Rare-earth Y-type zeolite

A zeolite and rare earth technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems that the unit cell cannot be further shrunk, rare earth is difficult to exchange, and the content of rare earth is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

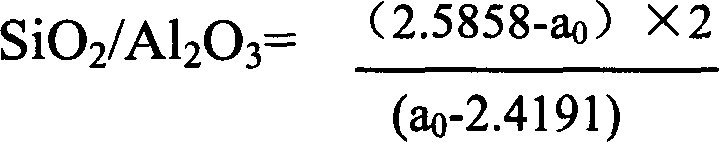

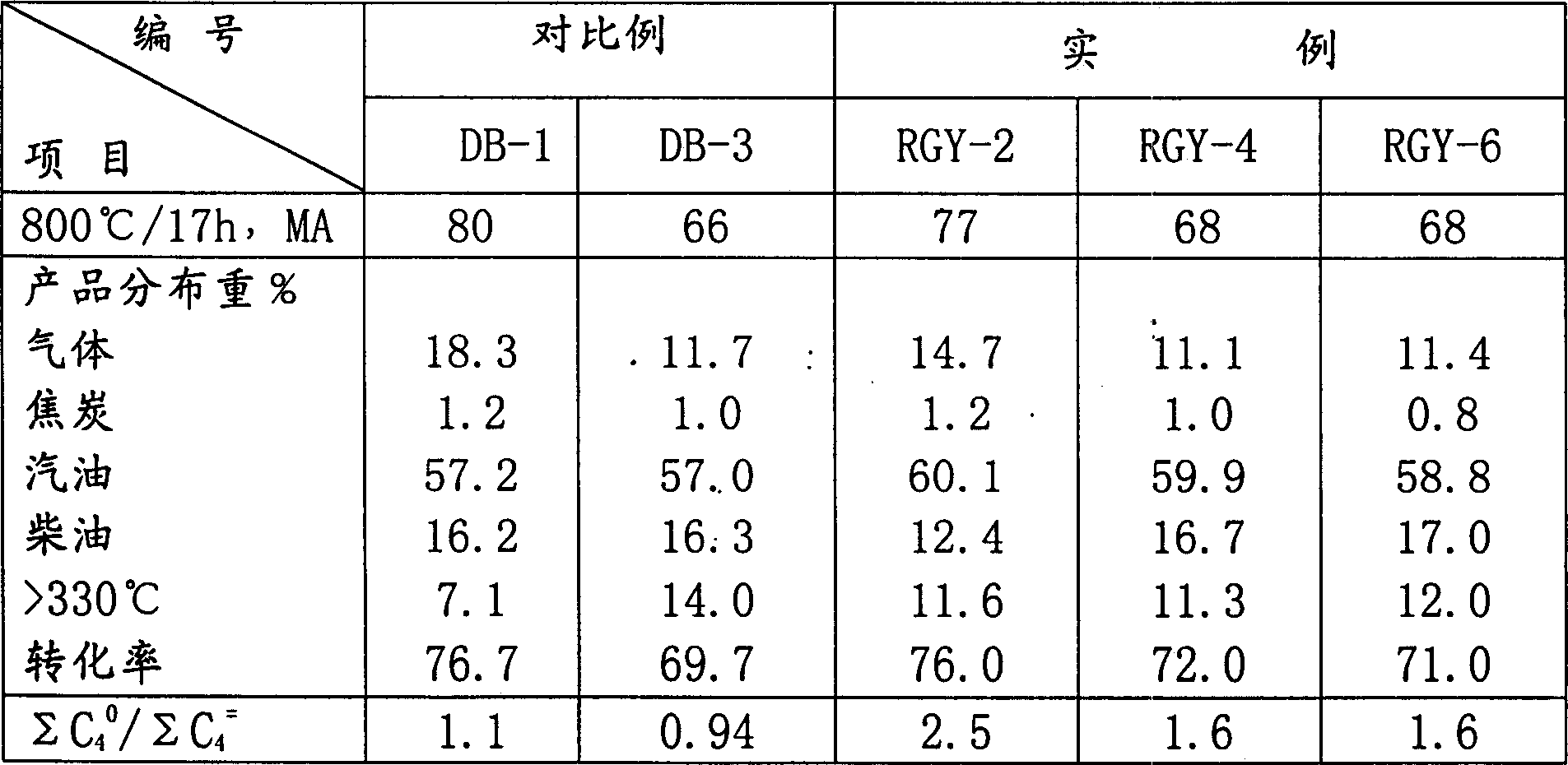

example 1

[0024] The NaY zeolite with a solid content of 85% (Zhoucun Catalyst Factory of Qilu Petrochemical Company, the ratio of silicon to aluminum is 4.0, the unit cell constant is 2.473nm, the alumina is 24.8%, and the sodium oxide is 16%), at 80-90°C Next, press NaY:RECl 3 :H 2 The ratio of O=1:0.21:10, the rare earth exchange was carried out for 60 minutes, so that RE 2 o 3 The content is 16%, of which La 2 o 3 4.16%, Ce 2 o 3 The content of other rare earth oxides is 3.68%. According to NaY:SiCl 4 = 1:0.5 ratio, carry SiCl with dry air 4 React at 450°C for 120 minutes, blow with dry air for 20 minutes, wash and filter to remove Cl in zeolite - and Na + , to obtain a sample, numbered RGY-1.

example 2

[0026]The NaY zeolite with a solid content of 75% (Zhoucun Catalyst Factory of Qilu Petrochemical Company, the ratio of silicon to aluminum is 5.05, the unit cell constant is 2.466nm, the alumina is 21.2%, and the sodium oxide is 15.8%), at 80-95°C Next, press NaY:RECl 3 :H 2 O=1:0.25:10 ratio, carry out rare earth exchange for 40 minutes, filter and wash. According to NaY:SiCl 4 = 1:0.5 ratio, carry SiCl with dry air 4 Reacted at 550°C for 60 minutes, purged with dry air for 120 minutes, washed and filtered to obtain a sample, numbered RGY-2.

example 3

[0028] Take REHY (Zhoucun Catalyst Factory of Qilu Petrochemical Company, RE 2 o 3 Content 13.4%, of which La 2 o 3 12.7% by weight, Ce 2 o 3 is 2.7% by weight, the content of other rare earth oxides is 1.9% by weight, the unit cell constant of zeolite is 2.469nm, the differential thermal differential thermal collapse temperature is 985 ° C, Na 2 O content is 4.4% by weight) into the reactor, dried to water content less than 5%, according to REY: SiCl 4 = 1:0.5 ratio, carry SiCl with dry air 4 Reacted at 350°C for 3 hours, purged with dry air for 60 minutes, washed and filtered to obtain a sample, numbered RGY-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

| Cell constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com