A kind of catalytic cracking catalyst and its preparation method and application

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as poor coke selectivity, achieve low coke selectivity, increase the content of mesopores, and high diesel oil yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the preparation method of the above-mentioned mesoporous active silicon-phosphorus-aluminum material, the steps before obtaining the solid product can be carried out with reference to the method disclosed in CN1565733A.

[0040] Specifically, the aluminum source can be various existing substances that can be converted into aluminum oxide, for example, can be selected from one or more of aluminum nitrate, aluminum sulfate and aluminum chloride.

[0041] The alkaline solution can be various existing alkaline substances, for example, can be selected from one or more of ammonia water, sodium hydroxide solution, potassium hydroxide solution and sodium metaaluminate solution. Wherein, the concentration of the alkaline solution can be a conventional choice in the art, and details are not described here.

[0042] The silicon source can be various existing substances that can be converted into silicon oxide, for example, can be selected from one or more of water glass, sodium...

preparation example 1

[0070] This preparation example is used to illustrate the mesoporous active silicon-phosphorus-aluminum material provided by the present invention and the preparation method thereof.

[0071] With a concentration of 90gAl 2 O 3 / L of Al 2 (SO 4 ) 3 Solution and concentration of 102gAl 2 O 3 / L, NaAlO with a caustic ratio of 2.5 2 The solution is the raw material for the reaction, which is co-flowed to form a gel at 85 °C and the pH value of the gel is controlled to be 9.5. A certain amount of gel-forming slurry is collected, and the SiO 2 : Al 2 O 3 = 1:6.56, the concentration is 60gSiO 2 / L sodium water glass was heated to 70°C and aged for 2 hours to obtain a solid precipitate. with NH 4 Cl solution as solid precipitate (dry basis): NH 4 Cl:H 2 O = 1:0.8:15 weight ratio The solid precipitate was ion-exchanged at 60°C to remove sodium ions. The ion-exchange was repeated twice for 0.5 hours each time. After filtration, the sodium oxide content was less than 0.3% b...

preparation example 2

[0074] This preparation example is used to illustrate the mesoporous active silicon-phosphorus-aluminum material provided by the present invention and the preparation method thereof.

[0075] The mesoporous active silicon-phosphorus-aluminum material was prepared according to the method of Preparation Example 1, except that the amount of diammonium hydrogen phosphate was such that P 2 O 5 : solid product dry basis=0.095:1, react at 70°C for 2 hours, filter and wash, and then dry at 120°C for 10 hours to obtain mesoporous active silicon-phosphorus-aluminum material, denoted as A-2.

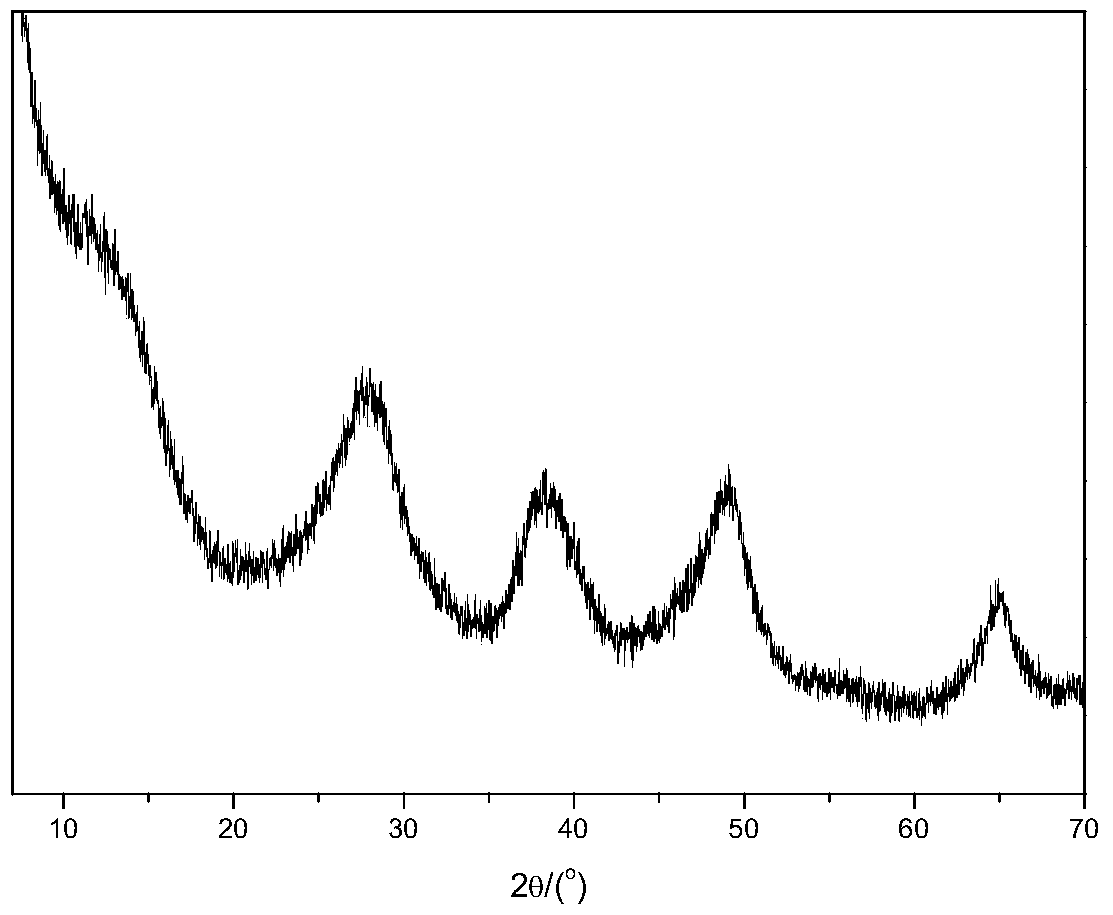

[0076] The mesoporous active silicon-phosphorus-aluminum material A-2 has a pseudo-boehmite structure, and its X-ray diffraction pattern is similar to the mesoporous active silicon-phosphorus-aluminum material A-1. Measured by X-ray fluorescence analysis, the chemical composition of the mesoporous active silicon-phosphorus-aluminum material A-2 in terms of the weight ratio of oxides is: 0.09Na 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com