Light oil type hydrocracking catalyst with composite molecular sieve as well as preparation method and application thereof

A composite molecular sieve and hydrocracking technology, which is applied in the field of hydrocracking catalyst and its preparation, can solve the problem of low catalyst activity and achieve high catalytic cracking performance, enhanced hydrophobicity, and outstanding isomerization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) The commercially available NaY molecular sieve (relative crystallinity 90%, unit cell constant 2.470nm, SiO 2 / Al 2 o 3 Molar ratio is 5.1, Na 2 The O content is 10.9wt%, the following examples and comparative examples are the same) mixed with the ammonium nitrate solution with a concentration of 2.0mol / L, the liquid-solid weight ratio is 10, the temperature is raised to 95°C, ion exchange is carried out under stirring for 1.5 hours, and the Remove the mother liquor, repeat the exchange once, filter and wash to obtain Na 2 NH with an O content of 2.9 wt% 4 NaY molecular sieve sample;

[0031] (2) Weigh 500 grams (dry basis) NH 4 NaY molecular sieves were placed in a three-necked flask, and 1M NH 4NO 3 2.5 liters, stirred and heated to 98 ° C, and then at a speed of 7.25 ml / min (NH 4 ) 2 SiF 6 Add 870ml of the aqueous solution into the three-necked flask, and continue to stir and react for 1 hour after the addition. Then stop stirring, let it stand for 10 ...

Embodiment 2

[0035] Take 100 grams of commercially available NaY molecular sieves and exchange them with 800ml of 1.5N ammonium nitrate solution at 90°C for 1.5 hours, filter off the mother liquor, repeat the exchange once, wash the filter cake with deionized water, put it back into the exchange tank and use 1.5N ammonium nitrate solution 800ml of ammonium nitrate solution was beaten, heated up to 95°C, and 1.2M (NH 4 ) 2 SiF 6 Add 150ml of aqueous solution into the exchange tank at a constant speed for 1.5 hours, then continue to react for 1.5 hours, stop stirring, let stand for 5 minutes, export the upper molecular sieve slurry, filter, wash, and dry to a moisture content of 15%; the sample is placed in a hydrothermal treatment furnace , the temperature of the control system is 580°C, the water vapor pressure is 0.08MPa, and the hydrothermal treatment is 2.0 hours; the sample is exchanged with 0.8 liters of 1.0N ammonium chloride solution (adjusted to pH=2.8 with hydrochloric acid) at 9...

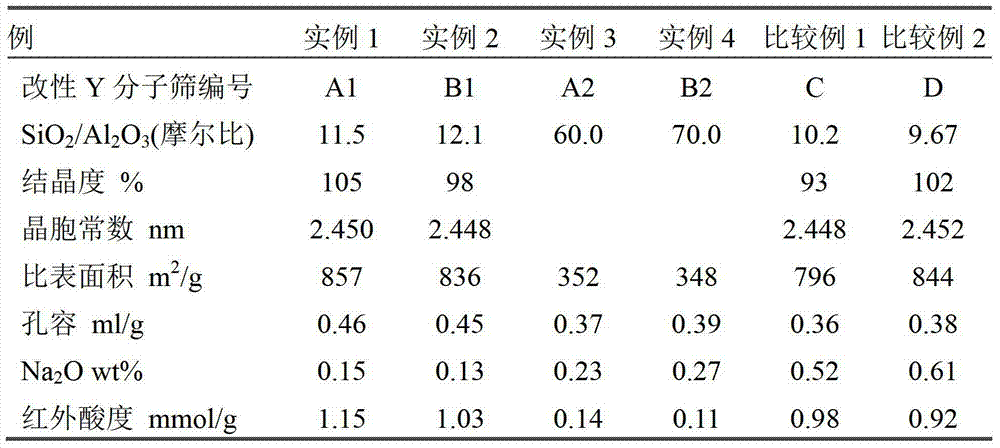

Embodiment 3

[0037] Take SiO 2 / Al 2 o 3 300 g of HZSM-23 molecular sieve with a molar ratio of 60 was placed in a hydrothermal treatment furnace, the temperature of the control system was 500 ° C, the water vapor pressure was 0.05 MPa, and the hydrothermal treatment was carried out for 1.0 hour to obtain modified ZSM-23 molecular sieve A2. The physical and chemical properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com