Deposition mask and method for manufacturing organic light emitting display using the same

a technology of light-emitting display and mask, which is applied in the manufacture of electrode systems, discharge tubes luminescnet screens, electrode systems, etc., can solve the problems of damage to organic films, negative influence of outgasing on organic films, and photolithography that exposes organic films to moisture during resist exfoliation or etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

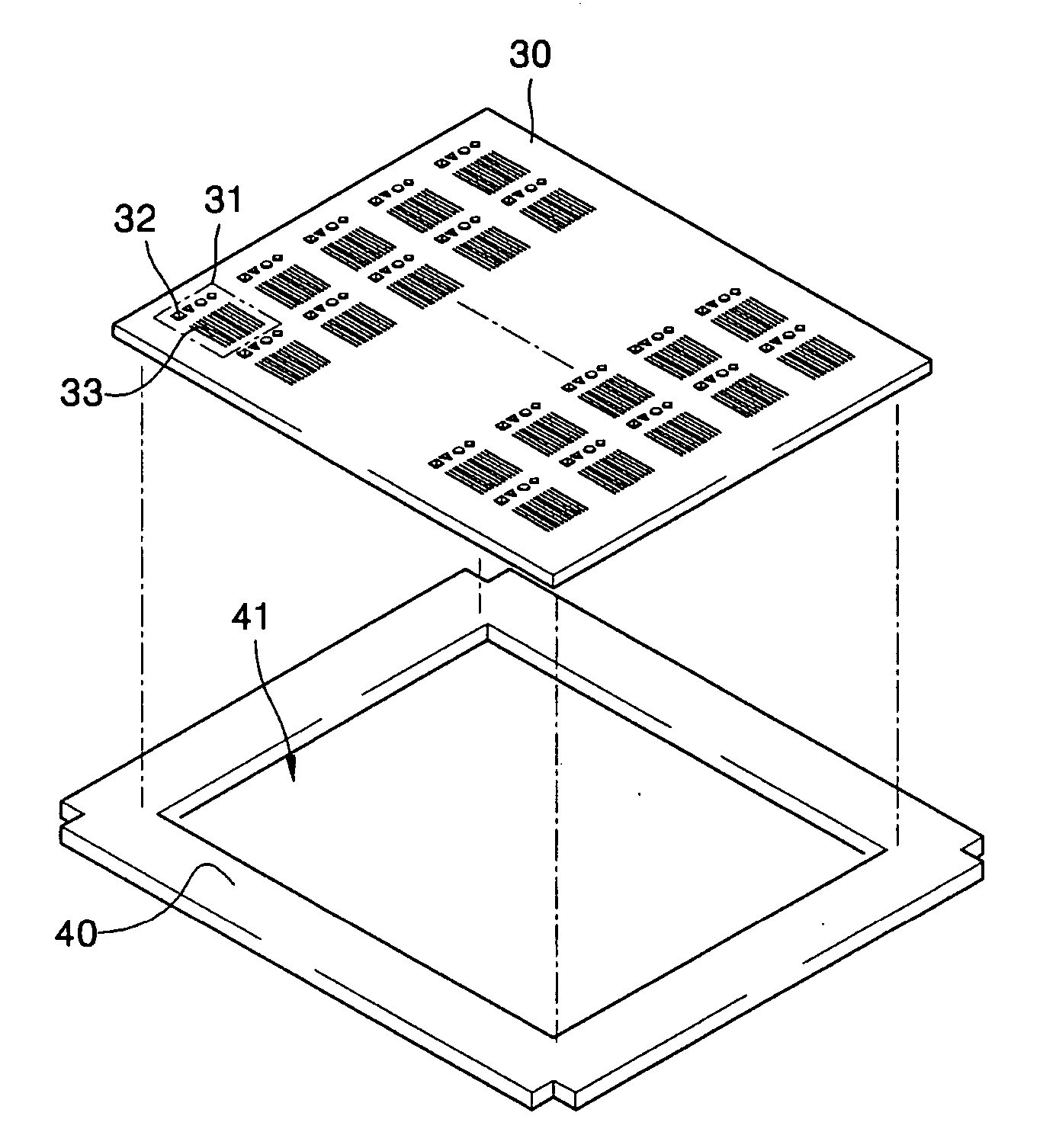

[0031] The present invention can be used to manufacture an OLED as illustrated in FIG. 1. As described above, the substrate 10 of FIG. 1 has four panel regions but the present invention is not necessarily limited to this. The present invention can have a plurality of panel regions and have the OLED formed on the respective panel regions.

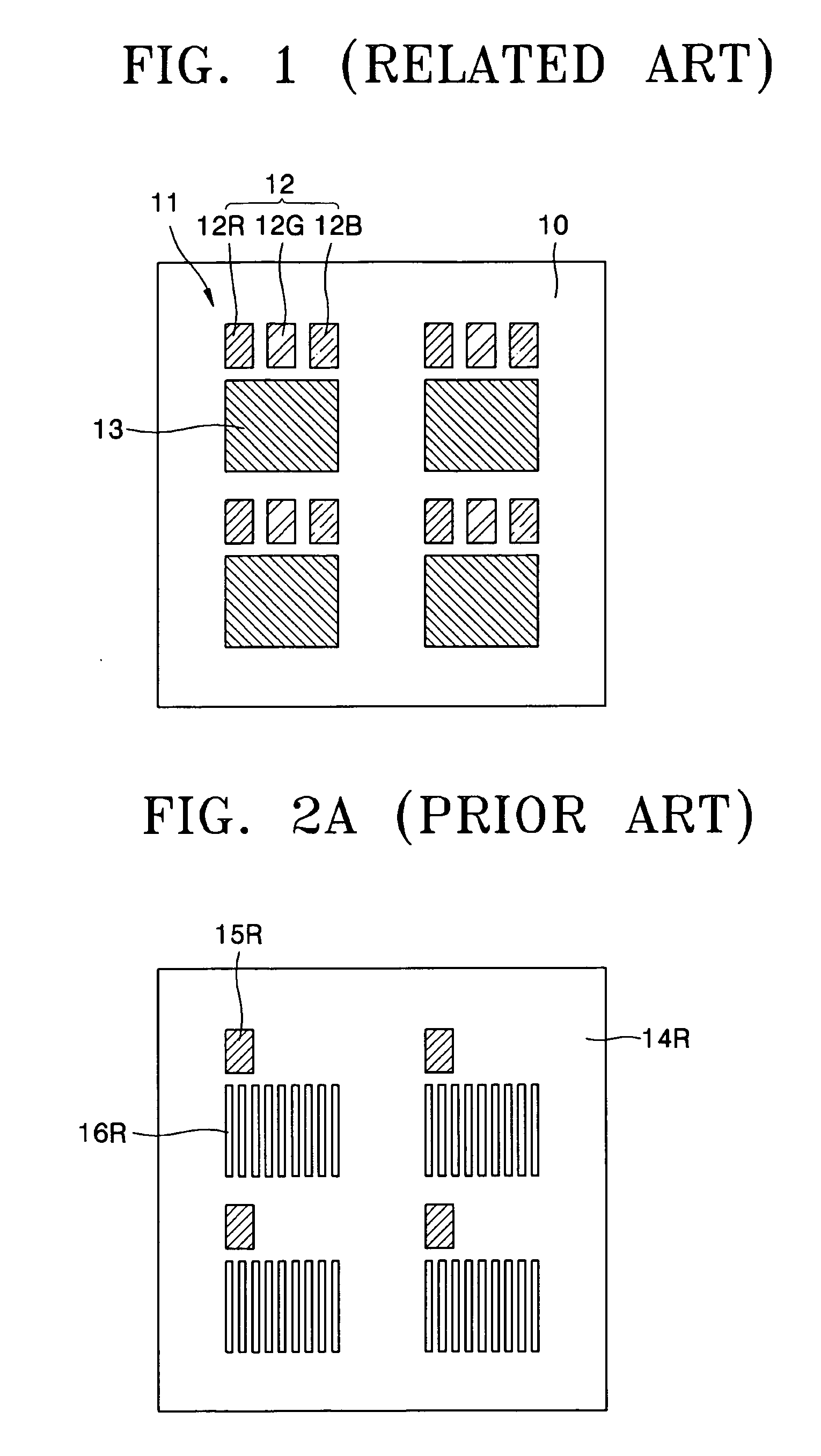

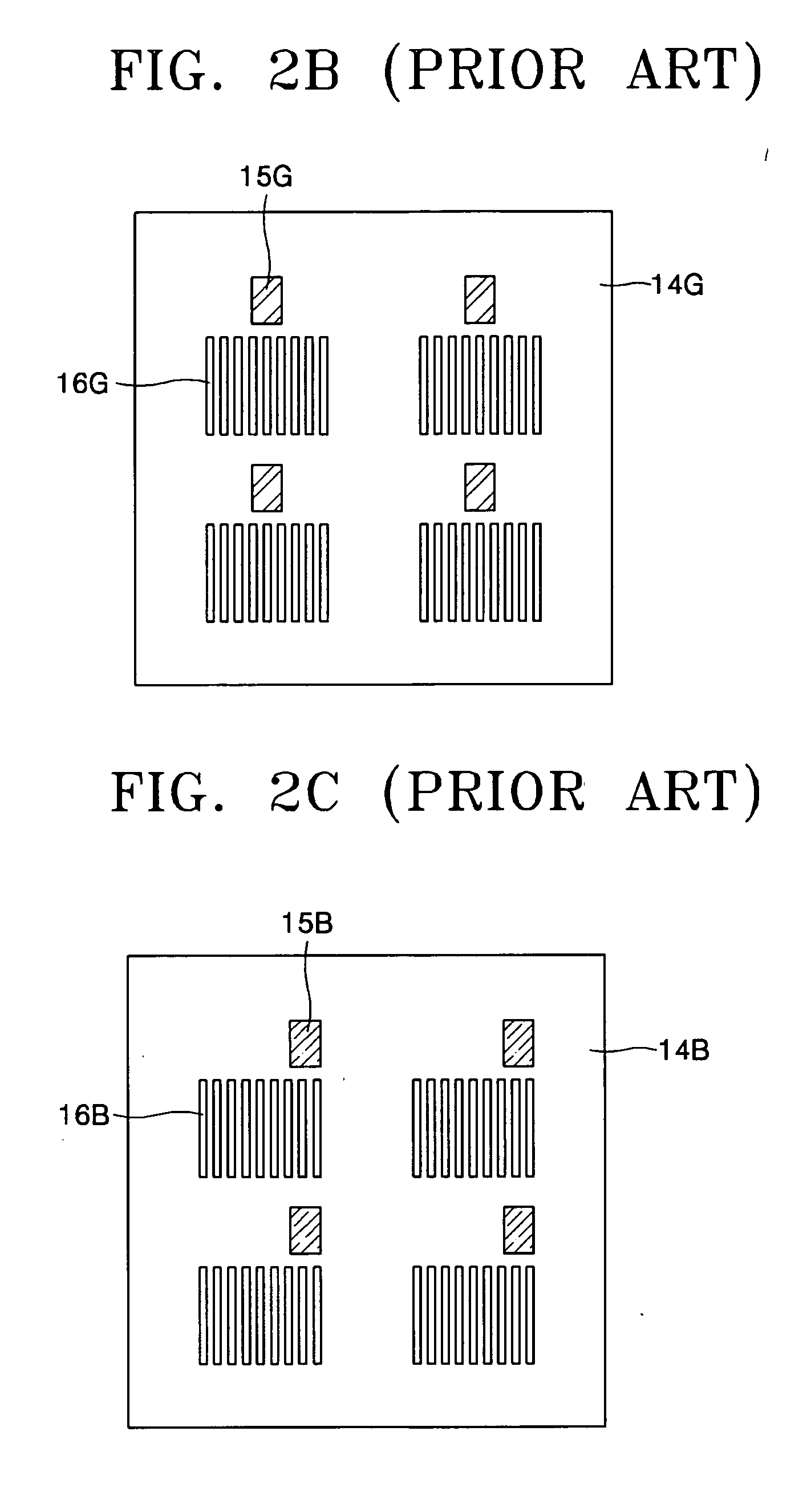

[0032] As described above, the OLED of the respective panels 11 can include an icon part 12 and a main image part 13. The icon part 12 can include a red emission region 12R, a green emission region 12G, and a blue emission region 12B. The main image part 13 can have a red sub-pixel, a green sub-pixel, and a blue sub-pixel so as to realize full color.

[0033] At this point, the icon part 12 and the main image part 13 can have the structure illustrated in FIG. 3. This structure is further ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com