Process for production of light olefins from hydrocarbon feedstock

A technology for light olefins and hydrocarbon raw materials, applied in the direction of hydrocarbon cracking, hydrocarbon oil treatment, hydrocarbon oil treatment products, etc., can solve the problems of structural collapse, easy deactivation of catalysts, dealumination of tetrahedral framework, etc., and achieve high cracking The effect of activity and excellent reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

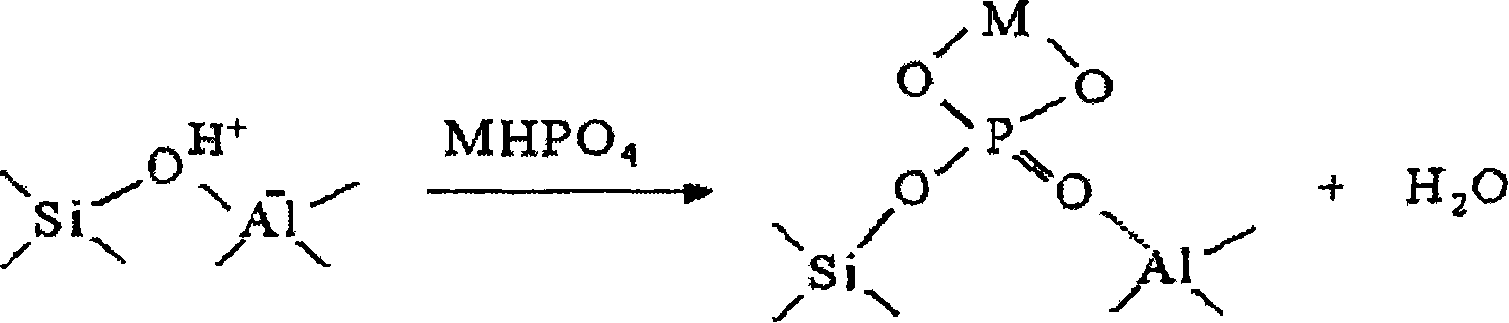

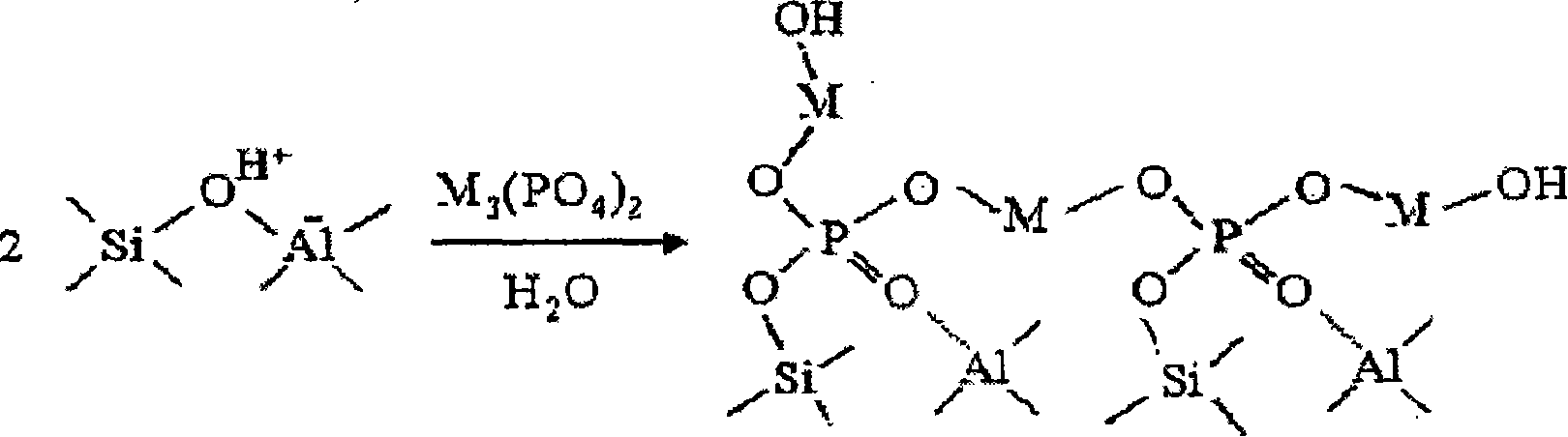

[0045] Although the description of the preparation of molecular sieve catalysts is not to be bound by a particular theory, it is believed that, as shown in Reaction Schemes 1 and 2 below, modification of -Si-OH-Al-groups forming molecular sieves using phosphate compound / metal composite structures Therefore, it is concentrated by the protons of zeolite. In this way, the ≡P=O group stabilizes the unstable Al, and at the same time, the two -OH groups are also stabilized by the metal. Therefore, even in high temperature and high humidity environments In this case, the skeleton structure can also be relatively stably maintained.

[0046] Reaction scheme 1

[0047]

[0048] Reaction scheme 2

[0049]

[0050] The methods for preparing porous molecular sieve catalysts can be broadly classified into two methods involving a step of removing water contained in the above raw material mixture by selective evaporation to recover a solid product.

[0051] A method of preparing a cat...

Embodiment 1

[0077] A) Preparation of catalyst

[0078] Add 10 g of HZSM-5 (Zeolyst) with a Si / Al molar ratio of 25 and 0.55 g of concentrated phosphoric acid (85% H 3 PO 4 ), and stirred for 20 minutes. To the stirred solution was added 0.36 g of Mg(OH) 2 , and the pH of the mixture was adjusted to 7-8 with ammonia water, followed by stirring at about 45° C. for about 20 minutes. The mixture was then stirred at about 50°C until the water was completely evaporated, then the solid product was isolated by vacuum filtration. The isolated solid product was calcined in air at 500 °C for 5 hours to obtain Mg-HPO 4 - HZSM-5 catalyst.

[0079] B) Procedure for steam treatment to evaluate hydrothermal stability

[0080] In order to evaluate the hydrothermal stability of the catalyst, the catalyst was placed in a 100% steam atmosphere at 750°C for 24 hours.

[0081] C) Preparation of light olefins

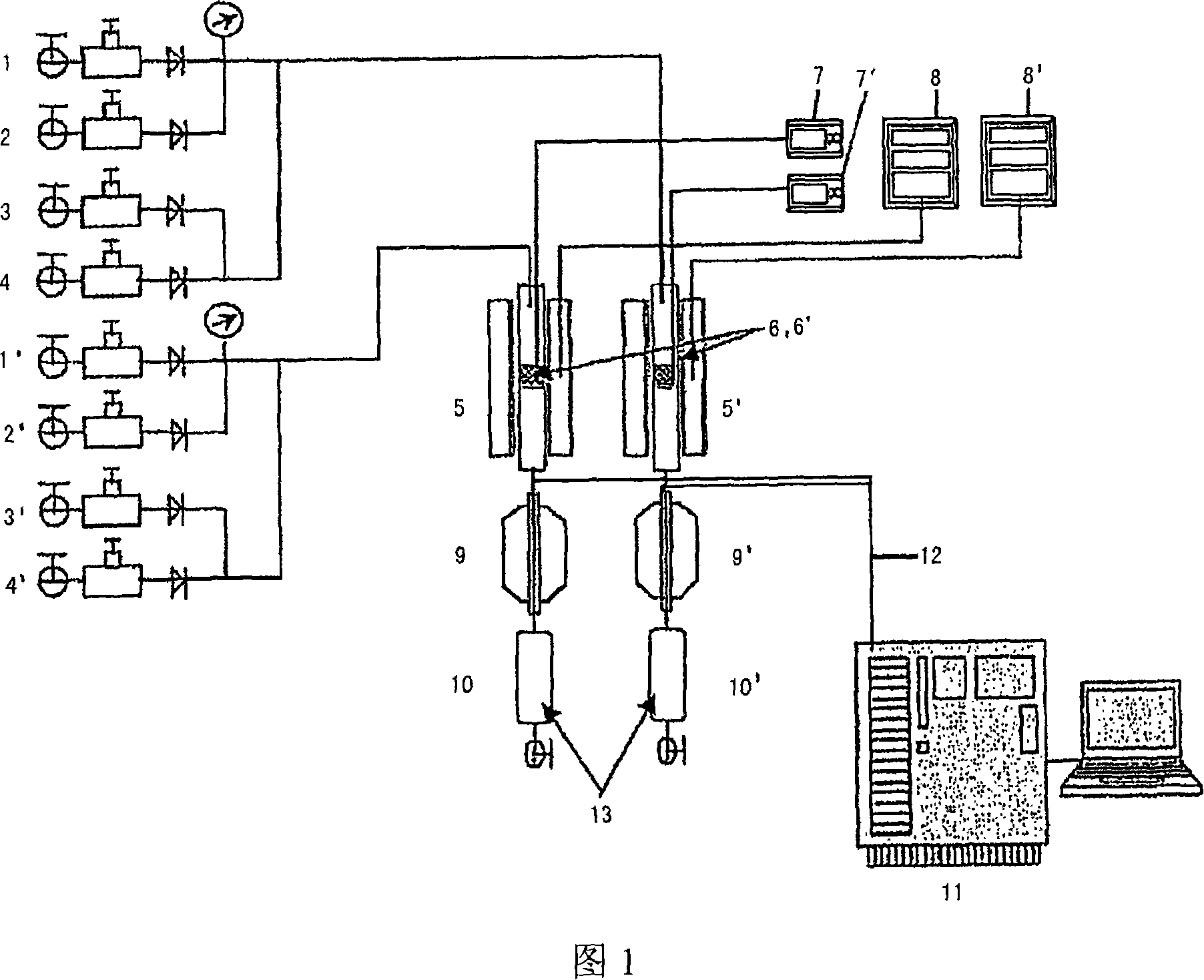

[0082] As shown in Figure 1, a kind of system that detects catalyst activity in the process o...

Embodiment 2

[0086] A) Preparation of catalyst

[0087] Add 10 g of HZSM-5 (Zeolyst) with a Si / Al molar ratio of 25 and 0.26 g of concentrated phosphoric acid (85% H 3 PO 4 ), and stirred for about 20 minutes. To the stirred solution was added 0.08 g of Mg(OH) 2 , and the pH of the mixture was adjusted to 2-3 with aqueous nitric acid, followed by stirring at about 45° C. for about 20 minutes. The mixture was stirred at about 50°C until the water was completely evaporated, then the solid product was isolated by vacuum filtration. The isolated solid product was calcined in air at 500°C for 5 hours to obtain Mg-H 2 PO 4 - HZSM-5 catalyst.

[0088] B) Procedure for steam treatment to evaluate hydrothermal stability

[0089] The steam treatment step was performed in the same manner as in Example 1.

[0090] C) Preparation of light olefins

[0091] Light olefins were prepared in the same manner as in Example 1.

[0092] The results obtained for conversion, selectivity of light olefins ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com