Patents

Literature

53results about How to "High thermal and hydrothermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst used for synthesizing middle distillate from synthetic gas, its preparation method and application

InactiveCN1785515AHigh thermal and hydrothermal stabilityGood stabilityLiquid hydrocarbon mixture recoveryCatalyst activation/preparationCOBALTOUS NITRATENon noble metal

A catalyst for synthesizing the intermediate oil from synthetic gas by Fischer-Tropsch reaction contains Co (5-35 Wt%), mesoporous ZrO2 as carrier (53-93), noble metal (0-2) and oxide of non-noble metal. Its preparing process includes such steps as impregnating said carrier in the aqueous solution of nitrate containing the oxide of non-noble metal or the alcohol solution of organic alkydester, and impregnating it in the equeous solution of cobalt nitrate and the nitrate (or chloride) or noble metal. It has high activity, stability, selectivity and mechanical performance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

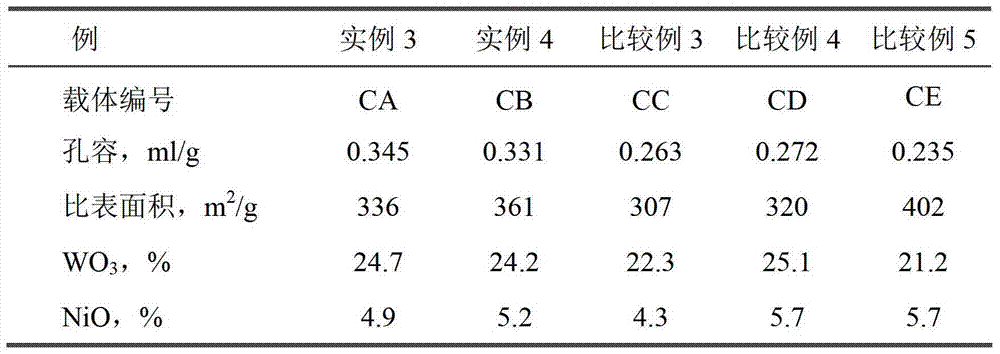

Light oil type hydrocracking catalyst with composite molecular sieve as well as preparation method and application thereof

ActiveCN103394368BGood catalytic cracking performanceGood catalyticMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a light oil type hydrocracking catalyst with a composite molecular sieve. The hydrocracking catalyst comprises the composite molecular sieve consisting of a modified Y-molecular sieve and a modified ZSM-23 molecular sieve, a carrier composed of micropore aluminum oxides, and a hydrogenation activity component composed of a VIB group metal and a VIII group metal. The hydrocracking catalyst is characterized in that the composite molecular sieve comprises the modified Y-molecular sieve and the modified ZSM-23 molecular sieve, and the Y-molecular sieve is modified and dealuminized, so that heat stability and hydrothermal stability are stably enhanced, the hydrophobicity is enhanced, the absorption and desorption properties of the molecular sieve are improved, and the catalyst achieves a high catalytic cracking property. The pore passages of the modified SM-23 molecular sieve are unobstructed, the number of the acid sites is small, the isomerism property is outstanding, and the octane value of the molecular sieve is increased because of light naphtha components. The modified Y-molecular sieve and the modified ZSM-23 molecular sieve are mixed and used according to a formula ratio of the hydrocracking catalyst, so that both the cracking activity and the isomerism property are considered, and the final catalyst achieves an ideal catalytic effect.

Owner:CHINA NAT OFFSHORE OIL CORP +3

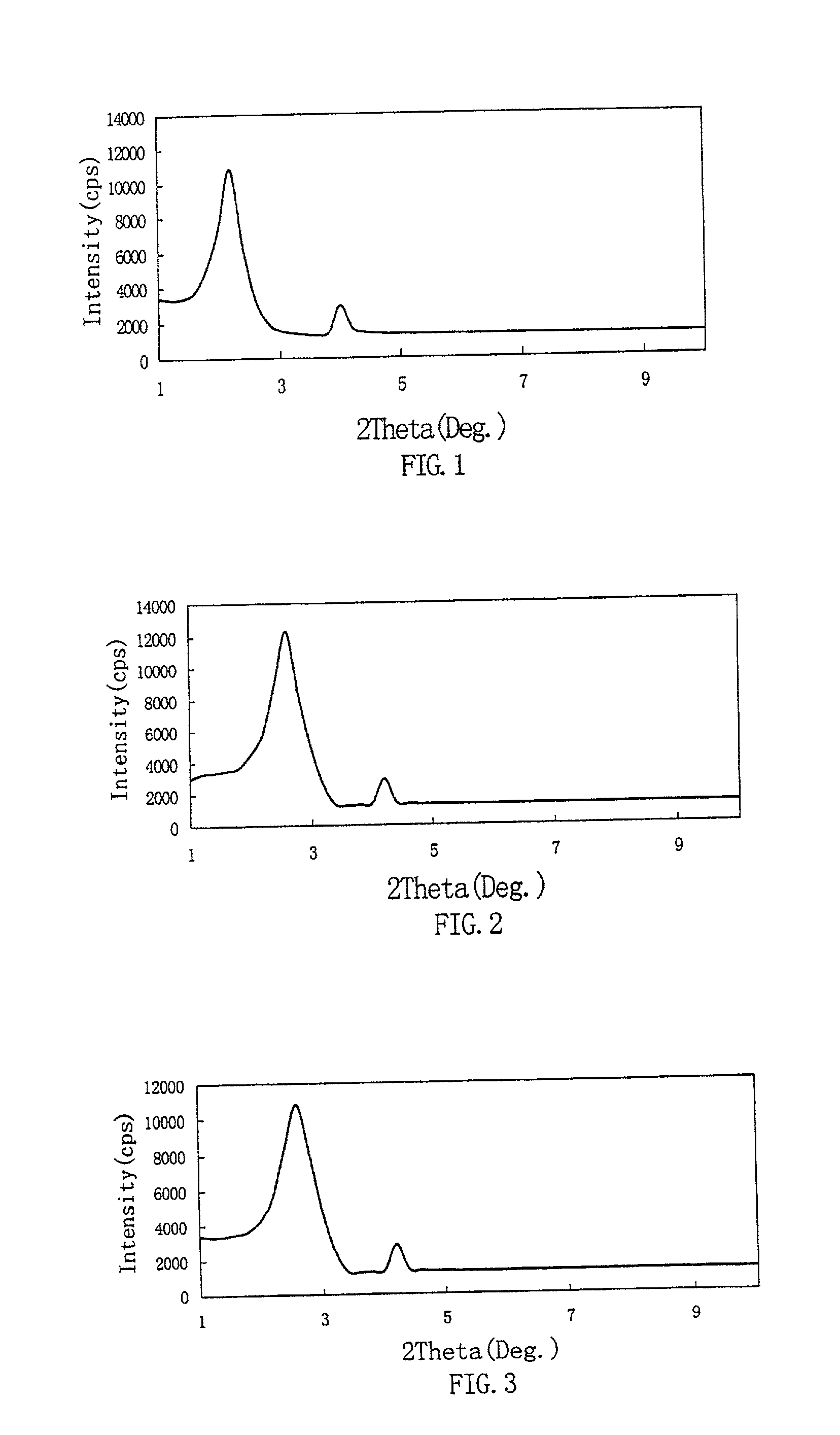

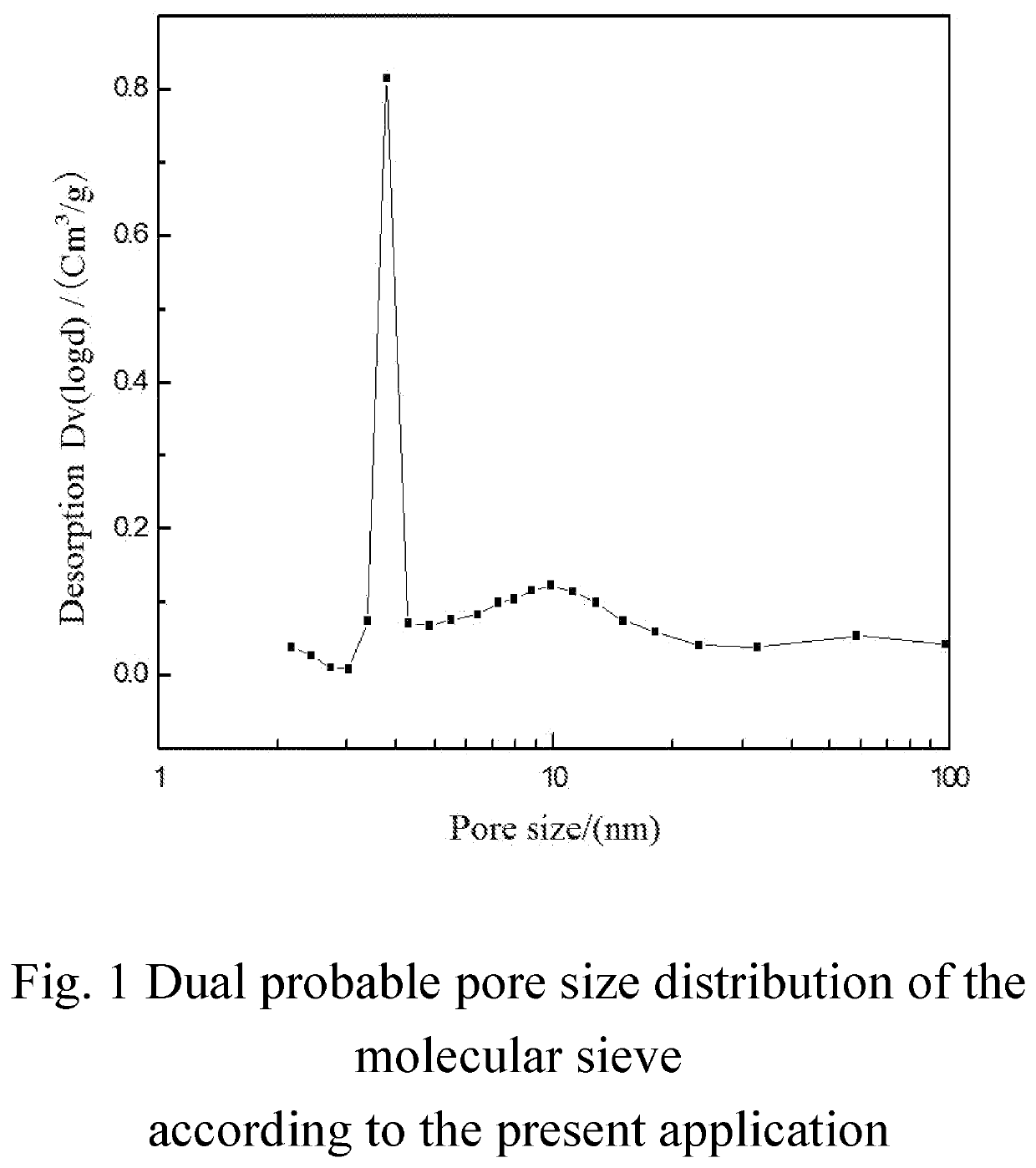

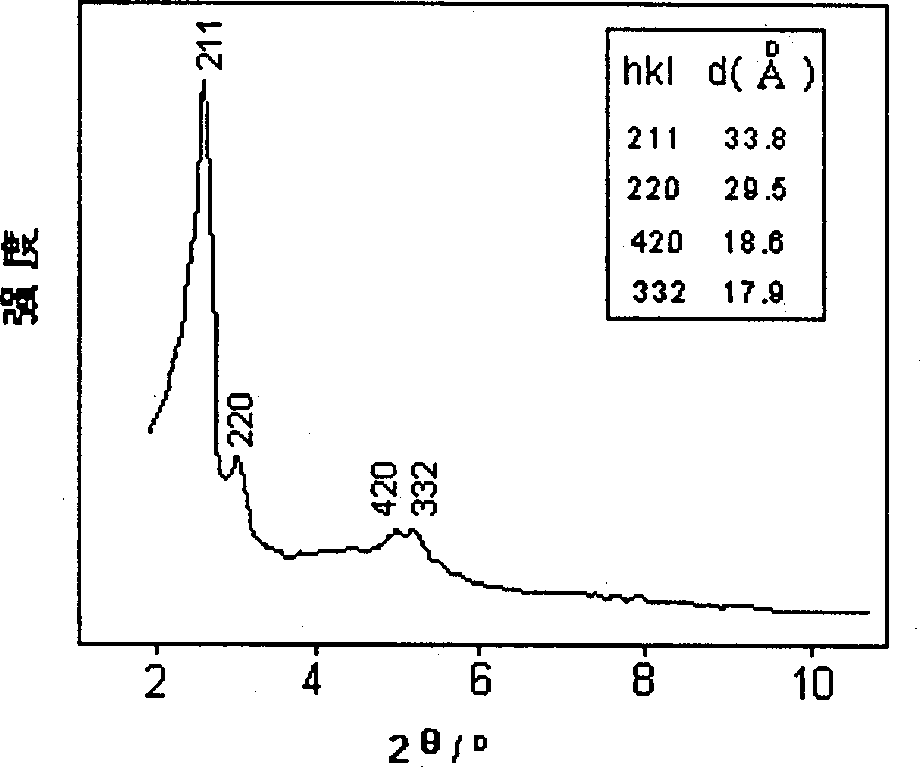

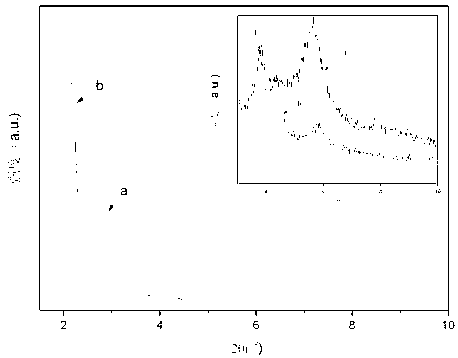

Method for pressure hydrothermal synthesis of MCM-41 mesoporous molecular sieve

InactiveCN1401568AThe synthesis method is simpleEasy to operateCrystalline aluminosilicate zeolitesHydrothermal synthesisNitrogen gas

A process for synthesizing the mesoporous molecular sieve MCM-41 includes mixing template agent with water and alkali catalyst, adding Si source, stirring to obtain mother liquid, feeding it in high-pressure reactor with teflon liner, filling nitrogen gas, heating, crystallizing, cooling, filtering, water washing, drying, heating, and calcining to remove template agent. The product has high stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Hydrodemetalizing catalyst and its prepn

InactiveCN101066530AHigh thermal and hydrothermal stabilityHigh carbon capacity and metal contentPhysical/chemical process catalystsPolymer scienceActive component

The present invention discloses one kind of hydrodemetalizing catalyst and its preparation process. The catalyst has alumina containing P, Mg and K as carrier, VIII and VIB metal element as the active component and optional auxiliary components. It is prepared through a simple preparation process. The catalyst is especially suitable for the hydrodemetalizing process of hydrocarbon with high oxygen content, high metal content and high easy-to-coke component content, such as light coal tar oil fraction, and has the features of high hydrodemetalizing activity, high stability and long service life.

Owner:林方 +4

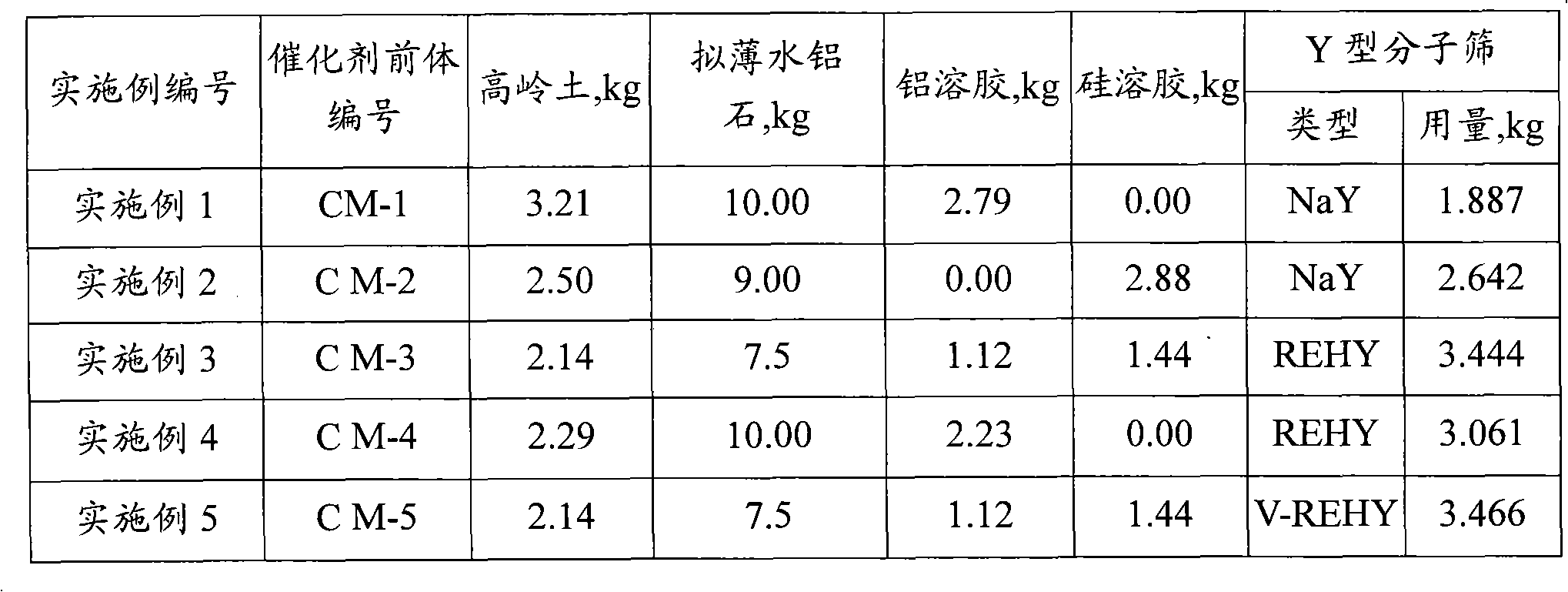

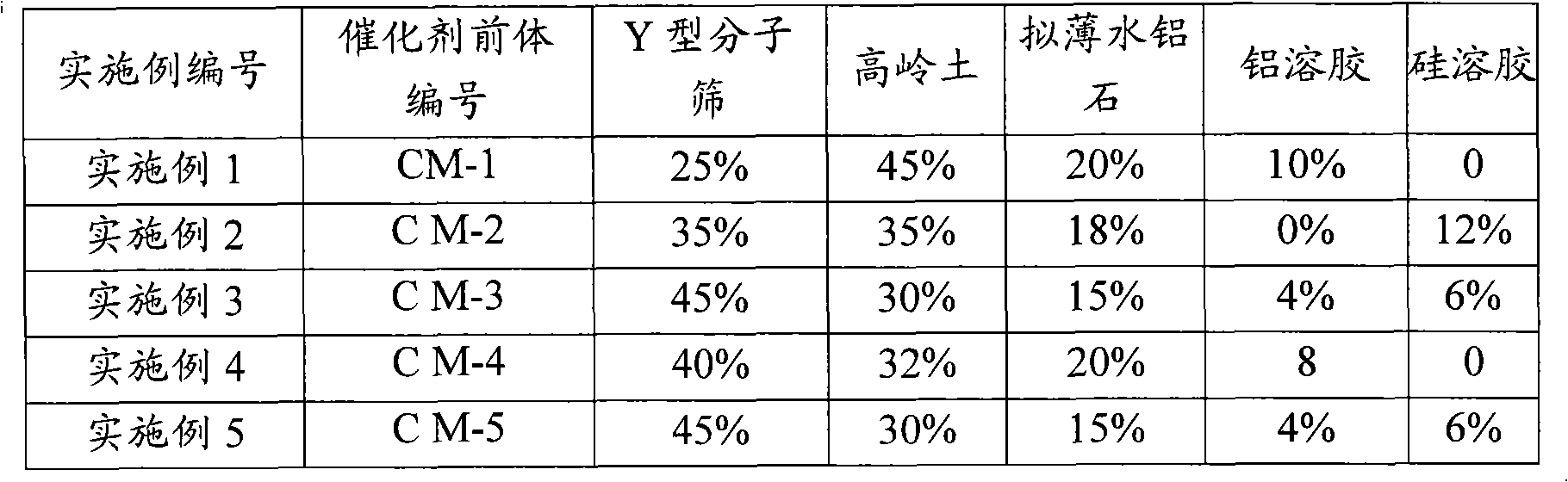

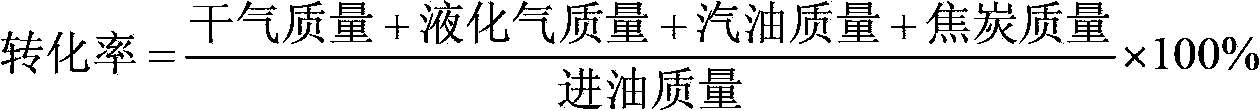

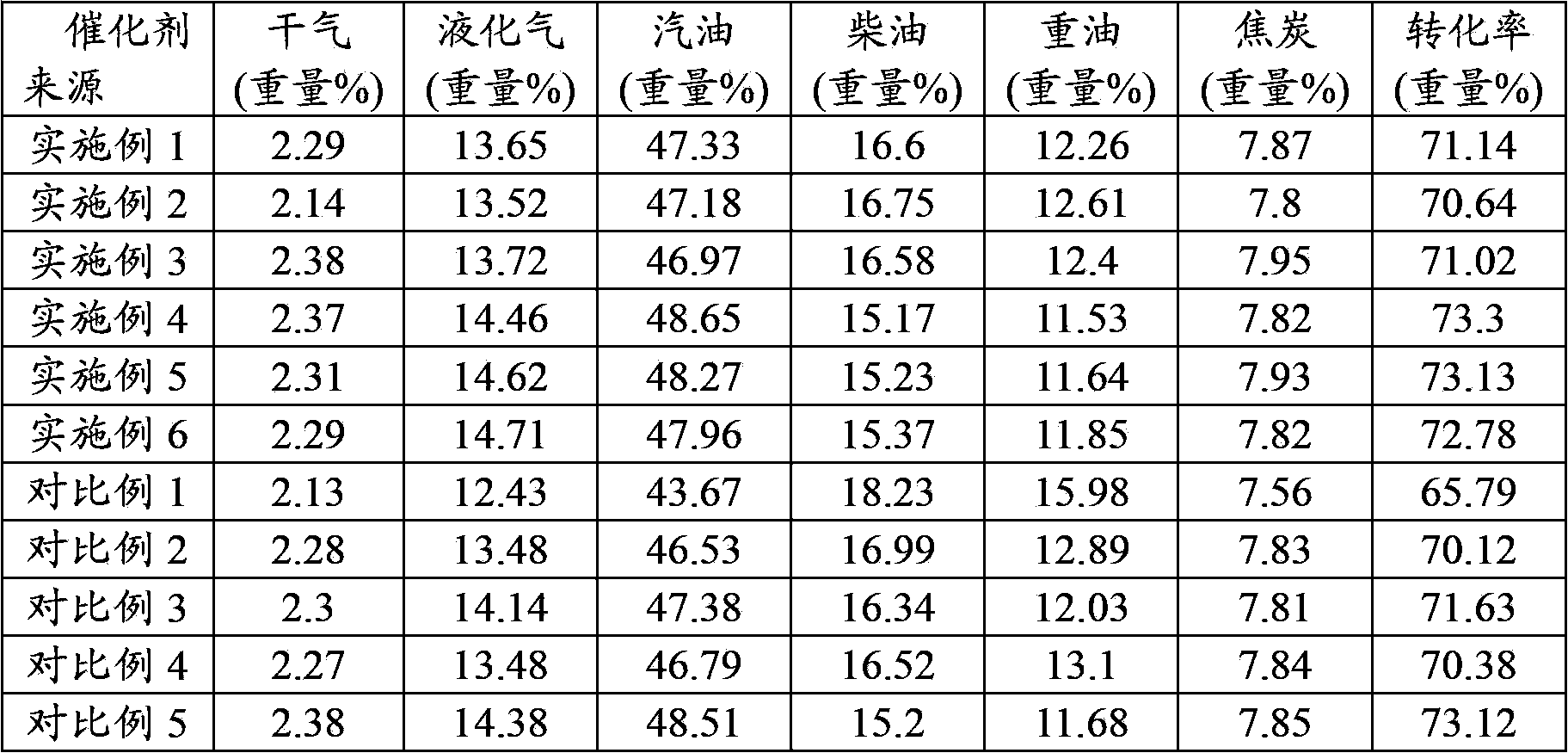

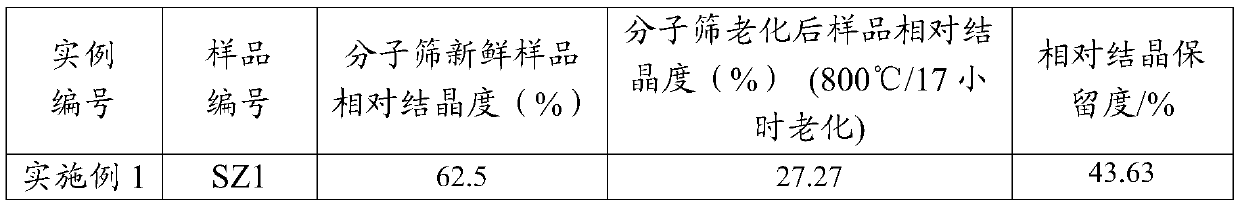

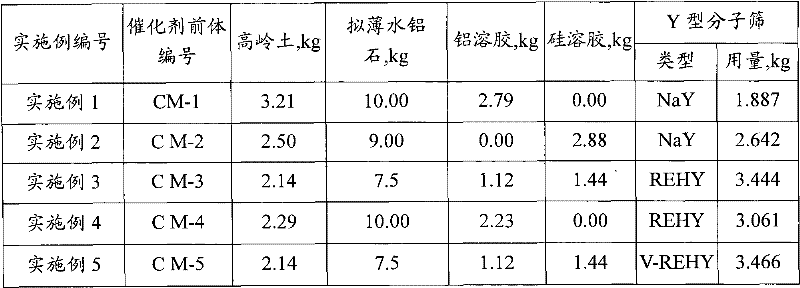

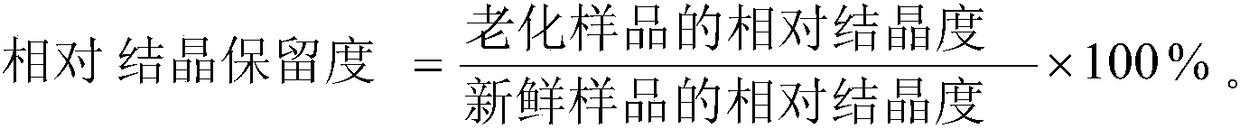

Cracking catalyst and preparation method thereof

ActiveCN102029177AHigh ratio of silicon to aluminumHigh crystallinityCatalytic crackingMolecular sieve catalystsMolecular sieveSulfur

The invention relates to a preparation method of a cracking catalyst, which comprises: raw materials and water are mixed to prepare a slurry solution by utilizing the catalyst containing a Y type molecular sieve and a silicon vector; the slurry solution is dried to obtain a catalyst precursor; the catalyst precursor is baked; and a contact reaction is carried out on the catalyst precursor and an acidic ammonium salt solution. The preparation method of the cracking catalyst can enhance the crystallization retaining degree of the Y type molecular sieve in the catalyst and the stability of the catalyst. The catalyst prepared by utilizing the method is used for the catalytic cracking of heavy oil and has the advantages of strong conversion capability of the heavy oil, high yield of gasoline, and low sulphur content in the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

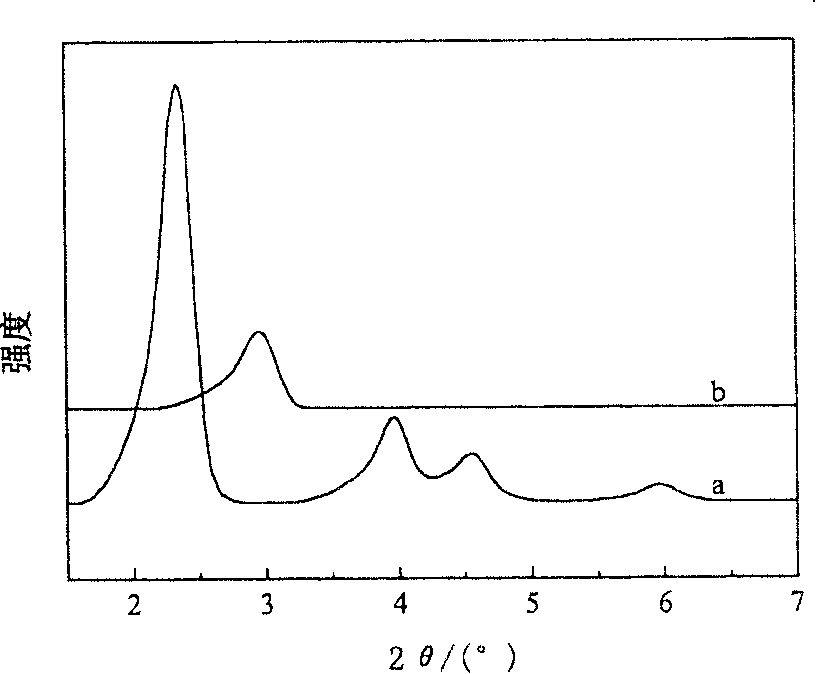

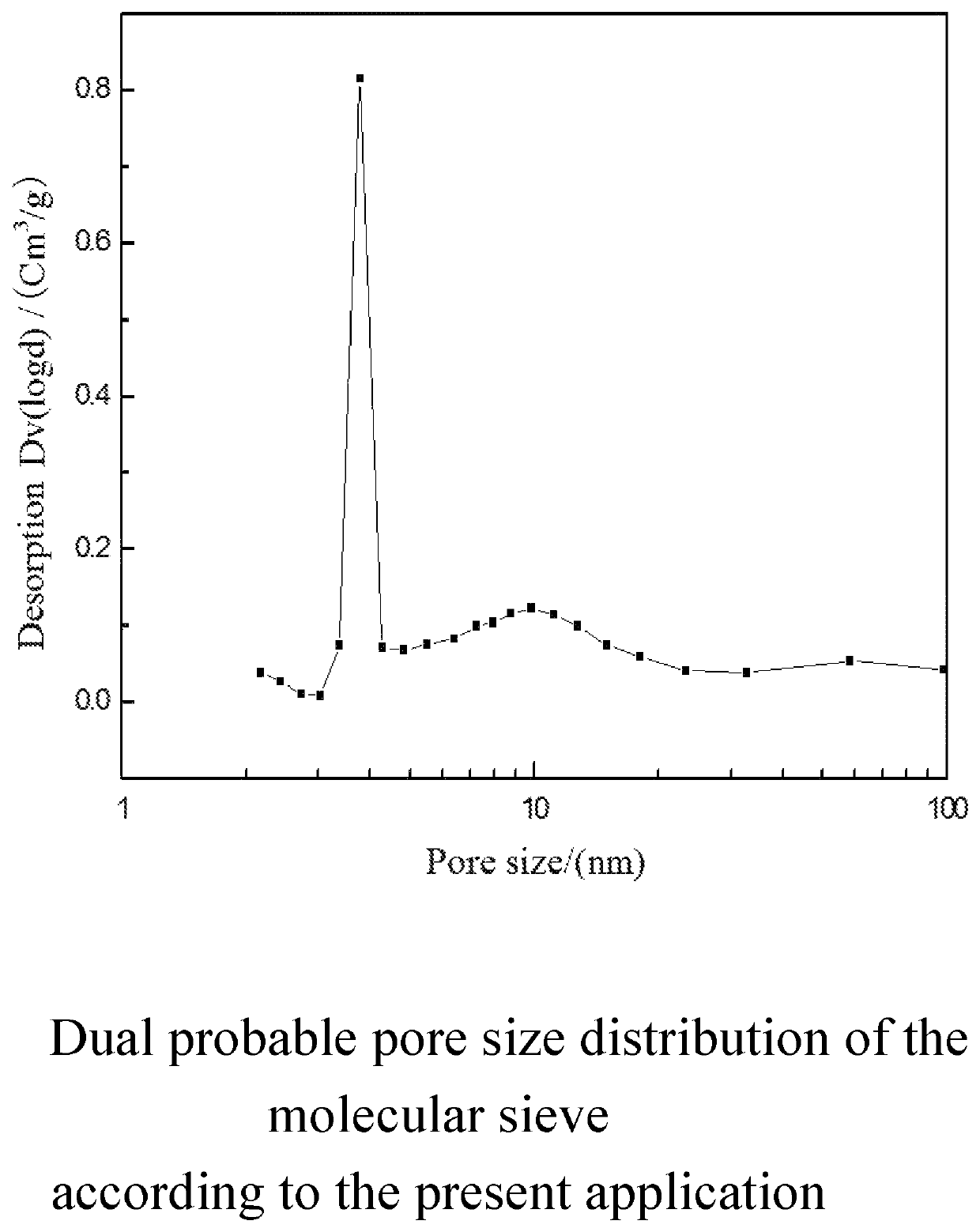

Mesoporous molecular sieve and a process for the preparation of the same

InactiveUS20020127164A1High hydrothermal stabilityHigh thermal and hydrothermal stabilityPhosphatesMolecular sieve catalystsMolecular sieveTitanium

The present invention relates to a mesoporous molecular sieve MPL-1 and its preparation process. The anhydrous composition of this molecular sieve contains at least three elements, i.e. aluminum, phosphorus and oxygen. The molecular sieve has larger pore diameters, generally 1.3 nm-10.0 nm, a larger specific surface area and adsorption capacity. It is synthesized under the hydrothermal process with an organic compound as template. Where necessary, silicon and / or titanium may be added to synthesize the aluminosilicophosphate, aluminotitanophosphate, or aluminosilicotitanophosphate molecular sieves having a mesoporous structure, and / or metal compounds may be added to synthesize derivatives of mesoporous aluminophosphate molecular sieves containing the corresponding hetero-atoms.

Owner:CHINA PETROLEUM & CHEM CORP +1

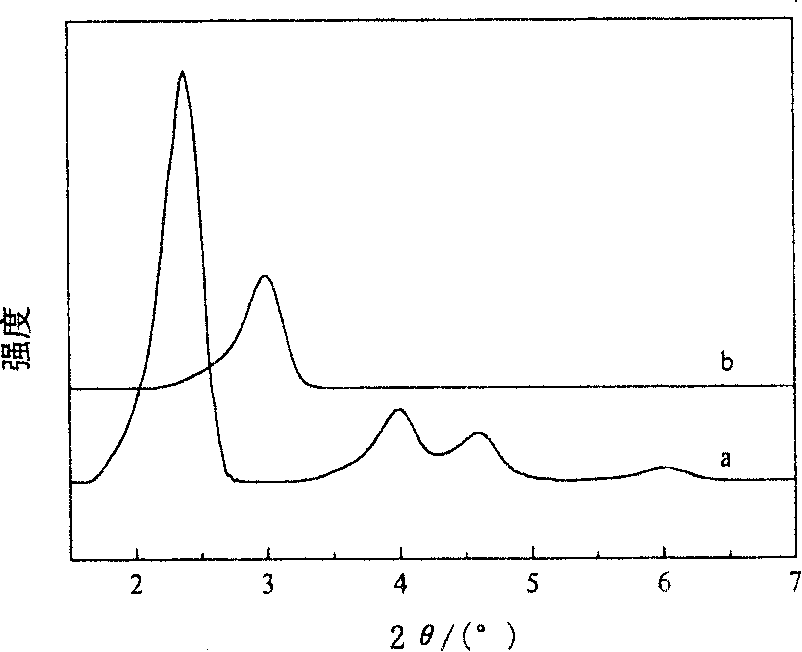

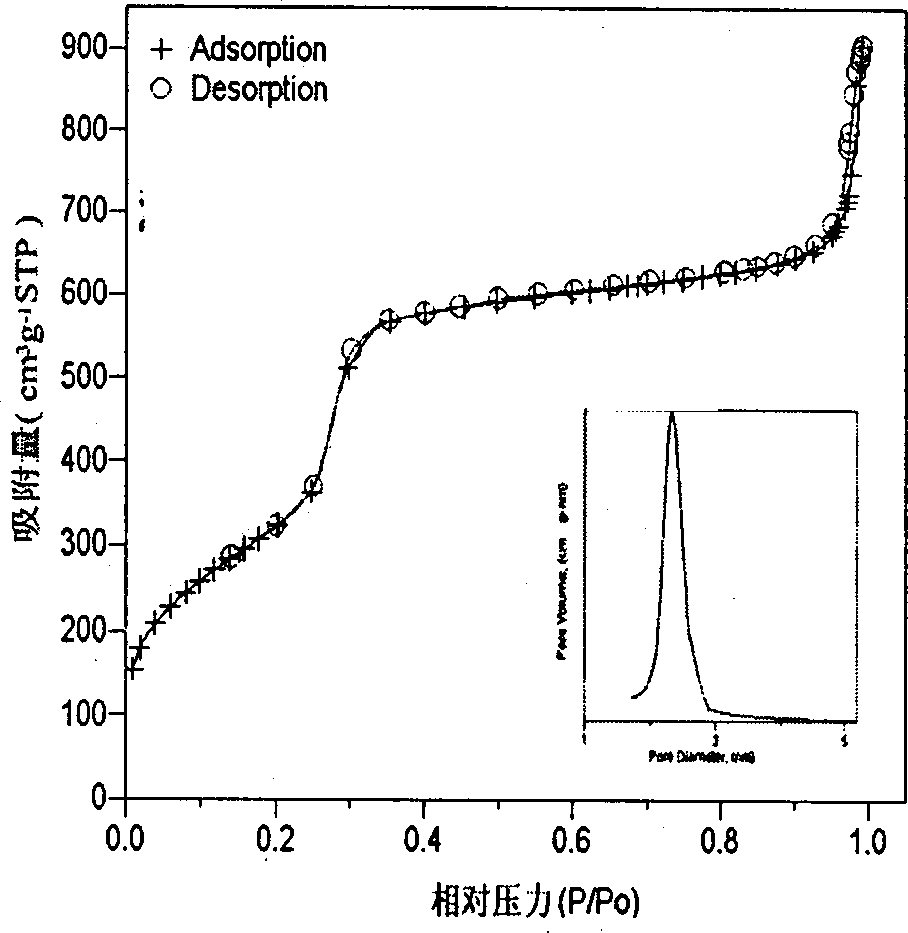

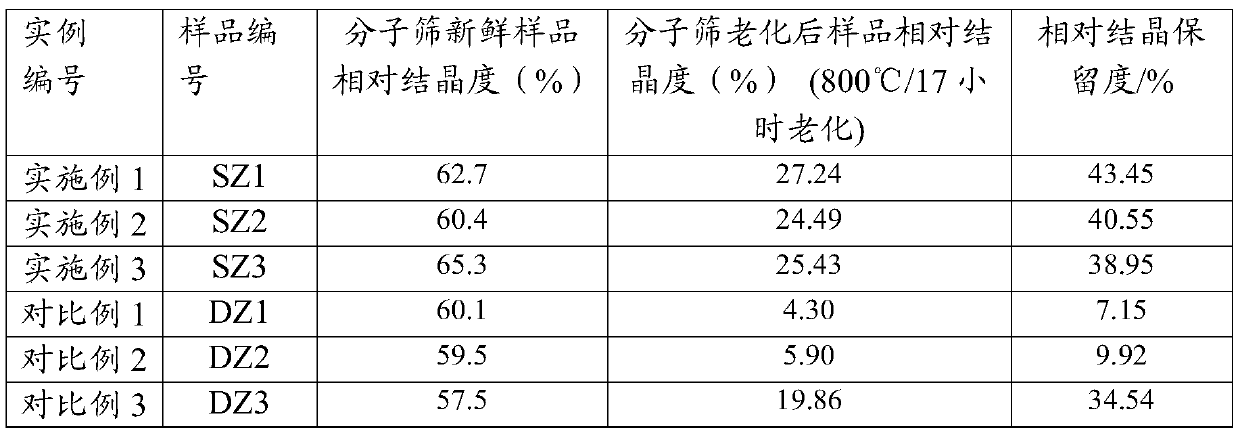

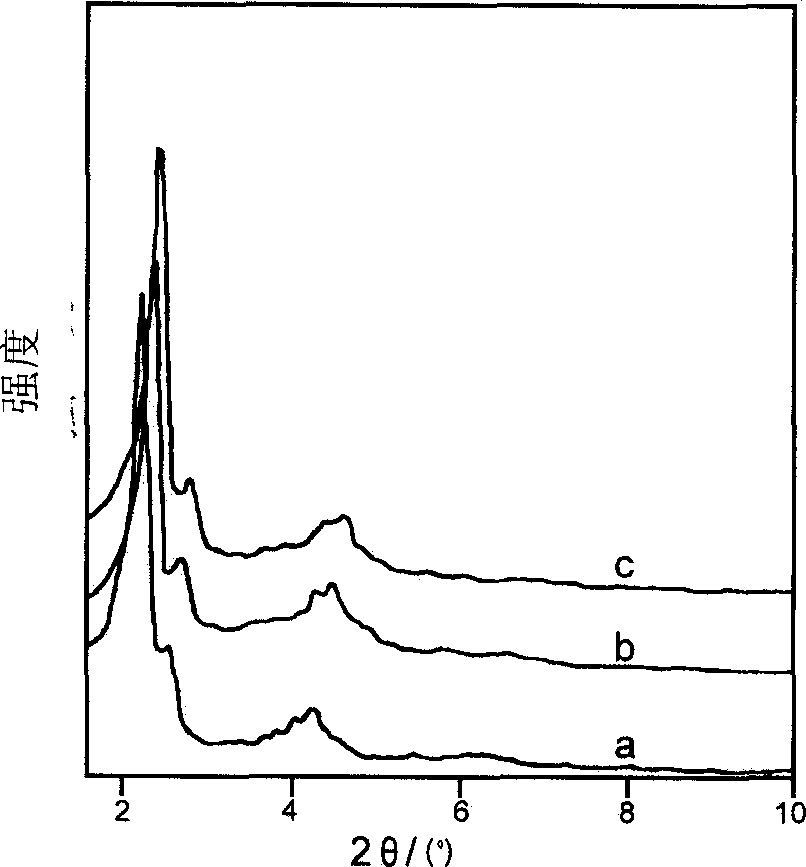

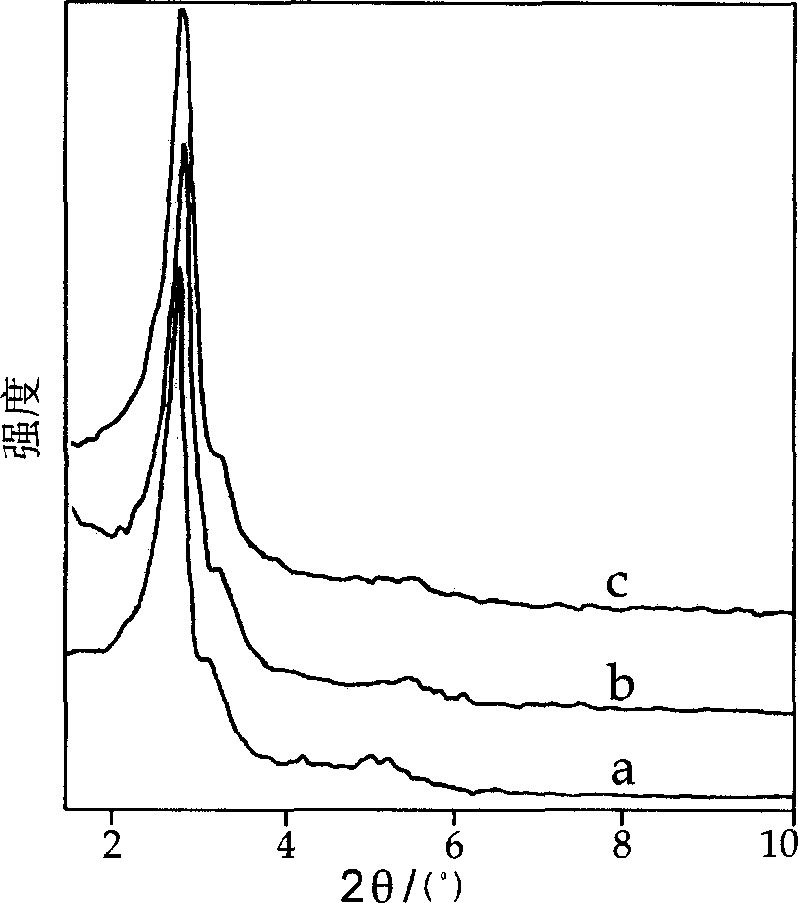

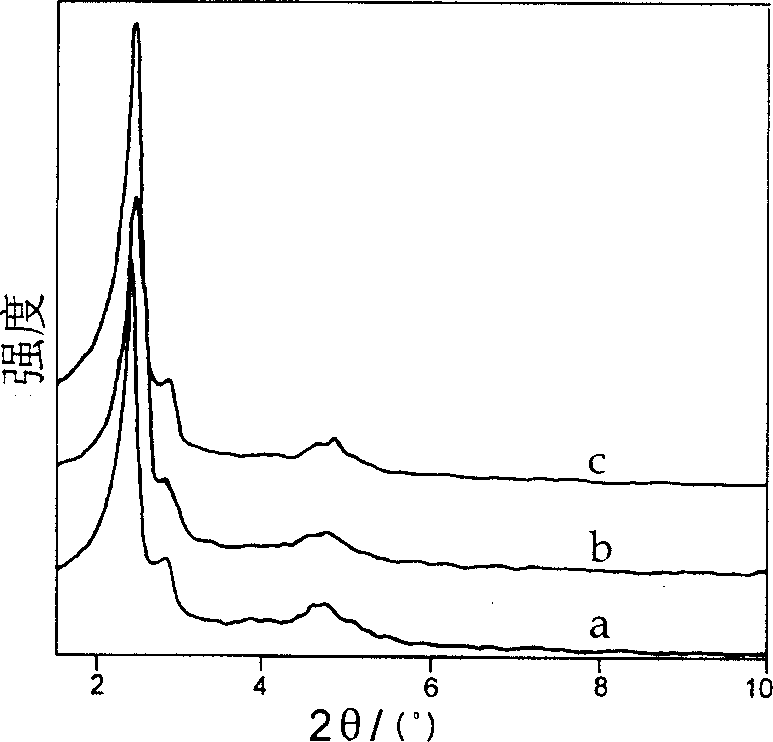

Method for preparing aluminium-containing MCM-41 molecular sieve

InactiveCN101205073AHigh hydrothermal stabilityHigh thermal and hydrothermal stabilityMolecular sieve catalystsCrystalline aluminosilicate zeolitesBoehmiteSodium silicate

The invention provides a method for preparing an aluminized molecular sieve of MCM-41 (ALMCM-41). The method adopts pseudo-boehmite as aluminum source, sodium silicate as silica source, and cety ltrimethyl ammonium bromide as template. By adopting dilute sulfuric acid to regulate acid, the molecular sieve of ALMCM-41 with high hydrothermal stability is prepared thereby. The invention solves the problem of poor hydrothermal stability of the ALMCM-41 in the prior art. The crystallization retention rate of the molecular sieve of ALMCM-41 prepared in the invention can reach 15 to 50 percent after the ALMCM-41 is aged in 100 percent of steam with temperature of 800 DEG C for 2 hours. The invention can be applied in the industrial preparation of the molecular sieve of ALMCM-41.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

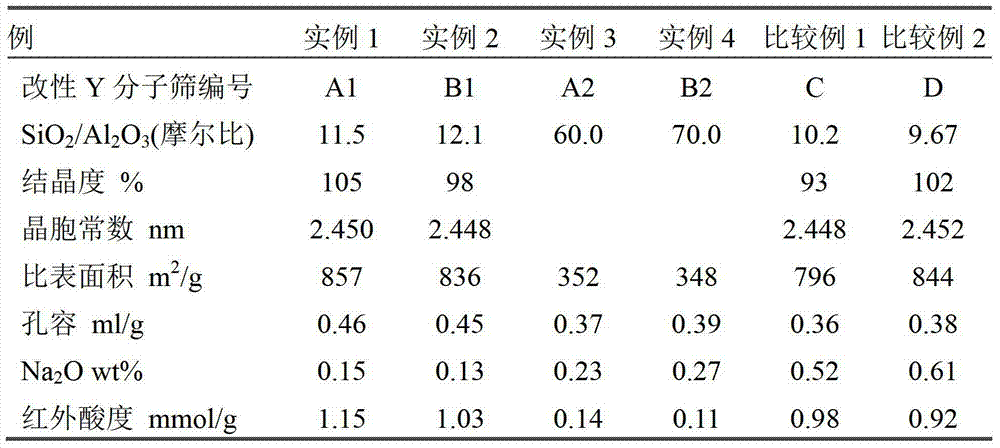

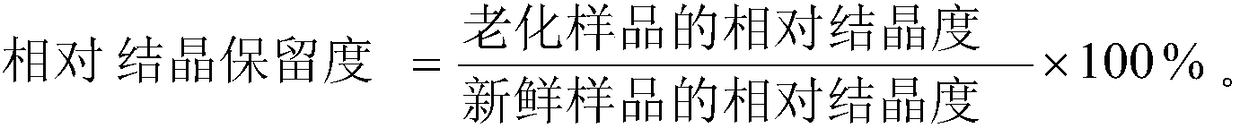

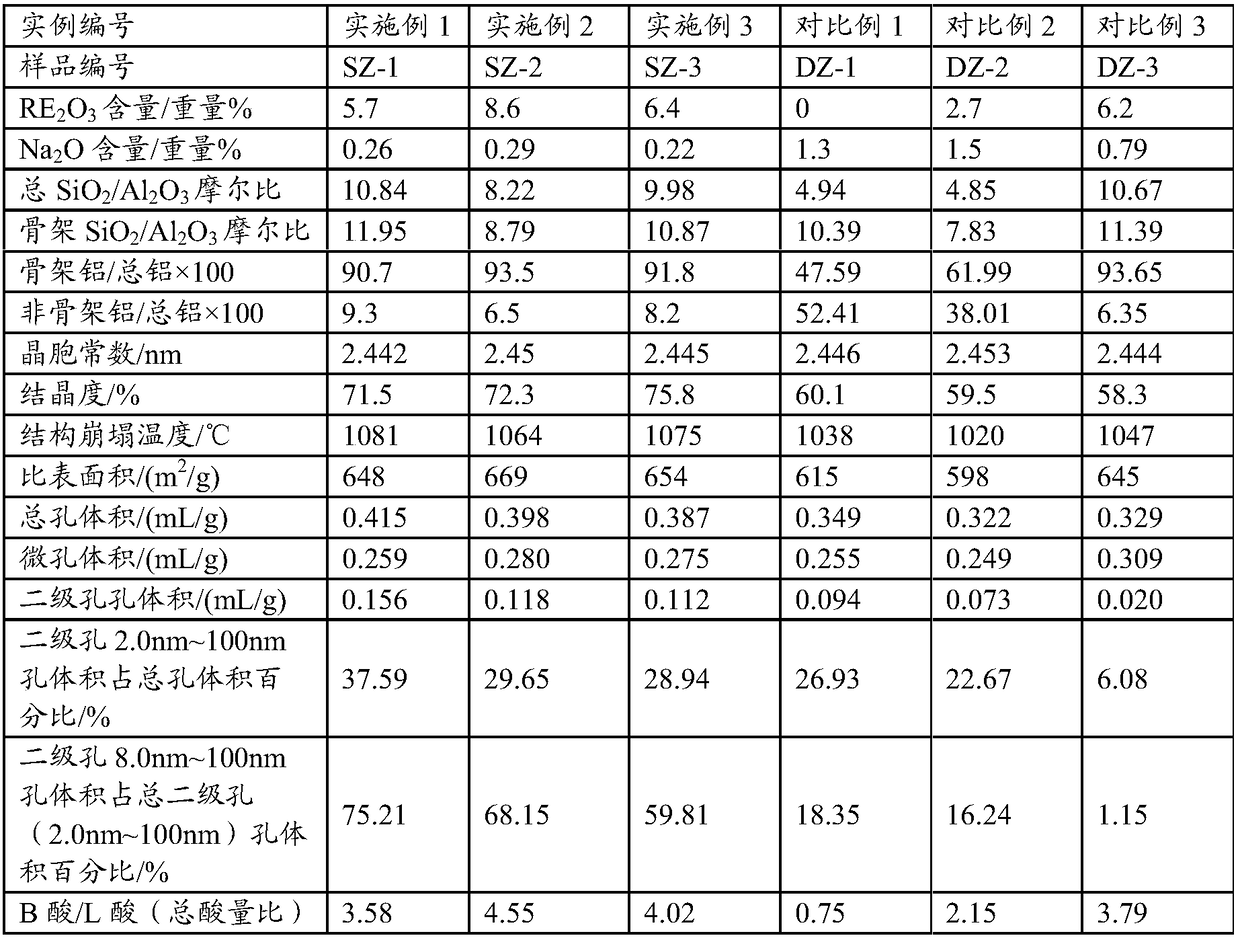

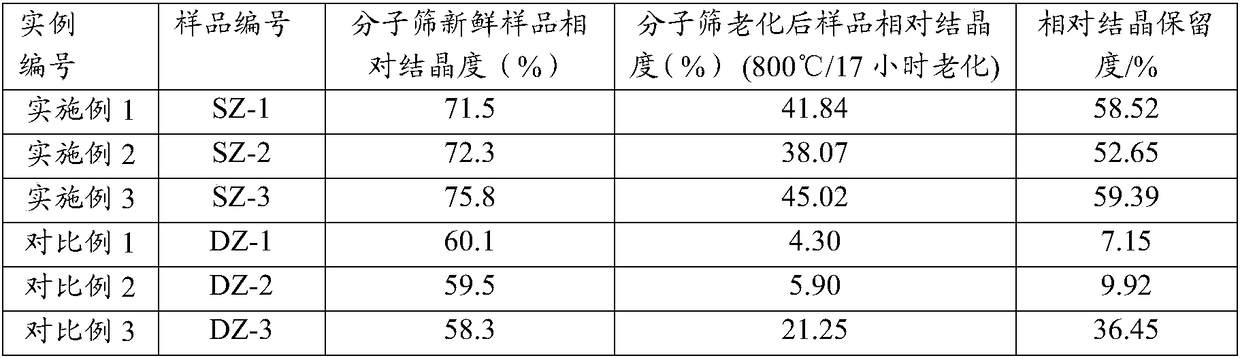

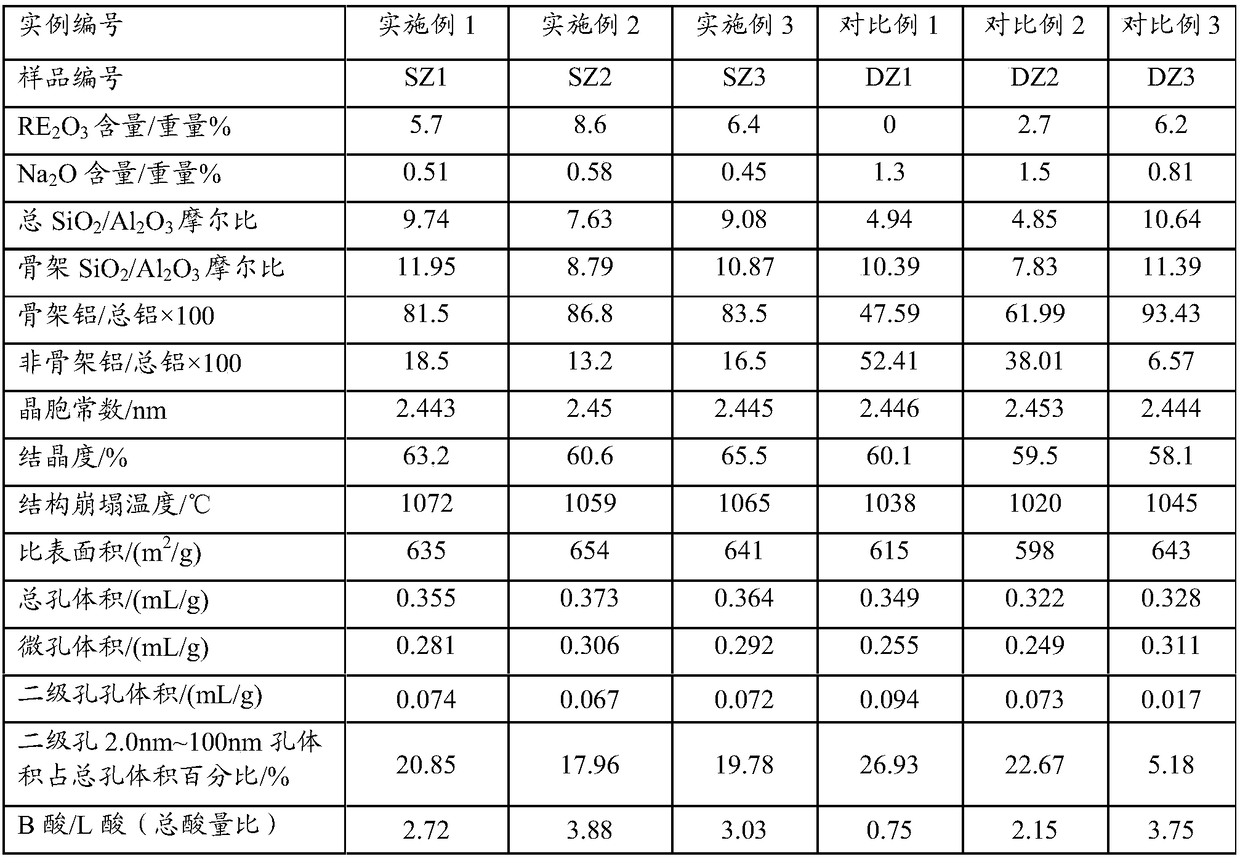

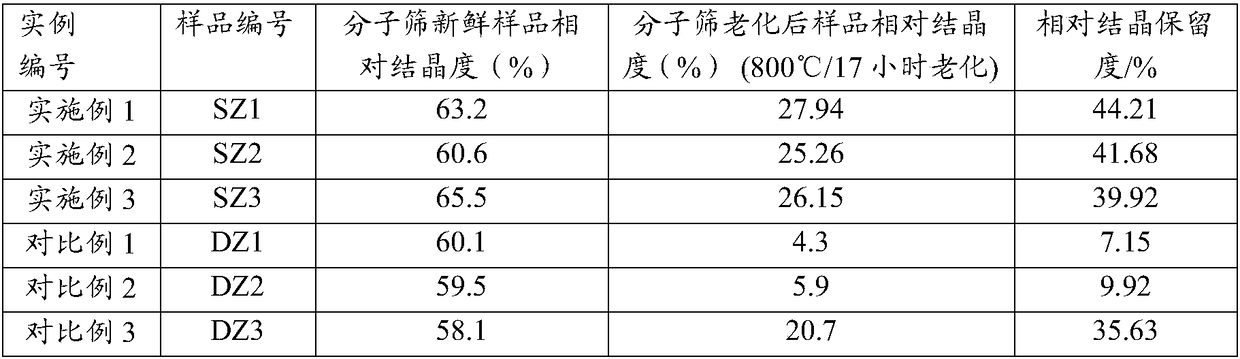

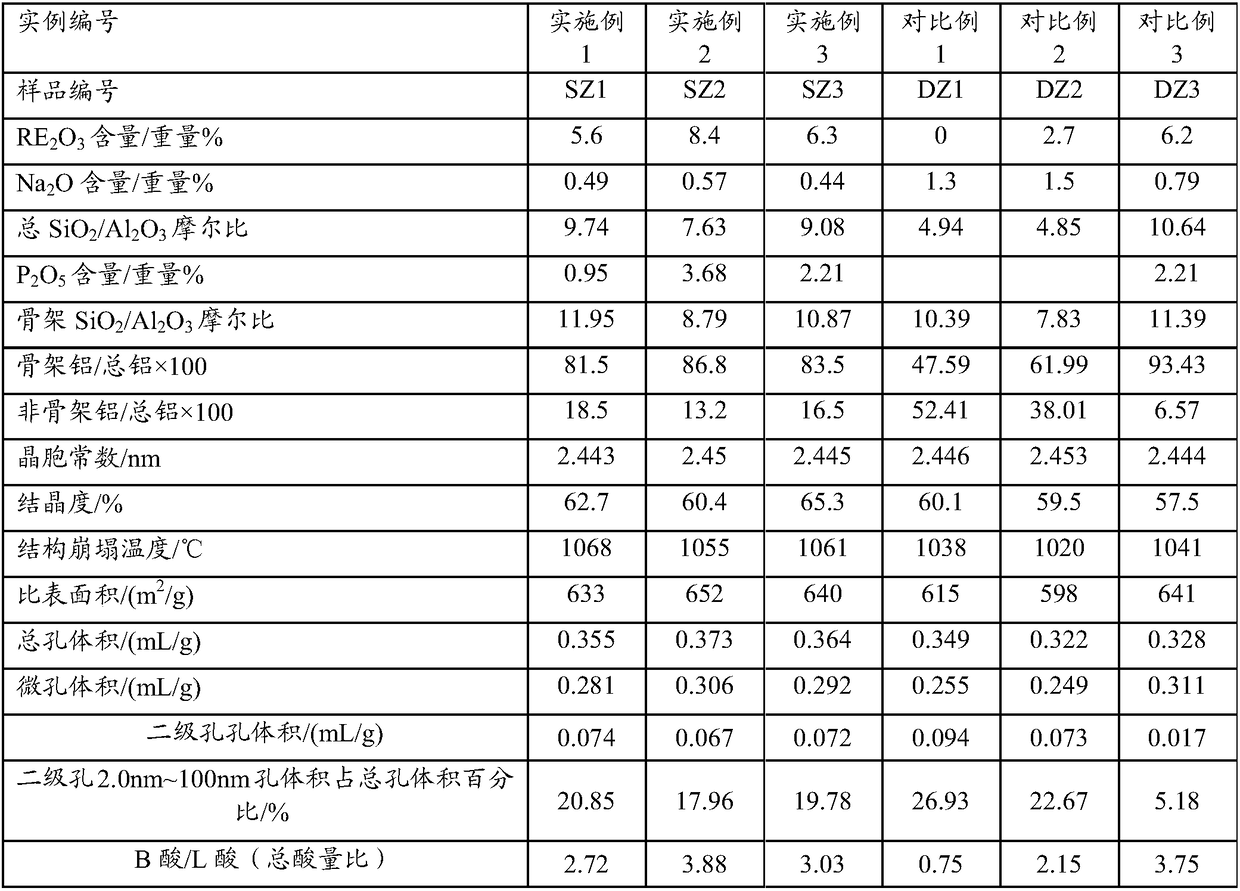

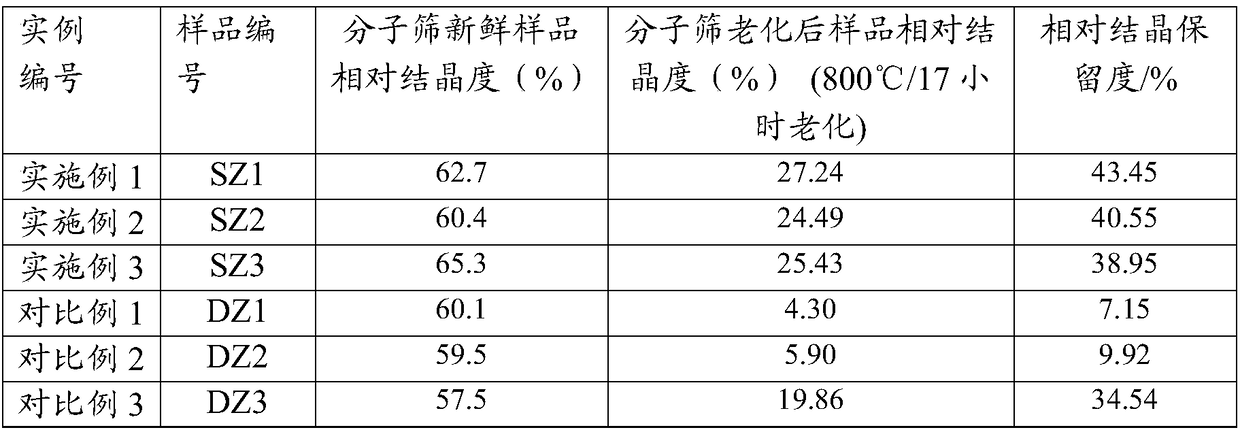

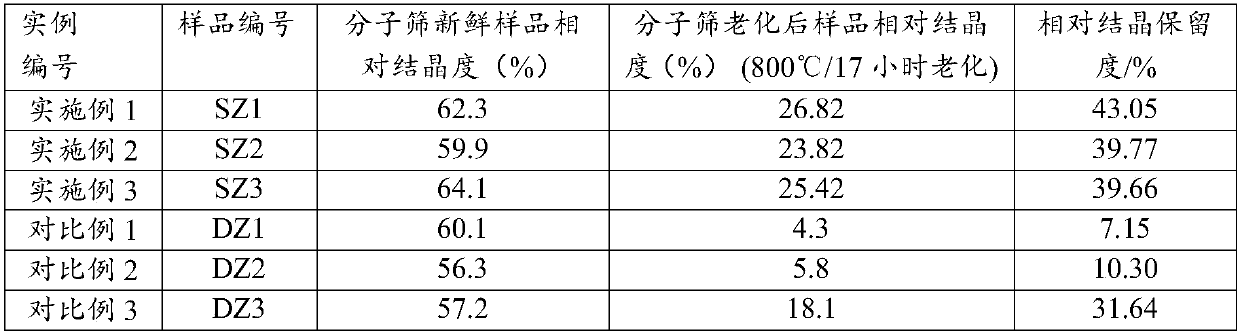

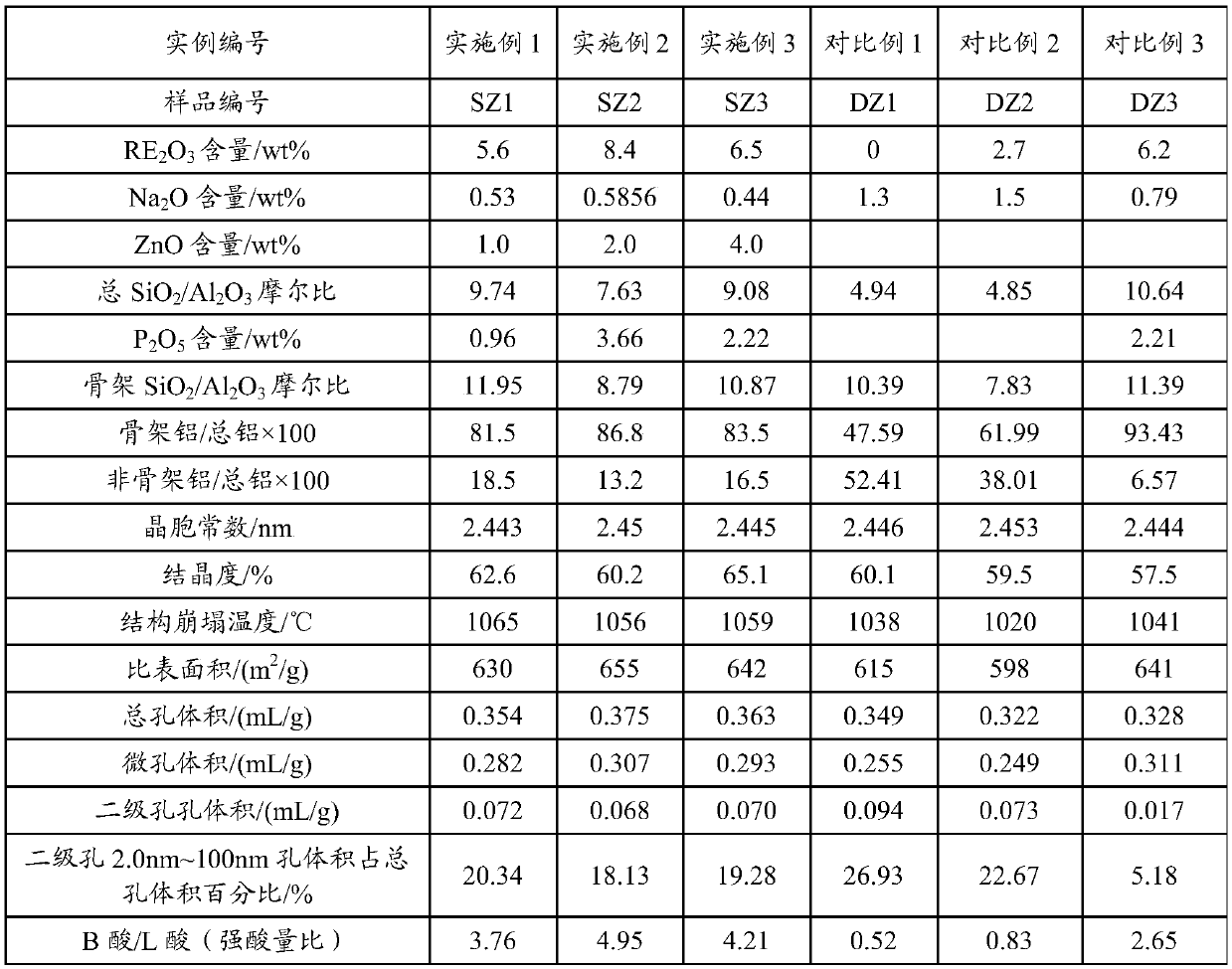

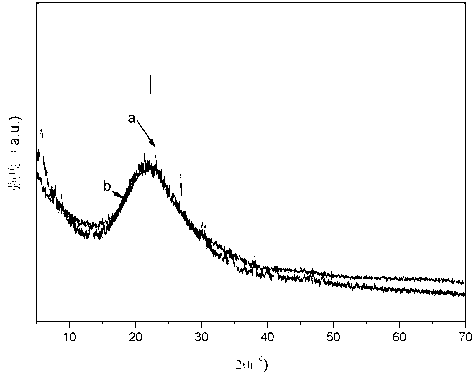

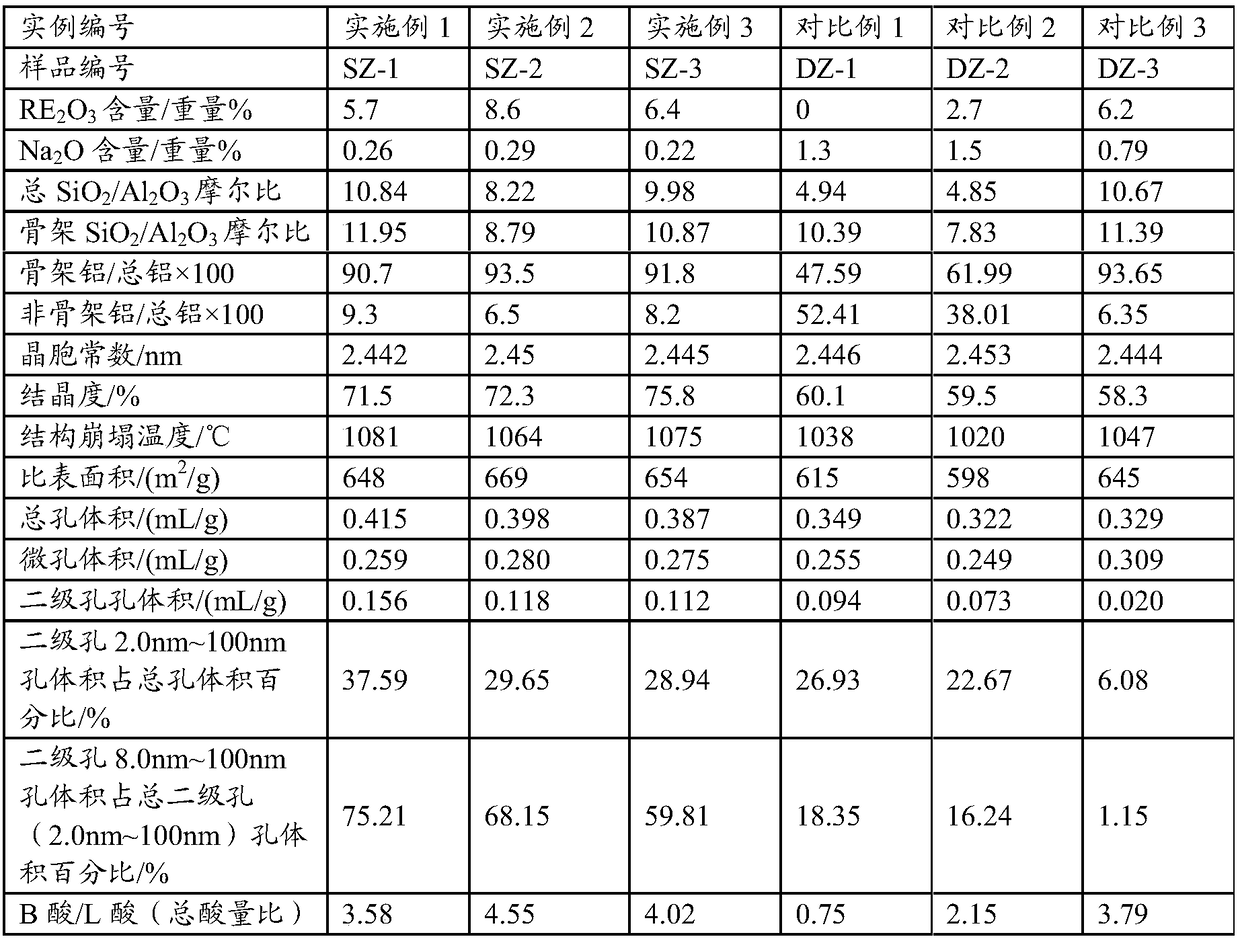

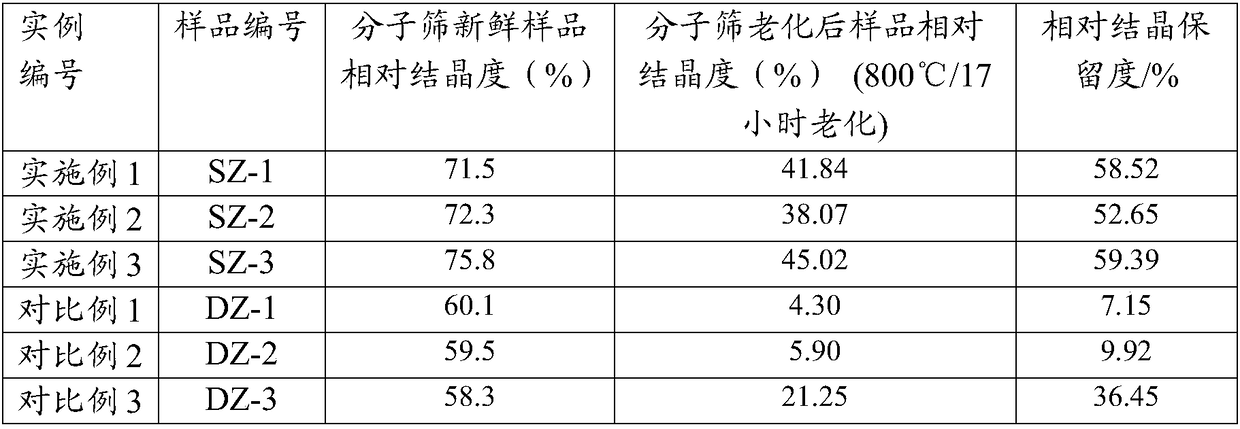

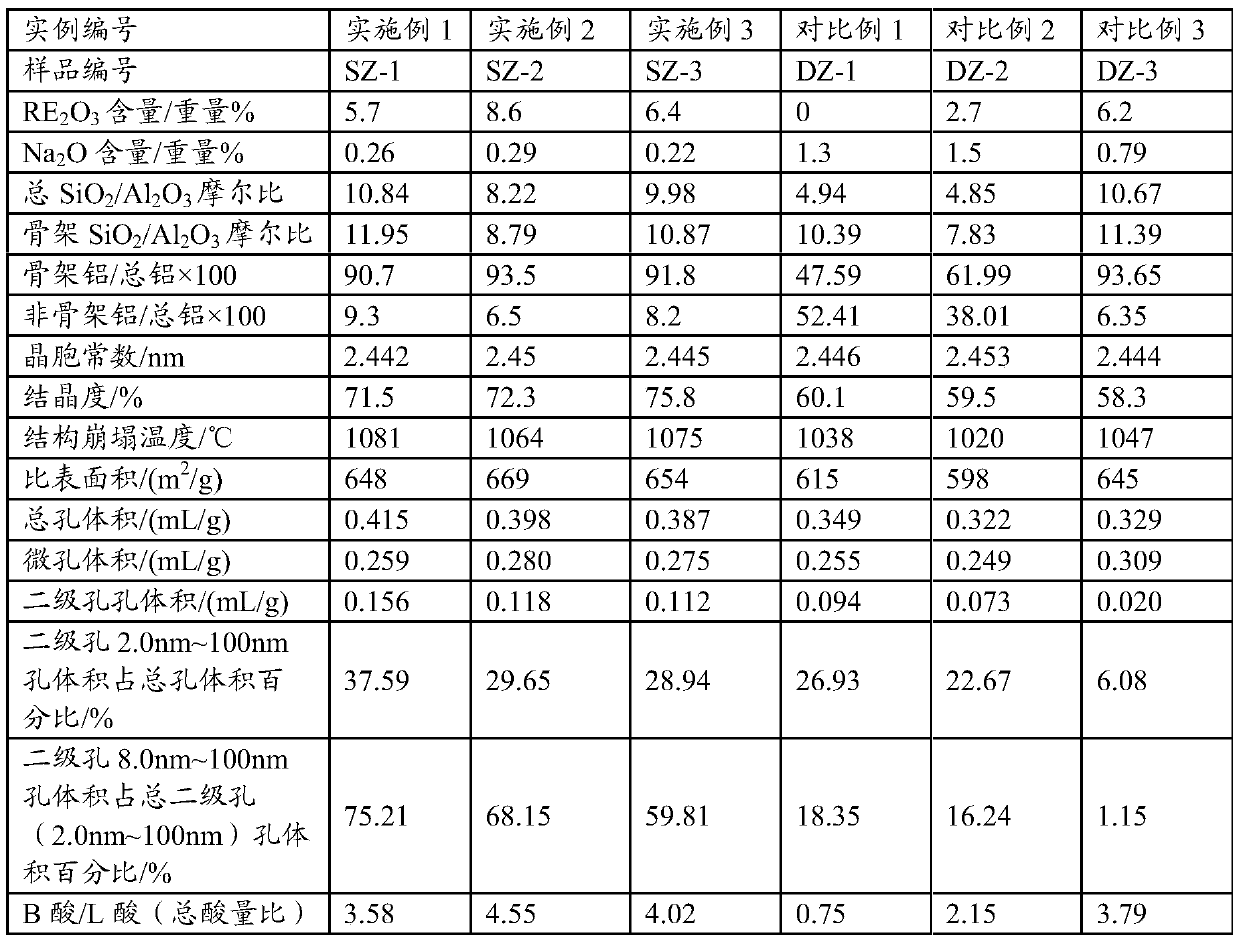

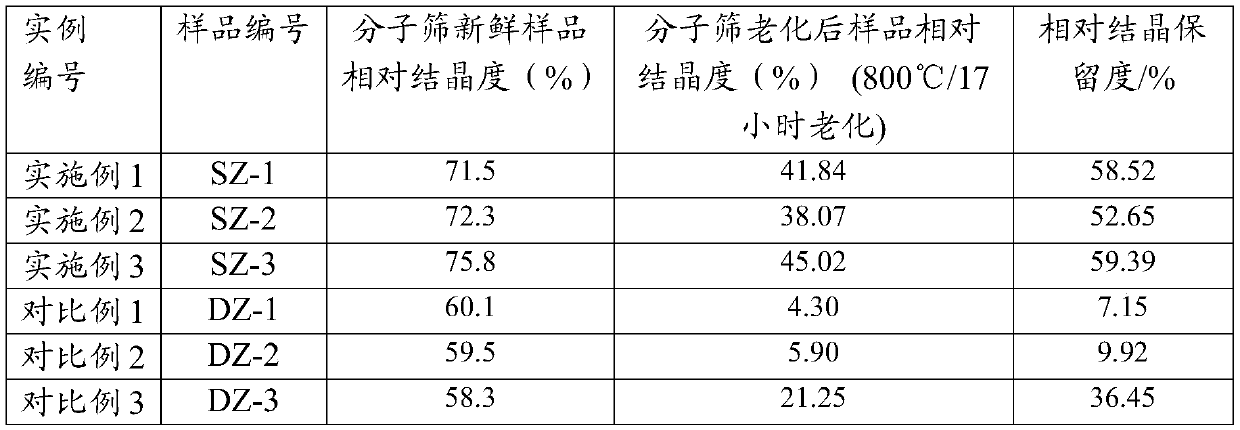

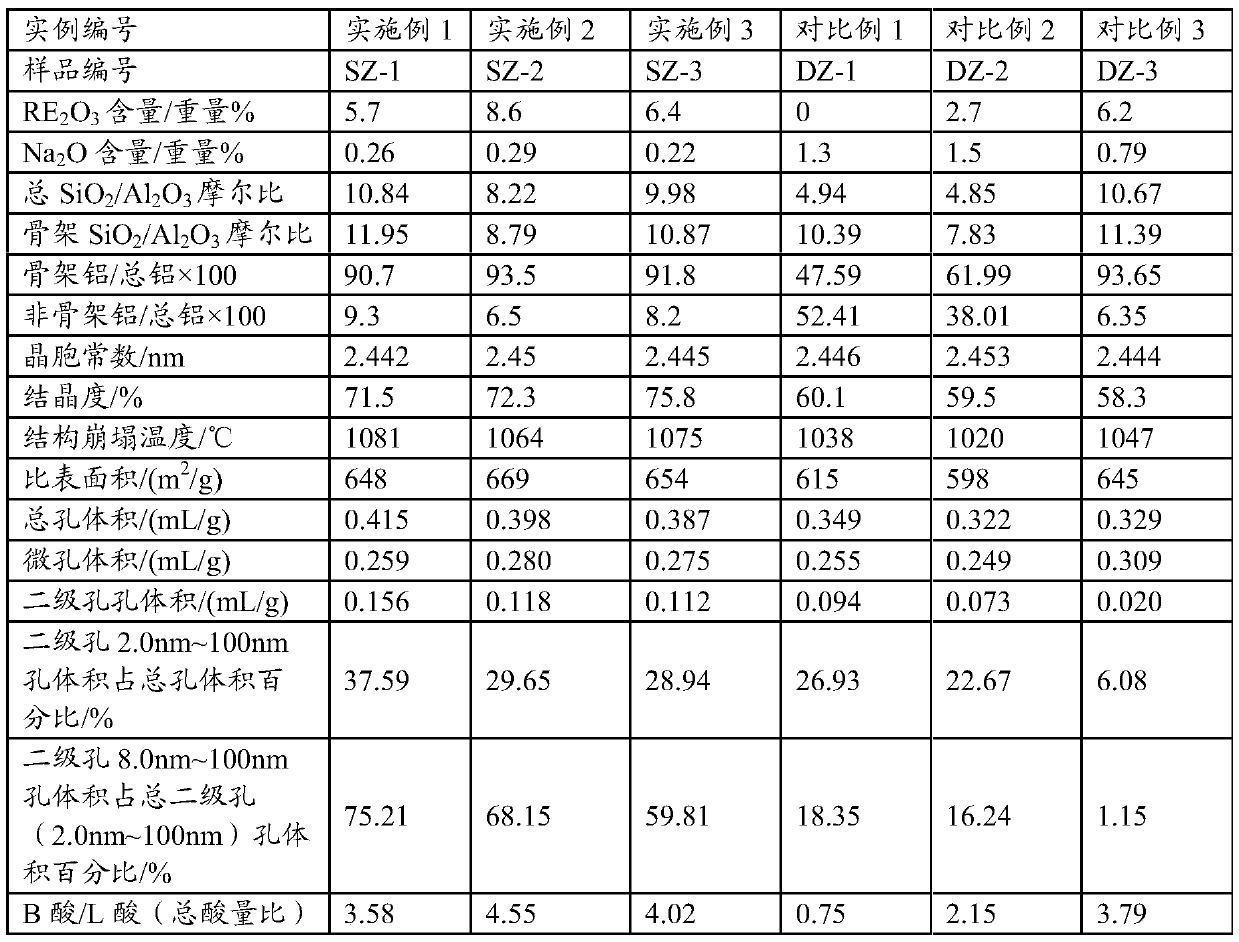

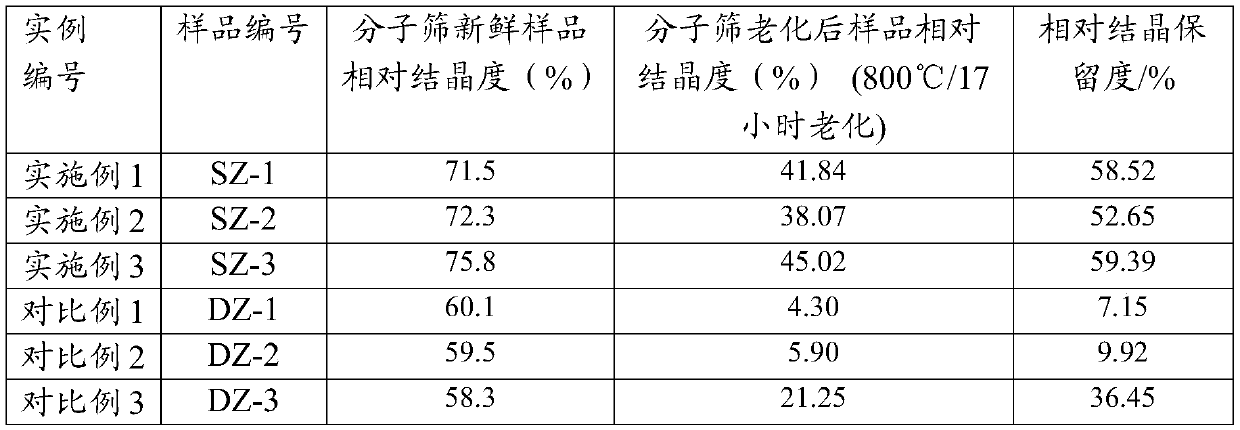

Modified Y-Type Molecular Sieve, Preparation Thereof and Catalyst Comprising the Same

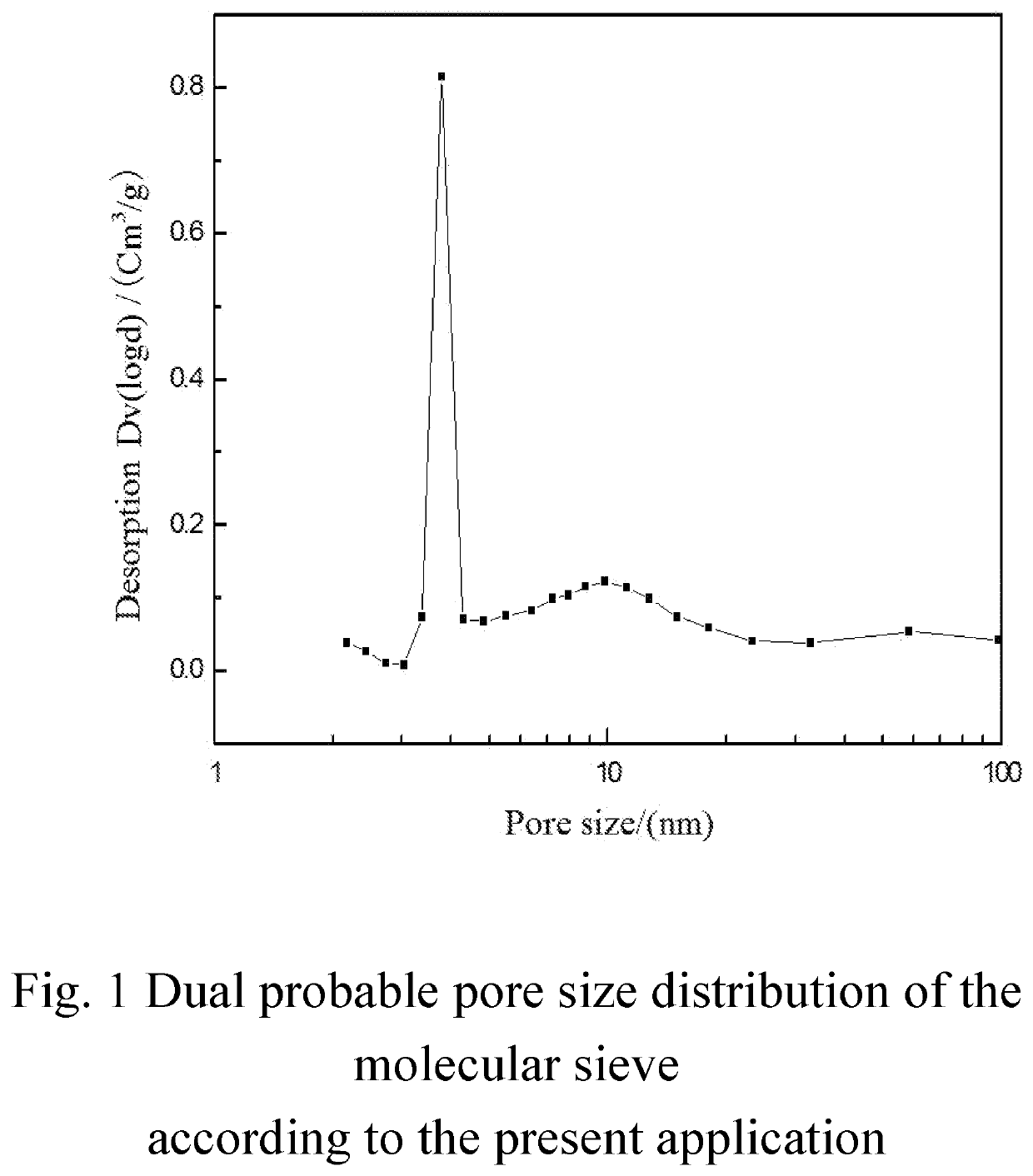

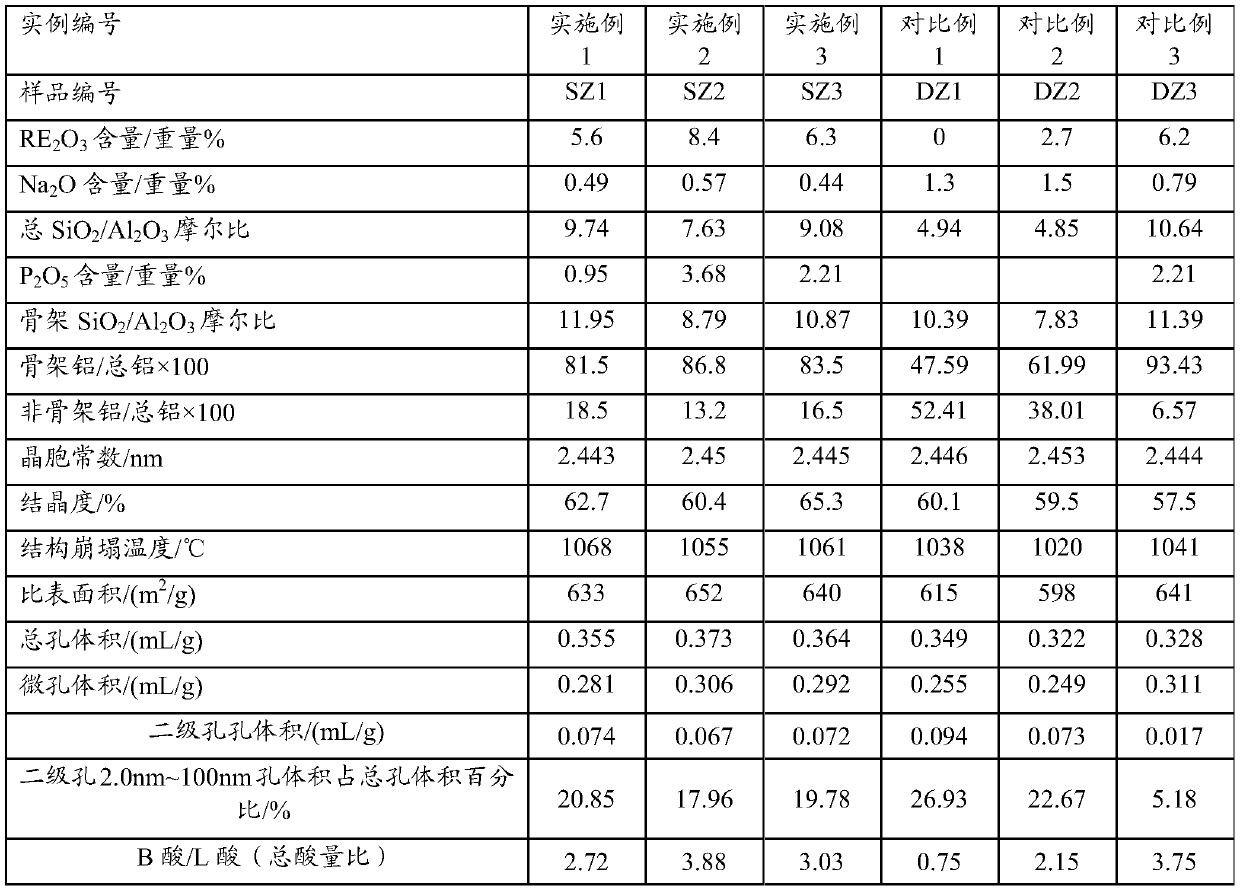

ActiveUS20200009541A1Increase lytic activityGood coke selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

A modified Y-type molecular sieve has a rare earth oxide content of about 4% to about 12% by weight, a phosphorus content of about 0% to about 10% by weight, a sodium oxide content of no more than about 1.0% by weight, a total pore volume of about 0.36 to 0.48 mL / g, a percentage of the pore volume of secondary pores to the total pore volume of about 20% to about 40%, a lattice constant of about 2.440 nm to about 2.455 nm, a percentage of the non-framework aluminum content to the total aluminum content of no more than about 10%, a lattice collapse temperature of not lower than about 1060° C., and a ratio of B acid to L acid of no less than about 3.50. The preparation of the molecular sieve includes ion-exchange with rare earth, hydrothermal roasting, gas phase ultra-stabilization, acid treatment, and an optional phosphorus modification.

Owner:CHINA PETROCHEMICAL CORP +1

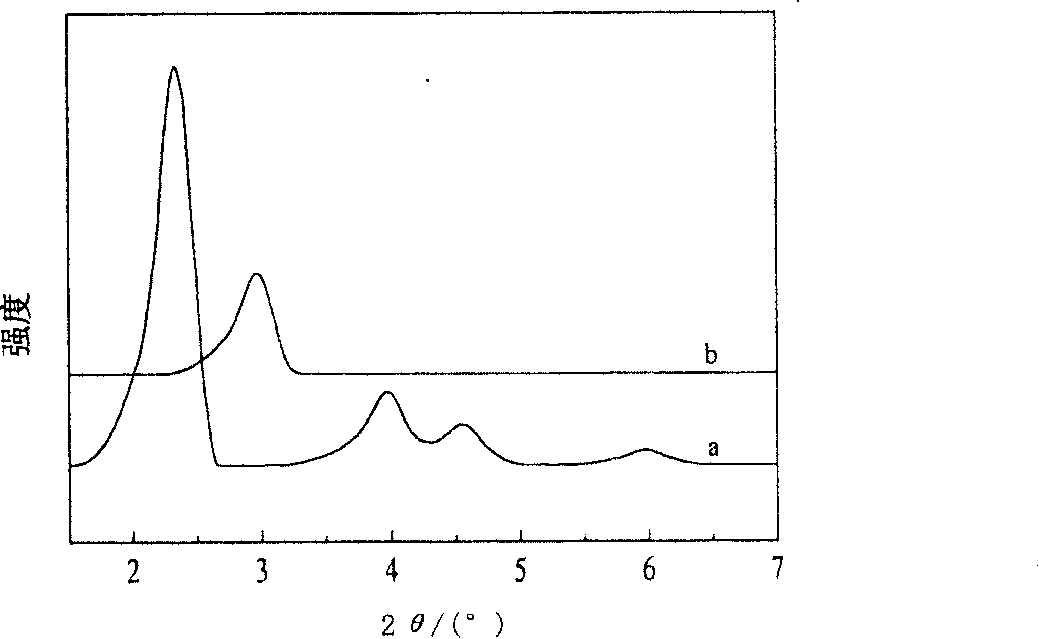

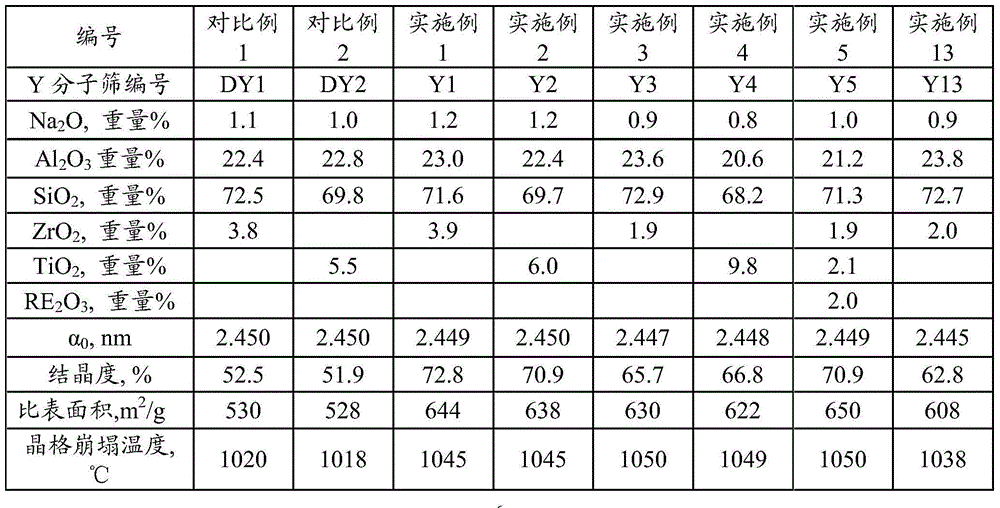

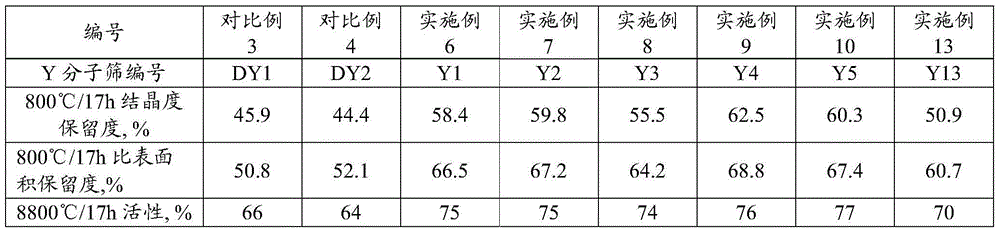

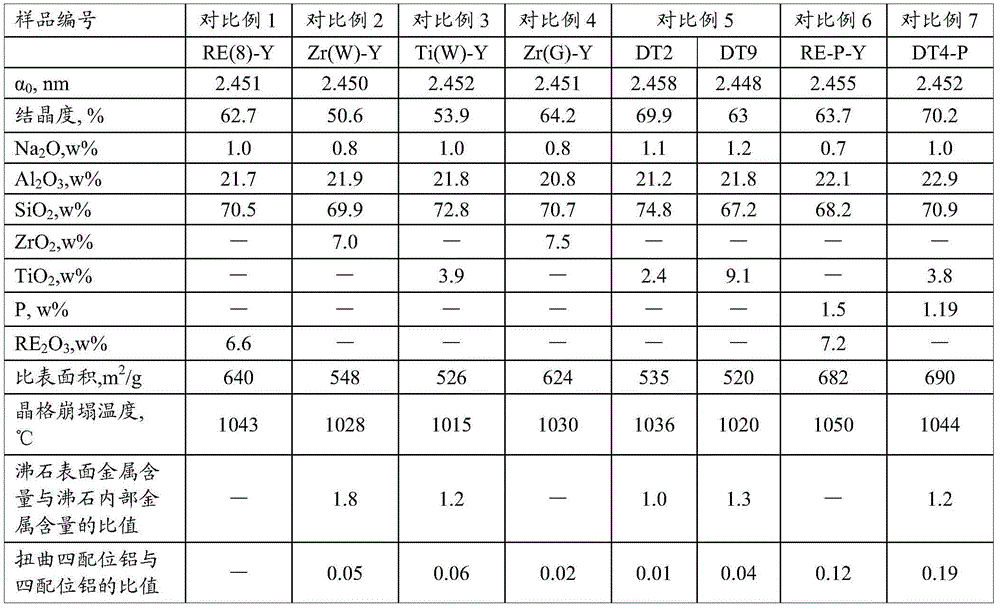

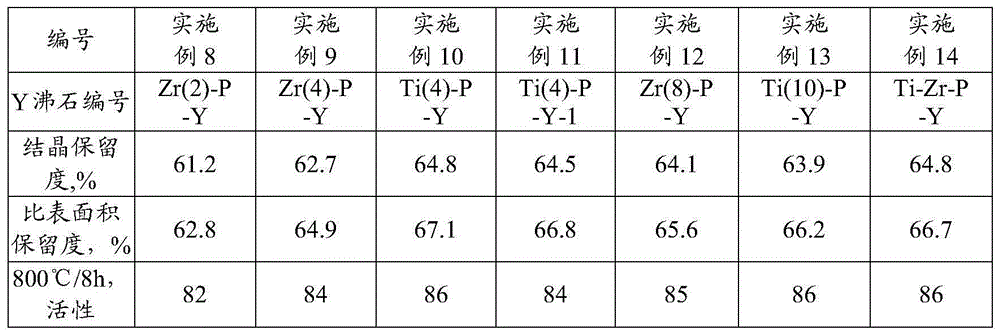

Modification method of Y-type molecular sieve

ActiveCN105618108AHigh thermal and hydrothermal stabilityEasy to produceCatalytic crackingMolecular sieve catalystsMolecular sieveTitanium

A modification method of Y-type molecular sieve comprises the following steps: (1) dispersing a compound containing titanium and / or zirconium into water, and adjusting pH value of the mixture to 3-10; (2) mixing molecular sieve and the mixture obtained in the Step (1), and stirring; and optionally filtering and / or drying; and (3) roasting at 300-700 DEG C. By the modification method of Y-type molecular sieve, production cost is low, and the modified Y-type molecular sieve obtained has high thermal and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Secondary-pore-rich modified Y type molecular sieve containing phosphorus and rare earth, and preparation method thereof

ActiveCN108452832AHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveAcid treatment

The invention provides a secondary-pore-rich modified Y type molecular sieve containing phosphorus and rare earth, and a preparation method thereof. In the modified Y type molecular sieve, the contentof rare earth oxide is 4 to 11 wt%; the content of phosphorus is 0.05 to 10 wt%; the content of sodium oxide is no more than 0.5 wt%; a total pore volume is 0.4 to 0.48 mL / g; the pore volume of secondary pores accounts for 20 to 38% of the total pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum is no more than 10% of total aluminum content; lattice collapse temperature is no less than 1060 DEG C; and a ratio of the amount of acid B to the amount of acid L is no less than 3.50. A preparation method for the molecular sieve comprises the following steps: exchanging of rare earth; hydrothermal roasting; gas-phase ultrastable modification; acid treatment; and introduction of phosphorus. The modified Y type molecular sieve has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

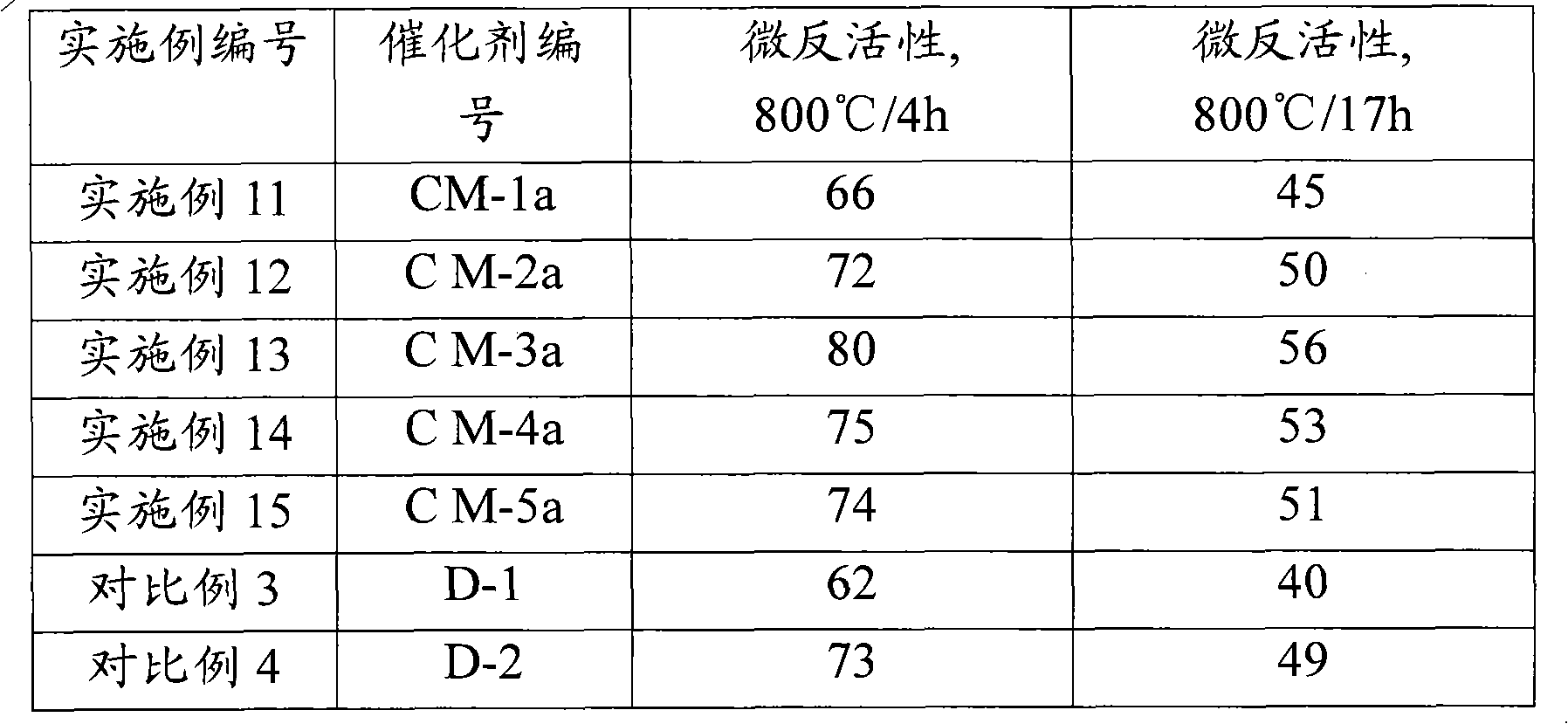

Catalytic cracking catalyst

ActiveCN108452838AHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveFuel oil

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains clay, alumina containing an additive and a modified Y type molecular sieve. The modified Y type molecularsieve comprises 5 to 12 wt% of rare earth and no more than 0.5 wt% of sodium oxide, and has a total pore volume of 0.36 to 0.48 mL / g; the pore volume of secondary pores accounts for 20 to 38% of thetotal pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum is no more than 10% of total aluminum content; lattice collapse temperature is higher than 1060 DEGC; and a ratio of the amount of acid B to the amount of acid L is no less than 3.50. A preparation method for the catalytic cracking catalyst comprises the following steps: preparing a rare earth-containing Y type molecular sieve with a conventional cell size; carrying out roasting in a water vapor atmosphere with a temperature of 350 to 520 DEG C and a volume percentage of 30 to 95% for 4.5 to 7h; carrying out a contact reaction with silicon tetrachloride; and carrying out acid treatment. The catalytic cracking catalyst has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

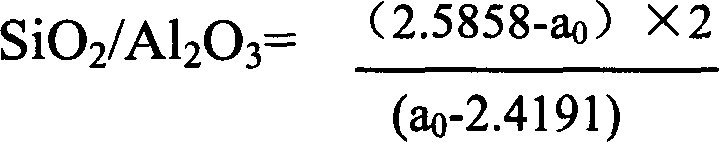

Rare-earth Y-type zeolite

InactiveCN1162327CGood heavy oil cracking activityGood choiceFaujasite aluminosilicate zeoliteRare earthGasoline

A rare-earth Y-zeolite used for preparing the cracking catalyst of petroleum hydrocarbon has 4-15 wt.% of rare-earth content, 2.45-2.458 nm of crystal cell contstant, 1000-1056 deg.C of differential thermal collapse temp, and 8.3-8.8 of Si / Al ratio. Its advantages are high activity and selectivity to heavy oil and coke, good hydrogen transfer activity, and high output rate of light oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Proess for preparing mesoporous molecular sieve MCM-48 by using mixture of cationic surfactant and non-ionic surfactant as template agent

InactiveCN1390785AImprove uniformityLow molar ratioCrystalline aluminosilicate zeolitesMolecular sievePolyethylene glycol

An MCM-48 mesoporous molecular sieve is prepared from industrial water glass as Si source and the template agent which is the mixture of cationic surfactant CTAB and non-ionic surfactant OP-10. Its advantages are high high-temp and hydrothermal stability, low cost and less pollution.

Owner:FUDAN UNIV

High-stability modified Y-type molecular sieve and preparation method thereof

ActiveCN108455625AHigh thermal and hydrothermal stabilityImprove transformation activityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveWater vapor

The invention relates to a high-stability modified Y-type molecular sieve and a preparation method thereof, wherein the modified Y-type molecular sieve contains 5-12 wt% of RE2O3 and 0.1-0.7 wt% of Na2O, and has the total pore volume of 0.33-0.39 mL / g, the pore volume of the secondary pores with the pore size of 2-100 nm accounts for 10-25% of the total pore volume, the unit cell constant is 2.440-2.455 nm, the non-framework aluminum content is not more than 20% of the total aluminum content, the lattice collapse temperature is not below 1050 DEG C, and the pyridine adsorption infrared methoddetermination results show that a ratio of the amount of B acid to the amount of L acid is not less than 2.50. The preparation method comprises: ion exchange, modification treatment at a certain temperature under water vapor conditions, and reaction with silicon tetrachloride. According to the present invention, the modified Y-type molecular sieve has advantages of high heavy oil conversion activity, low coke selectivity, high diesel yield, high liquefied gas yield, high light-oil yield and high total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Super-stable Y-type molecular sieve containing phosphorus and rare earth, and preparation method thereof

ActiveCN108452828AHigh thermal and hydrothermal stabilityHigh heavy oil conversion activityCatalytic crackingMolecular sieve catalystsMolecular sieveAluminium

The invention relates to a super-stable Y-type molecular sieve containing phosphorus and rare earth, wherein the Y-type molecular sieve contains 4-11 wt% of rare earth, 0.05-10 wt% of phosphorus and 0.1-0.7 wt% of sodium oxide, and has the pore volume of 0.33-0.39 mL / g, the pore volume of the pores with the pore size of 2-100 nm accounts for 15-30% of the total pore volume, the unit cell constantis 2.440-2.455 nm, the non-framework aluminum accounts for less than 20% of the total aluminum, the lattice collapse temperature is more than 1050 DEG C, and a ratio of the amount of B acid to the amount of L acid is not less than 2.50. The preparation method comprises: preparing a rare earth-containing Y-type molecular sieve having a conventional unit cell size, calcining for 4.5-7 h at a temperature of 350-480 DEG C under 30-90% by volume of steam atmosphere, carrying out phosphorus modification treatment, and carrying out a contact reaction with silicon tetrachloride gas. According to the present invention, the Y-type molecular sieve has advantages of good hydrothermal stability, high heavy oil conversion activity, low coke selectivity, high heavy oil conversion diesel yield, high liquefied gas yield and high total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN103657700AHigh thermal and hydrothermal stabilityImprove structural stabilityCatalytic crackingMolecular sieve catalystsAdhesiveX-ray

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, clay and an adhesive, wherein the cracking activity component comprises a rare-earth Y-type molecular sieve; and the rare-earth content in the Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50. The preparation method comprises the following steps: preparing a mixed slurry containing the cracking activity component, adhesive and clay, carrying out spray drying, washing and drying. Compared with the prior art, the rare-earth-containing Y-type molecular sieve has higher structural stability and activity stability; and the catalyst has higher thermal and hydrothermal stability, and can reduce the consumption of the molecular sieves in the catalyst, thereby lowering the catalyst production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

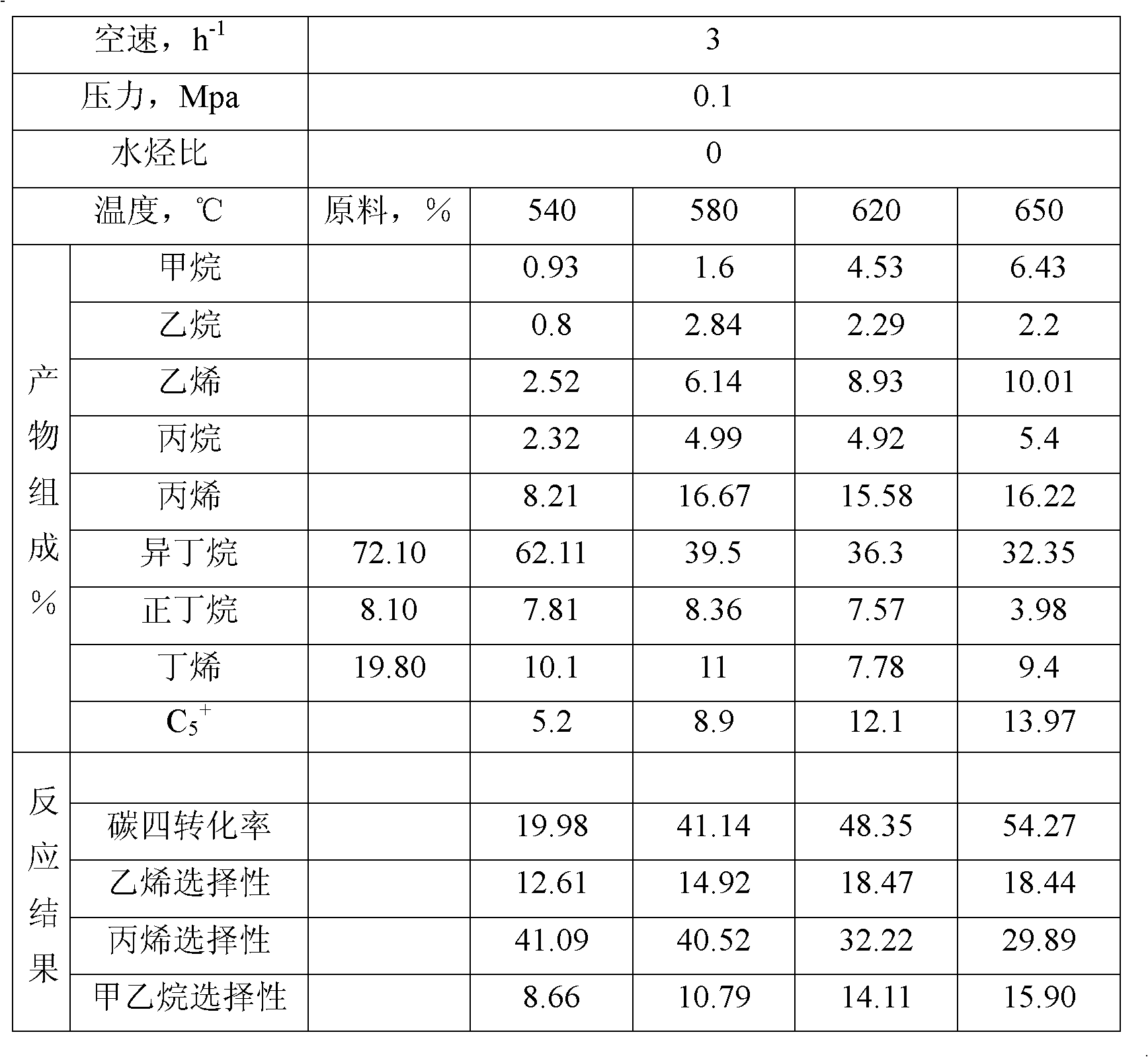

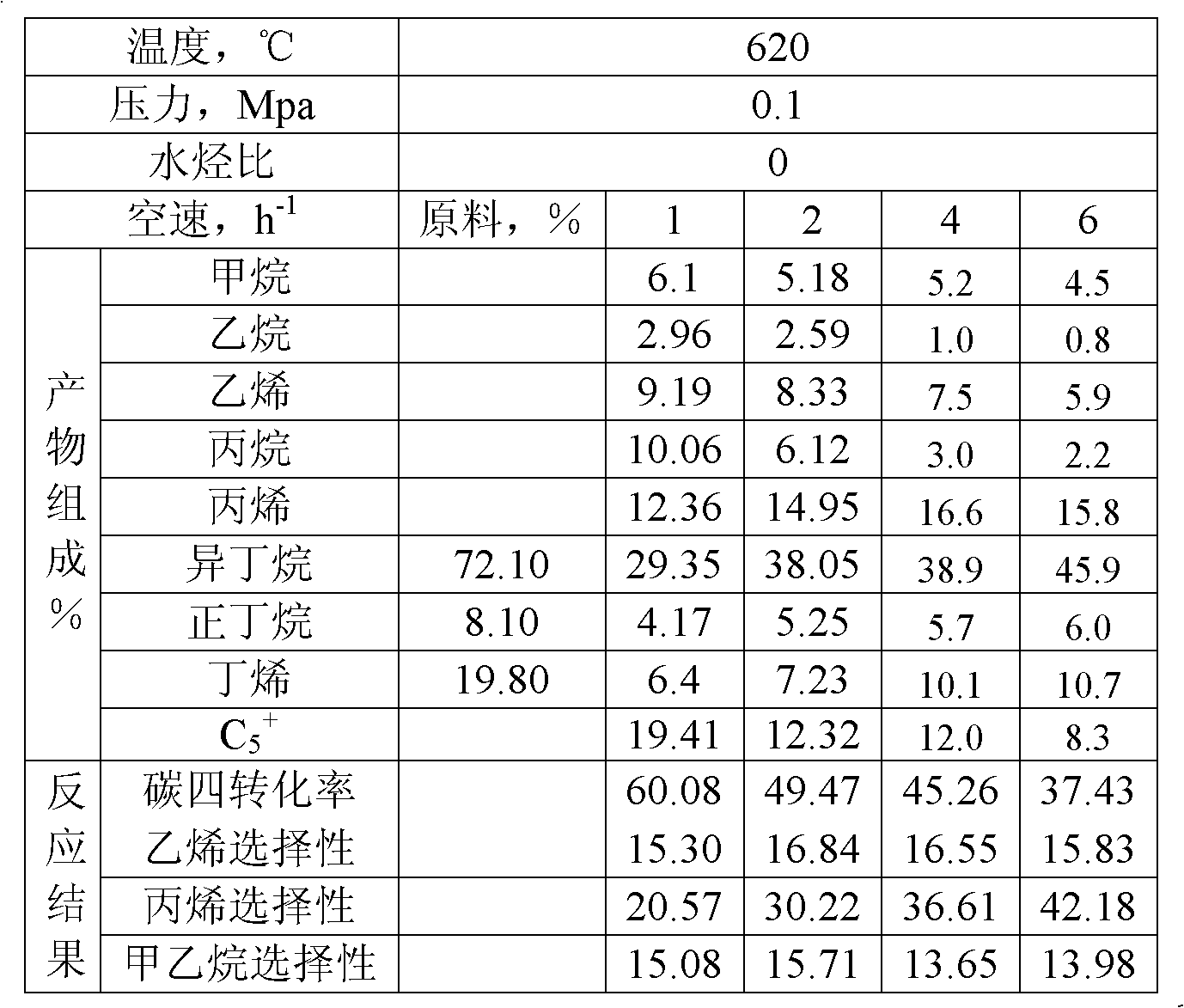

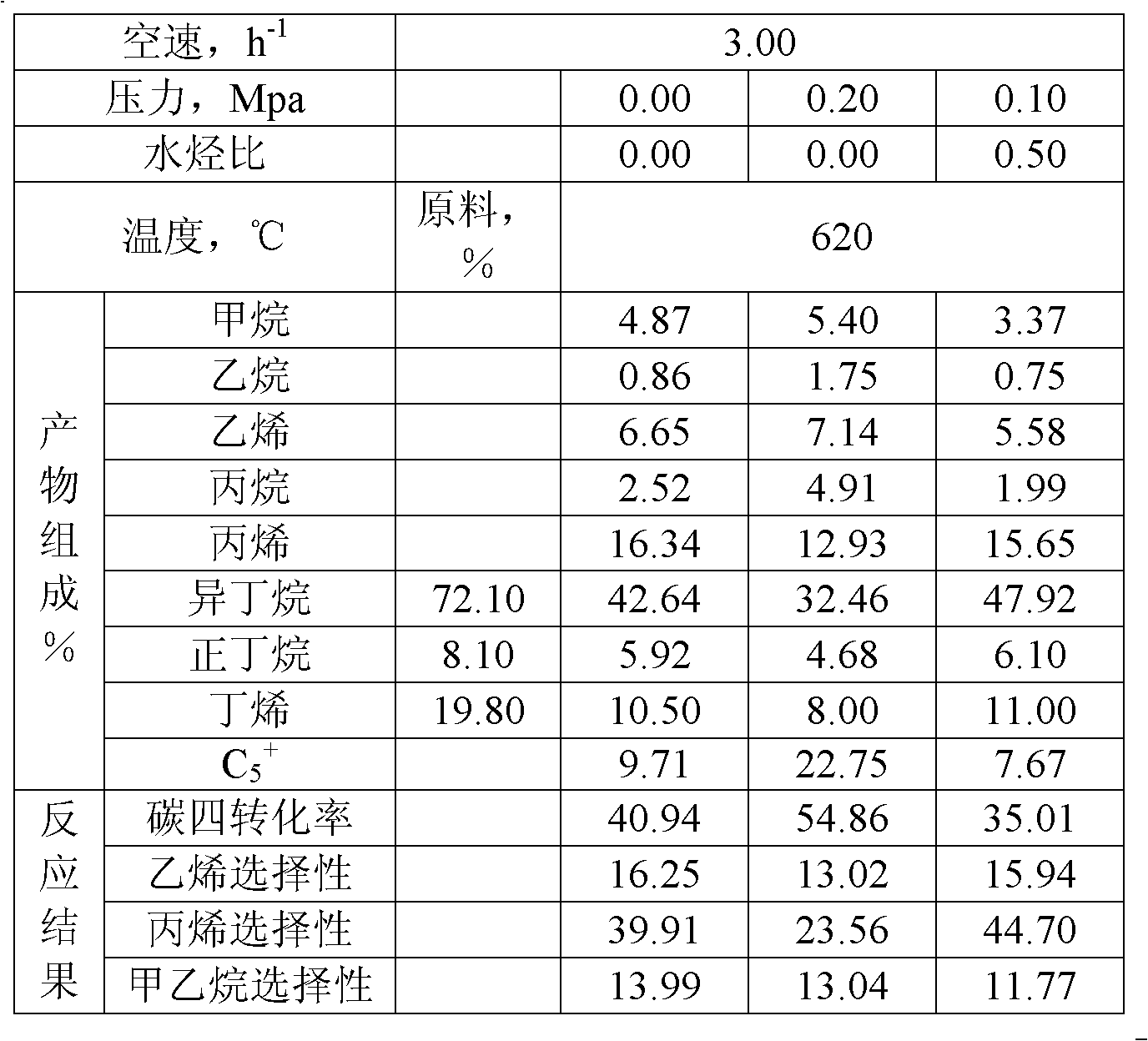

Method for producing low-carbon olefin

ActiveCN103121891AHigh thermal and hydrothermal stabilityImproved reactivity and mechanical strengthBulk chemical productionHydrocarbon by hydrocarbon crackingMolecular sieveAliphatic hydrocarbon

The invention relates to a method for producing a low-carbon olefin, mainly solving the problems that in the prior art, the olefin contained in a reactant is easily coked and the light olefin as a product is poor in selectivity due to the high reaction temperature; and the device productivity is low and the separation cost is high due to the utilization of a large number of diluents. The method provided by the invention comprises the following steps: by taking an aliphatic hydrocarbon flow liquid which is lack of the olefin as a raw material, contacting the raw material with aZSM molecular sieve catalyst to carry out cracking reaction to generate flow liquid rich in propylene and ethylene under the conditions that reaction temperature is 500-700 DEG C, the weight ratio of a diluting agent to the raw material is (0-3):1, reaction pressure is in a range from -0.08 MPa to 0.2MPa and the liquid-phase space velocity is from 0.5 to 15 per hour. According to the adopted technical scheme, the problems are solved well. The method provided by the invention can be applied to the industrial production of the low-carbon olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

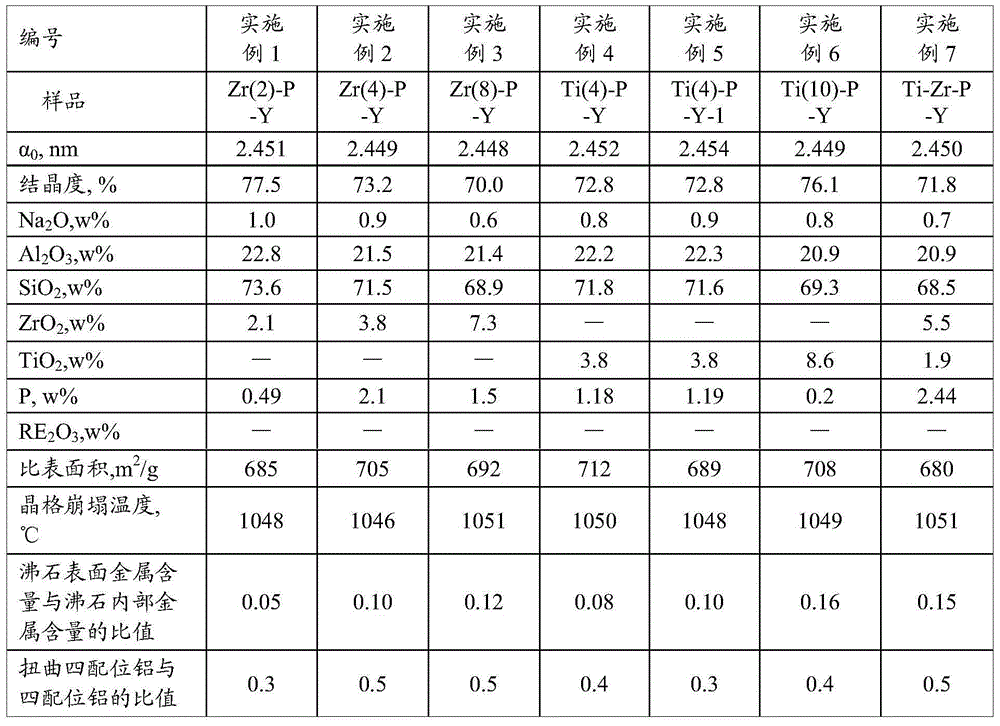

Modified Y zeolite and preparation method thereof

ActiveCN106145154AHigh crystallinityLarge specific surface areaCatalytic crackingMolecular sieve catalystsOrganic solventRare earth

The invention provides modified Y zeolite and a preparation method thereof. The modified Y zeolite contains 1-15 wt% of IVB family metal according to oxide and 0.1-10.0 wt% of phosphorus according to P. The ratio of the content of metal on the surface of the zeolite to the content of metal in the zeolite is not higher than 0.2. The preparation method of the modified Y zeolite includes the steps of processing Y zeolite with water content not exceeding 5 wt% through organic solvent and modified metallic compound, conducting calcinating, and then conducting processing through a phosphorous containing compound and acid. The modified Y zeolite has heat and hydrothermal stability not lower than that of the rare earth modified Y zeolite and has higher coke selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method of molecular sieve, modified molecular sieve and application of modified molecular sieve

ActiveCN108928833AHigh crystallinitySimple structureCatalytic crackingMolecular sieve catalystsMolecular sieveGas phase

The invention relates to the field of molecular sieve preparation, and discloses a modification method of a molecular sieve, a modified molecular sieve and an application of the modified molecular sieve. The modification method of the molecular sieve includes the steps of carrying out an ion exchange reaction on a NaY molecular sieve, carrying out hydrothermal superstability treatment, carrying out roasting, carrying out a gas-phase chemical dealumination and silicon supplementation reaction and carrying out gas-solid separation. The hydrothermal superstability treatment and roasting method make the temperature of the roasted molecule sieve be 350-600 DEG C, and the solid content not less than 98% by weight. The modification method provided by the invention has simple process flow, greatlyreduces the production energy consumption of high-silicon molecular sieves, and the prepared modified molecular sieve has high crystallinity and secondary pore structure, as well as high thermal andhydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic Cracking Catalyst and Preparation Thereof

ActiveUS20190351396A1Increase lytic activityGood coke selectivityCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

A catalytic cracking catalyst has a rare earth modified Y-type molecular sieve, an additive-containing alumina binder, and a clay. The rare earth modified Y-type molecular sieve has a rare earth oxide content of about 12 wt %, a phosphorus content of about 0-10 wt %, a sodium oxide content of no more than about 1.0 wt %, a total pore volume of about 0.36-0.48 mL / g, a percentage of the pore volume of secondary pores having a pore size of 2-100 nm to the total pore volume of about 20-40%, a lattice constant of about 2.440-2.455 nm, a percentage of non-framework aluminum content to the total aluminum content of no more than about 10%, a lattice collapse temperature of not lower than about 1060° C., and a ratio of B acid to L acid in the total acid content of the modified Y-type molecular sieve of no less than about 3.50.

Owner:CHINA PETROCHEMICAL CORP +1

A kind of ultra-stable Y-type molecular sieve containing phosphorus and rare earth and preparation method thereof

ActiveCN108452828BHigh crystallinityHigh thermal and hydrothermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveHeat stability

An ultra-stable Y-type molecular sieve containing phosphorus and rare earth and a preparation method thereof. The Y-type molecular sieve contains 4 to 11 wt% rare earth, 0.05 to 10 wt% phosphorus, 0.1 to 0.7 wt% sodium oxide, and has a pore volume of 0.33 to 0.39 mL / g, the volume of 2-100nm pores accounts for 15-30% of the total pore volume, the unit cell constant is 2.440-2.455nm, non-framework aluminum accounts for less than 20% of the total aluminum, the lattice collapse temperature is greater than 1050°C, and the B acid content The ratio to the amount of L acid is not less than 2.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earth, roasting it for 4.5-7 hours in an atmosphere of 350-480°C and 30-90 volume % water vapor, phosphorus modification treatment and mixing with silicon tetrachloride gas. Contact reaction steps. The Y-type molecular sieve has good hydrothermal stability, high heavy oil cracking activity, good coke selectivity, and high yields of heavy oil converted into gasoline, liquefied gas and total liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparation MCM-48 medium pore molecular sieve thermostable in high heat and water in buffer system

InactiveCN1686798AInhibition transitionQuality improvementMolecular-sieve and base-exchange compoundsActive agentPhenyl Ethers

The present invention use cetyl trimethyl ammonium bromide (CTAB, cation surface active agent) and polyoxyethylene octyl phenyl ether (OP-10), non-ionic surface active agent) mixed surface active agent as template agent, and uses buffer solution with a certain pH as synthesis medium, and utilizes surface active agent supermolecular self-assembling process to synthesize MCM-48 metaporous molecular sieve with higher thermal (stability and hydrothermal stability.

Owner:FUDAN UNIV

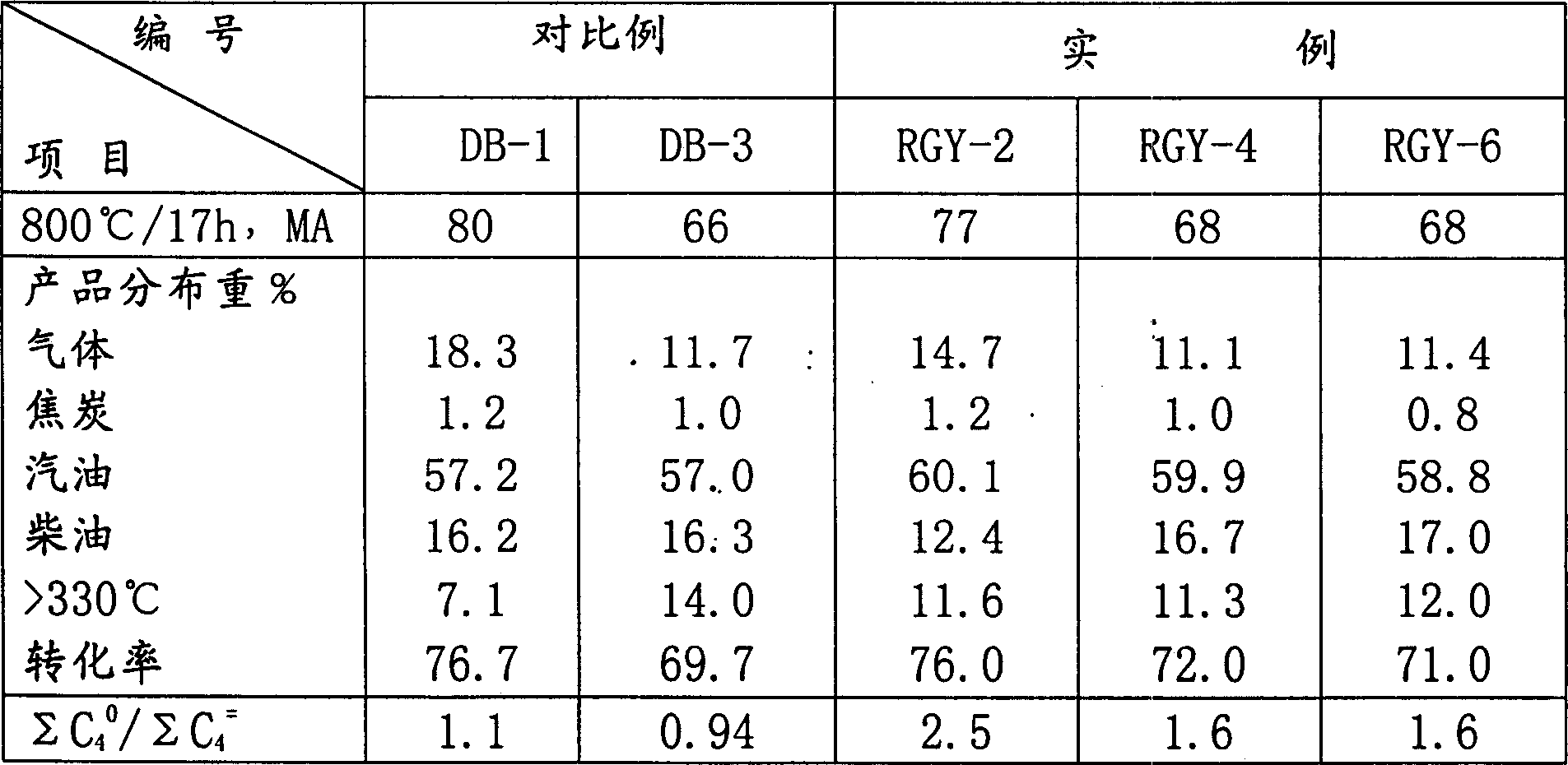

High-stability modified Y-type molecular sieve for high production of isomerized C4 and preparation method of high-stability modified Y-type molecular sieve

ActiveCN110652999AHigh thermal and hydrothermal stabilityHigh selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePhysical chemistry

The invention discloses a high-stability modified Y-type molecular sieve for high production of isomerized C4 and a preparation method of the high-stability modified Y-type molecular sieve. The CaO content of the modified Y-type molecular sieve is 0.3-4 wt%, the RE2O3 content is 2 to 7 wt%; the content of Na2O is 0.1 to 0.5 wt%; the total pore volume is 0.33 mL / g to 0.39 mL / g; the pore volume of the secondary pores of 2-100nm accounts for 10-25% of the total pore volume; the lattice constant is 2.440-2.455 nm, the content of non-framework aluminum accounts for not more than 20% of the total aluminum content, the lattice collapse temperature is not lower than 1050 DEG C, and the ratio of the amount of acid B to the amount of acid L measured by a pyridine adsorption infrared method at 200 DEG C is not lower than 2.30. The preparation method comprises the steps of ion exchange, modification treatment under certain temperature and water vapor conditions and reaction with silicon tetrachloride. The modified Y-type molecular sieve has higher heavy oil conversion activity, lower coke selectivity, higher gasoline yield and isomeric C4 yield, and higher isomeric hydrocarbon content in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y-type molecular sieve and a preparation method thereof

ActiveCN110841695AHigh thermal and hydrothermal stabilityLow coke selectivityCatalytic crackingMolecular sieve catalystsMolecular sieveAluminium

One embodiment of the invention provides a modified Y-type molecular sieve and a preparation method thereof, wherein the modified Y-type molecular sieve comprises 4-11 wt% of rare earth (calculated asrare earth oxide), not more than 0.7 wt% of sodium (calculated as sodium oxide), 0.5-5 wt% of zinc (calculated as zinc oxide), and 0.05-10 wt% of phosphorus (calculated as phosphorus pentoxide), theskeleton silicon-alumina ratio is 7-14 based on SiO2 / Al2O3 molar ratio, the mass of the non-skeleton aluminum accounts for not more than 20% of the total aluminum mass, and the pore volume of secondary pores with a pore size of 2-100 nm accounts for 15-30% of the total pore volume. According to the invention, the modified Y-type molecular sieve contains phosphorus, rare earth and zinc modificationcomponents, has advantages of high crystallinity, high thermal stability, high hydrothermal stability and rich secondary pores, is used for catalytic cracking of hydrogenated LCO (light cycle oil), and has advantages of low coke selectivity and high conversion efficiency of reactants.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation thereof

ActiveUS10888848B2Increase lytic activityGood coke selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

Owner:CHINA PETROCHEMICAL CORP +1

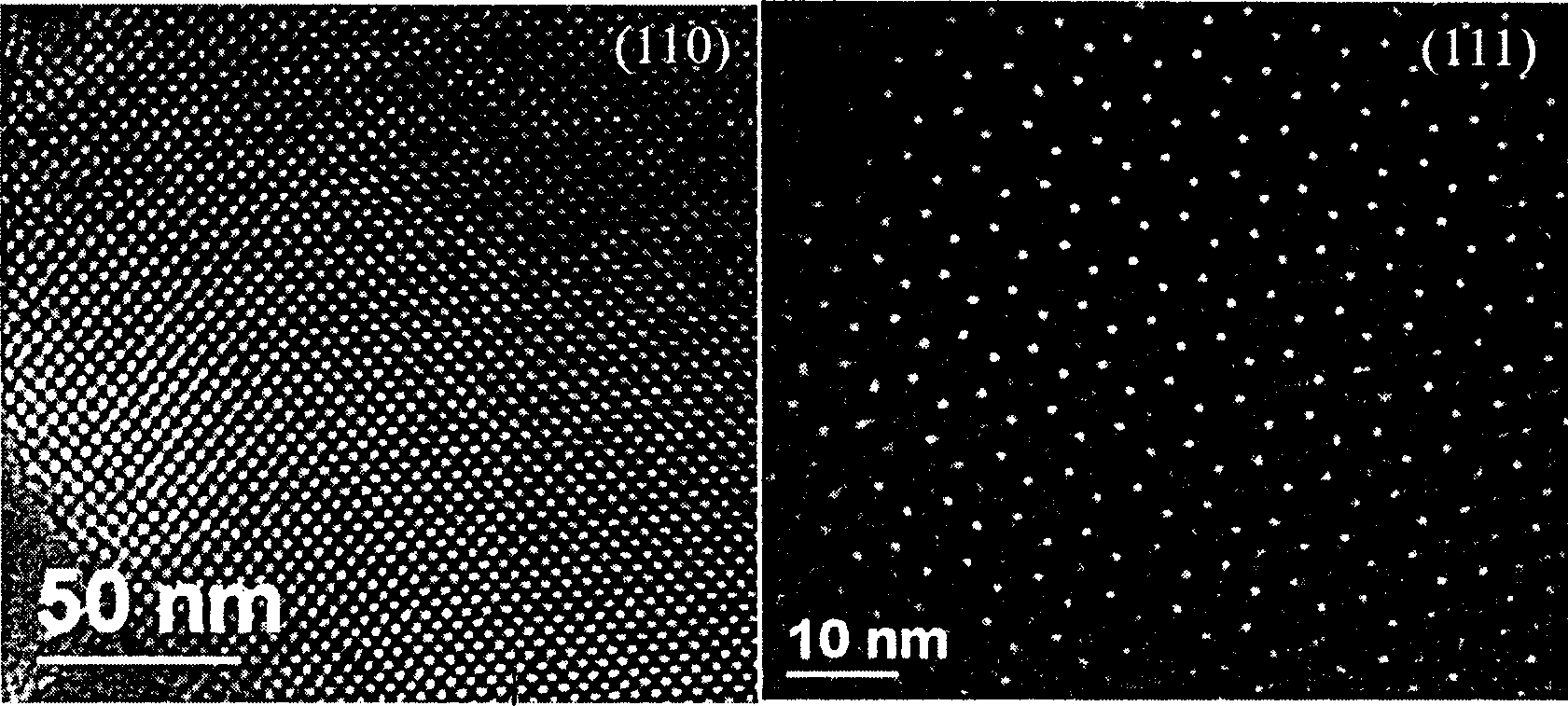

Method for directly synthesizing multi-stage ordered mesoporous molecular sieve

ActiveCN102515194BMesopore heightHigh degree of orderFaujasite aluminosilicate zeoliteChemical industryMolecular sieve

The invention relates to a method for directly synthesizing a multi-stage ordered mesoporous molecular sieve, which comprises the following steps that: a silicon source, an aluminum source, water and template agent are mixed to obtain a mixture; an alkali source and surfactant are added into the mixture, and a gel mixture is obtained; and the gel mixture is moved into a synthesis reactor to be sealed and subjected to crystallization reaction, washed, dried and calcinated, and the multi-stage ordered mesoporous molecular sieve is obtained. The method has the advantages of simple process and reduced production cost, and is applicable to industrialized production. The synthesized molecular sieve has the advantages of high-order mesopores, higher mechanical strength, good hydrothermal stability, and can be used in petroleum chemical industry, fine preparation of chemicals, environmental catalysis and other fields.

Owner:ZHEJIANG UNIV

Cracking catalyst and preparation method thereof

ActiveCN102029177BHigh ratio of silicon to aluminumHigh crystallinityCatalytic crackingMolecular sieve catalystsMolecular sieveSulfur

The invention relates to a preparation method of a cracking catalyst, which comprises: raw materials and water are mixed to prepare a slurry solution by utilizing the catalyst containing a Y type molecular sieve and a silicon vector; the slurry solution is dried to obtain a catalyst precursor; the catalyst precursor is baked; and a contact reaction is carried out on the catalyst precursor and an acidic ammonium salt solution. The preparation method of the cracking catalyst can enhance the crystallization retaining degree of the Y type molecular sieve in the catalyst and the stability of the catalyst. The catalyst prepared by utilizing the method is used for the catalytic cracking of heavy oil and has the advantages of strong conversion capability of the heavy oil, high yield of gasoline, and low sulphur content in the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN108452837AHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsWater vaporRare earth

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains clay, an alumina binder and a modified Y type molecular sieve. The modified Y type molecular sieve comprises 5 to 12 wt% of rare earth and no more than 0.5 wt% of sodium oxide, and has a total pore volume of 0.36 to 0.48 mL / g; the pore volume of secondary pores accounts for 20 to 38% of the total pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum is no more than 10% of total aluminum content; lattice collapse temperature is higher than 1060 DEG C; and a ratio of the amount of acid B to the amount of acid L is no less than 3.50. A preparation method for the catalytic cracking catalyst comprises the following steps: preparing a rare earth-containing Y type molecular sieve with a conventional cell size; carrying out roasting in a water vapor atmosphere with a temperature of 350 to 520 DEG C and a volume percentage of 30 to 95% for 4.5 to 7 h; carryingout a contact reaction with silicon tetrachloride; and carrying out acid treatment. The catalyst has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalytic cracking catalyst

ActiveCN108452837BHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

A catalytic cracking catalyst contains clay, alumina binder and modified Y-type molecular sieve. The modified Y-type molecular sieve contains 5 to 12 wt% rare earth, no more than 0.5 wt% sodium oxide, and a total pore volume of 0.36 to 0.48 mL / g, the secondary pore volume accounts for 20~38% of the total pore volume, the unit cell constant is 2.440~2.455nm, non-framework aluminum accounts for less than 10% of the total aluminum, the lattice collapse temperature is higher than 1060℃, B acid content The ratio to the amount of L acid is not less than 3.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earths, roasting it for 4.5 to 7 hours in an atmosphere of 350 to 520°C and 30 to 95 volume % water vapor, contacting with silicon tetrachloride gas and treating with acid. . The catalytic cracking catalyst has higher heavy oil conversion activity and lower coke selectivity, and has higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A rare earth-containing modified Y-type molecular sieve rich in secondary pores and its preparation method

ActiveCN108452831BHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveWater vapor

A rare earth-containing modified Y-type molecular sieve rich in secondary pores and a preparation method thereof. The Y-type molecular sieve has a rare earth content of 5 to 12% by weight, a sodium content of no more than 0.5% by weight, and a total pore volume of 0.36 to 0.48 mL. / g, the secondary pore volume accounts for 20~38% of the total pore volume, the unit cell constant is 2.440~2.455nm, the non-framework aluminum content accounts for less than 10% of the total aluminum content, the lattice collapse temperature is higher than 1060°C, B acid The ratio of the amount to the amount of L acid is not less than 3.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earths, roasting it for 4.5 to 7 hours in an atmosphere of 350 to 520°C and 30 to 95 volume % water vapor, contacting with silicon tetrachloride gas and treating with acid. A step of. The modified Y-type molecular sieve has higher heavy oil conversion activity and lower coke selectivity, and has higher gasoline yield, liquefied gas yield, light oil yield and total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com