Method for preparation MCM-48 medium pore molecular sieve thermostable in high heat and water in buffer system

A technology of mesoporous molecular sieve and MCM-48, applied in the field of MCM-48 mesoporous molecular sieve material, can solve problems such as unsatisfactory results, and achieve the effect of perfect pore wall structure, high degree of crystallization and simplified operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

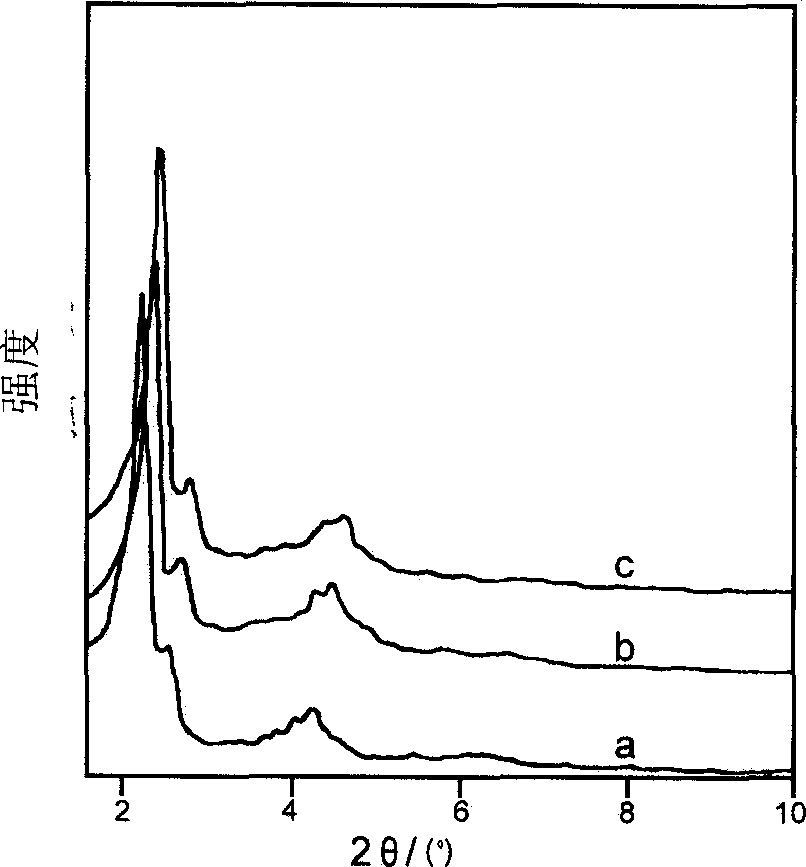

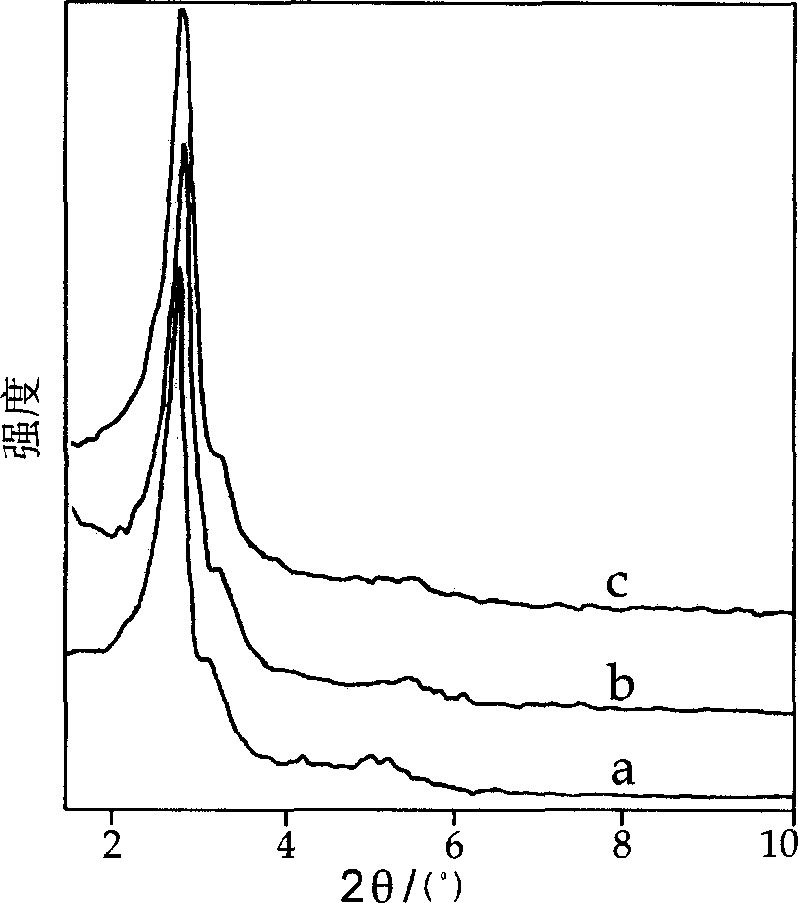

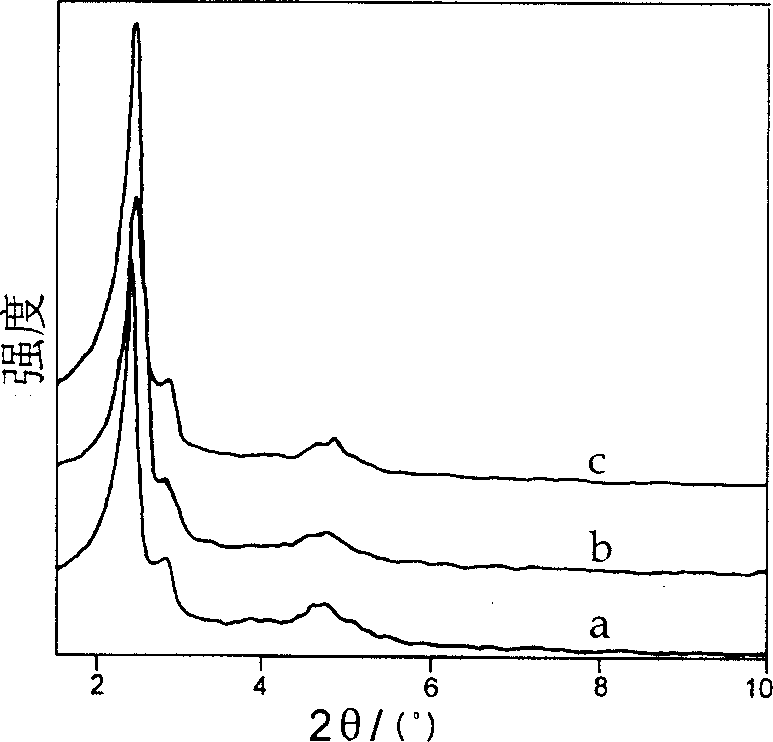

example 1

[0022] 0.403gNa 2 HPO 4 ·12H 2 O and 0.035g sodium hydroxide dissolved in 45ml water, then add a certain amount of CTAB and OP-10, stir at 30 ℃ until clear, and then add water glass (Na 2 O: 7.4%, SiO 2 : 25.4%), a uniformly mixed starting gel was obtained after stirring for 1 hour. At this time, the molar composition of the synthetic mixture is: 1.0SiO 2 :0.12CTAB:0.04OP-10:0.35Na 2 O: 0.025P 2 O 5 :58H 2 O. Then, it was crystallized at 100°C for 48 hours to obtain MCM-48 mesoporous molecular sieve.

example 2

[0024] 0.282gNa 2 HPO4 ·12H 2 O and 0.041g of sodium hydroxide are dissolved in 49.5ml of water, then add a certain amount of CTAB and OP-10, stir at 38 ℃ until clear, then add water glass (Na 2 O: 7.4%, SiO 2 : 25.4%), a uniformly mixed starting gel was obtained after stirring for 1 hour. At this time, the molar composition of the synthetic mixture is: 1.0SiO 2 : 0.12CTAB: 0.04OP-10: 0.31Na 2 O: 0.018P 2 O 5 :64H 2 O. Then, it was crystallized at 105°C for 52 hours to obtain MCM-48 mesoporous molecular sieve.

example 3

[0026] 0.32gNa 2 HPO 4 ·12H 2 O and 0.039g of sodium hydroxide are dissolved in 41.3ml of water, then add a certain amount of CTAB and OP-10, stir at 25℃ until clear, then add water glass (Na 2 O: 7.4%, SiO 2 : 25.4%), a uniformly mixed starting gel was obtained after stirring for 1 hour. At this time, the molar composition of the synthetic mixture is: 1.0SiO 2 : 0.12CTAB: 0.04OP-10: 0.0.309Na 2 O: 0.02P 2 O 5 : 54.8H 2 O. Then, it was crystallized at 110°C for 40 hours to obtain MCM-48 mesoporous molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com