Catalytic cracking catalyst, as well as preparation method and application thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as poor coke selectivity, and achieve the effects of high gasoline yield, low gasoline sulfur content, and low coke selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Wherein, the preparation method of the first rare earth-containing Y-type molecular sieve includes: contacting the rare-earth-containing Y-type molecular sieve with silicon tetrachloride under stirring, the contact temperature is 100-500°C, and the stirring time is 1- For 10 hours, the weight ratio of the rare earth-containing Y-type molecular sieve to silicon tetrachloride is 1:0.05-0.5;

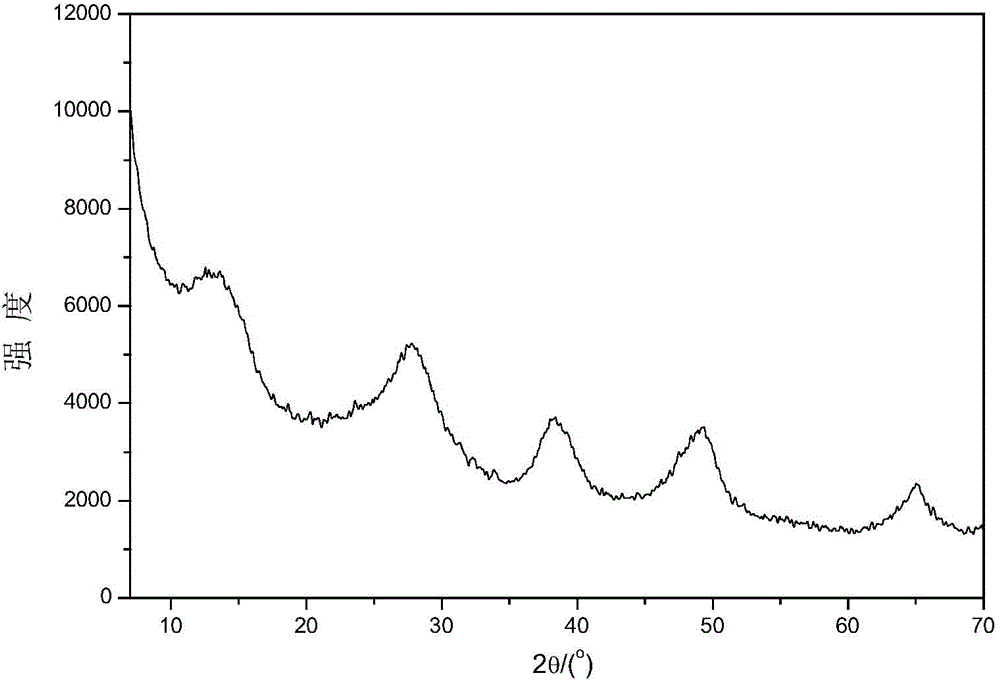

[0024] The silicon to aluminum ratio of the second rare earth-containing Y-type molecular sieve is 5-30:1, and the initial unit cell constant is 2.430-2.460 nm, based on the total weight of the second rare-earth-containing Y-type molecular sieve and based on oxidation The content of the rare earth in the material is 10-20% by weight, and the ratio of the equilibrium cell constant to the initial cell constant is at least 0.985. The X-ray diffraction analysis of the molecular sieve is two of 12.43±0.06° and 11.87±0.06° in 2θ. Diffraction peak intensity ratio I 1 / I 2 Greater than 1;

[002...

preparation example 1

[0080] This preparation example is used to illustrate the phosphorus and metal modified mesoporous silicon-aluminum material and the preparation method thereof provided by the present invention.

[0081] (1) First change the concentration to 90gAl 2 O 3 / L of Al 2 (SO 4 ) 3 The solution is placed in a beaker, and 25wt.% ammonia water is added with stirring until the pH of the system is 10.0, and the gel forming temperature is maintained at 40°C, and the gelling temperature is collected and measured into a gel slurry; (2) under stirring conditions according to SiO 2 : Al 2 O 3 =1:3 by weight ratio, add 60g SiO to the colloidal slurry 2 / L of water glass, heated to 80°C and aged for 1 hour to obtain the first solid precipitate; (3) The first solid precipitate was dried according to its precipitate: HCl:H 2 The weight ratio of O=1:0.08:12 was exchanged at 50°C for 30 minutes, filtered and washed to obtain a second solid precipitate with a sodium oxide content of less than 0.3%; (4) The...

preparation example 2

[0084] This preparation example is used to illustrate the phosphorus and metal modified mesoporous silicon-aluminum material and the preparation method thereof provided by the present invention.

[0085] (1) Take the concentration as 90gAl 2 O 3 / L of Al 2 (SO 4 ) 3 Solution and concentration is 102gAl 2 O 3 / L, NaAlO with a caustic ratio of 2.5 2 The solution is the raw material for the reaction, and the co-current gel forming method is adopted, and the gel is mixed under vigorous stirring. The temperature of the system is controlled to 40°C, the pH of the system is 10.5, and the solution is collected and measured into a gel slurry; 2 : Al 2 O 3 =1:1.2 by weight ratio, add 100g SiO to the colloidal slurry 2 / L of water glass, heated to 70°C and aged for 2 hours to obtain the first solid precipitate; (3) The first solid precipitate was dried according to its precipitate: HCl:H 2 The weight ratio of O=1:0.08:15 was exchanged at 60°C for 30 minutes, filtered and washed with water to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com