Proess for preparing mesoporous molecular sieve MCM-48 by using mixture of cationic surfactant and non-ionic surfactant as template agent

A non-ionic surface, mixed cation technology, applied in the field of MCM-48 mesoporous molecular sieve, can solve the problems of pollution, poor hydrothermal stability, cumbersome and other problems, and achieve uniform pore size distribution, improved hydrothermal stability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

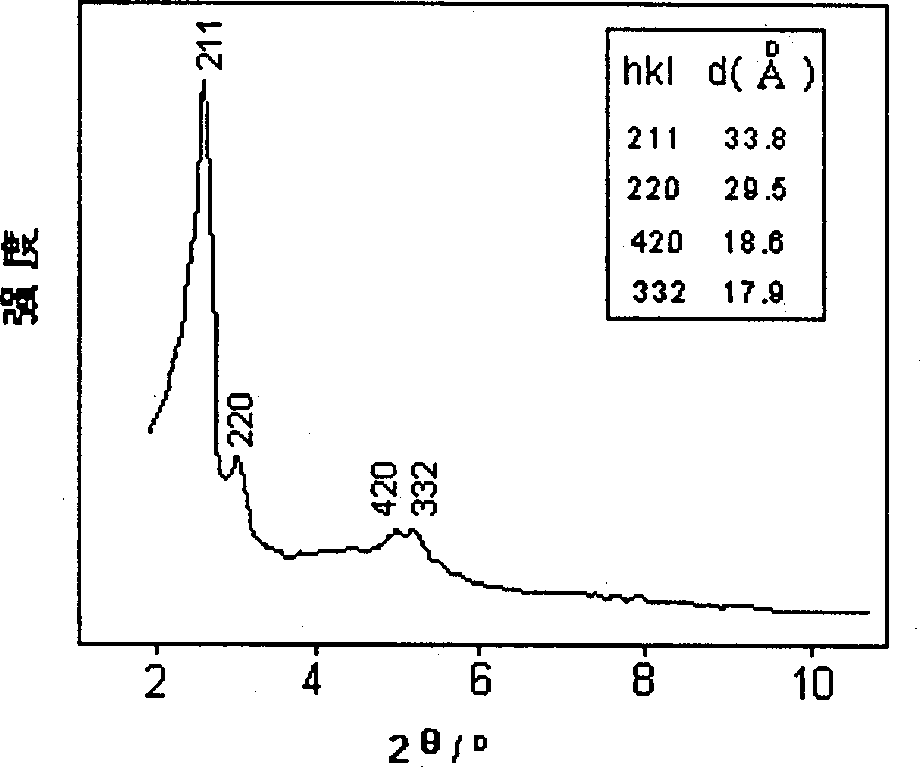

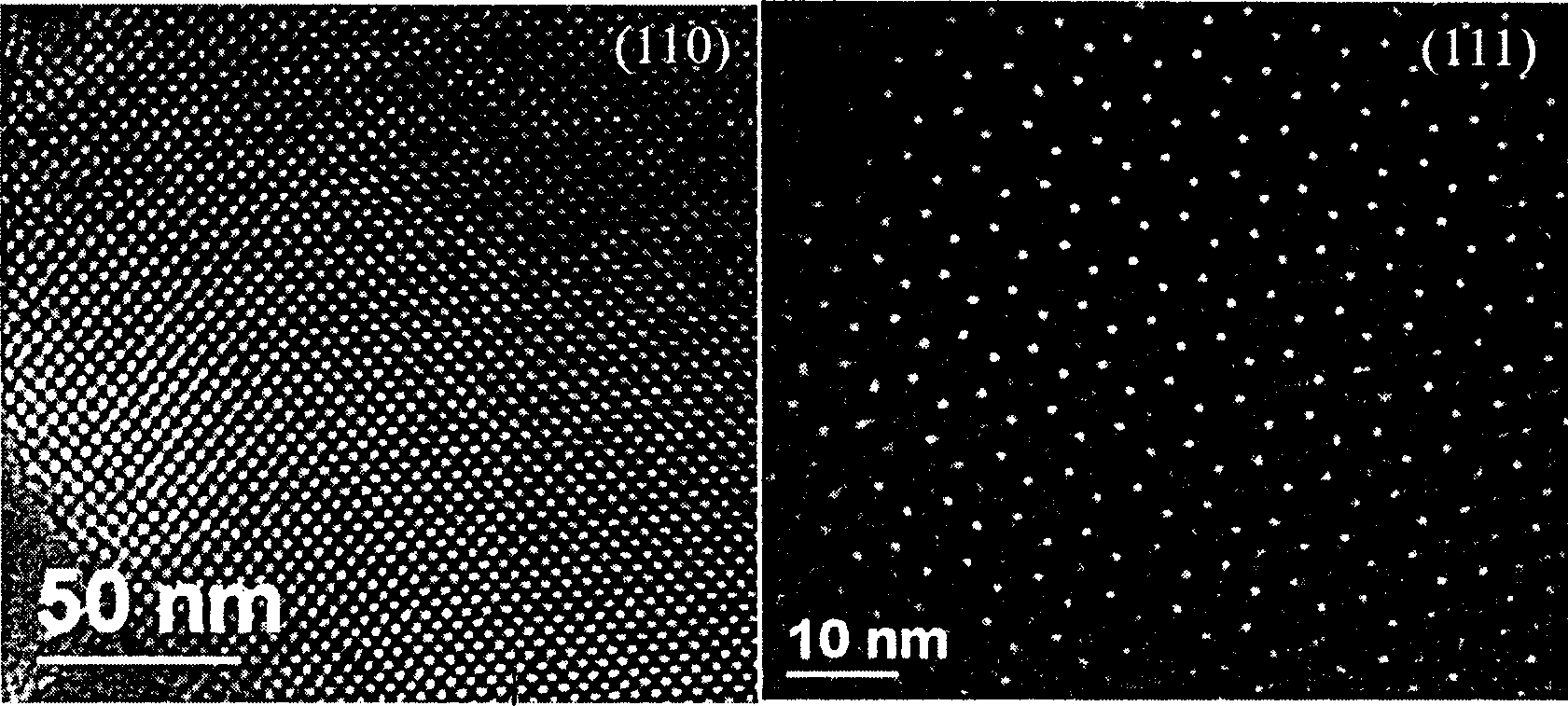

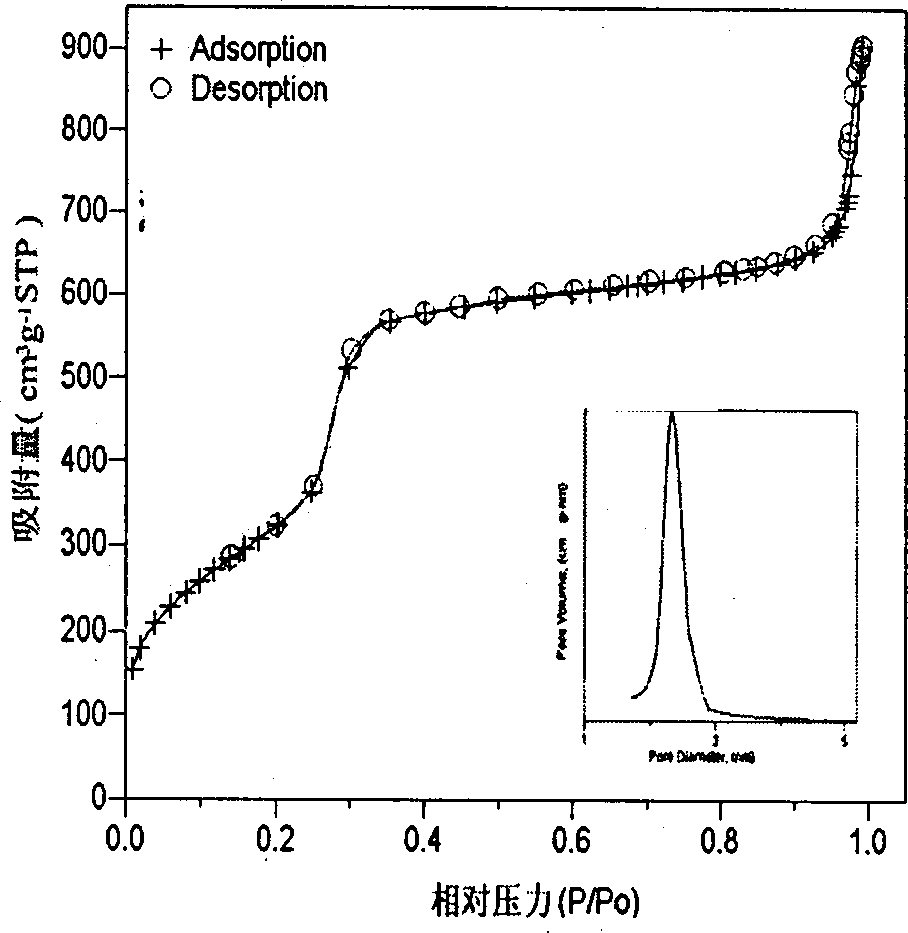

[0022] At a constant stirring speed, add a certain amount of water glass dropwise into the 4:1 mixed aqueous solution of CTAB and OP-10, and stir at 30°C for 1 hour to obtain a molar composition of 1.0 SiO 2 :0.15CTAB:0.03OP-10:0.282Na 2 O: 58H 2 O mixture. Move the mixture into a stainless steel reaction kettle and let it stand at 100°C for 2 days. The product is washed, filtered and then dried to obtain the synthetic MCM-48. The sample was directly calcined at 650°C in air for 5 hours, and then heated to 850°C for 2 hours to obtain MCM-48 mesoporous molecular sieve. Typical XRD pattern, TEM photo, N 2 Adsorption-desorption isotherms and thermal analysis results are shown in Figure 1 to Figure 4 . And the XRD figure, N of the sample after thermal and hydrothermal treatment 2 Adsorption-desorption isotherms and pore structure parameters are shown in Figure 5 , Figure 6 and table one. Table.1 Pore structure parameters of MCM-48 sample Sample Unitcell BET Pore Pore F...

example 2

[0029] The process of preparing synthetic MCM-48 is the same as Example 1. Take the synthetic MCM-48 and directly roast it in the air at 650°C for 5 hours to obtain the MCM-48 mesoporous molecular sieve

example 3

[0031] At 20°C, add a certain amount of water glass dropwise into a 10:1 mixed aqueous solution of CTAB and OP-10 and stir for 1 hour to obtain a molar composition of 1.0 SiO 2 :0.30CTAB:0.02OP-10:0.282Na 2 O: 58H 2 O mixture. The mixture was transferred into a stainless steel reaction kettle, crystallized at 100°C for 3 days, the product was washed, filtered and then dried to obtain synthetic MCM-48. The sample was first calcined at 550°C in nitrogen for 1 hour, and then calcined at 700°C for 4 hours to obtain MCM-48 mesoporous molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com