FCC equilibrium catalyst reactivation and modification method

A balancing agent and modification technology, which is applied in the direction of chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve the problem of no significant improvement in catalytic cracking product selectivity, poor product selectivity, balancing agent Inability to use and other problems, to achieve the effect of improved selectivity of cracking products, improved performance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

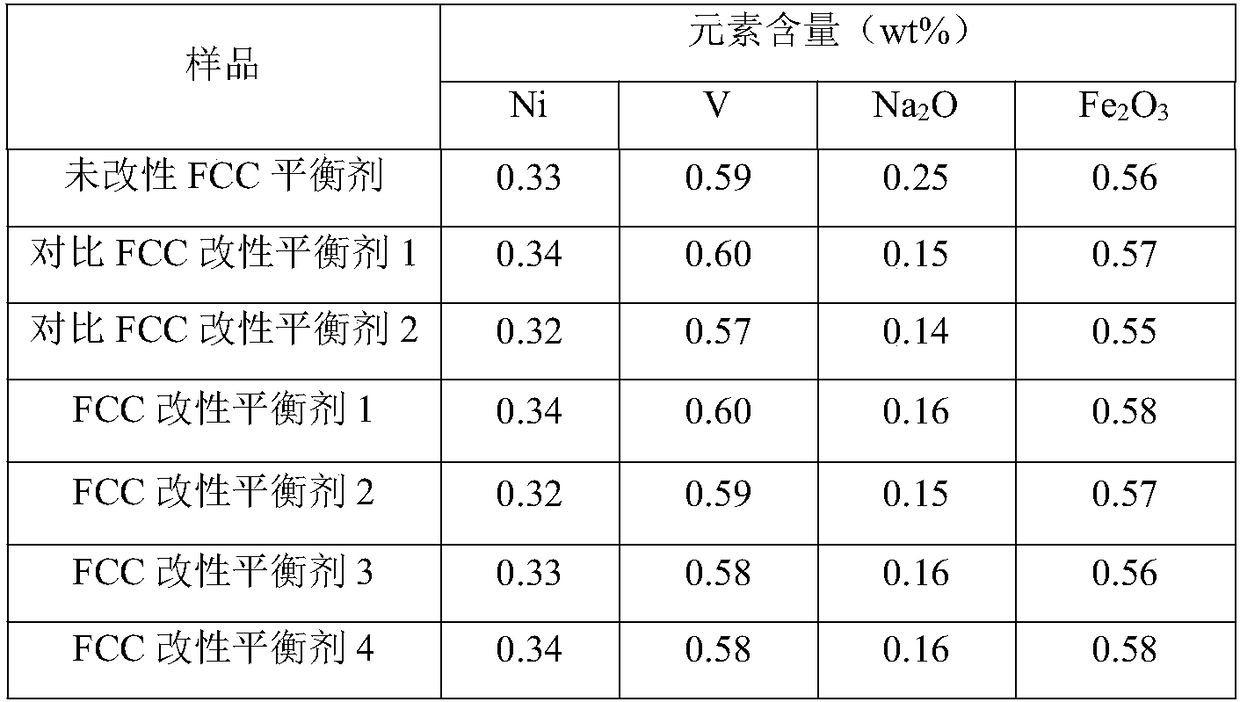

Embodiment 1

[0035] (1) Ammonium ion exchange: Mix 100g of balancing agent with 200g of chemical water, add 5g of ammonium chloride and continue stirring at 95°C for 1h of ammonium ion exchange, then filter, wash and dry.

[0036] (2) 50g (1) gained balancing agent is mixed with 50g chemical water, adds magnesium chloride (magnesium / balancing agent mass ratio=0.5wt%) and phosphoric acid (phosphorus / magnesium mass ratio=0.5), keeps stirring coprecipitation 10min, then Filter, dry, and bake at 800°C for 1 hour to obtain FCC modified balancer 1.

Embodiment 2

[0038] (1) Ammonium ion exchange: Mix 100g of balancing agent with 400g of chemical water, add 9g of ammonium chloride and continue to stir at 80°C for ammonium ion exchange for 1.5h, then filter, wash and dry.

[0039] (2) Mix 50g (1) of the resulting balancing agent with 150g of chemical water, add magnesium nitrate (magnesium / balancing agent mass ratio=1.5wt%) and ammonium phosphate (phosphorus / magnesium mass ratio=0.9), and continue to stir and co-precipitate for 20min , then filtered, dried, and calcined at 700°C for 2 hours to obtain FCC modified balancer 2.

Embodiment 3

[0041] (1) Ammonium ion exchange: Mix 100g of balancing agent with 600g of chemical water, add 13g of ammonium chloride and continue to stir at 70°C for ammonium ion exchange for 2 hours, then filter, wash and dry.

[0042] (2) 50g (1) gained balancing agent is mixed with 150g chemical water, adds magnesium sulfate (magnesium / balancing agent mass ratio=2.5wt%) and ammonium dihydrogen phosphate (phosphorus / magnesium mass ratio=2.0), continues stirring Precipitate for 30 minutes, then filter, dry, and bake at 600°C for 3 hours to obtain FCC modified balancer 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com