Method for producing low-carbon olefin

A technology for low-carbon olefins and olefins is applied in the field of catalytic cracking of ethylene and C3-C8 hydrocarbons to produce propylene. Effect of thermal and hydrothermal stability, good alkane cracking reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, add 300 grams of hydrogen-type ZSM-5 molecular sieve with a silicon-aluminum ratio of 100 to a solution consisting of 600 grams of water and 19.5 grams of ammonium dihydrogen phosphate. After dipping and stirring at room temperature for two hours, place it in an oven at 80°C overnight, and then 500 °C for 2 hours.

[0023] Put 148 grams of kaolin (15% reduction on ignition) and 250 grams of water to soak for 10 minutes, then beat for 10 minutes, add 625 grams of aluminum sol (20% alumina content) and stir for 5 minutes, and add 20% nitric acid to adjust the pH value to 3.5 Finally, add 100 grams of PHZSM-5 (Si / Al=100) molecular sieves containing 4% phosphorus oxide and beat for 15 minutes to obtain a slurry. The slurry was spray-dried at an inlet air temperature of 600°C and an outlet air temperature of 350°C, and then calcined at 650°C to obtain a catalyst. The catalyst heap ratio was measured to be 0.83 g / ml, and the main particle size of the catalyst was ~60 ...

Embodiment 2

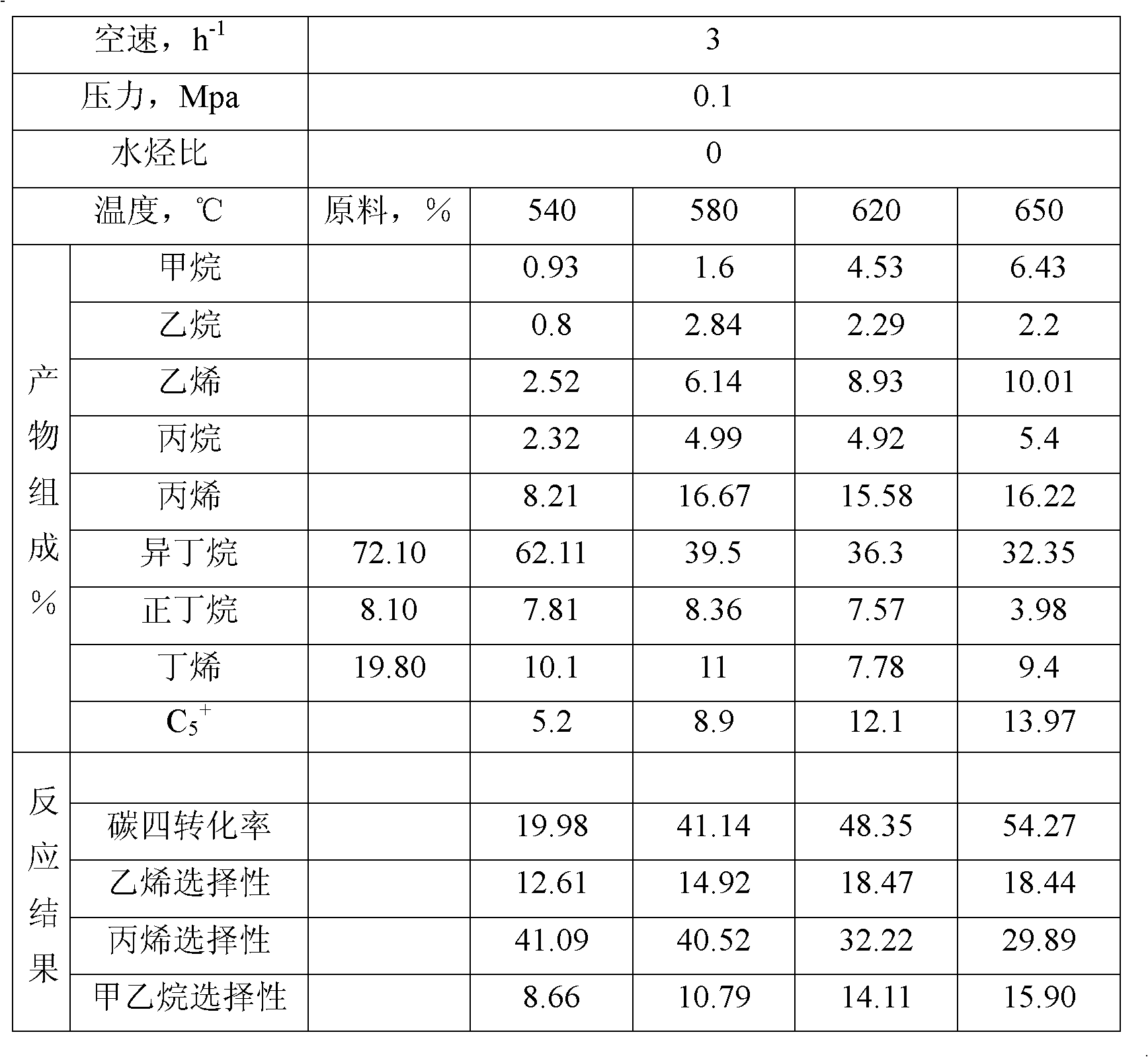

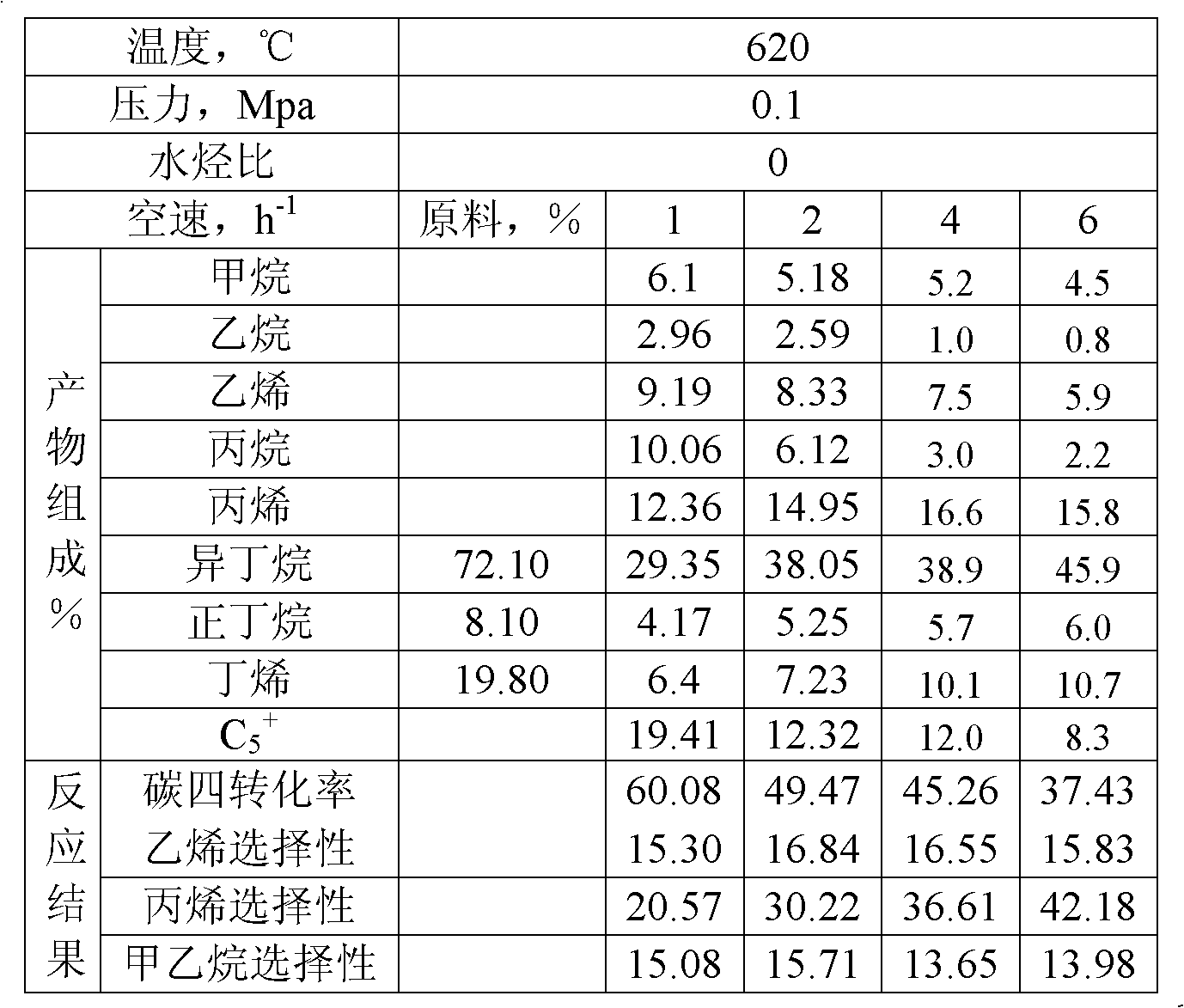

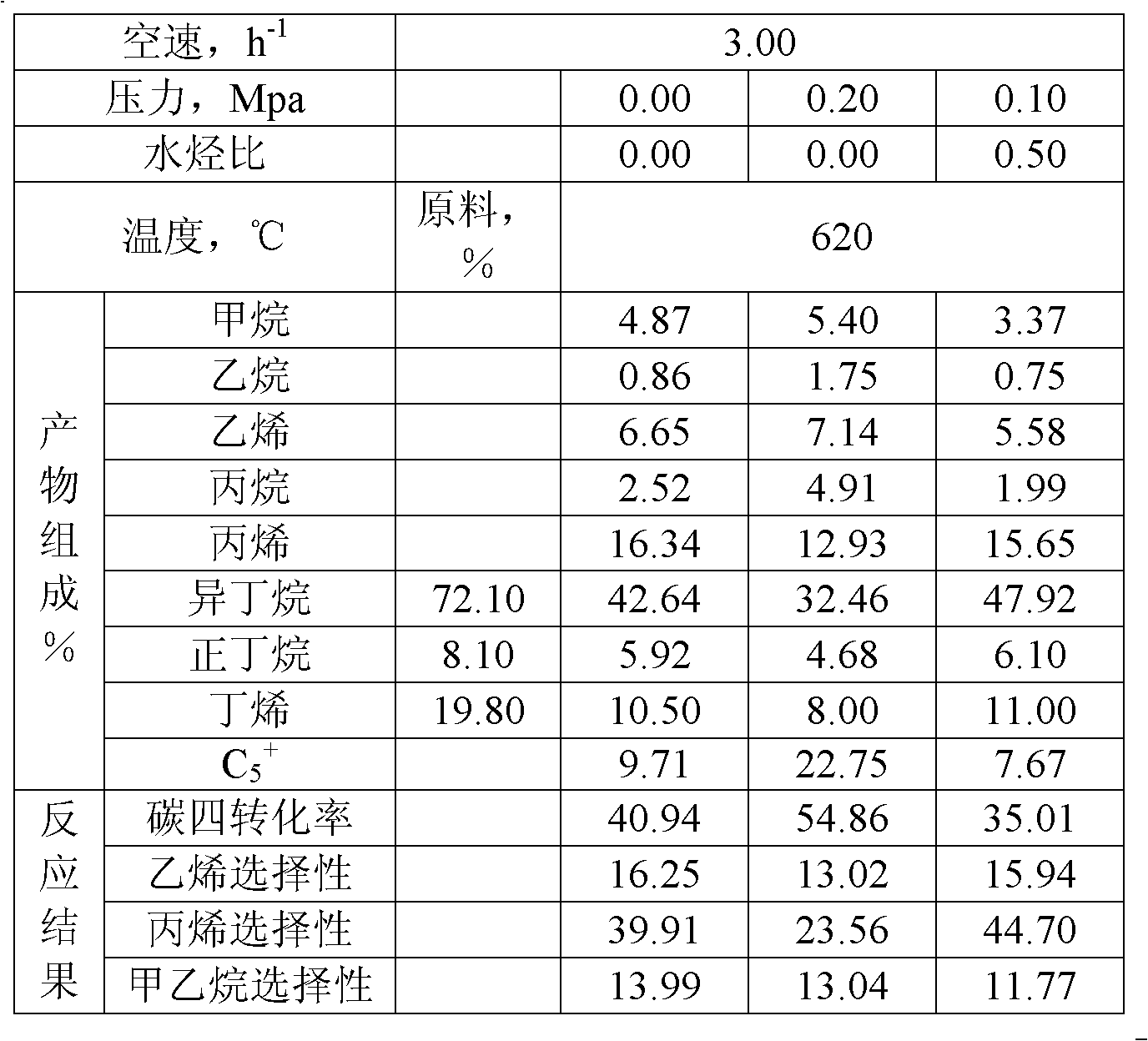

[0028] With the same catalyzer and raw material of embodiment 1, test is carried out under other different conditions, result tabulation 2, table 3.

[0029] The reaction result of table 2 different technological conditions

[0030]

[0031] The reaction result of table 3 different technological conditions

[0032]

Embodiment 3

[0034] Using pure isobutane as the raw material instead of the raw material of Example 1, the evaluation was carried out, and the results are listed in Table 4.

[0035] The reaction result of table 4 isobutane raw material

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com