Modified Y zeolite and preparation method thereof

A zeolite and modification technology, applied in the field of modified Y-type zeolite and its preparation, can solve the problems of low thermal and hydrothermal stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

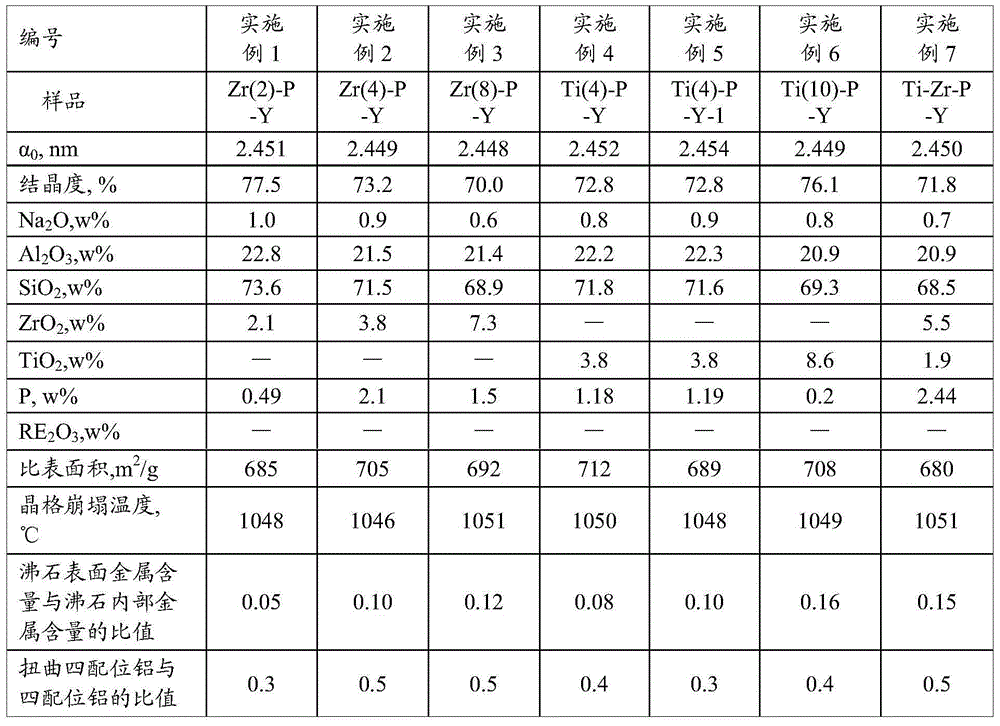

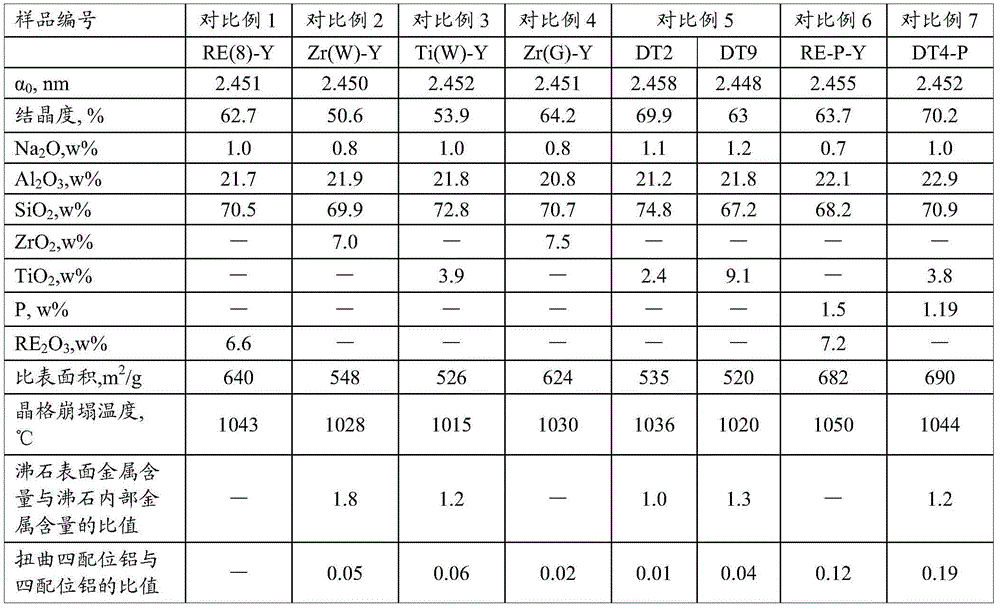

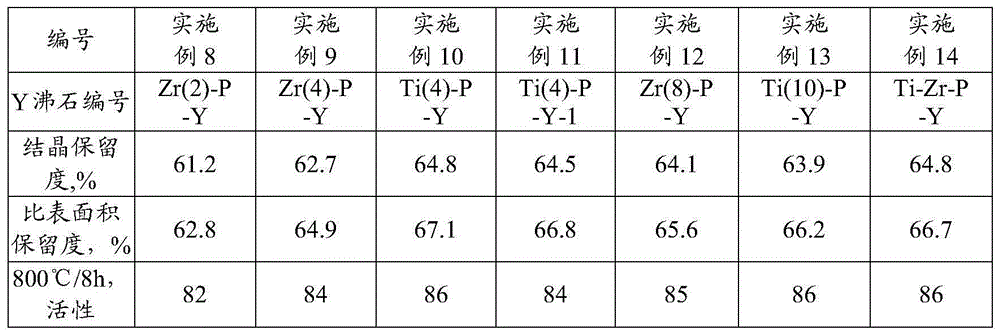

Examples

Embodiment 1

[0042] Get 200g of NaY zeolite and roast at 300°C for 3 hours (the water content after roasting is 1% by weight), place it in 2000g of ethanol (99.9% by weight of ethanol) after cooling to room temperature and stir evenly, add 10.5g of zirconium nitrate Zr (NO 3 ) 4 ·5H 2 O, then stirred at room temperature for 2 hours, filtered, and the filter cake was dried in an oven at 100°C for 24 hours, and then calcined in a nitrogen atmosphere at 600°C for 2 hours.

[0043] The Y zeolite after the above-mentioned roasting is added to 2000g acid concentration is in the inorganic acid aqueous solution (dilute hydrochloric acid solution) of 1.0mol / L, then adds 2.79g (NH 4 )H 2 PO 4 , mix evenly, stir at 80°C for 3 hours, then filter, wash with deionized water (the amount of washing water is 15 times the dry basis weight of the molecular sieve), filter, take out the filter cake and place it in 600°C, 100% steam for 1 hour . Finally, Zr(2)-P-Y zeolite compositely modified by zirconium...

Embodiment 2

[0045] Take 200g NaY zeolite at 200°C, 10 -3 Vacuumize under Pa for 4 hours, after cooling to room temperature (water content 0.5% by weight), place in 1500g ethanol (ethanol content 99.9% by weight) and stir evenly, add 15.7g zirconium oxychloride ZrOCl in the above slurry 2 ·8H 2 O, continue stirring at room temperature for 3 hours, after filtering, put the filter cake in an oven and dry it at 100°C for 24 hours, and then roast it in a nitrogen atmosphere at 500°C for 3 hours.

[0046] The Y zeolite after the above-mentioned roasting is joined in the oxalic acid aqueous solution of 2.0mol / L in 1500g acid concentration, then add 12.8g (NH 4 ) 2 HPO 4 , mix evenly, heat up to 90°C, stir for 1 hour, then filter, wash with deionized water (the amount of washing water is 15 times the dry basis weight of the molecular sieve), take out the filter cake and place it in 500°C, 100% steam for 2 hours . Finally, Zr(4)-P-Y zeolite compositely modified by zirconium and phosphorus was...

Embodiment 3

[0048] Get 200g of NaY zeolite and roast it at 300°C for 3 hours, put it in 1000g of n-hexane (99.5% by weight of n-hexane) after cooling to room temperature, and stir evenly, add 37.8g of isopropanol to the slurry Zirconium C 15 h 36 o 5 Zr, continue to stir at room temperature for 3 hours, filter and dry in an oven at 120°C for 48 hours, and then bake at 500°C (dry air atmosphere, the water content in the air does not exceed 0.2% by volume) for 4 hours.

[0049] The Y zeolite after above-mentioned roasting is joined in the inorganic acid (sulfuric acid) aqueous solution of 0.5mol / L in 1000g acid concentration, then adds 14.78g (NH 4 ) 3 PO 4 , stirred at 80°C for 3 hours, then filtered, washed with deionized water (the amount of washing water is 20 times the dry weight of the molecular sieve), and the filter cake was taken out and roasted for 3 hours at 500°C and 100% steam. Finally, Zr(8)-P-Y zeolite compositely modified by zirconium and phosphorus was obtained, and it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com