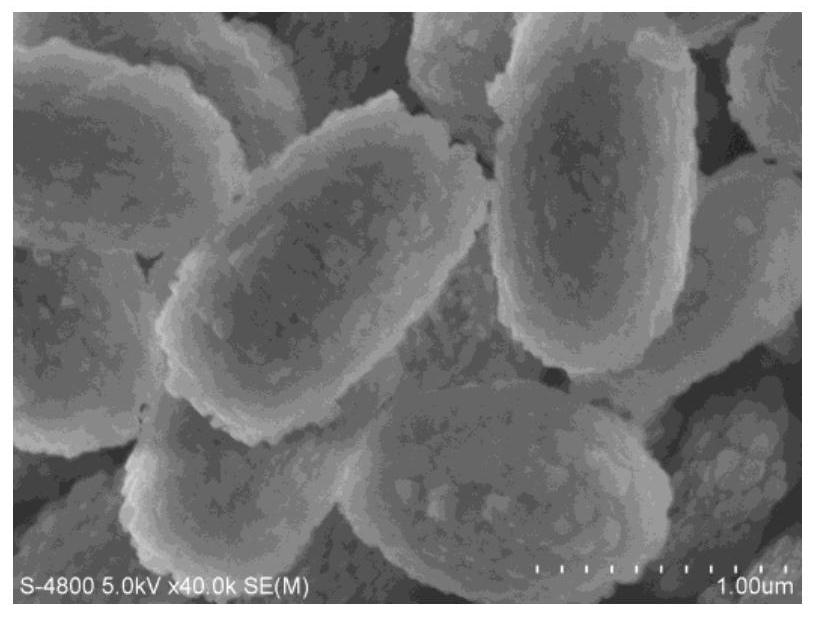

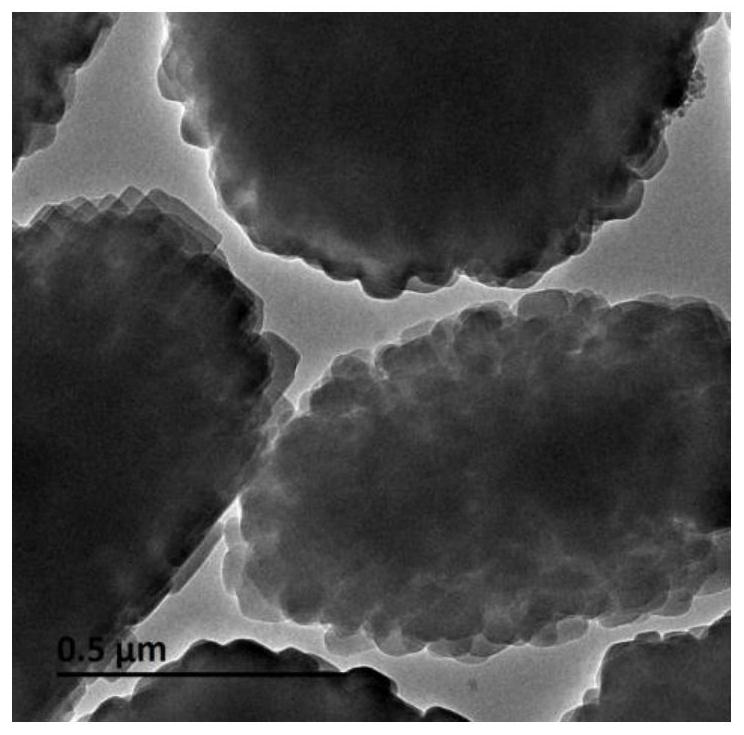

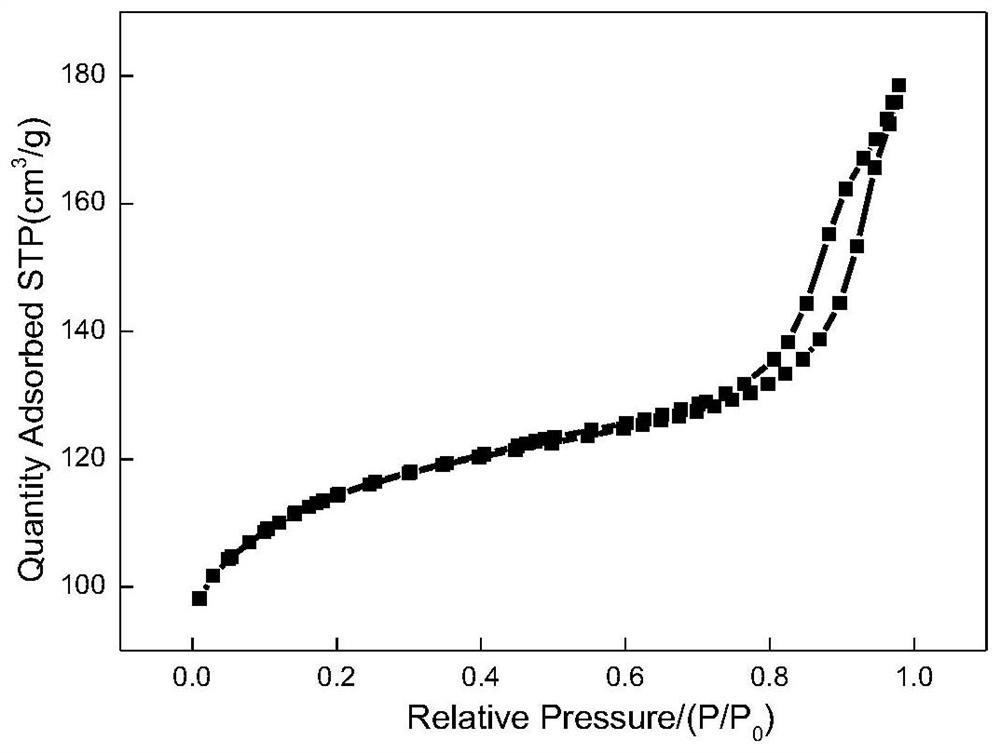

Nanocluster mesoporous ZSM-5 molecular sieve and preparation method thereof

A ZSM-5, nano-cluster technology, applied in nanotechnology, crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of long time, complicated process, etc., and achieve low cost , Simple operation, high crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] According to the nano-cluster mesoporous ZSM-5 molecular sieve and synthesis method provided by the present invention, an implementation method includes the following steps:

[0053] (1) The template agent and deionized water are mixed uniformly, and then the silicon source is added, and stirred at 30°C-50°C for 0.5-3.0 h; wherein the molar ratio of the template agent and the silicon source calculated as silica is 0.1-0.5: 1. The molar ratio of water and silicon source in terms of silica is 80-120:1;

[0054] (2) Add alkali metal hydroxide to deionized water to dissolve, then add aluminum source, and stir at room temperature preferably at 20-30°C for 0.5-2.0 h; wherein, the molar ratio of water and alkali metal hydroxide is 75-300:1 For example 140-250, H 2 O / Al 2 O 3 Molar ratio = 600-1500;

[0055] (3) The product of step (2) is slowly added to the product of step (1), mixed uniformly, and preferably stirred at room temperature at 25-30° C. for 1.0-5.0 h to obtain...

Embodiment 1

[0066] (1) Weigh 103 grams of tetrapropylammonium hydroxide (concentration 25.0% by weight), add 758 grams of deionized water, stir at room temperature for 10 min, then add 110 grams of ethyl orthosilicate, and stir for 2.0 h;

[0067] (2) Weigh 2.5 grams of sodium hydroxide particles, add 244 grams of deionized water to completely dissolve the sodium hydroxide, then add 16.0 grams of aluminum nitrate, and stir at 25 ° C for 1.0 h;

[0068] (3) slowly adding the solution of step (2) into step (1), mixing evenly, and stirring at 25°C for 4.0h;

[0069] (4) Transfer the precursor liquid into the synthesis kettle, and dynamically crystallize it at 170°C for 48h;

[0070] (5) After crystallization, centrifugal filtration, washing, drying, and calcination at 550° C. for 4 h.

Embodiment 2

[0072] (1) Weigh 53 grams of tetrapropylammonium bromide (25.0%), add 700 grams of deionized water, stir at room temperature for 10min, then add 100 grams of methyl orthosilicate, and stir for 5.0h under 30°C water bath conditions;

[0073] (2) Weigh 2.5 grams of sodium hydroxide particles, add 180 grams of deionized water to completely dissolve the sodium hydroxide, then add 4.0 grams of sodium aluminate, and stir at room temperature for 2.0h;

[0074] (3) adding the solution of step (2) into step (1), mixing uniformly, and stirring at room temperature for 4.0h;

[0075] (4) Transfer the precursor liquid into the synthesis kettle, and dynamically crystallize it at 180°C for 24h;

[0076] (5) After crystallization, centrifugal filtration, washing, drying, and calcination at 500° C. for 6 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com