, high activity and stability, and low cost.

Owner:QILU PETRO CHEM - SINOPEC

Hydrogenation catalyst steeping fluid composition and preparation method of hydrogenation catalyst

ActiveCN101462078AImprove hydrogenation activityHigh cracking activityCatalyst activation/preparationHydrocarbon oil crackingReaction temperatureFluid composition

The invention provides a hydrogenation catalyst soaking solution composition, which comprises a precursor of a hydrogenation active ingredient, a soaking additive and water, wherein the soaking additive has similar pKa value with that of the precursor of the hydrogenation active ingredient and comprises carbon-carbon double bond and / or carbon-carbon triple bond substances in molecular structure. The invention also provides a method for preparing a hydrogenation catalyst, which comprises: using the soaking solution to soak a catalyst carrier, and drying and roasting the catalyst carrier, wherein the soaking solution is the hydrogenation catalyst soaking solution composition. The hydrogenation catalyst prepared from the hydrogenation catalyst soaking solution composition has higher hydrogenation activity and higher cracking activity at the same reaction temperature compared with a hydrogenation catalyst prepared by the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high activity fluid catalytic eracking catalyst

InactiveCN1429883AHigh zeolite contentStrong resistance to heavy metalsCatalytic crackingCatalyst activation/preparationHigh resistanceAdhesive

A high-activity catalyst for catalytic cracking process is prepared from kaolinite, solid seed, assistant, organic disperser and adhesive through spray drying, shaping, microspheres, high-temp calcining, crystallizing reaction on sodium silicate and sodium hydroxide to obtain crystallized microspheres content of zeolit is 20-70%, ratio of zeolit silica-alumina is 4.0-6.0), calcining, and exchanging with NH4 and Re3 three times. Its advantages are high resistance to heavy metal, high activity and stability, and low cost.

Owner:CHINA PETROLEUM & CHEM CORP

Catalytic conversion process for producing ethylene and propylene using low-density oil fraction

InactiveCN1566272AExtended service lifeHigh yieldCatalytic crackingChemical recyclingDistillates petroleumReaction zone

The invention discloses a catalytic conversion process for producing ethylene and propylene using low-density oil fraction which comprises, contacting lightweight petroleum distillate containing rich olefin with heated five-membered ring high silicon zeolite catalyst, reacting under catalytic conversion condition, thus separating the reaction product and catalyst to be produced, leading out the resultant from the main reaction zone and further separating, then loading the catalyst into regenerator after stripping for carbon burning reproduction at the presence of oxygen-containing gas, finally loading the heated regenerated catalyst into pre-reaction zone for recycling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for heavy oil catalytic cracking and preparation method thereof

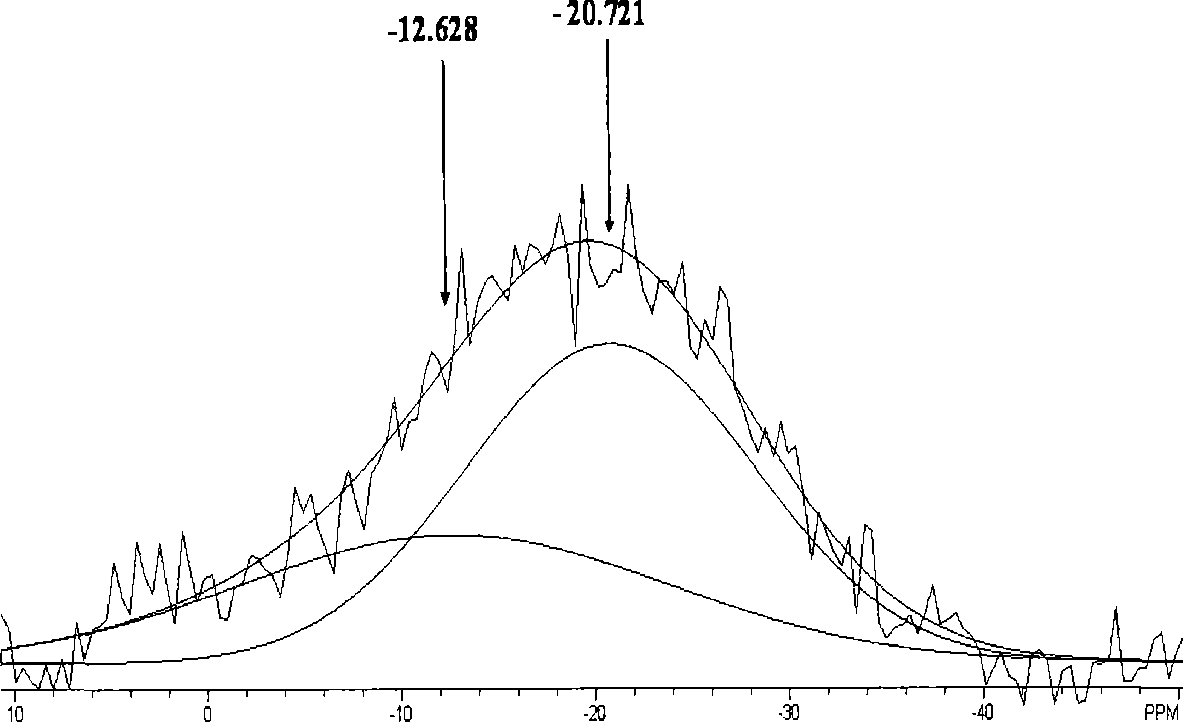

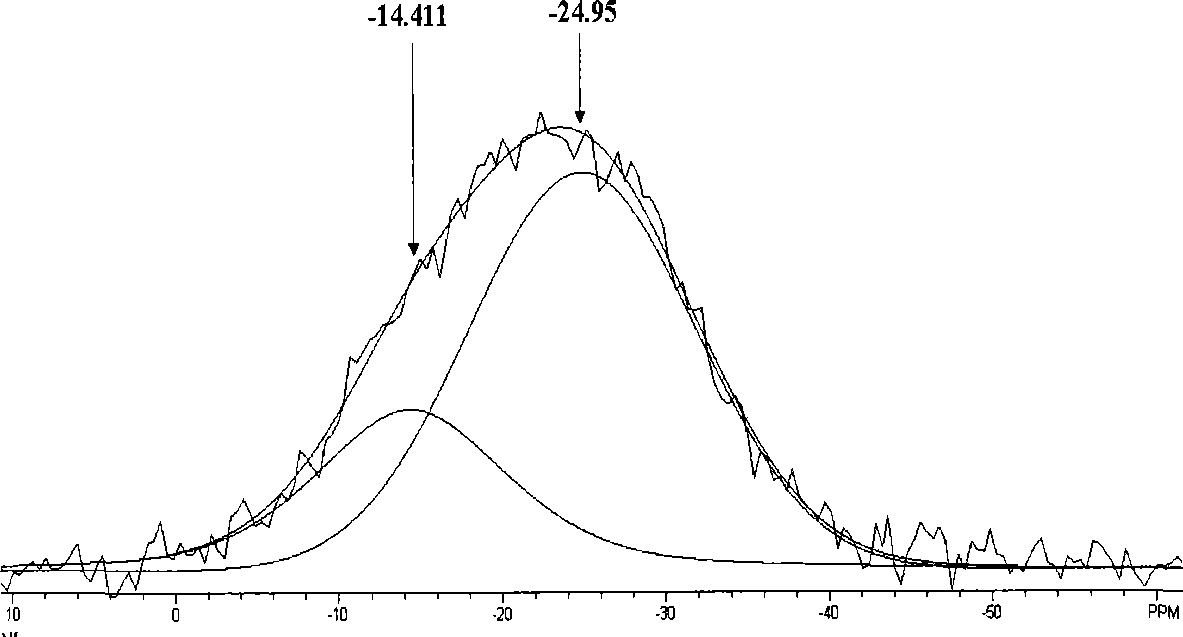

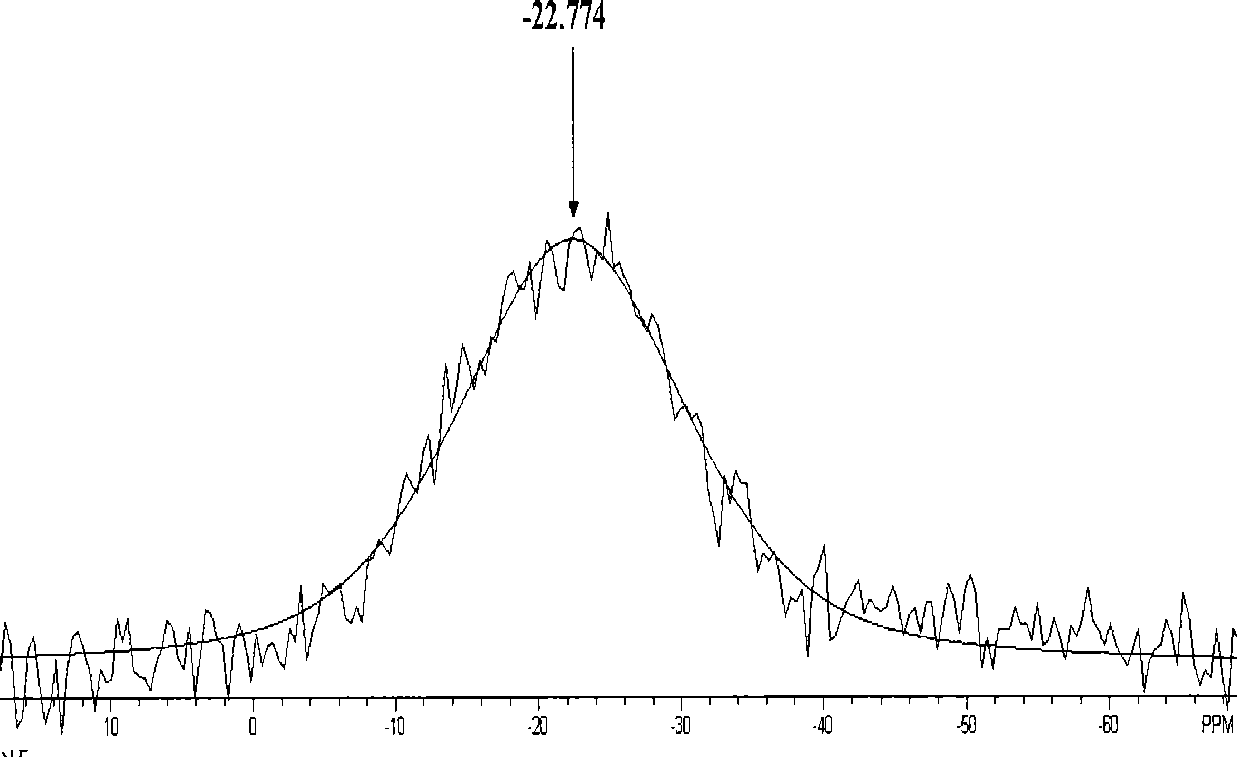

ActiveCN101386788AHeavy oil cracking ability is strongPollution abilityCatalytic crackingMolecular sievePtru catalyst

The invention discloses a cracking catalyst, which contains 10 to 50 weight percent of Y -shaped molecular sieve containing phosphorus and rare earth, 10 to 40 weight percent of an inorganic oxide adhesive and 10 to 70 weight percent of clay. In the Y-shaped molecular sieve containing the phosphorus and the rare earth, the content of rare earth oxide accounts for 12.0 to 16.0 weight percent, and P2O5 accounts for 0.5 to 7.0 weight percent; in a <31>P MAS NMR spectrum of the molecular sieve, peak areas of resonance signals of between -16 and -12 ppm and between -25 and -21 ppm as chemical displacements account for more than 85 percent of the total peak area; and in a <27> Al MAS NMR spectrum of the molecular sieve, the peak area of a resonance signal of between -2 and 2 ppm as the chemical displacement accounts for more than 20 percent of the total peak area. The Y-shaped molecular sieve containing the phosphorus and the rare earth can be obtained by the following steps: a NaY molecular sieve is contacted with an aqueous solution containing rare earth ions and an aqueous solution containing a phosphorus-aluminum modifying agent, then is subject to hydro-thermal treatment, and finally is contacted with an ammonium salt aqueous solution. The cracking catalyst is used for catalytic cracking reactions, and has strong cracking capability of heavy oil, high yield of gasoline, and strong anti-metallic contamination capability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing super-stable Y zeolite containing rare-earth elements

InactiveCN1159101CAchieve the purpose of exchangeLower activation energyCatalytic crackingMolecular sieve catalystsHigh resistanceRare-earth element

A rare-earth contained super-stable Y zeolite is prepared from the super-stable Y zeolite containing sodium oxide (3-5 wt.%), rare-earth compound and water in wt ratio of 1:(0.001-0.5):(1-10) through preparing solution of rare-earth compound, mixing and the said Y zeolite, and grinding with shearing stress of at least 10 kg / cm2 for at least 1 min. Its advantages are higher hydrothermal stability, high stability of activity, and high resistance to sodium and heavy metal pollutions.

Owner:CHINA PETROLEUM & CHEM CORP +1

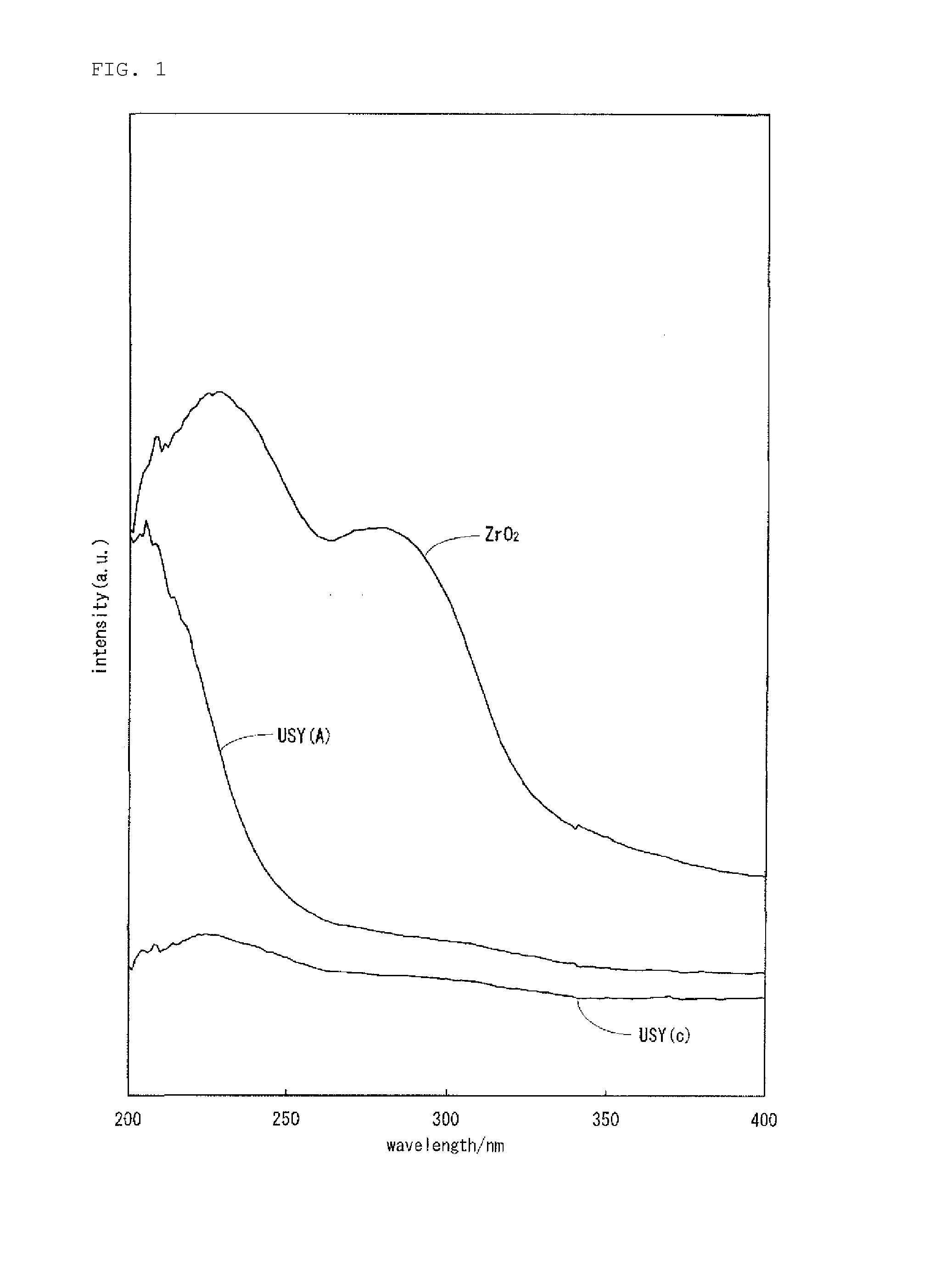

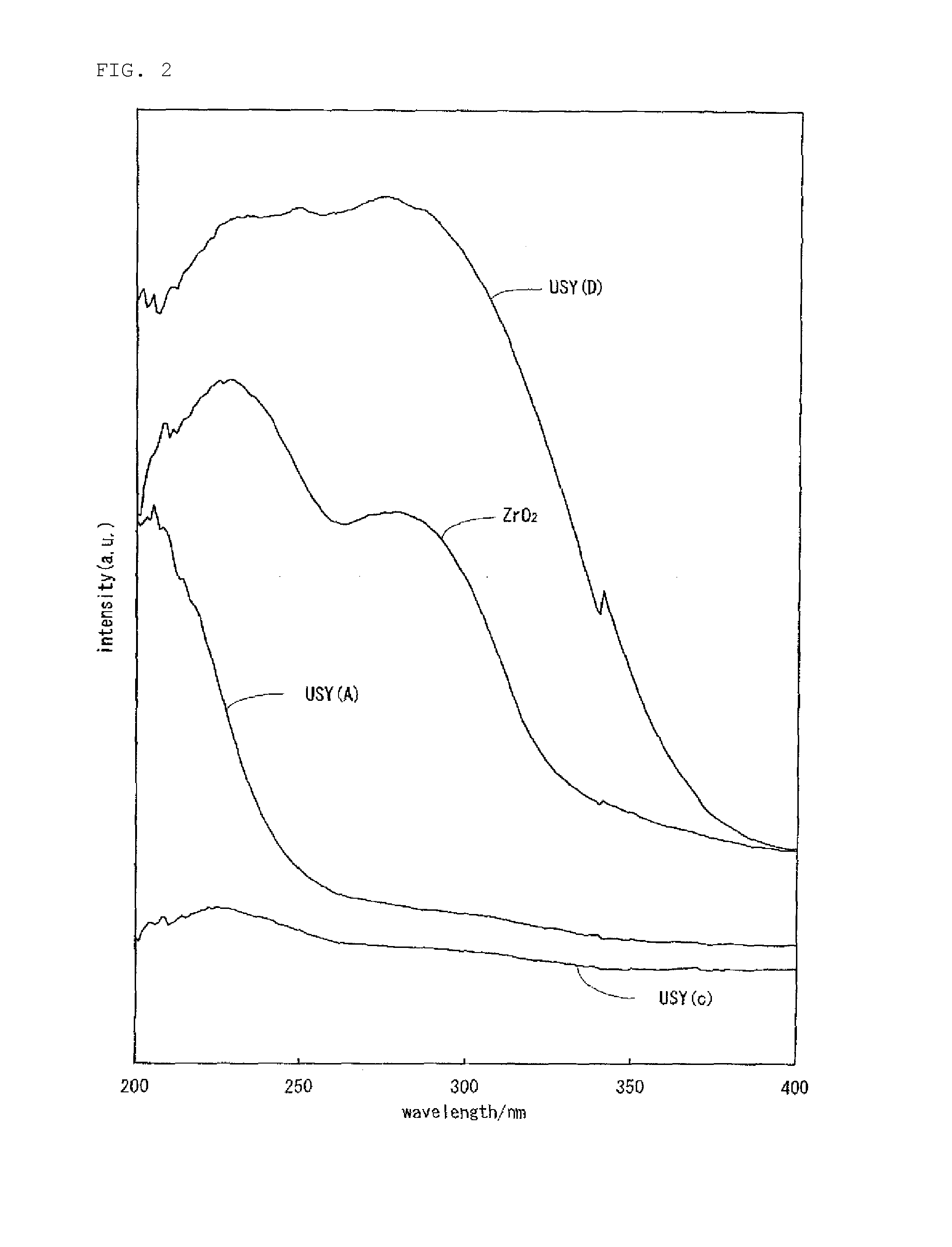

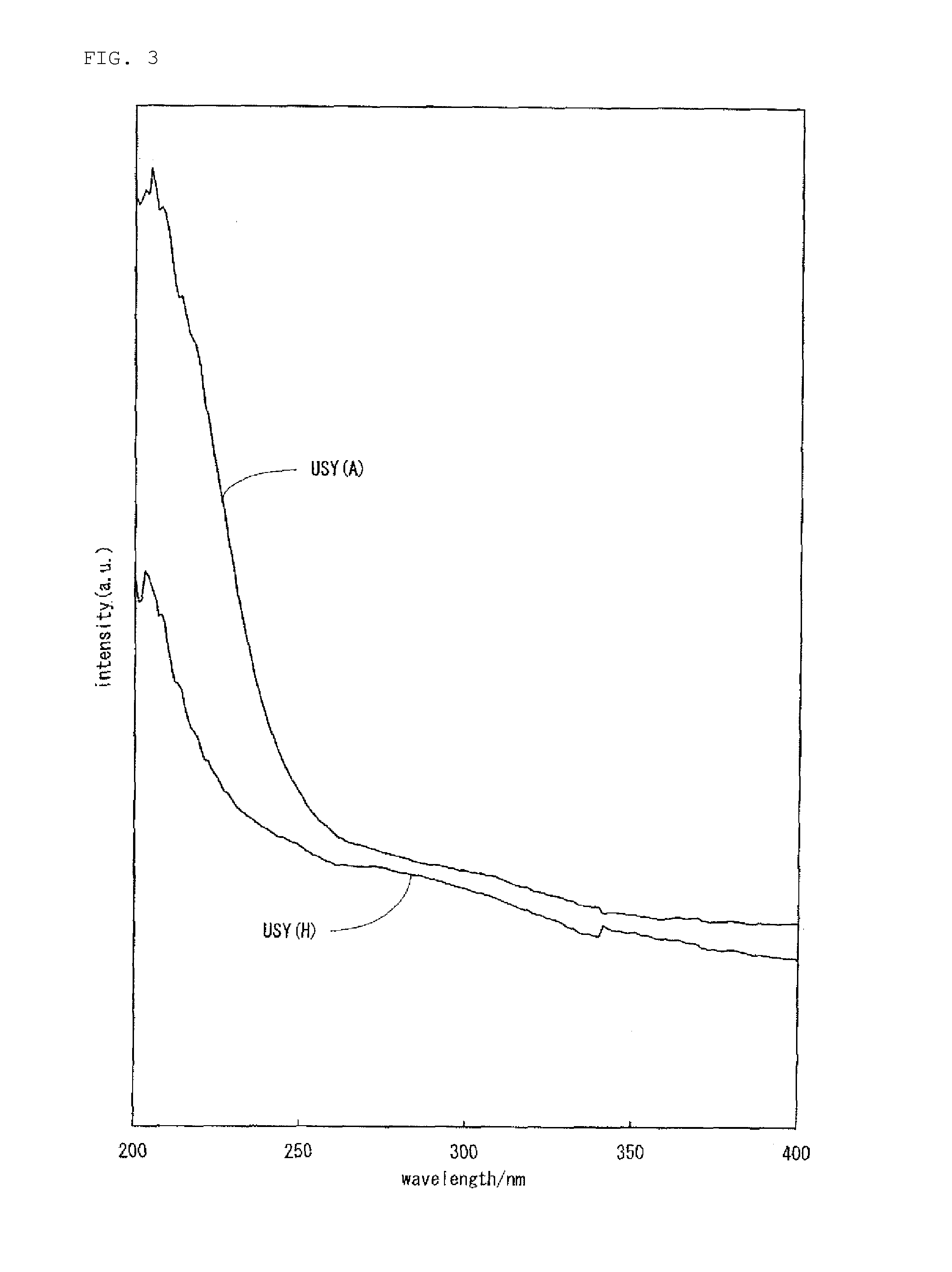

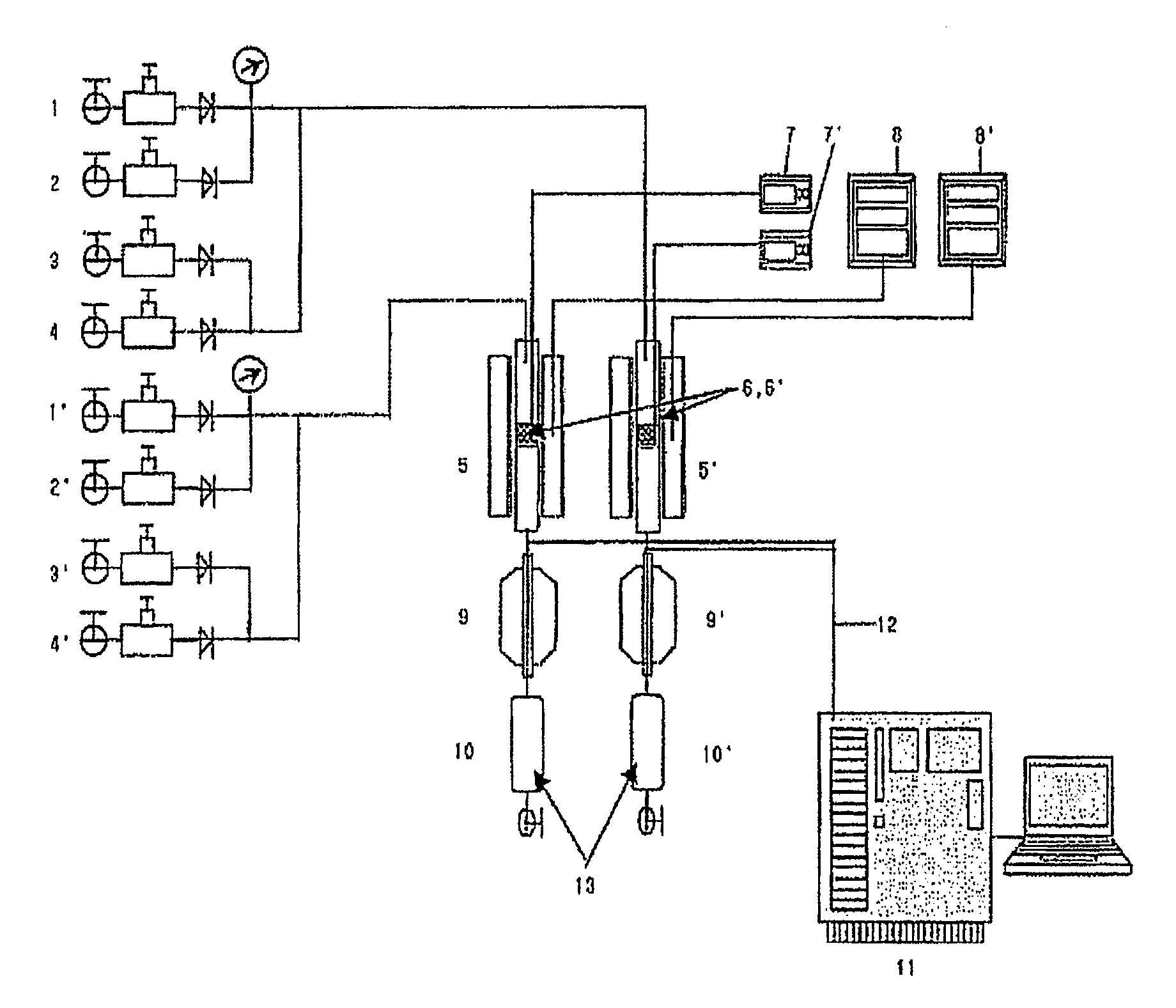

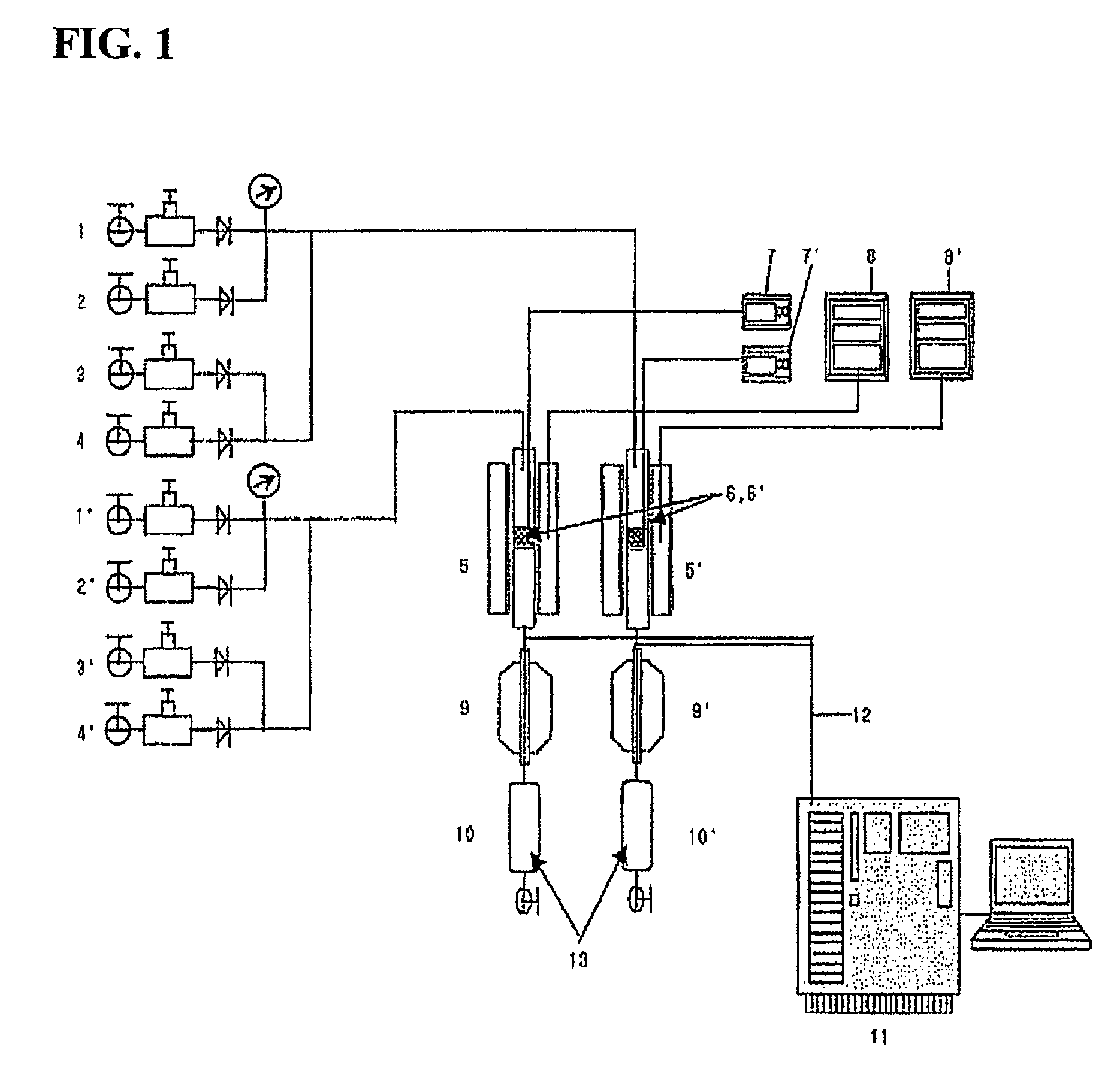

Hydrocracking catalyst for hydrocarbon oil, method for producing hydrocracking catalyst, and method for hydrocracking hydrocarbon oil with hydrocracking catalyst

ActiveUS20130175202A1High yieldCracking activity is improvedMolecular sieve catalystsCatalyst activation/preparationPtru catalystProcess engineering

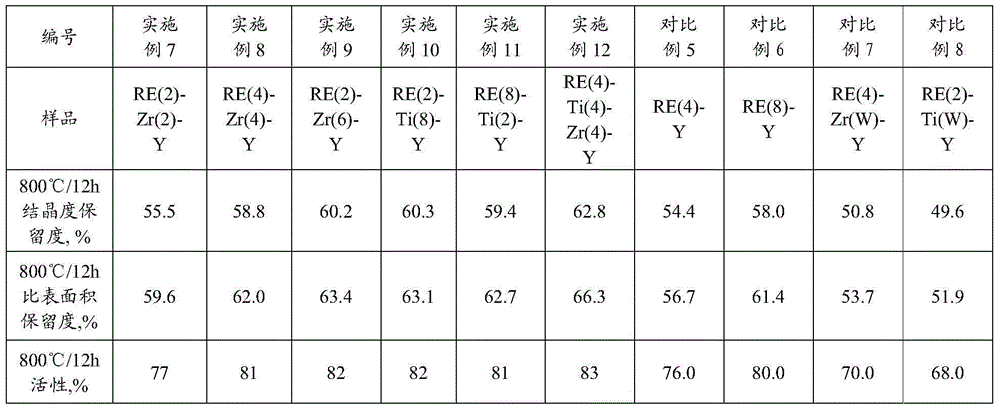

The present invention relates to a hydrocracking catalyst for hydrocarbon oil comprising a support containing a framework-substituted zeolite-1 in which zirconium atoms and / or hafnium atoms form a part of a framework of an ultrastable y-type zeolite and a hydrogenative metal component carried thereon and a method for producing the same. The hydrocracking catalyst of the present invention makes it easy to diffuse heavy hydrocarbon oils such as VGO, DAO and the like into mesopores, is improved in a cracking activity and makes it possible to obtain a middle distillate at a high yield as compared with catalysts prepared by using zeolite comprising titanium and / or zirconium carried thereon.

Owner:JAPAN COOP CENT FOR PETROLEUM & SUSTAINABLE ENERGY +2

Process for production of light olefins from hydrocarbon feedstock

ActiveUS20070010699A1High yieldReduce reactivityCatalytic crackingMolecular sieve catalystsMolecular sieveNaphtha

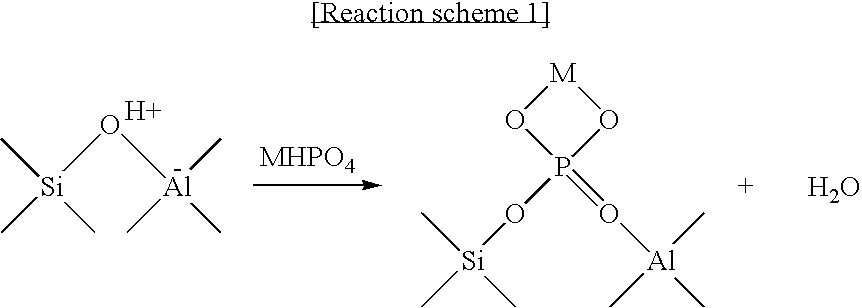

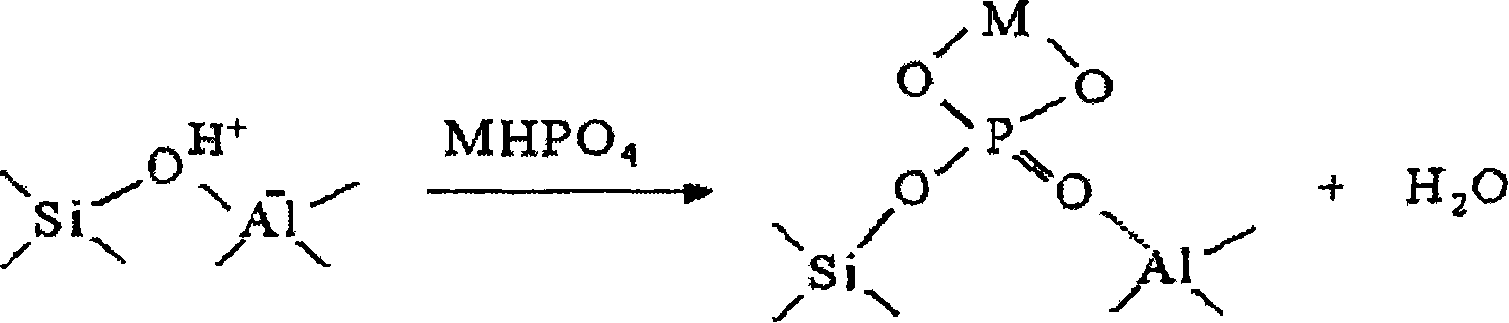

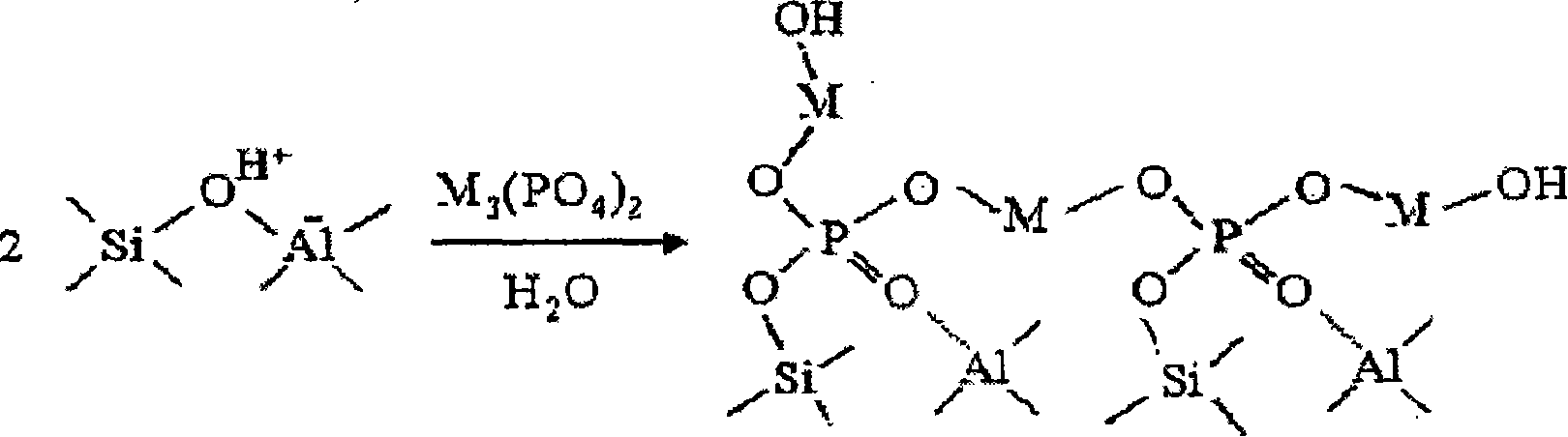

Disclosed is a process for producing light olefins from hydrocarbon feedstock. The process is characterized in that a porous molecular sieve catalyst consisting of a product obtained by evaporating water from a raw material mixture comprising a molecular sieve with a framework of Si—OH—Al— groups, a water-insoluble metal salt, and a phosphate compound, is used to produce light olefins, particularly ethylene and propylene, from hydrocarbon, while maintaining excellent selectivity to light olefins. According to the process, by the use of a specific catalyst with hydrothermal stability, light olefins can be selectively produced in high yield with high selectivity from hydrocarbon feedstock, particularly full-range naphtha. In particular, the process can maintain higher cracking activity than the reaction temperature required in the prior thermal cracking process for the production of light olefins, and thus, can produce light olefins with high selectivity and conversion from hydrocarbon feedstock.

Owner:SK INNOVATION CO LTD +1

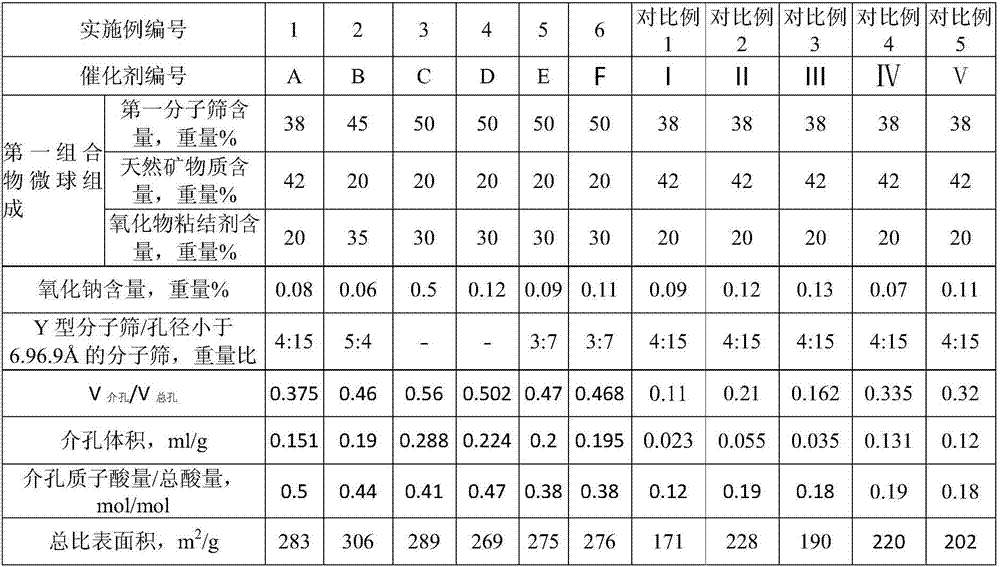

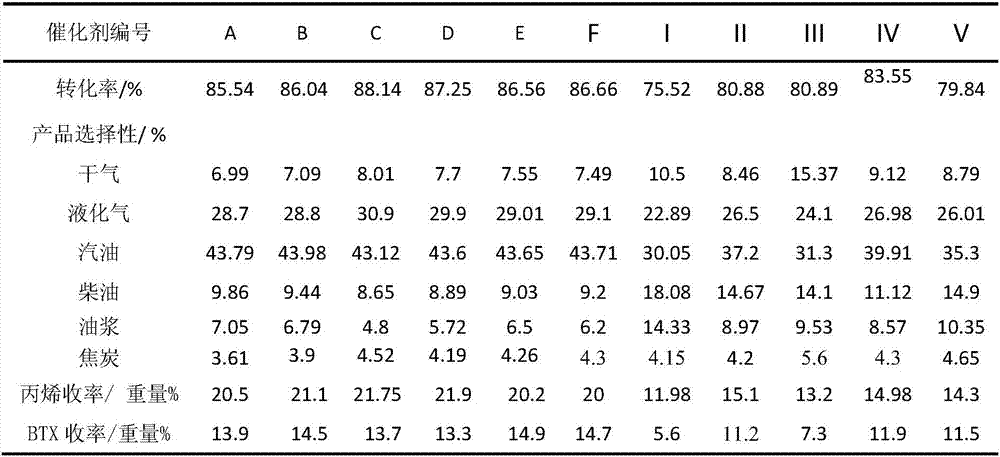

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971018ARich mesostructureHigh hydrothermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveSpray dried

The invention provides a catalytic cracking catalyst and a preparation method thereof. The catalyst comprises 5 to 65% of natural mineral matters, 10 to 60% of an oxide binder, 24 to 75% of first molecular sieves, wherein the first molecular sieves are composed of molecular sieves with pore diameters of less than 6.9 angstroms and optional Y type molecular sieves, and the amount of mesoporous protonic acid in the catalyst accounts for 20 to 70% of total acid amount. The preparation method comprises the following steps: formation of slurry including the first molecular sieves, the natural mineral matters and the inorganic oxide binder; spray drying; and treatment with alkali and compound acid. The catalytic cracking catalyst has the advantages of higher propylene yield and BTX yield when applied to catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alumina supporter containing flurine and its preparing process

The fluoride bearing alumina carrier consists of (accounting in the weight of catalyst): fluorine 0.5-15 wt%, assistant M 1.0-30 wt% and alunina the rest. Fluorine and assistant M are added during forming the alumina carrier in kneading mode. The said process can prepare carrier with F and M contents and F / M ratio adjustable within certain range and physical and chemical properties adjustable within certain range. The carrier can meet the requirement for various hydrogenating catalyst and features less loss of F inside the carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

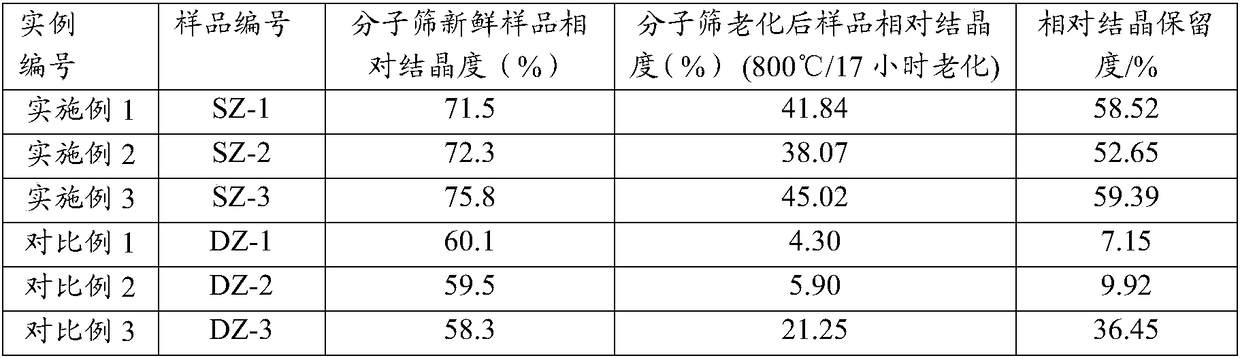

Cracking Catalyst and a Preparation Process for the Same

ActiveUS20080261802A1Improve catalyst binding propertyImprove catalyst strengthCatalytic crackingMolecular sieve catalystsRare earthCell size

The present invention provides a cracking catalyst, containing a rare-earth Y-zeolite and a support, which is characterized in that the rare-earth content in crystal lattice of the rare-earth Y-zeolite is 4-15 wt % of RE2O3; the original unit cell size is 2.440-2.465 nm; the equilibrium unit cell size of the catalyst after 100% stream-aging at 800° C. for 17 hours is larger than 2.435 nm; the rare-earth atom content in the support is 1.0-8.0 wt % of the support. The present invention also relates to a preparation process for the same catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

Method for raising content of rare earth of ultra stable Y type zeolite

ActiveCN100497175CHigh cracking activityStrong ability to convert heavy oilFaujasite aluminosilicate zeoliteRare earth ionsActive component

Owner:CHINA PETROLEUM & CHEM CORP +1

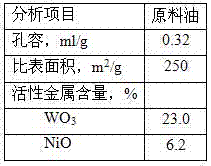

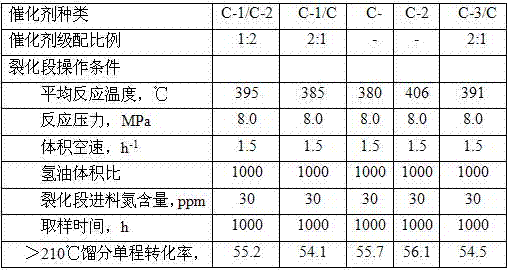

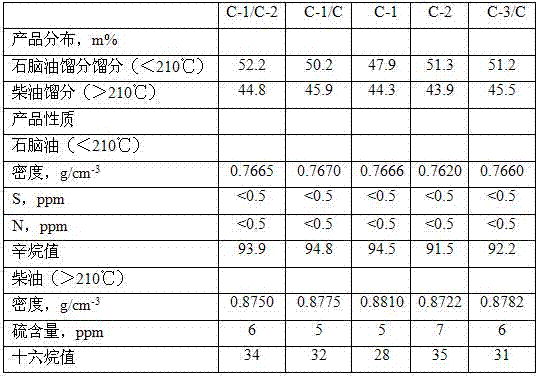

Hydro-conversion technology for catalytic diesel oil

ActiveCN107304373AImprove nitrogen resistanceHigh reactivityMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sieveHydrogen

The invention discloses a hydro-conversion technology for catalytic diesel oil. The technology comprises the following steps: firstly, putting a mixture of catalytic diesel oil and hydrogen into a hydrogenation reactor and performing hydrofining reaction, and then guiding into a cracking reactor and generating contact reaction with hydrocracking catalyst layers, wherein upper and lower catalyst layers are arranged in the hydrocracking reactor; the hydrocracking catalyst in the upper layer has the properties as follows: on the basis of the total weight of the catalyst, 10%-18% of MoO3, 2%-10% of Co, 40%-90% of modified Y-shaped molecular sieve, preferably 50-80%, and the balance of aluminum silicon carrier; the hydrocracking catalyst in the lower layer has the properties as follows: on the basis of the total weight of the catalyst, 15-30% of MoO3 or WO3, 2-15% of NiO, 10%-60% of modified Y-shaped molecular sieve, preferably 20-40%; the filling mass ratio of the hydrocracking catalysts in the upper layer and the lower layer is (1:5)-(5:1). The hydro-conversion technology disclosed by the invention can further increase the device liquid yield, can reduce the hydrogenation saturation of the generated gasoline component and can increase the octane value of the gasoline component under the condition of better meeting the requirement for the conversion rate of catalytic diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

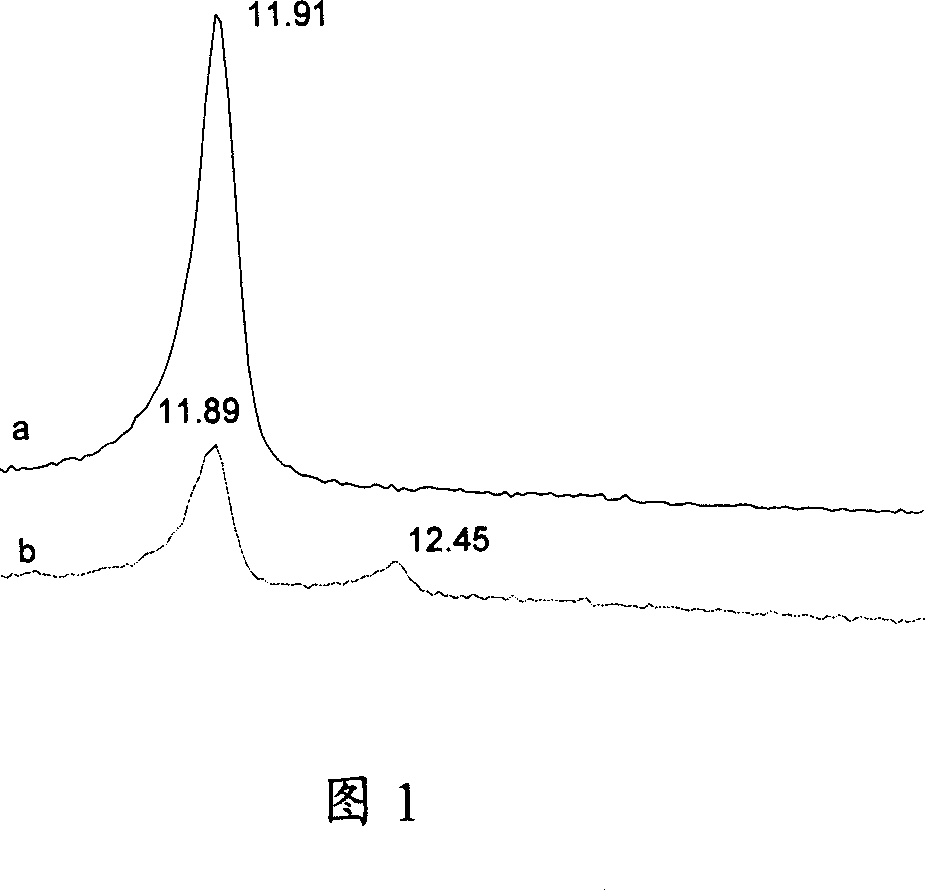

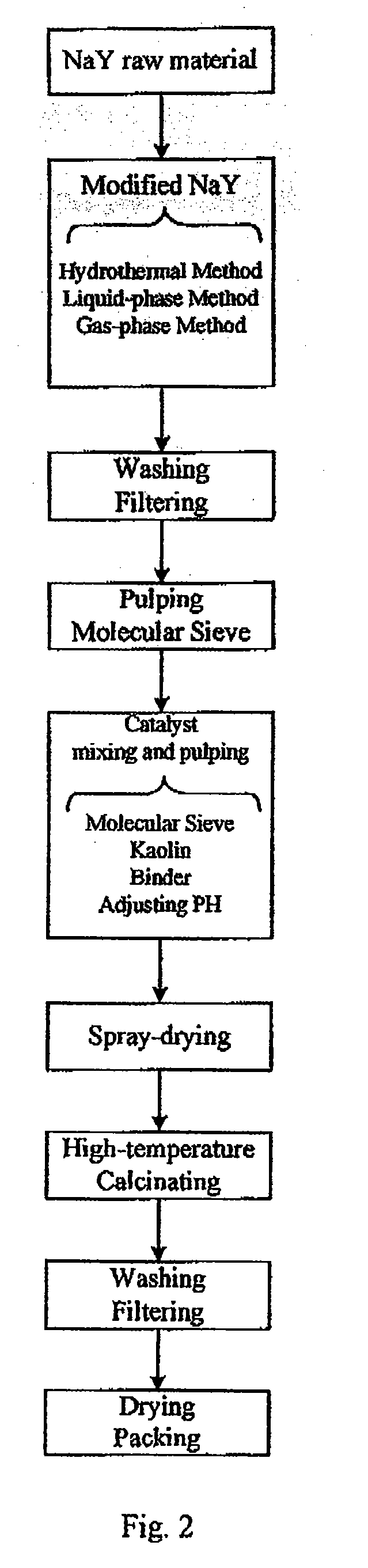

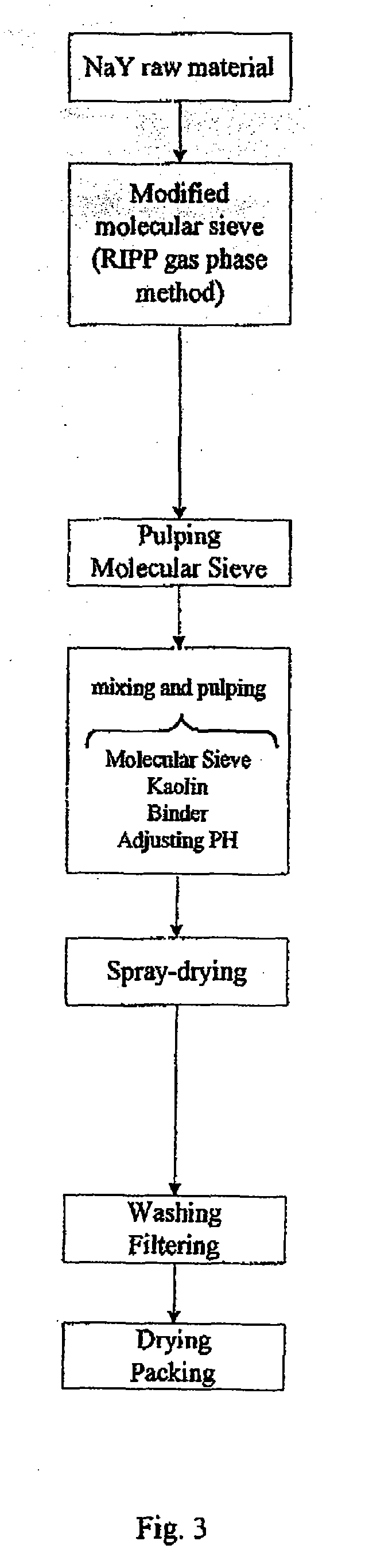

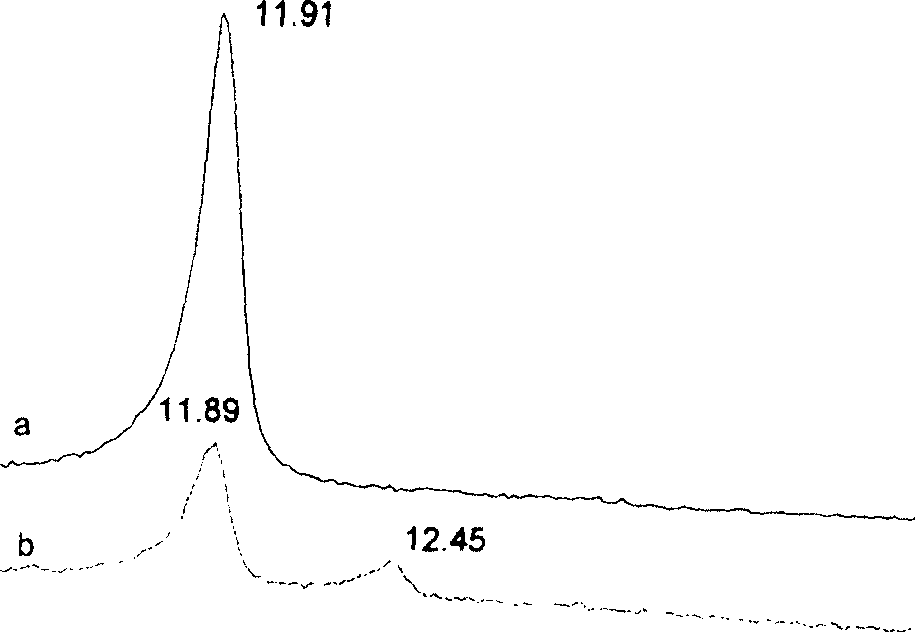

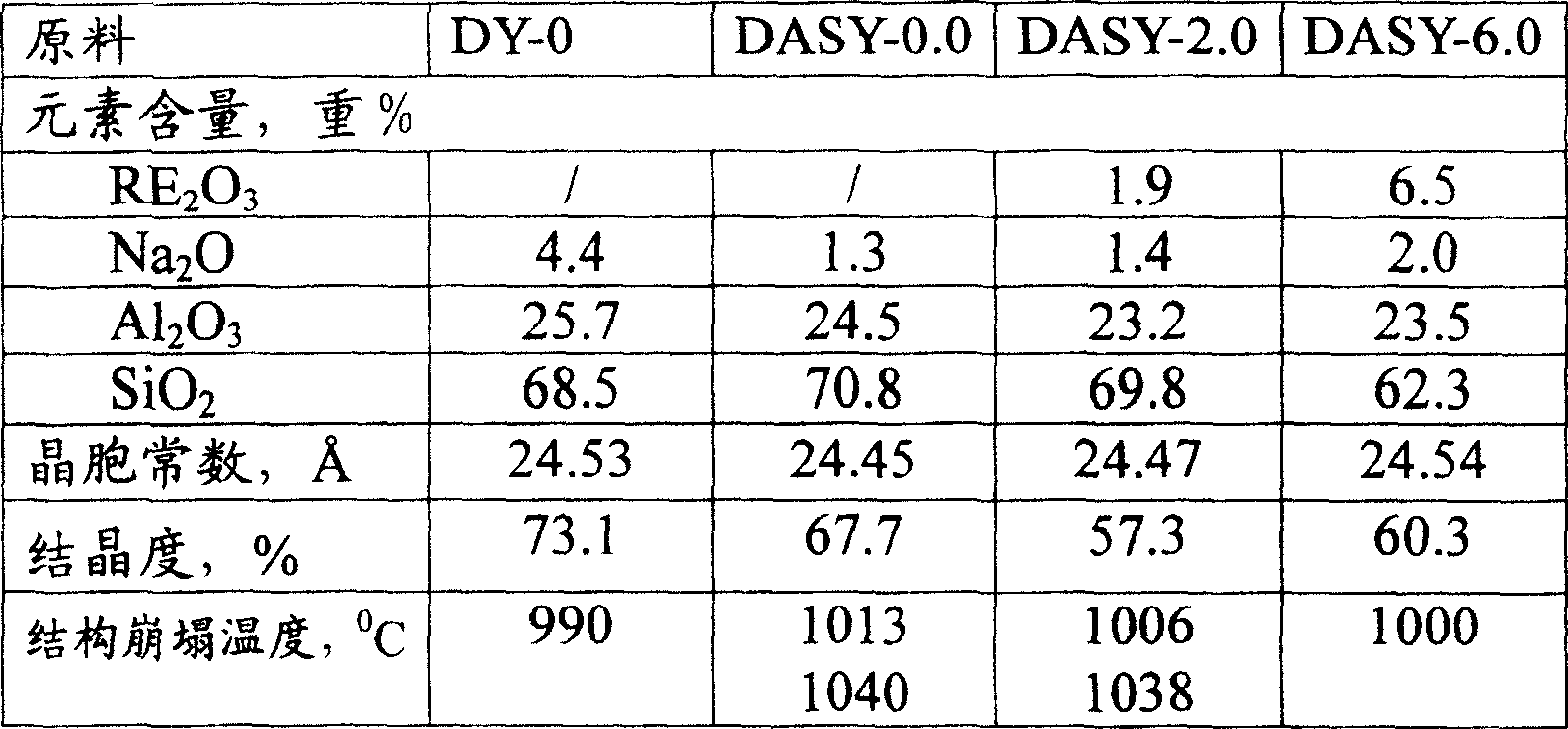

ActiveCN103657711AIncrease profitSave resourcesCatalytic crackingMolecular sieve catalystsAdhesiveGas phase

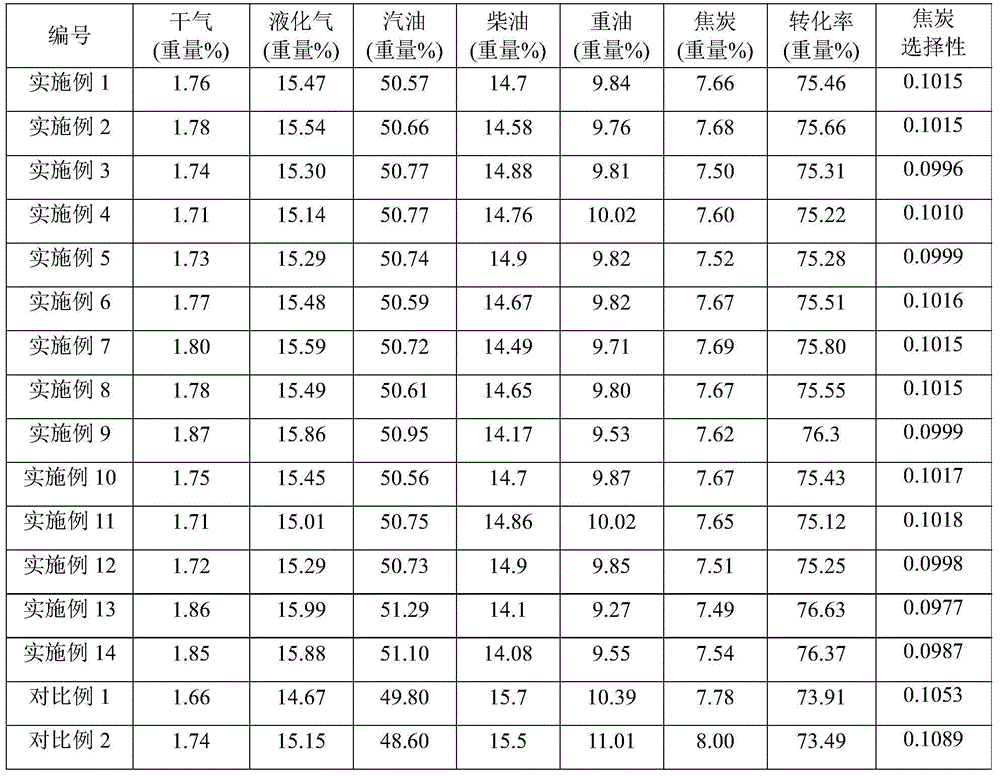

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, clay and an adhesive, wherein the cracking activity component a first Y-type molecular sieve, a second Y-type molecular sieve and a third Y-type molecular sieve; the first Y-type molecular sieve is a rare-earth Y-type molecular sieve, the rare-earth content in the first Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50; the second Y-type molecular sieve is a rare-earth-containing gas-phase overstable Y-type molecular sieve; and the third Y-type molecular sieve is a rare-earth-containing DASY molecular sieve. The preparation method comprises the following steps: preparing a slurry containing the cracking activity component, adhesive and clay, and carrying out spray drying. The catalyst has higher conversion rate and gasoline yield, and can reduce the consumption of the molecular sieves, thereby lowering the cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst, preparation method thereof and application

ActiveCN105148985AGood bonding performanceLow coke selectivityCatalytic crackingMolecular sieve catalystsChemistryMolecular sieve

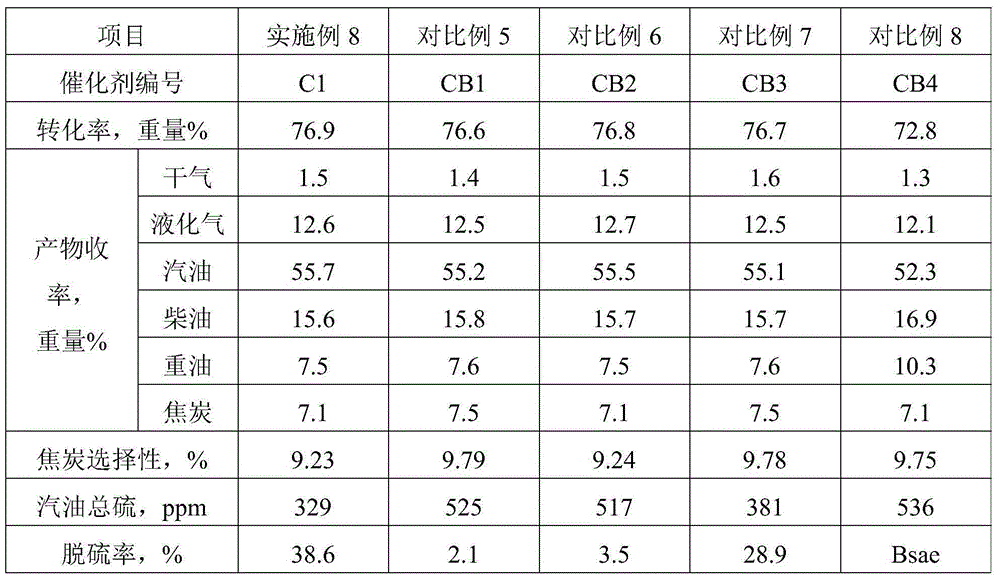

The invention discloses a catalytic cracking catalyst, a preparation method thereof and application. The catalytic cracking catalyst comprises cracking active components, clay and a binder, wherein the cracking active components include, by weight, a first Y-type molecular sieve 35-70%, a second Y-type molecular sieve 20-60% and a third Y-type molecular sieve 2-20%, and the binder is a modified alumina sol containing Cl and Si. The content of Al is 8-13 wt%, the content of Cl is 4-9 wt%, and the content of Si is 0.1-1 wt% based on the total weight of the modified alumina sol. The weight ratio of Al to Cl is 1.2-2.2:1, and the pH of the modified alumina sol is in a range of 2.2 to 5.2. The catalytic cracking catalyst has low coke selectivity and high catalytic cracking activity in heavy oil catalytic cracking process, and can obtain high yield of diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aromatizatian catalytic material and preparation method thereof

ActiveCN101550352AHigh crystallinityLarge specific surface areaCatalytic crackingMolecular sieve catalystsMolecular sieveCompound (substance)

The invention relates to an aromatizatian catalytic material and a preparation method thereof. The aromatizatian catalytic material is a metal-modified molecular sieve and has the absolute chemical expression formula of (0-0.3) Na2O.(0.5-15) Al2O3.(0.5-15) MXOY.(70-99) SiO2 by the weight of oxide, wherein the M is modified metal loaded on the molecular sieve, x represents the atomic number of the M, the y represents a number required for meeting the oxidation state of the M, one part of the metal is partially acted with Al2O3 on the surface of the molecular sieve to form an MXOY-Al2O3 surface compound, the other part of the metal exists in a form of an independent phase of a metal oxide MXOY, and the proportion between one part of the metal and the other part of the metal is: MXOY-Al2O3 : MXOY is equal to (0.5-2) : 1. The provided aromatizatian catalytic material has the advantages of high degree of crystallization, large pore volume and specific surface area, high acid content and high cracking activity and aromatizatian selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst, and preparation method and application thereof

ActiveCN105268469AImprove adhesionHigh matrix activityCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

The invention discloses a catalytic cracking catalyst, and a preparation method and application thereof. The catalytic cracking catalyst contains a cracking active composition, a mesoporous silicon aluminium material, clay and a binder, wherein the cracking active composition contains 70-100 wt% of a first Y type molecular sieve, and the first Y type molecular sieve is a rare earth Y type molecular sieve; the binder is a modified aluminium sol containing Cl and Si, and by taking the total weight of the modified aluminium sol as a reference, Al content is 8-13 wt%, Cl content is 4-9 wt%, the Al-to-Cl weight ratio is 1.2-2.2:1, the Si content is 0.1-1 wt%, and the pH value of the modified aluminium sol is 2.2-5.2. The catalytic cracking catalyst possesses relatively low coke selectivity and relatively high catalytic cracking activity during catalytic cracking of heavy oil, and also helps to obtain relatively high light oil yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

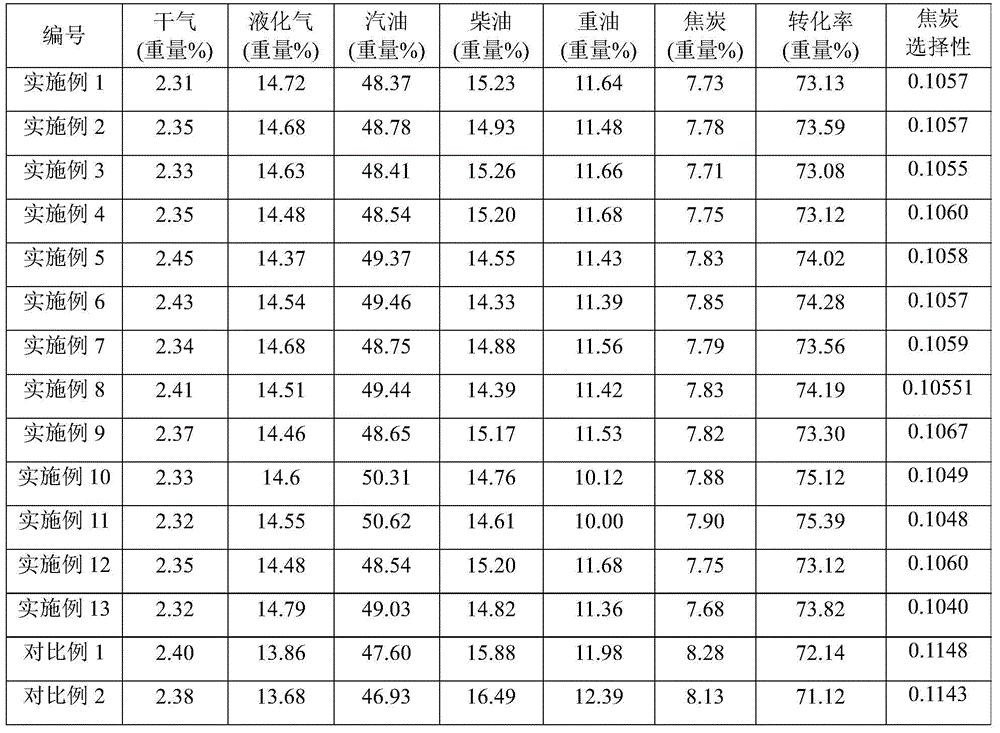

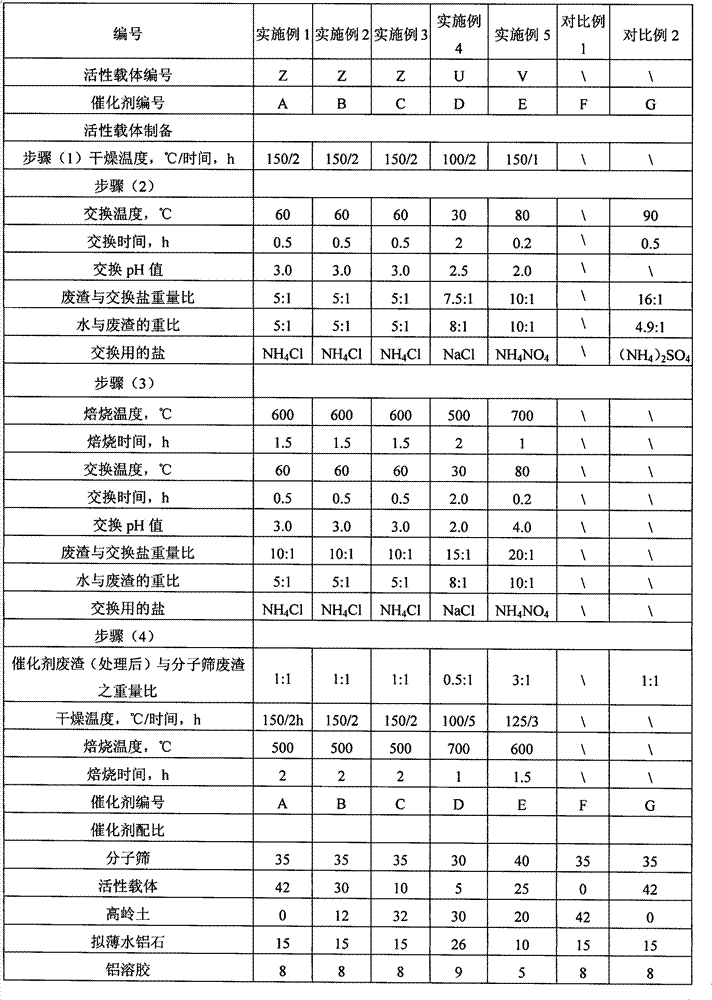

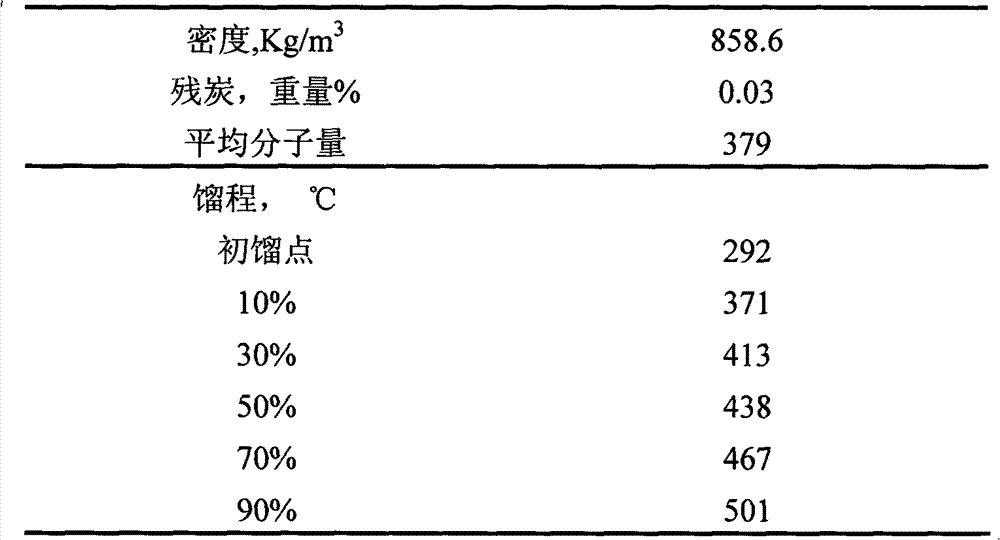

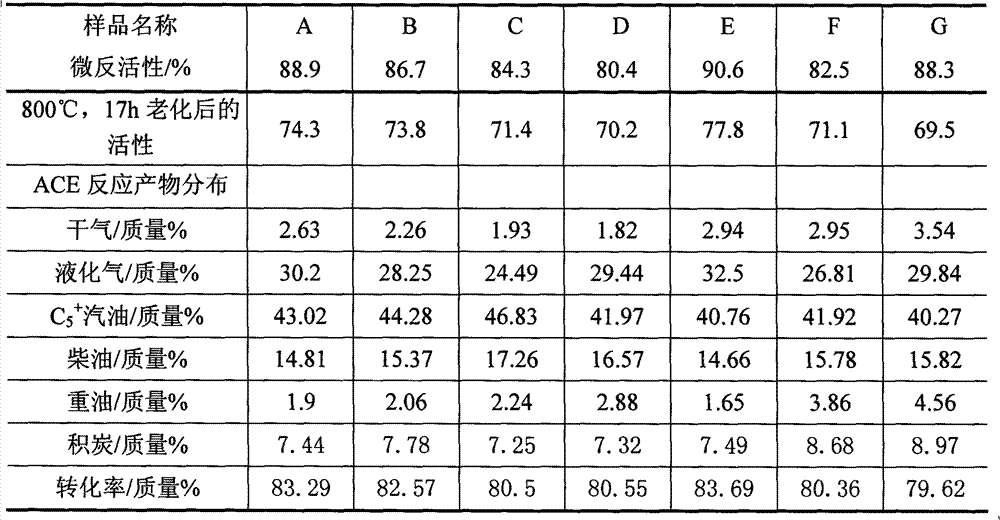

Method for utilizing residues of catalyst production

ActiveCN102896000AOvercoming the disadvantages of poor direct exchangeIdeal for removing impuritiesCatalyst carriersCatalytic crackingMolecular sieveIon exchange

The invention discloses a method for utilizing residues of catalyst production, comprising the following steps: (1) drying catalyst residues; (2) contacting the material obtained by the step (1) with an ammonium salt solution or alkali metal saline solution to conduct ion exchange and washing, then filtering; (3) roasting the material obtained by the step (2) at 450-750 DEG C, then exchanging, washing and filtering; and (4) mixing the material obtained by the step (3) with molecular sieve residues and water and beating, filtering, drying, and then roasting at 500-700 DEG C to obtain an active carrier; and carrying out beating and spray drying on the active carrier, ultrastable Y-type molecular sieve, alumina binder and clay to obtain a cracking catalyst. The obtained catalytic cracking catalyst has the advantages of high cracking activity, high active stability, and low yields of dry gas and coke.

Owner:CHINA PETROLEUM & CHEM CORP +1

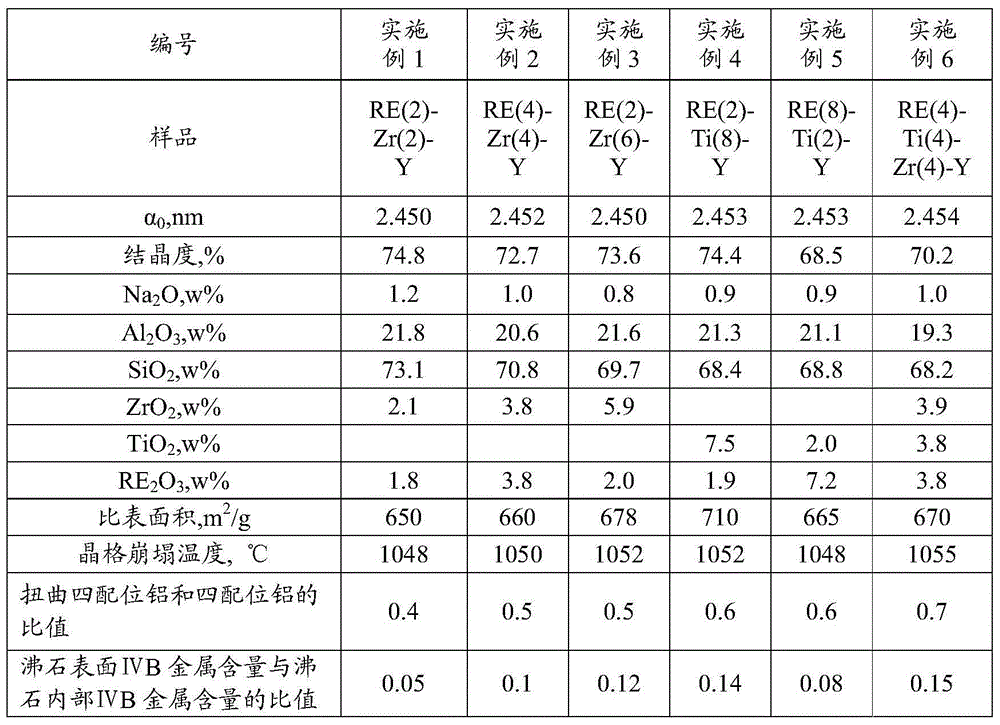

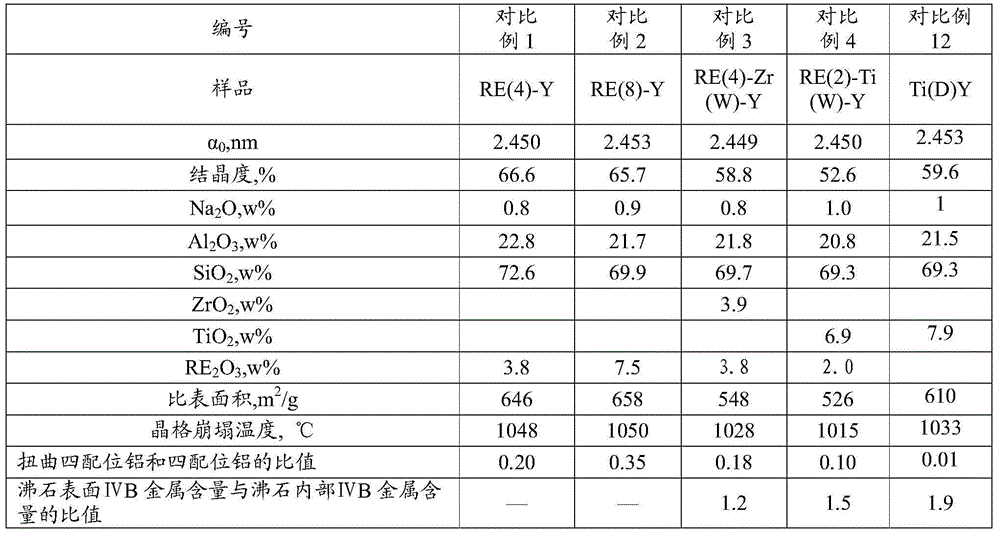

Isomorphous composite molecular sieve and preparation method and application thereof

ActiveCN104556125AHigh hydrothermal stabilityHigh cracking activityCatalyst carriersMolecular sieve catalystsMolecular sieveSodium silicate

The invention discloses a method for preparing composite molecular sieves. The method includes the following steps: (1) aging a mixture of sodium silicate, sodium hydroxide, water and aluminum source at a temperature of 25-100 DEG C for 1-72 hours to obtain a directing agent, wherein the molar ratio of each material in the mixture is as follows: n(Na2O):n(Al2O3):n(SiO2):n(H2O)=(12-20):1:(12-20):(320-450); (2) adding Y-type molecular sieves and the directing agent prepared in step (1) into the mixture of sodium silicate, sodium hydroxide, aluminum source and water, stirring to obtain gelatin and crystallizing the gelatin at a constant temperature of 90-120 DEG C for 12-72 hours, and then cooling, washing, extracting and filtering, and drying to obtain Y-Y composite molecular sieves, wherein the mass of the added Y-type molecular sieves accounts for 4-40% of the total mass of the gelatin system, and the mass of the added directing agent accounts for 2-20% of the total mass of the gelatin system. The hydrothermal stability of the nanoscale Y-type molecular sieves in the prepared composite molecular sieves is improved remarkably, and the prepared composite molecular sieves have more prominent hydrocracking performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phosphorus-containing MFI structure molecular sieve and preparation method thereof

ActiveCN107973317APromote generationFacilitated DiffusionMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveActive component

The invention discloses a phosphorus-containing MFI structure molecular sieve and a preparation method thereof, wherein the n(SiO2) / n(Al2O3) of the molecular sieve is more than 18 and is less than 70,the phosphorus content (calculated as P2O5) of the molecular sieve is 1-15 wt% by using the dry base weight of the molecular sieve as the reference, the volume of the mesopores of the molecular sieveaccounts for 40-70% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 85% of the total mesopore volume, the amount of the strong acid of the molecular sieve accounts for 45-75% of the total acid amount, and a ratio of the acid B to the acid L is 8-30. According to the present invention, with the catalyst or the auxiliary agent prepared by using the phosphorus-containing MFI structure molecular sieve as the active component, the propylene yield and the propylene selectivity can be effectively increased in the catalytic cracking or catalytic cracking reaction of petroleum hydrocarbons while the yield of BTX can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

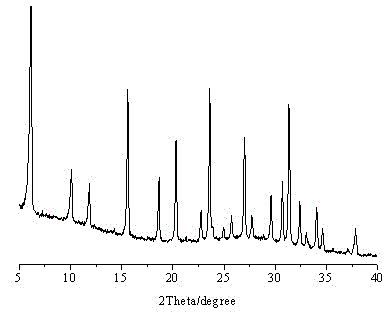

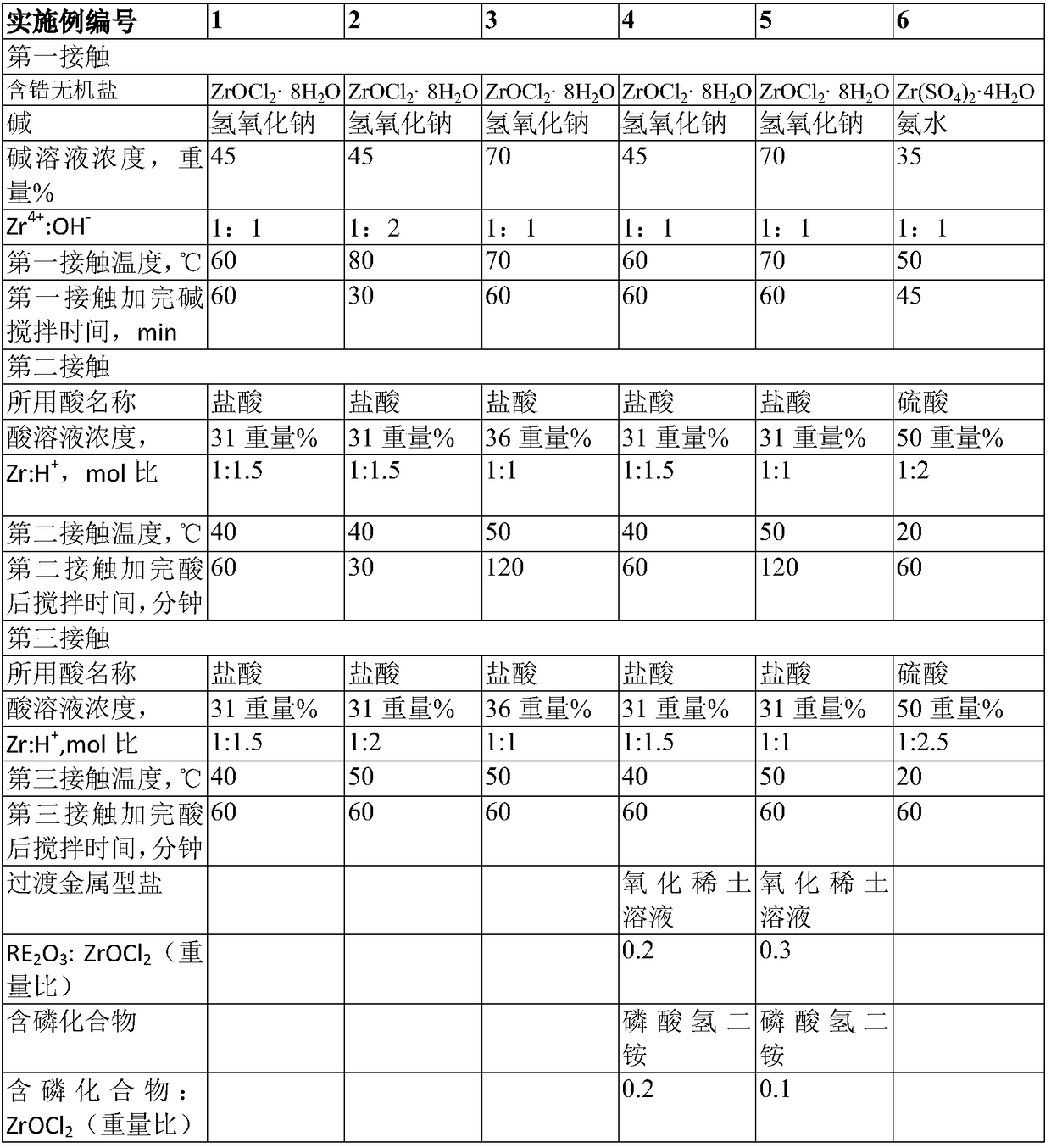

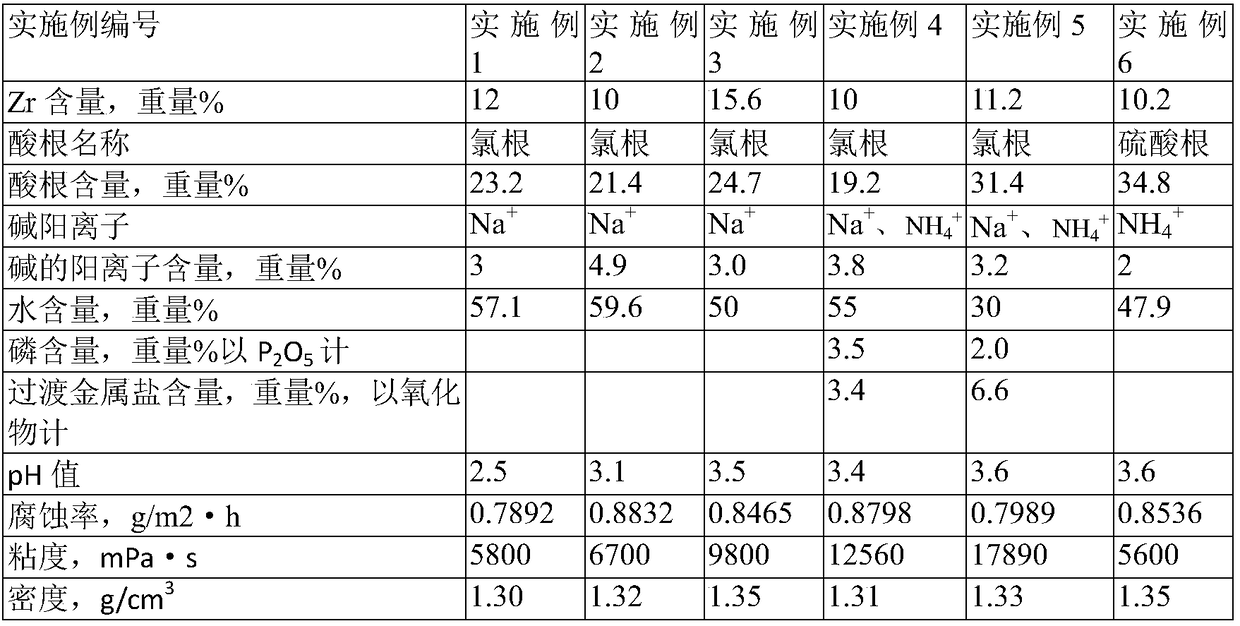

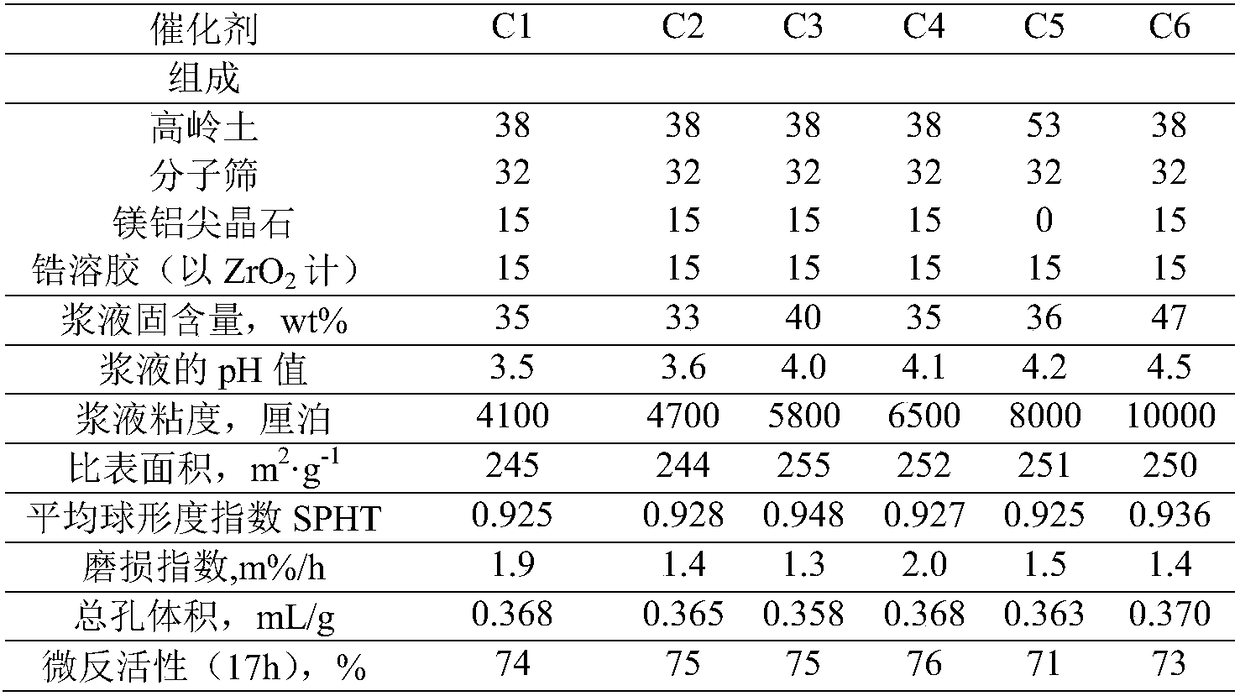

Zirconium sol, preparation method and applications thereof

ActiveCN109110808AImprove adhesionLess corrosiveCatalytic crackingMolecular sieve catalystsCracking reactionViscosity

The invention relates to a zirconium sol, a preparation method and applications thereof, wherein the zirconium sol has a corrosion rate of not more than 1 g / m<2>.h, the pH value of 2.5-4, and the viscosity of more than 1000 mPa.s. The preparation method comprises: carrying out first contact on a zirconium-containing salt and an alkali solution, wherein a molar ratio of Zr to OH<-> is 1:1-2; carrying out second contact on the first contact mixture and an acid, wherein a molar ratio of Zr to H<+> is 1:1-3, and preferably the temperature of the first contact is 20-30 DEG C higher than the temperature of the second contact; and carrying out third contact on the second contact mixture and an acid, wherein a molar ratio of Zr to H<+> is 1:1-3. According to the present invention, the zirconium sol is used for preparing catalytic cracking catalysts, can improve the sphericity of the catalyst, and can improve the hydrocarbon oil cracking reaction effect of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mesoporous catalytic material containing phosphorus, magnesium and rare earth

ActiveCN104588071ARegulates and improves acid centersAdjust and improve the situationCatalytic crackingMolecular sieve catalystsTO-18Rare earth

The invention provides a mesoporous catalytic material containing phosphorus, magnesium and rare earth. The material is characterized in that the material has a pseudo-boehmite phase structure; the anhydrous compound composition of the material is, in terms of the weight of oxides, (0-0.2)Na2O.(40-85)Al2O3.(10-55)SiO2.(0.5-10)P2O5.(0.5-5)MgO.(0.5-5)RE2O3; the specific surface area of the material is 200 to 500 m2 / g; the total pore volume is 0.5 to 1.5 cm3 / g; and the average pore size is 8 to 18 nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst, as well as preparation method and application thereof

ActiveCN106179458AIncrease the content of poresFacilitated DiffusionCatalytic crackingMolecular sieve catalystsRare-earth elementLanthanide

The invention provides a catalytic cracking catalyst, as well as a preparation method and applications thereof. Based on the total weight of the catalytic cracking catalyst, the catalyst contains 1-50wt% of a mesoporous active material, the anhydrous chemical expression of the mesoporous active material in the weight ratio of oxides is: (0-0.2)Na2O.(40-85)Al2O3.(10-55)SiO2.(0.5-10)P2O5.(0.5-10)M<x>O<y>, wherein metal M is selected from one or more of Mg, and IIB, IIIB, IVB and VIIB group elements in a periodic table, as well as lanthanide rare earth elements, y is the highest valency state of the metal M when the metal M is formed into an M oxide, and numerical value of x and the numerical value of y enable the valence of M and the valence of O to be balanced. The catalytic cracking catalyst has low coke selectivity and high catalytic cracking activity in the catalytic cracking process of heavy oil, and can obtain lower gasoline sulfur content and higher gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method and application thereof

ActiveCN105195218AImprove adhesionHigh matrix activityCatalytic crackingMolecular sieve catalystsMolecular sieveActive component

The invention discloses a catalytic cracking catalyst and a preparation method and application thereof. The catalytic cracking catalyst comprises cracking active components, clay and binders, wherein the cracking active components comprise, by weight, 25%-70% of first Y-type molecular sieves, 10%-70% of second Y-type molecular sieves and 5%-20% of third Y-type molecular sieves; the binders are modified aluminum sol containing Cl and Si, based on the total weight of the modified aluminum sol, the content of Al ranges from 8% to 13% by weight, the content of Cl ranges from 4% to 9% by weight, the weight ratio of Al to Cl is 1.2-2.2 to 1, the content of Si ranges from 0.1% to 1% by weight, and the pH value of the modified aluminum sol ranges from 2.2 to 5.2. The catalytic cracking catalyst has lower coke selectivity and higher catalytic cracking activity in the heavy oil catalytic cracking process, and a higher gasoline yield can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN108452838AHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveFuel oil

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains clay, alumina containing an additive and a modified Y type molecular sieve. The modified Y type molecularsieve comprises 5 to 12 wt% of rare earth and no more than 0.5 wt% of sodium oxide, and has a total pore volume of 0.36 to 0.48 mL / g; the pore volume of secondary pores accounts for 20 to 38% of thetotal pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum is no more than 10% of total aluminum content; lattice collapse temperature is higher than 1060 DEGC; and a ratio of the amount of acid B to the amount of acid L is no less than 3.50. A preparation method for the catalytic cracking catalyst comprises the following steps: preparing a rare earth-containing Y type molecular sieve with a conventional cell size; carrying out roasting in a water vapor atmosphere with a temperature of 350 to 520 DEG C and a volume percentage of 30 to 95% for 4.5 to 7h; carrying out a contact reaction with silicon tetrachloride; and carrying out acid treatment. The catalytic cracking catalyst has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y zeolite and preparation and application thereof

ActiveCN106145153AGood choiceHigh gasoline yieldCatalytic crackingMolecular sieve catalystsMolecular sieveOrganic solvent

Provided are modified Y zeolite and preparation and application thereof. The modified Y zeolite is prepared from, by oxide, 1-15 wt% of group IV B metal and 1-15 wt% of rare earth. The ratio of distorted tetrahedral-coordinated framework aluminum to tetrahedral-coordinated framework aluminum in the lattice structure of the modified Y zeolite is (0.2-0.8):1, and the ratio of the metal content on the surface of the zeolite to the metal content in the zeolite is not larger than 0.2. A preparation method of the modified Y zeolite comprises the steps that rare earth ion exchange calcination is carried out; Y zeolite with the water content not larger than 5 wt% is treated with an organic solvent and a modified metallic compound; calcination is carried out. The modified Y zeolite has high thermal and hydrothermal stability, and a cracking catalyst prepared from the modified Y molecular sieve has good activity and coke selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for production of light olefins from hydrocarbon feedstock

ActiveCN101233213AReactiveHigh selectivityCatalytic crackingHydrocarbon by hydrocarbon crackingMolecular sieveNaphtha

Disclosed is a process for producing light olefins from hydrocarbon feedstock. The process is characterized in that a porous molecular sieve catalyst consisting of a product obtained by evaporating water from a raw material mixture comprising a molecular sieve with a framework of -Si-OH-Al- groups, a water-insoluble metal salt, and a phosphate compound, is used to produce light olefins, particularly ethylene and propylene, from hydrocarbon, while maintaining excellent selectivity to light olefins. According to the process, by the use of a specific catalyst with hydrothermal stability, light olefins can be selectively produced in high yield with high selectivity from hydrocarbon feedstock, particularly full-range naphtha. In particular, the process can maintain higher cracking activity than the reaction temperature required in the prior thermal cracking process for the production of light olefins, and thus, can produce light olefins with high selectivity and conversion from hydrocarbon feedstock.

Owner:SK INNOVATION CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com