In-situ synthesized ZSM-5/Beta symbiotic molecular sieve based catalyst and preparation method thereof

A symbiotic molecular sieve, ZSM-5 technology, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low propylene yield and low catalytic cracking activity, so as to improve the relative content and yield Improve, enhance the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

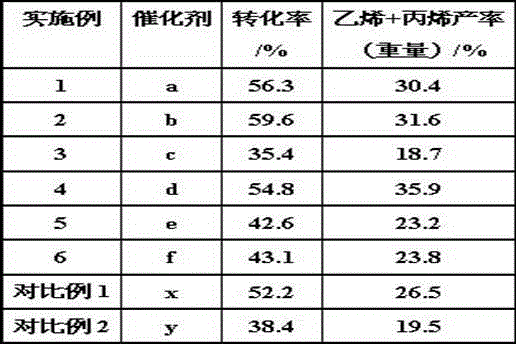

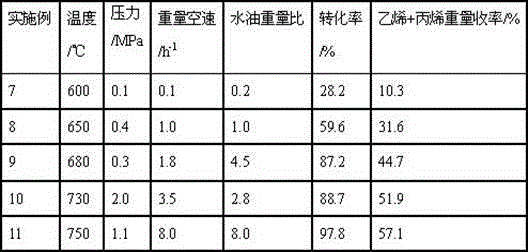

Examples

Embodiment 1

[0031] 60 grams of dry base kaolin (55.3% SiO 2 , 42.5%Al 2 o 3 , 2.2% other oxides), 60 grams of Beta molecular sieve (SiO 2 with Al 2 o 3 The molar ratio is 50), 200 grams of silica sol (40wt% SiO 2 ) and 520 grams of water were evenly mixed, and sprayed to obtain 10-200 μm pellets, which were roasted at 900°C for 4 hours to obtain sprayed microspheres WQ1.

[0032] Get 100 grams of spray microspheres a, 10.8 grams of sodium hydroxide, 10 grams of aluminum nitrate, 12.4 grams of ethylenediamine and 600 grams of water and mix well (in this mixture, kaolin is not included, and the silicon-aluminum molar ratio of the remaining raw materials is 50 ), transferred to a closed reactor for crystallization at 120°C for 120 hours. After crystallization, the product was washed, dried at 120°C for 4 hours, and calcined at 550°C for 8 hours to obtain sodium molecular sieve microspheres GWQ1. GWQ1 was exchanged with 1 mole of ammonium nitrate solution, washed, dried at 120°C for 8 ...

Embodiment 2

[0037] Mix 40 grams of kaolin on a dry basis, 100 grams of Beta molecular sieve (silicon-aluminum molar ratio of 120), 150 grams of silica sol and 310 grams of water, spray molding to obtain 10-200 μm pellets, and roast at 1000 ° C for 4 hours to obtain spray microspheres. Ball WQ2.

[0038] Get 50 grams of spray microspheres a, 16.0 grams of sodium hydroxide, 5.6 grams of aluminum sulfate, 6.2 grams of triethylamine and 300 grams of water and mix well (in this mixture, kaolin is not included, and the silicon-aluminum molar ratio of the remaining raw materials is 120 ), transferred to a closed reactor for crystallization at 160°C for 72 hours. After crystallization, the product was washed, dried at 120°C for 4 hours, and calcined at 550°C for 8 hours to obtain sodium molecular sieve microspheres GWQ2. GWQ2 was exchanged with 1 mole of ammonium nitrate solution, washed, dried at 120°C for 8 hours, and calcined at 600°C for 3 hours to obtain hydrogen microspheres HGWQ2. The rel...

Embodiment 3

[0042] 140 grams of dry base kaolin, 40 grams of Beta molecular sieve (mole ratio of silicon to aluminum is 75.0), 20.2 grams of white carbon black (99.0% SiO 2 ) and 640 grams of water were evenly mixed, and sprayed to obtain 10-200 μm pellets, which were roasted at 900°C for 4 hours to obtain sprayed microspheres WQ3.

[0043] Get 100 grams of spray microspheres a, 4.0 grams of sodium hydroxide, 1.1 grams of aluminum chloride, 12.4 grams of hexamethylenediamine and 600 grams of water and mix well (in this mixture, kaolin is not included, and the silicon-aluminum molar ratio of the remaining raw materials is 75.0 ), transferred to a closed reactor for crystallization at 180°C for 12 hours. After crystallization, the product was washed, dried at 120°C for 4 hours, and calcined at 550°C for 8 hours to obtain sodium molecular sieve microspheres GWQ3. GWQ3 was exchanged with 1 mole of ammonium nitrate solution, washed, dried at 120°C for 8 hours, and calcined at 600°C for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com