Modified Y zeolite and preparation and application thereof

A zeolite, modified technology, applied in the field of modified Y zeolite and its application in catalytic cracking agent, can solve the problem of low yield of cracking catalyst gasoline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

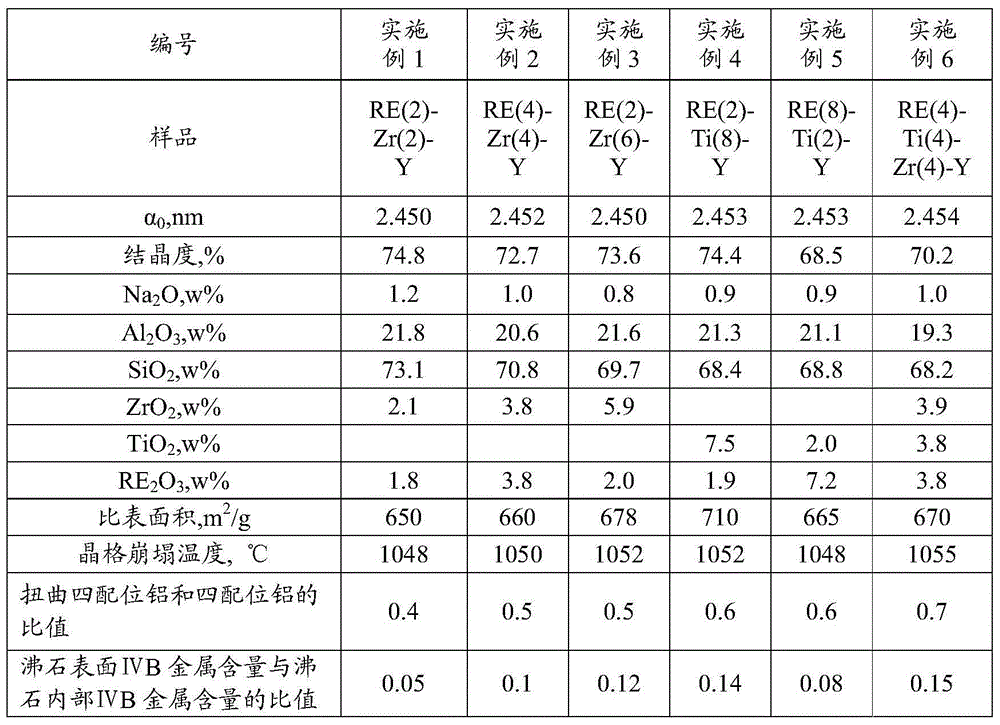

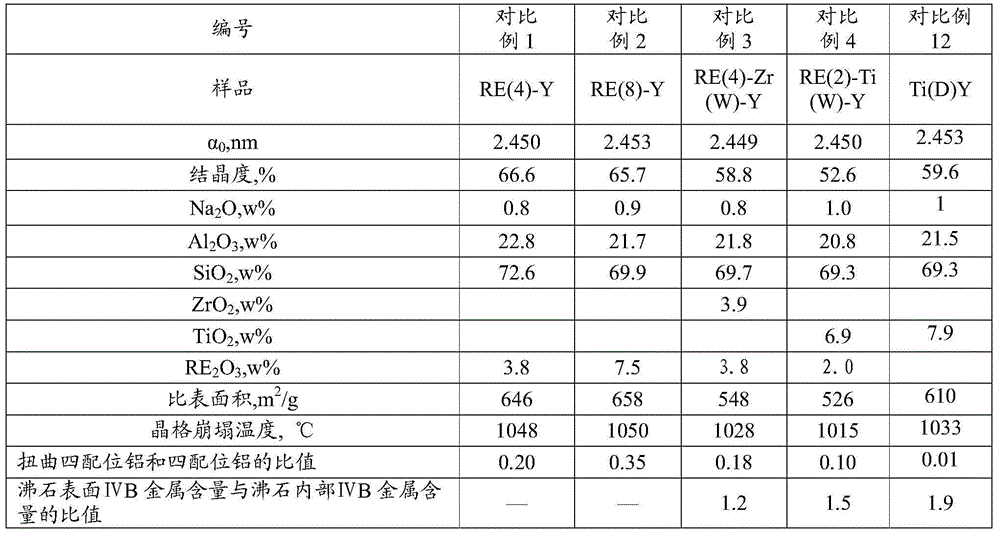

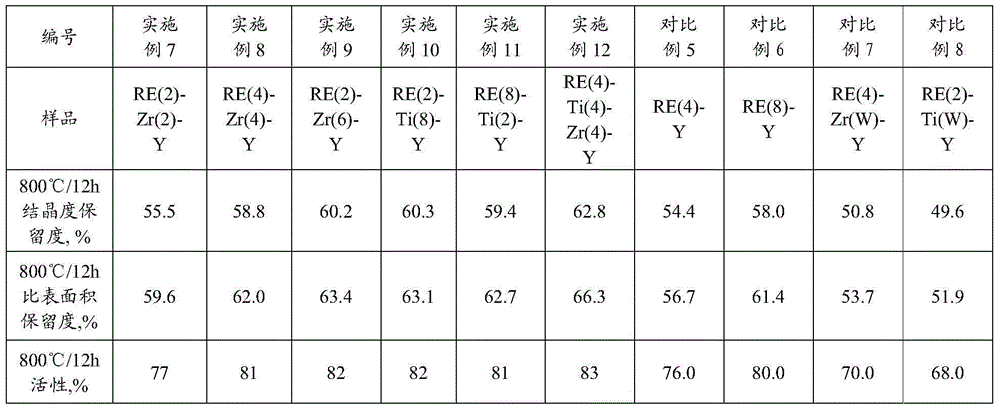

Examples

Embodiment 1

[0056] At room temperature, get 200g NaY zeolite (dry basis accounts for 75% by weight), after beating with 1500g deionized water, add 45 grams (NH 4 ) 2 SO 4 and 11.3 mL of RECl 3 Solution (RE 2 o 3 The concentration is 270 g / L, the same below), rare earth salt (in RE 2 o 3 Calculate): ammonium salt: NaY zeolite: the weight ratio of deionized water is 0.02:0.3:1:10, the pH value of the slurry is adjusted to 3.8 with dilute hydrochloric acid with a concentration of 5% by weight, and then the temperature is raised to 90° C. for exchange for 1 hour. After filtering and washing with deionized water, the filter cake was calcined at 600° C. in 100% water vapor for 2 hours to obtain a rare earth modified Y zeolite with a water content of 3% by weight.

[0057] Place the Y zeolite modified by the above rare earth in 2000g ethanol (99.9% by weight of ethanol content) at room temperature and stir evenly, add 10.5g zirconium nitrate Zr (NO 3 ) 4 ·5H 2 O, then stirred at room te...

Embodiment 2

[0059] At room temperature, take 200g of NaY zeolite (dry basis accounts for 75% by weight), after beating with 2250g of deionized water, add 75g of ammonium chloride and 22.2ml of RECl 3 Solution (concentration 270 g / L), rare earth salt (in RE 2 o 3 Meter): ammonium salt: NaY zeolite: the weight ratio of deionized water is 0.04:0.5:1:15, the pH value of the slurry is adjusted to 3.6 with dilute hydrochloric acid with a concentration of 5% by weight, and then the temperature is raised to 90° C. for exchange for 1 hour, After filtering and washing with deionized water, the filter cake was dried, and then calcined at 650° C. in 100% water vapor for 2 hours to obtain a rare earth modified Y zeolite with a water content of 2% by weight.

[0060] Place the above rare earth modified Y zeolite in 1500g ethanol (99.9% by weight) of ethanol at room temperature and stir evenly, add 15.7g zirconium oxychloride ZrOCl to the above slurry 2 ·8H 2 O, continue to stir at room temperature f...

Embodiment 3

[0062] At room temperature, take 200g of NaY zeolite (dry basis is 75% by weight), after beating with 3000g of deionized water, add 30g of ammonium chloride and 11.1ml of RECl 3 Solution (concentration 270 g / L), rare earth salt (in RE 2 o 3 Meter): ammonium salt: NaY zeolite: the weight ratio of deionized water is 0.02:0.2:1:20, the pH value of the slurry is adjusted to 3.8 with dilute hydrochloric acid with a concentration of 5% by weight, and then the temperature is raised to 85° C. for exchange for 2 hours. After filtering and washing with deionized water, the filter cake was dried and then calcined at 550° C. in 100% steam for 3 hours to obtain a rare earth modified Y zeolite with a water content of 3% by weight.

[0063] Put the Y zeolite modified by rare earth above in 1000g of n-hexane (n-hexane content 99.5% by weight) and stir evenly at room temperature, add 28.3g of zirconium isopropoxide C 15 h 36 o 5 Zr, continue to stir at room temperature for 3 hours, filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com