Modification method of molecular sieve, modified molecular sieve and application of modified molecular sieve

A molecular sieve and modification technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, catalytic cracking, etc., can solve the problems of high crystallinity and secondary pore structure, poor thermal and hydrothermal stability of high-silicon molecular sieves, etc. , to achieve high heat and hydrothermal stability, reduce coke formation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0053] According to a preferred embodiment of the present invention, the conditions of the hydrothermal ultra-stable treatment include: the temperature is 350-480°C, the time is 0.5-3h, and the amount of superheated steam is 0.15-0.45 per kilogram of molecular sieve. kg, more preferably, the temperature is 390-460°C, the time is 1-2.5h, and the amount of superheated steam is 0.3-0.42 kg per kg of molecular sieve. Adopting the preferred embodiment of the present invention is more conducive to improving the relative crystallinity of the prepared modified molecular sieve.

[0054] In the present invention, the amount of steam used refers to the amount passed into the reaction device (calcination furnace) during the hydrothermal ultra-stable treatment process.

[0055] In the present invention, the hydrothermal ultra-stable treatment refers to relatively mild hydrothermal treatment.

[0056] The present invention has a wide range of conditions for the roasting, as long as the mol...

Embodiment 1

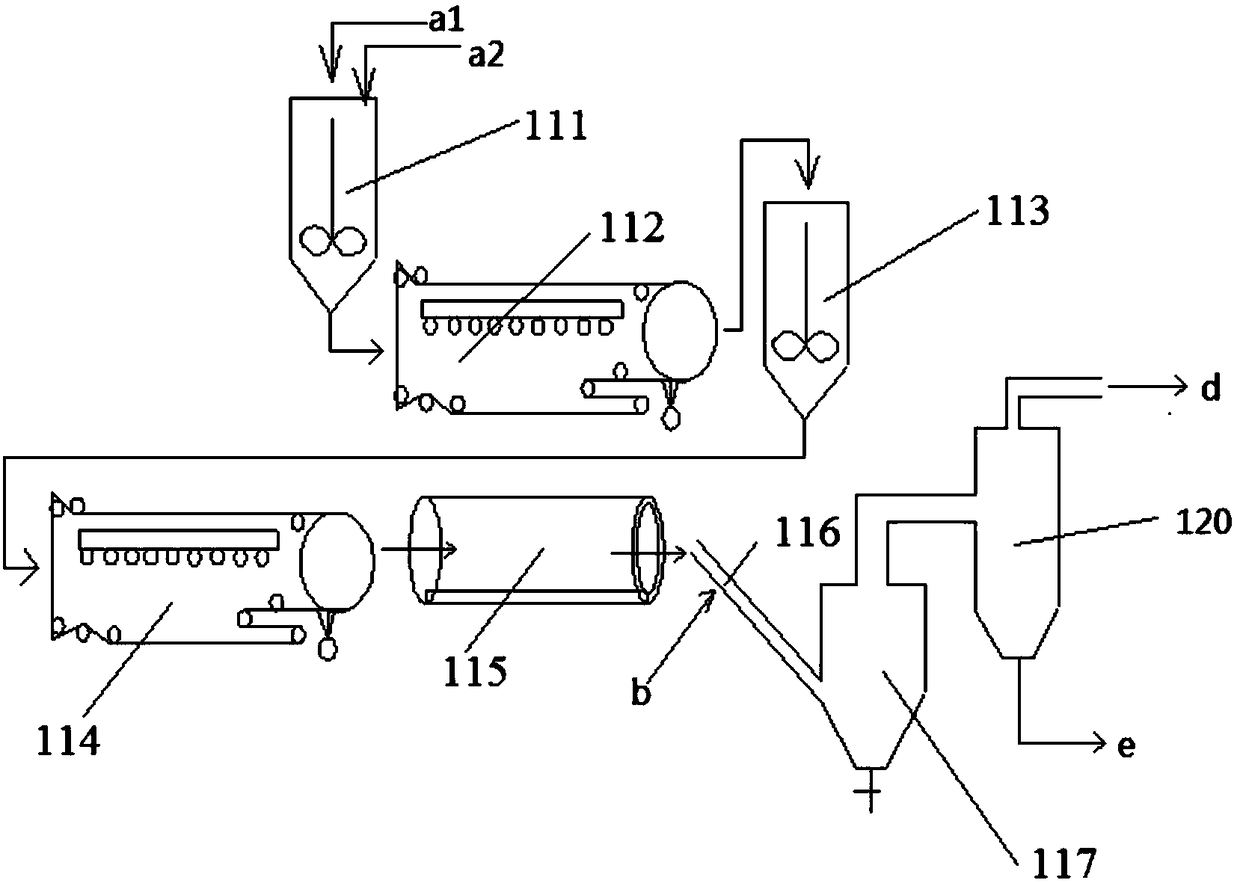

[0174] The modification method provided in this embodiment is as in figure 2 The modification of the molecular sieve shown in the equipment (the NaY molecular sieve is commercially available, so the NaY molecular sieve synthesis reactor 111 and the first filter device 112 were not used). in,

[0175](1) In the NaY molecular sieve exchange device 113, 3000kg NaY molecular sieve (on a dry basis) is mixed with decationized water, and then RE (NO 3 ) 3 Solution (rare earth solution concentration is RE 2 o 3 Calculated as 335g / L), among them, NaY molecular sieve (in dry basis), rare earth salt (in RE 2 o 3 ) and water with a weight ratio of 1:0.18:15, carry out ion exchange reaction in NaY molecular sieve exchange device 113, the temperature of ion exchange reaction is 95°C, the time is 50min, and the molecular sieve slurry that has been exchanged is passed through the second filter The device 114 (belt filter) filters and washes to obtain a filter cake.

[0176] (2) The fi...

Embodiment 2

[0180] (1) In the NaY molecular sieve exchange device 113, 4000kg NaY molecular sieve (on a dry basis) is mixed with decationized water, and then RE (NO 3 ) 3 Solution (rare earth solution concentration is RE 2 o 3 Calculated as 335g / L), among them, NaY molecular sieve (in dry basis), rare earth salt (in RE 2 o 3 ) and water with a weight ratio of 1:0.18:12, carry out the ion exchange reaction in the NaY molecular sieve exchange device 113, the temperature of the ion exchange reaction is 90°C, and the time is 60min, and the molecular sieve slurry that has been exchanged is passed through the second filter The device 114 (belt filter) filters and washes to obtain a filter cake.

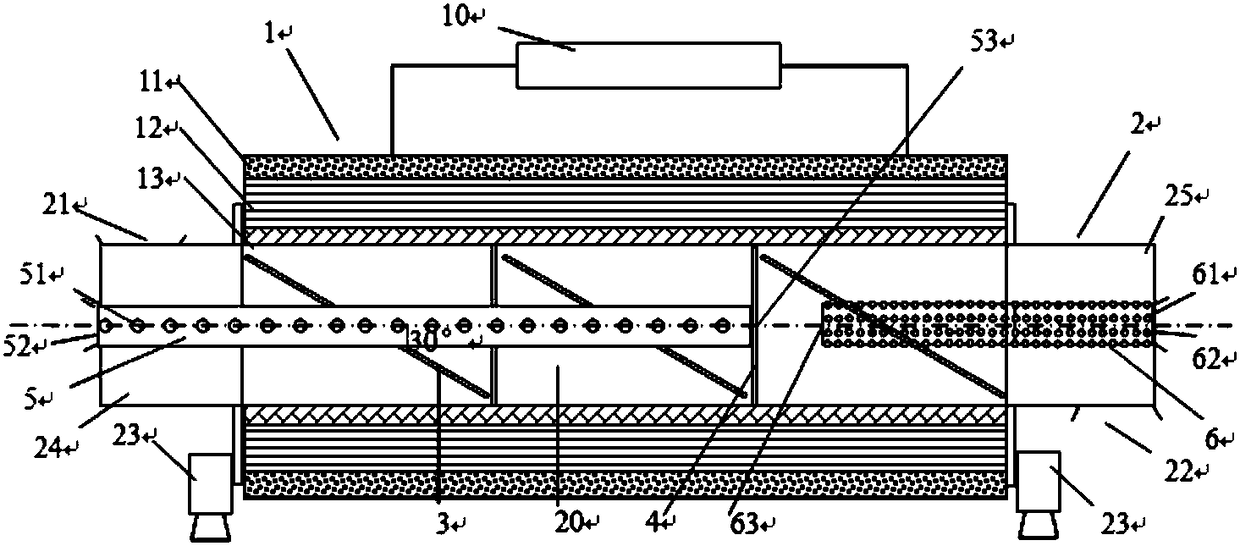

[0181] (2) The filter cake of step (1) is directly sent into the dual-function roasting furnace 115 for hydrothermal ultra-stable treatment and roasting. The difference between the dual-function roasting furnace 115 and the dual-function roasting furnace disclosed in Embodiment 1 is that, The enti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com