Method for raising content of rare earth of ultra stable Y type zeolite

A zeolite and rare earth technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve problems such as inability to stabilize the zeolite framework, achieve increased rare earth content, smooth channels, and strong heavy oil conversion capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

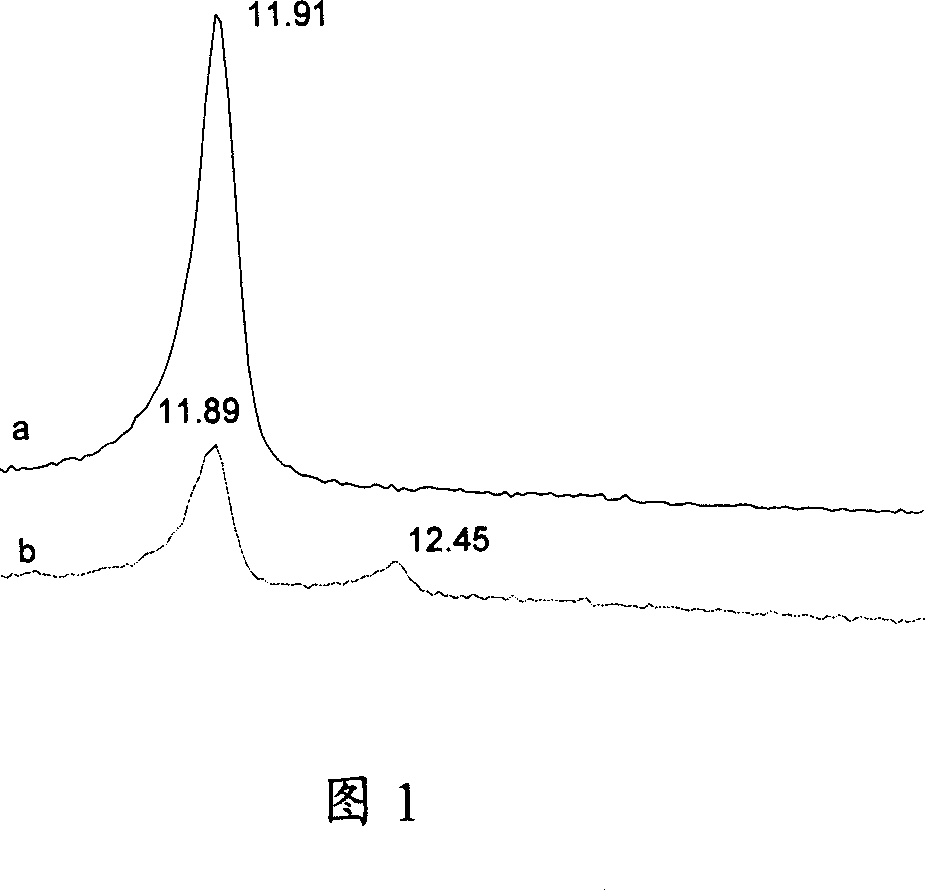

Image

Examples

Embodiment 1

[0030] Take 100 grams of DASY2.0 (dry basis), add it to 1 liter of 0.2N oxalic acid aqueous solution, stir to mix evenly, raise the temperature to 90-100°C and keep it for 1 hour, then filter, wash, take out the filter cake, and place it in 1 liter of decationization water, add 32ml of RECl 3 solution (319g / L), stirred, heated up to 90-95°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a rare earth ultra-stable Y-type zeolite sample, which was recorded as A1. Table 2.

Embodiment 2

[0032]Take 100 grams of DASY2.0 (dry basis), add it to 1 liter of 0.1N oxalic acid aqueous solution and stir to make it evenly mixed, raise the temperature to 90-100 ℃ and keep it for 1 hour, filter, wash, take out the filter cake, and place it in a 1 liter cationic water and add 32ml of RE(NO 3 ) 3 Solution (319g / L), stirred, heated up to 90-95°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a rare earth ultra-stable Y-type zeolite sample, which was recorded as A2, and its physical properties are shown in the table 2.

Embodiment 3

[0034] Take 100 grams of DASY2.0 (dry basis), add it to 1 liter of 0.2N citric acid aqueous solution and stir to make it evenly mixed, raise the temperature to 90-100°C and keep it for 1 hour, filter, wash, take out the filter cake, and place it in 1 liter deionized water and add 32ml of RECl 3 Solution (319g / L), stirred, heated up to 90-95°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a rare earth ultra-stable Y-type zeolite sample, which was recorded as A3, and its physical properties are shown in the table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com