Cracking catalyst and preparation method thereof

A cracking catalyst and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of low molecular sieve yield, small molecular sieve stack ratio, and difficult recovery, etc. Stability, increase pore volume, reduce the effect of broken ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In the cracking catalyst preparation method provided by the present invention, can also comprise the step of introducing auxiliary component, described auxiliary component can be introduced in the process of preparing slurry in step (1), also can be after step (1), Before step (5), add a step of contacting the catalyst precursor with the auxiliary component. The additive component such as rare earth compound, based on the weight of the catalyst, the content of the rare earth element of the catalyst is no more than 5% by weight (in RE 2 o 3 ), wherein the rare earth element is a mixed rare earth element based on lanthanum and / or cerium, wherein the content of lanthanum and / or cerium is more than 50% by weight of the total amount of rare earth elements, preferably more than 60% by weight. Preference is given to incorporating soluble salts of rare earths.

[0029] In the catalyst preparation method provided by the invention, the relative crystallinity retention of the Y-...

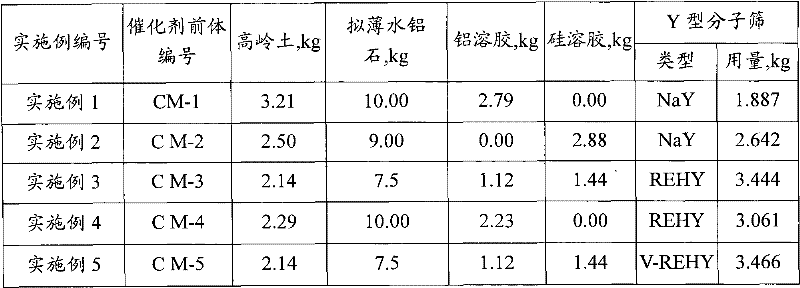

Embodiment 1-5

[0035] These examples illustrate the preparation of the catalyst precursors provided by the present invention.

[0036] Among the raw materials used, the molecular sieves are all produced by Sinopec Catalyst Qilu Branch. Among them, the unit cell constant of NaY molecular sieve is 2.473 nanometers, the content of sodium oxide is 14% by weight, the solid content is 79.48% by weight, and the crystallinity is 100%. The unit cell constant of REHY molecular sieve 2.470 nanometers, sodium oxide content 3.8 wt%, rare earth oxide content 6.5 wt%, solid content 78.4 wt%, crystallinity 86%; V-REHY molecular sieve unit cell constant is 2.469 nm, sodium oxide content 3.8 wt%, rare earth oxide The vanadium content is 6.5% by weight, the vanadium (calculated as simple substance) content is 1.0% by weight, the solid content is 77.9% by weight, and the crystallinity is 77%. Kaolin is an industrial product of China Kaolin Company, and its solid content is 84% by weight; pseudoboehmite is pro...

Embodiment 6~7

[0046] In 100 grams (dry basis weight) catalyst precursor CM-1, CM-2, add deionized water respectively, make the water content in the catalyst precursor be 15% by weight (based on the dry basis weight of the catalyst precursor), At 450° C., 100% water vapor atmosphere was roasted for 1.5 hours, and then mixed with 2 liters of ammonium ion concentration of 6% by weight (NH 4 ) 2 SO 4 Mix the aqueous solution, conduct ion exchange at 90°C for 45 minutes, add hydrochloric acid during the exchange process, keep the pH value of the slurry at 4.0, then filter, wash the filter cake with deionized water until no sulfate is detected in the washed water, and wet filter The cake was baked at 750° C. for 2 hours, and then mixed with 2 liters of ammonium ion concentration of 3% by weight (NH 4 ) 2 SO 4 The aqueous solution was ion-exchanged at 85°C for 30 minutes. During the exchange process, the pH value of the slurry was controlled to 3.5 with hydrochloric acid, filtered, and the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com