Patents

Literature

54 results about "Lamellar phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lamellar phase refers generally to packing of polar-headed long chain nonpolar-tail molecules in an environment of bulk polar liquid, as sheets of bilayers separated by bulk liquid. In biophysics, polar lipids (mostly, phospholipids, and rarely, glycolipids) pack as a liquid crystalline bilayer, with hydrophobic fatty acyl long chains directed inwardly and polar headgroups of lipids aligned on the outside in contact with water, as a 2-dimensional flat sheet surface. Under transmission electron microscope (TEM), after staining with polar headgroup reactive chemical osmium tetroxide, lamellar lipid phase appears as two thin parallel dark staining lines/sheets, constituted by aligned polar headgroups of lipids. 'Sandwiched' between these two parallel lines, there exists one thicker line/sheet of non-staining closely packed layer of long lipid fatty acyl chains. This TEM-appearance became famous as Robertson's unit membrane - the basis of all biological membranes, and structure of lipid bilayer in unilamellar liposomes. In multilamellar liposomes, many such lipid bilayer sheets are layered concentrically with water layers in between.

Extrudable multiphase composition comprising a lamellar phase and an isotropic phase

InactiveUS6534456B2Cosmetic preparationsPreparation by hydrogen halide split-offLotionLamellar phase

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Registered structure formation via the application of directed thermal energy to diblock copolymer films

Owner:MICRON TECH INC

Extrudable multiphase composition comprising a lamellar phase and an isotropic phase

InactiveUS20020010110A1Cosmetic preparationsPreparation by hydrogen halide split-offLotionLamellar phase

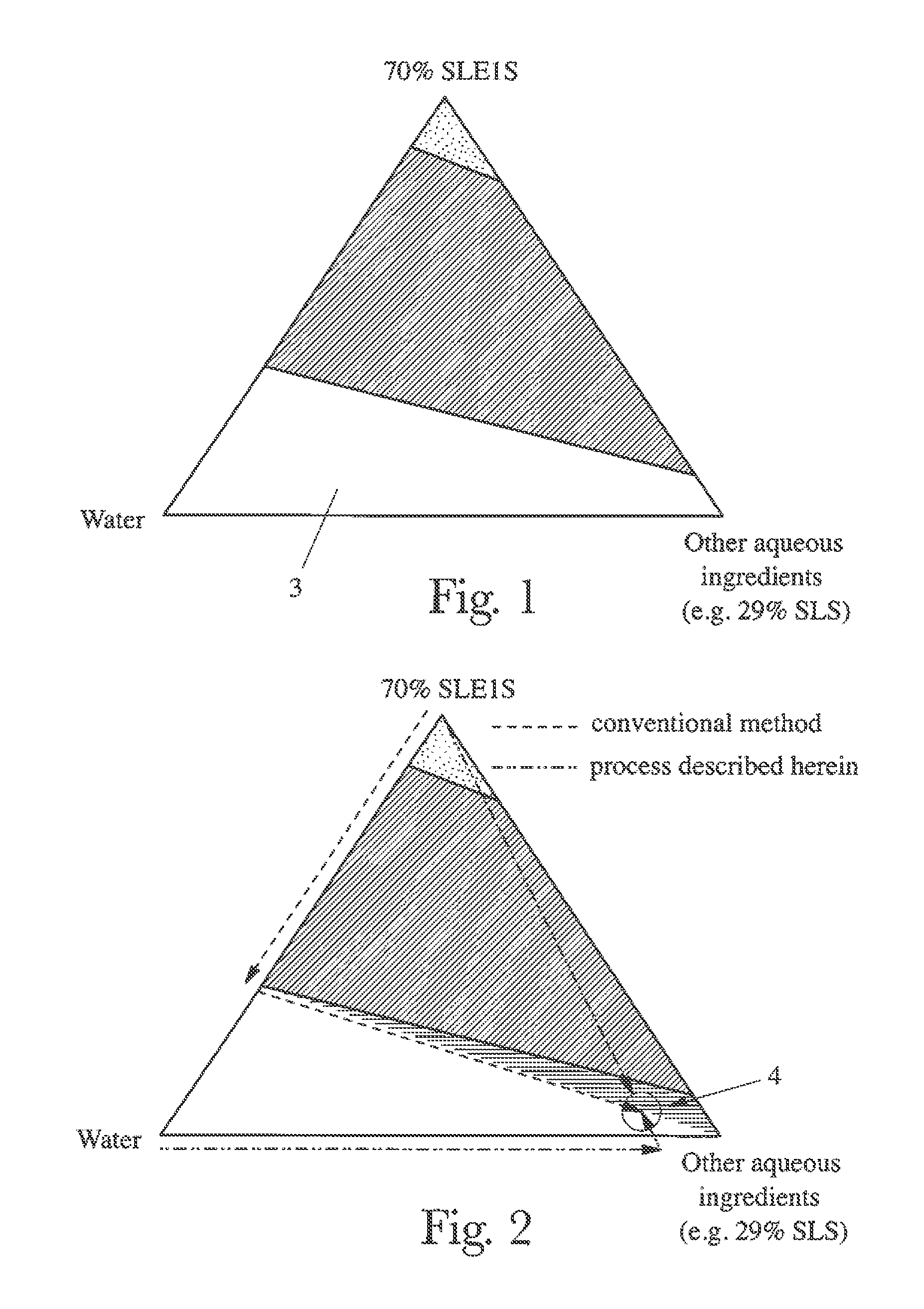

The invention relates to a plurality of liquid cleansing compositions having at least one lamellar phase which possesses a lotion-like appearance conveying signals of enhanced moisturization and at least one abutting isotropic phase having enhanced cleansing ability. The inventive composition is contained in a partitionless container in one embodiment conveying signals of a plurality of compositions. This multiphase composition is stable upon storage and is dispensed as a striped product where typically one stripe has primarily a cleansing function and a second stripe has primarily a moisturization function.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Extrudable multiphase composition comprising lamellar phase inducing structurant in each phase

InactiveUS6534457B2Advantageously and economically and visually communicatedIncrease volumeCosmetic preparationsMake-upLotionLamellar phase

The invention relates to a plurality of liquid cleansing compositions in lamellar phase which possess a lotion-like appearance conveying signals of enhanced moisturization in one embodiment and are contained in a partitionless container in another embodiment conveying signals of a plurality of compositions. This multiphase composition is stable upon storage and is dispensed as a striped product where typically one stripe has a cleansing function and a second stripe has a moisturization function.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

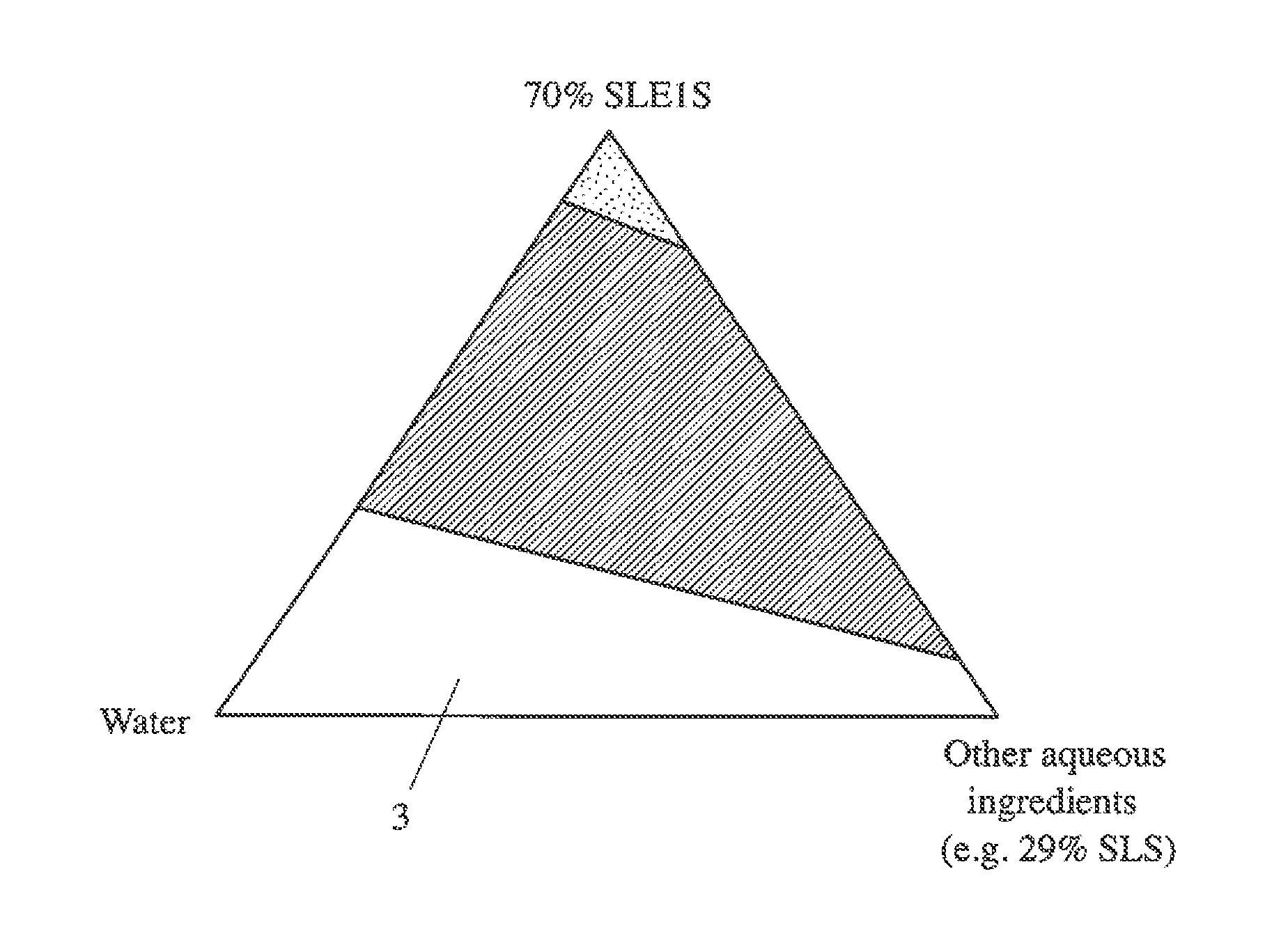

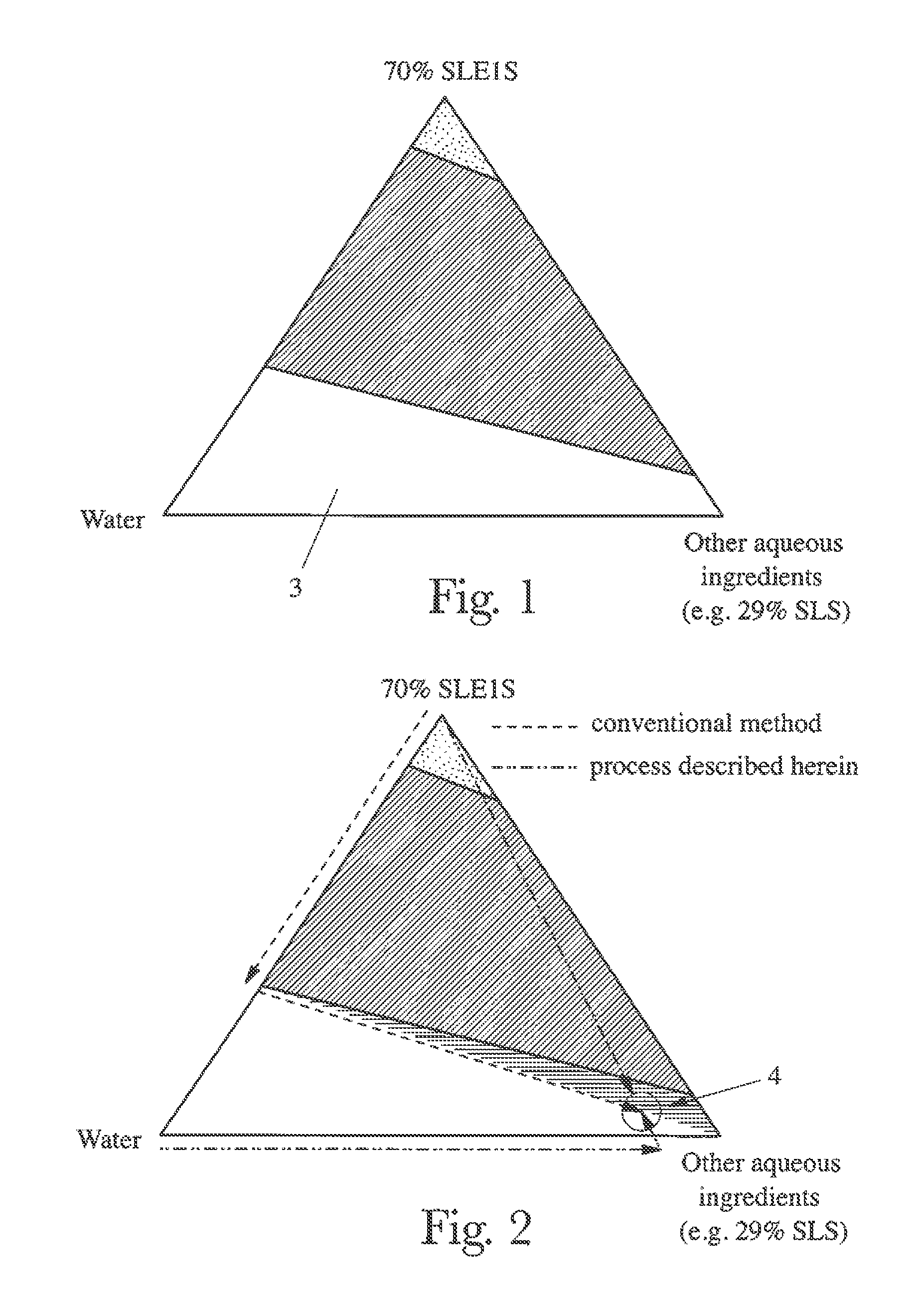

Process for making a cleaning composition employing direct incorporation of concentrated surfactants

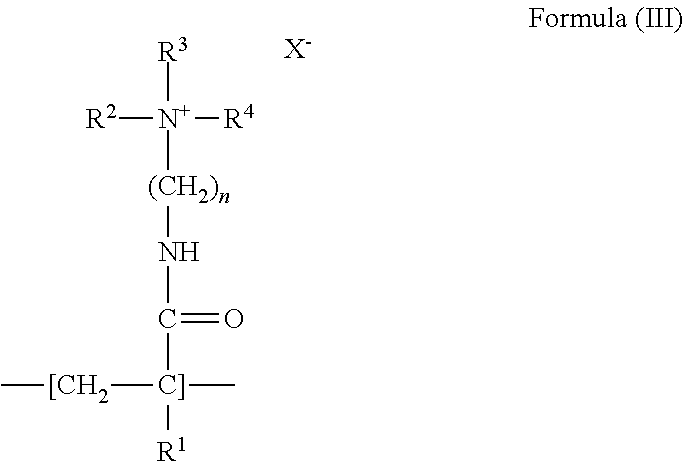

The proposed process of the present application passes a concentrated surfactant in a lamellar phase though a high-shear device diluting the concentrated surfactant in a lamellar phase to an isotropic phase without encountering the highly viscous middle phase.

Owner:THE PROCTER & GAMBLE COMPANY

Concentrated lamellar liquid personal cleansing composition

The invention relates to concentrated liquid cleansing compositions in lamellar phase which possess a lotion-like appearance conveying signals of enhanced moisturization. The use of a specific ratio of synthetic anionic surfactant(s) and co-surfactant(s) to fatty acid(s) in a structured liquid product was found to improve lather production by moderating or eliminating the increase in viscosity upon dilution. In a further embodiment, specific small hydrophobic molecules were found to improve freeze / thaw stability and thereby cause the inventive composition to maintain noticeable moisturization signals.

Owner:CONOPCO INC D B A UNILEVER

Lubricant composition and mechanical element

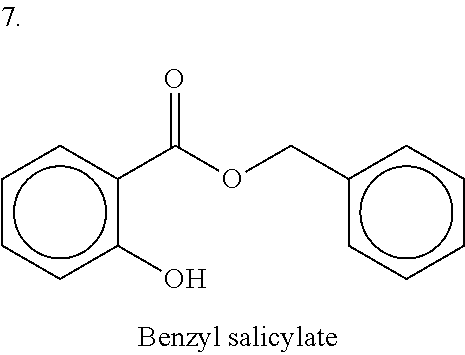

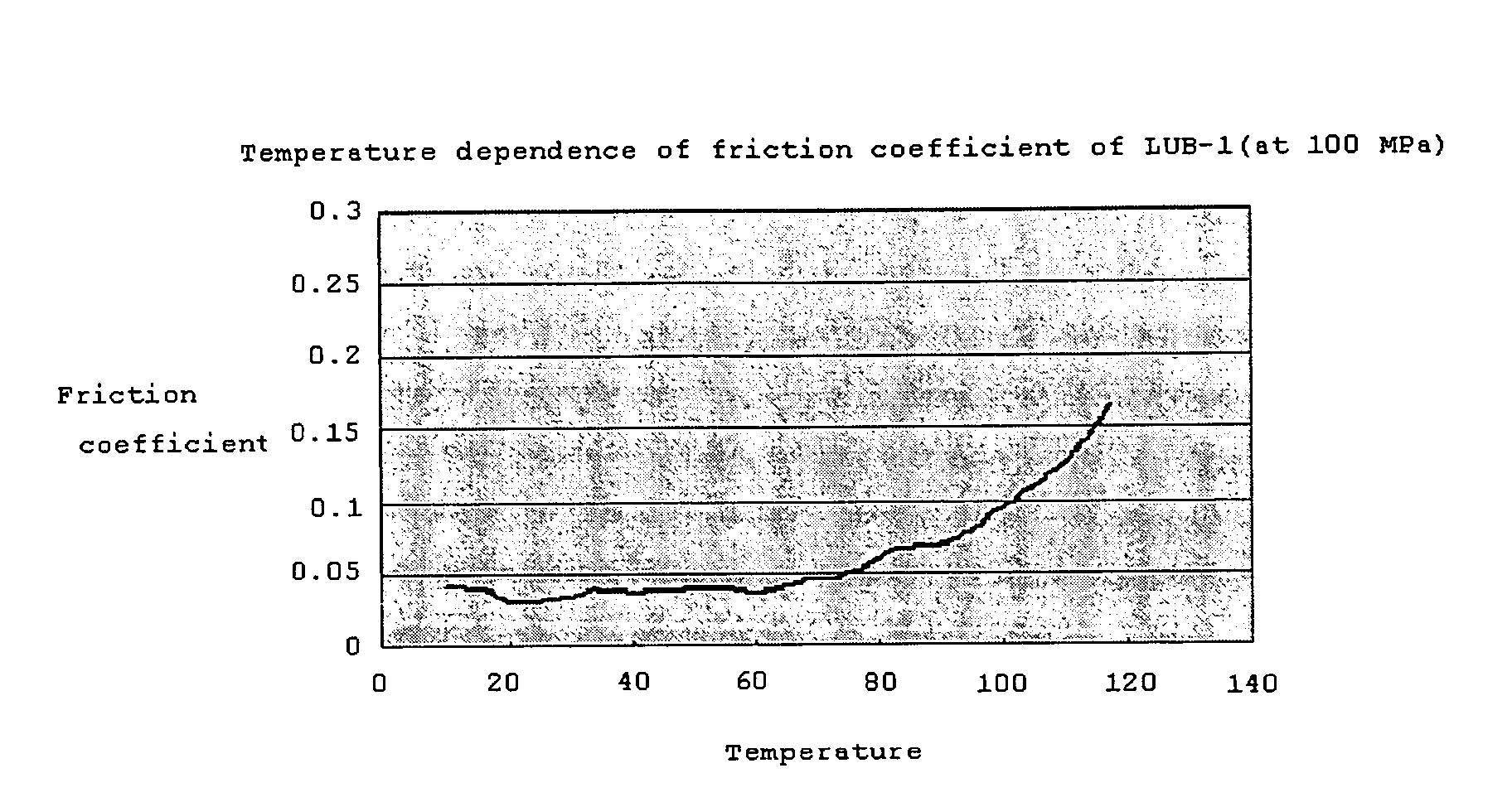

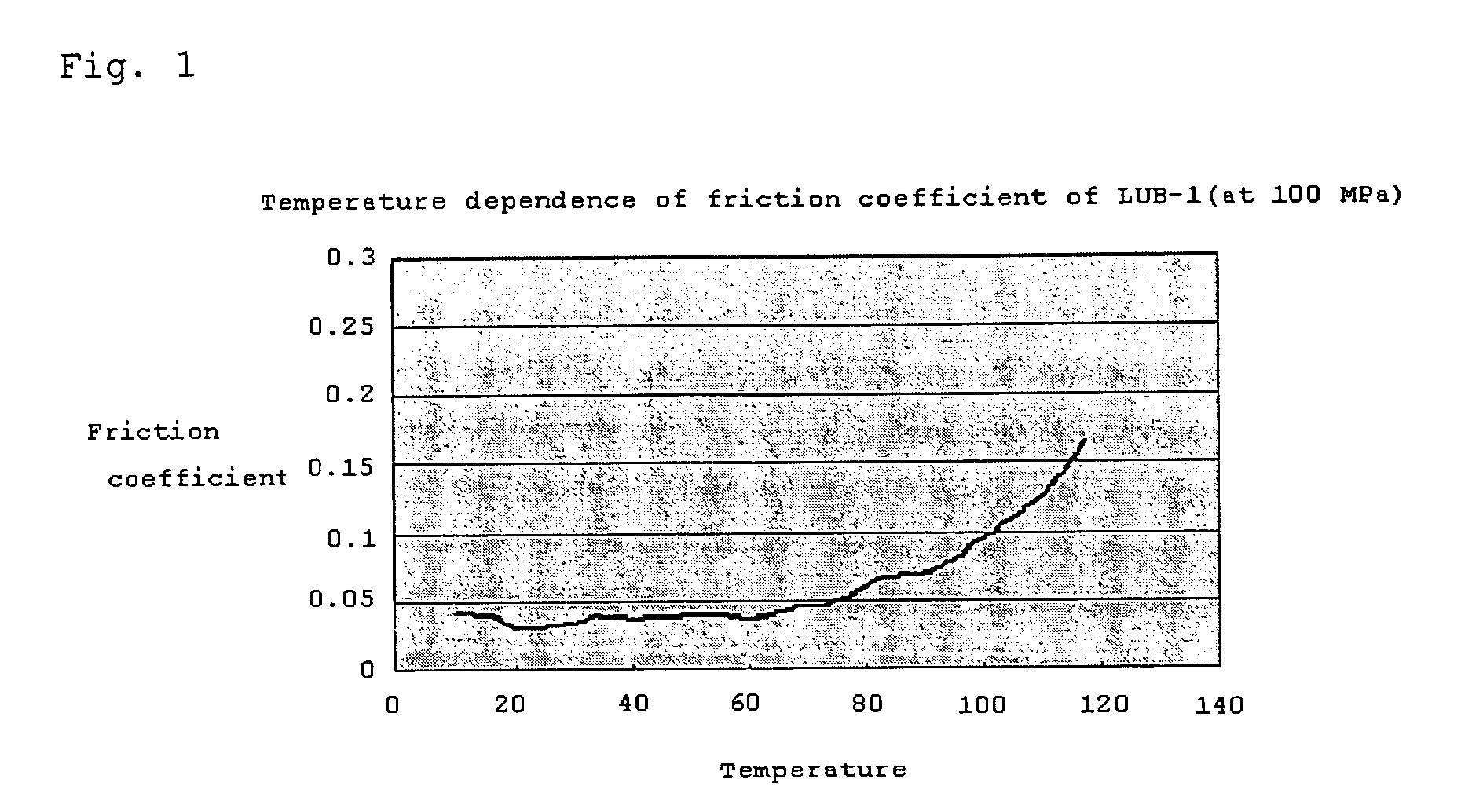

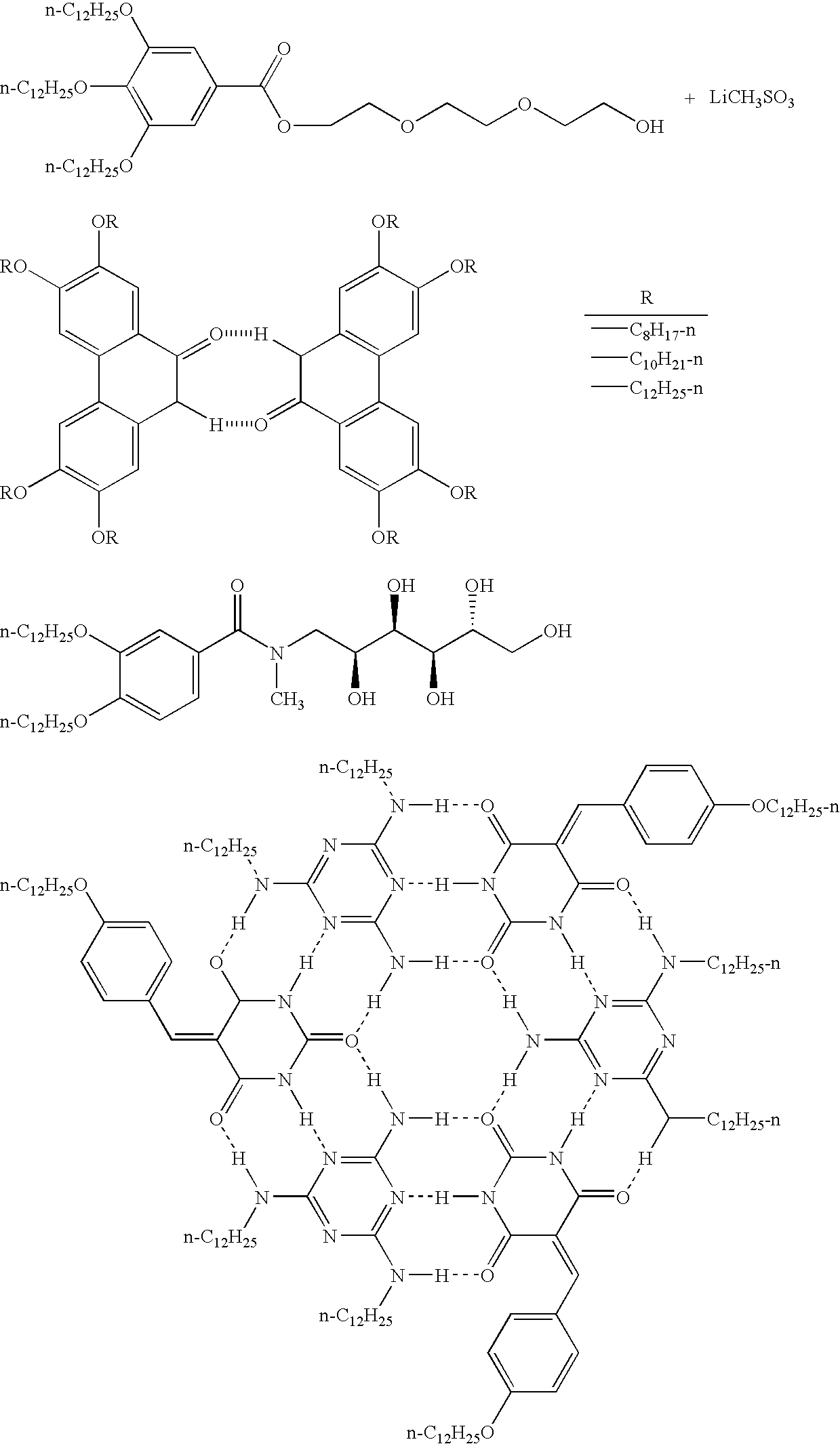

InactiveUS20060270568A1Low viscosityImprove friction resistanceLiquid carbonaceous fuelsAdditivesOrganic compoundLamellar phase

A novel lubricant composition is disclosed. The lubricant composition comprises at least one organic compound, and, when disposed between two surfaces moving at peripheral speeds differing from each other, is capable of exhibiting a discotic columnar phase or a discotic lamellar phase in which a plurality of molecules of said organic compound is assembled.

Owner:FUJIFILM CORP

Multiphase liquid detergent composition

InactiveUS20130029895A1Simple methodImprove performanceOrganic detergent compounding agentsDetergent mixture composition preparationReactive materialLamellar phase

The invention relates to a multiphase liquid detergent composition comprising at least one cleaning phase and at least one benefit phase, a surfactant, and a crystalline structurant. The crystalline structurant being substantially present in a non-lamellar phase. The invention also relates to a multiphase liquid detergent composition comprising at least two visually distinct liquid phases, a surfactant, and at least two incompatible or reactive materials. The first incompatible or reactive material is distributed in a first visually distinct phase and a second incompatible or reactive material is distributed in a second visually distinct phase. The present invention further relates to methods of cleaning dishware using such multiphase liquid detergent compositions.

Owner:THE PROCTER & GAMBLE COMPANY

Hair colouring or bleaching compositions

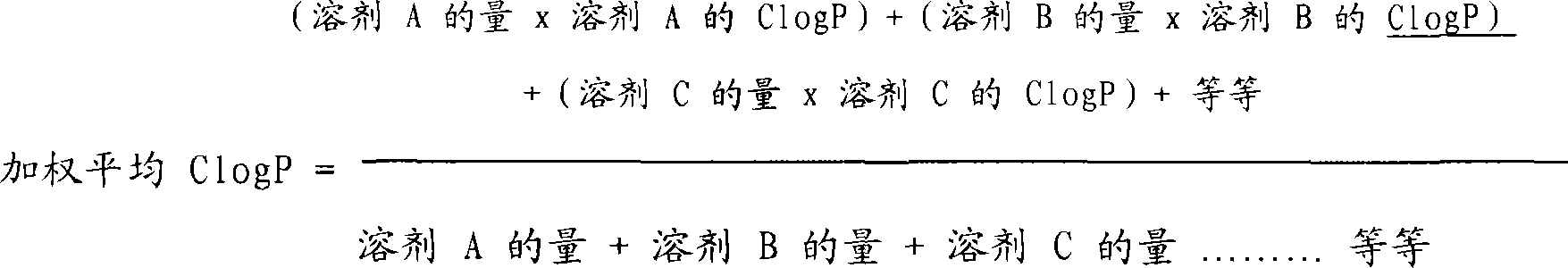

This invention is a two part system for coloring or bleaching hair which comprises (i) a thin lotion optionally comprising an oxidative dye and comprising a solvent system and a surfactant system to trigger a thickening upon dilution with a developer, and (ii) a developer which comprises a scalp-irritating amount of an oxidising agent. In the system of the invention, the lotion has a Lamellar Phase Index of greater than 80%.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method of cadmium sulfide-titanium oxide nanosheet composite photocatalyst

InactiveCN102626642AReduce usageAvoid harmPhysical/chemical process catalystsCadmium CationTitanium oxide

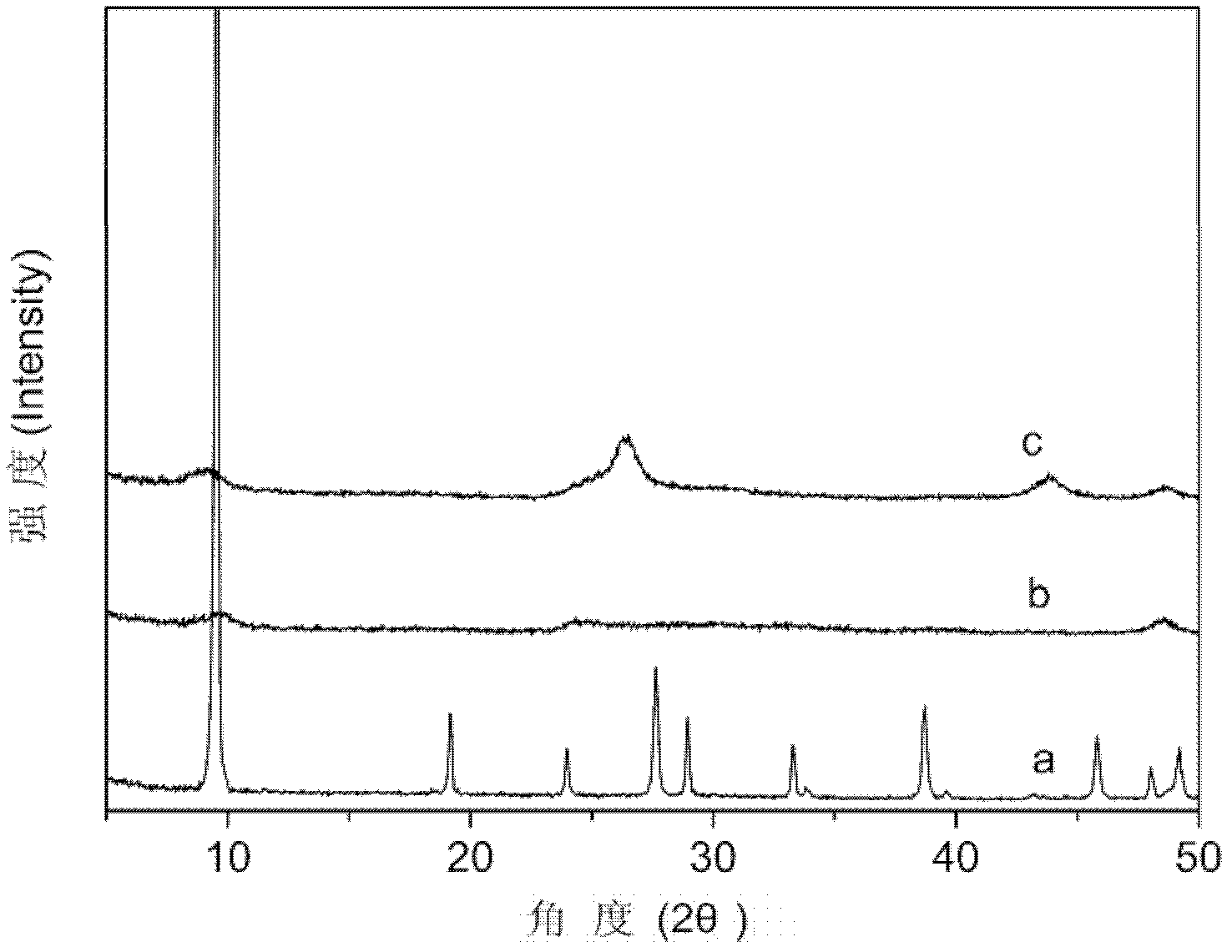

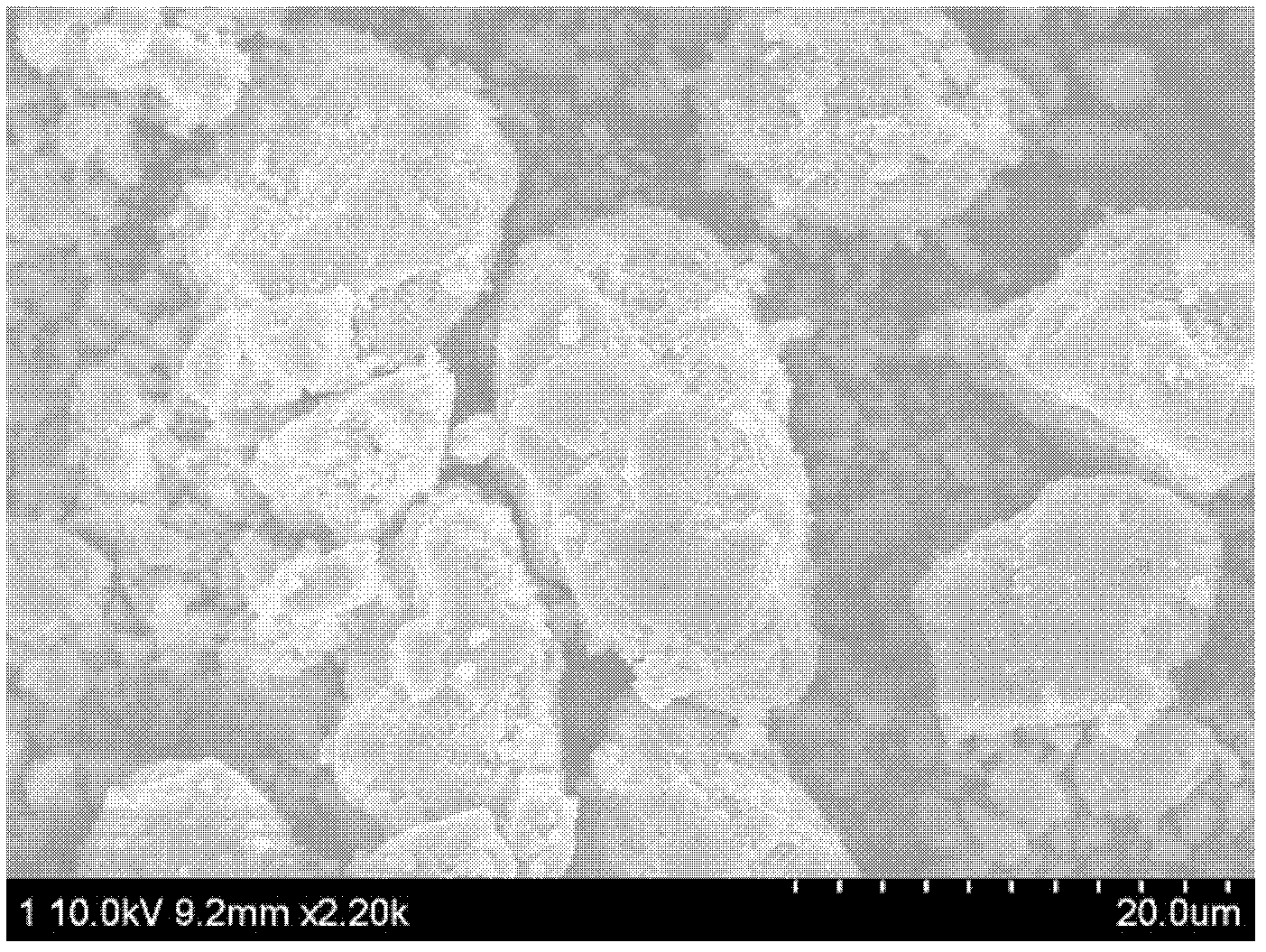

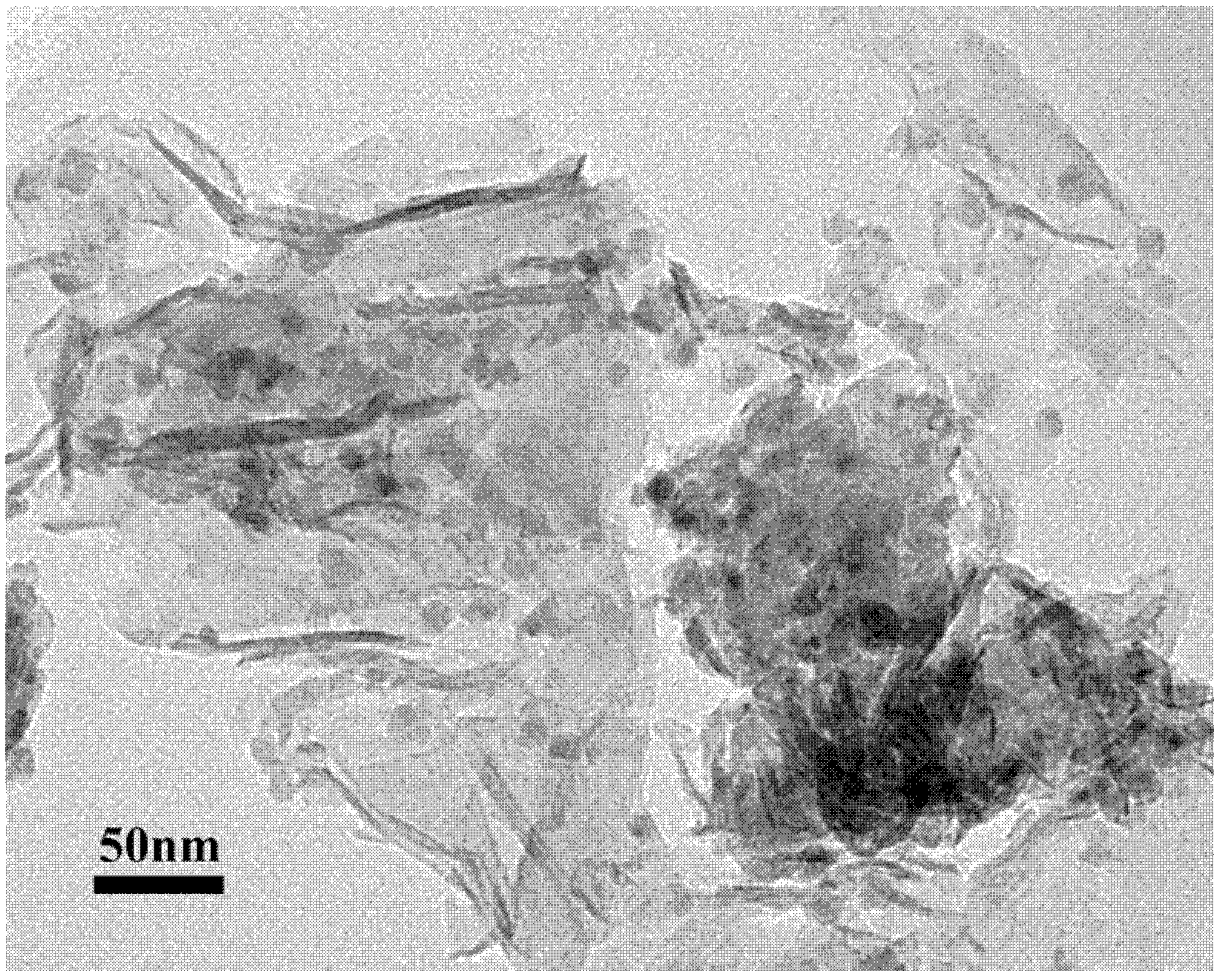

The invention discloses a preparation method of a cadmium sulfide-titanium oxide nanosheet composite photocatalyst. The preparation method comprises the following steps: carrying out electrostatic self-assembly on titanium oxide nanosheets having negatively charged surfaces, and divalent cadmium ions to obtain a metal cadmium ion intercalated lamellar phase; and reacting the metal cadmium ion intercalated lamellar phase with thioacetamide to obtain the cadmium sulfide-titanium oxide nanosheet composite photocatalyst. The preparation method which allows cadmium sulfide to be intercalated into the titanium oxide nanosheets to extend the absorption spectrum to a visible light region makes a visible light response purpose be realized and the utilization rate of solar energy by the catalyst be improved. The preparation method of the invention has the advantages of simple preparation, environmental protection, low preparation cost and the like; and the prepared cadmium sulfide-titanium oxide nanosheet composite photocatalyst has the advantages of good stability, high catalytic activity and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Lithium ion battery anode material adopting in-situ developed heterogeneous core-shell structure and preparation method of material

ActiveCN105514362AImprove first-time efficiencyImprove cycle stabilityMaterial nanotechnologyCell electrodesElectrochemistryCarbonate

The invention provides a lithium ion battery anode material adopting an in-situ developed heterogeneous core-shell structure and a preparation method of the material. The lithium ion battery anode material is a composite with a lithium-rich lamellar phase material as a core layer and a heterogeneous spinel phase generated on the surface of the core layer in an in-situ manner. The lithium ion battery anode material is prepared in the steps as follows the lithium-rich lamellar phase material containing Ni, Mn and M is prepared from carbonate or hydroxides with a coprecipitation method and then dispersed in a mixed salt solution of Ni, Mn and M, the amount-of-substance ratio of Ni to Mn to M in the solution is the same with that in the lithium-rich lamellar phase material, the coprecipitation reaction is performed again, and the mixed metal carbonate (or metal hydroxide) coated lithium-rich lamellar phase material is obtained, the lithium-rich lamellar phase material is sintered at the high temperature in the absence of a Li source, and the lithium ion battery anode material adopting the in-situ developed heterogeneous core-shell structure can be obtained. The lithium ion battery anode material adopting the in-situ developed heterogeneous core-shell structure has the advantages as follows the shell layer coats the core layer in a uniform, complete and thickness-controllable manner, no obvious phase boundaries exist between the core layer and the shell layer, and the electrochemical performance of the material is improved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

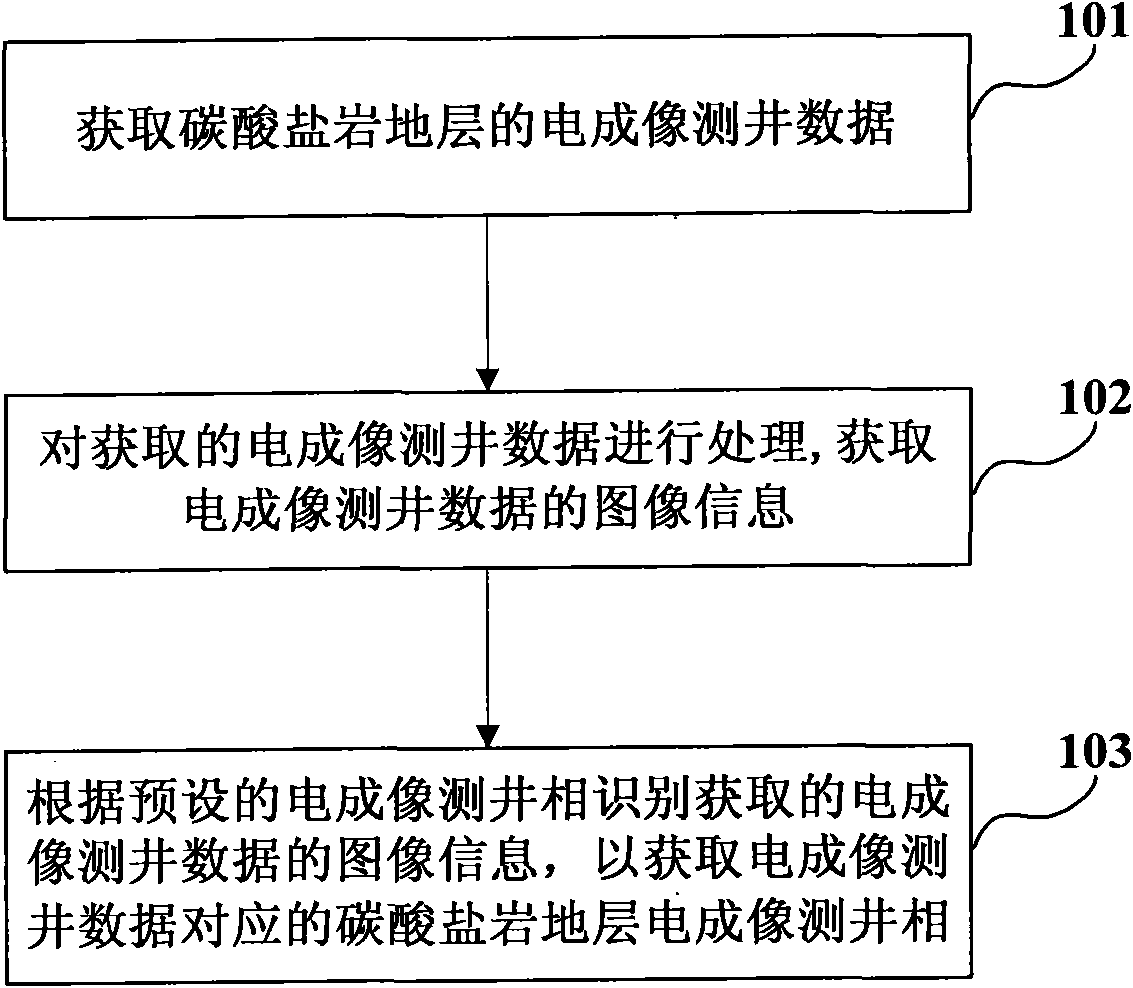

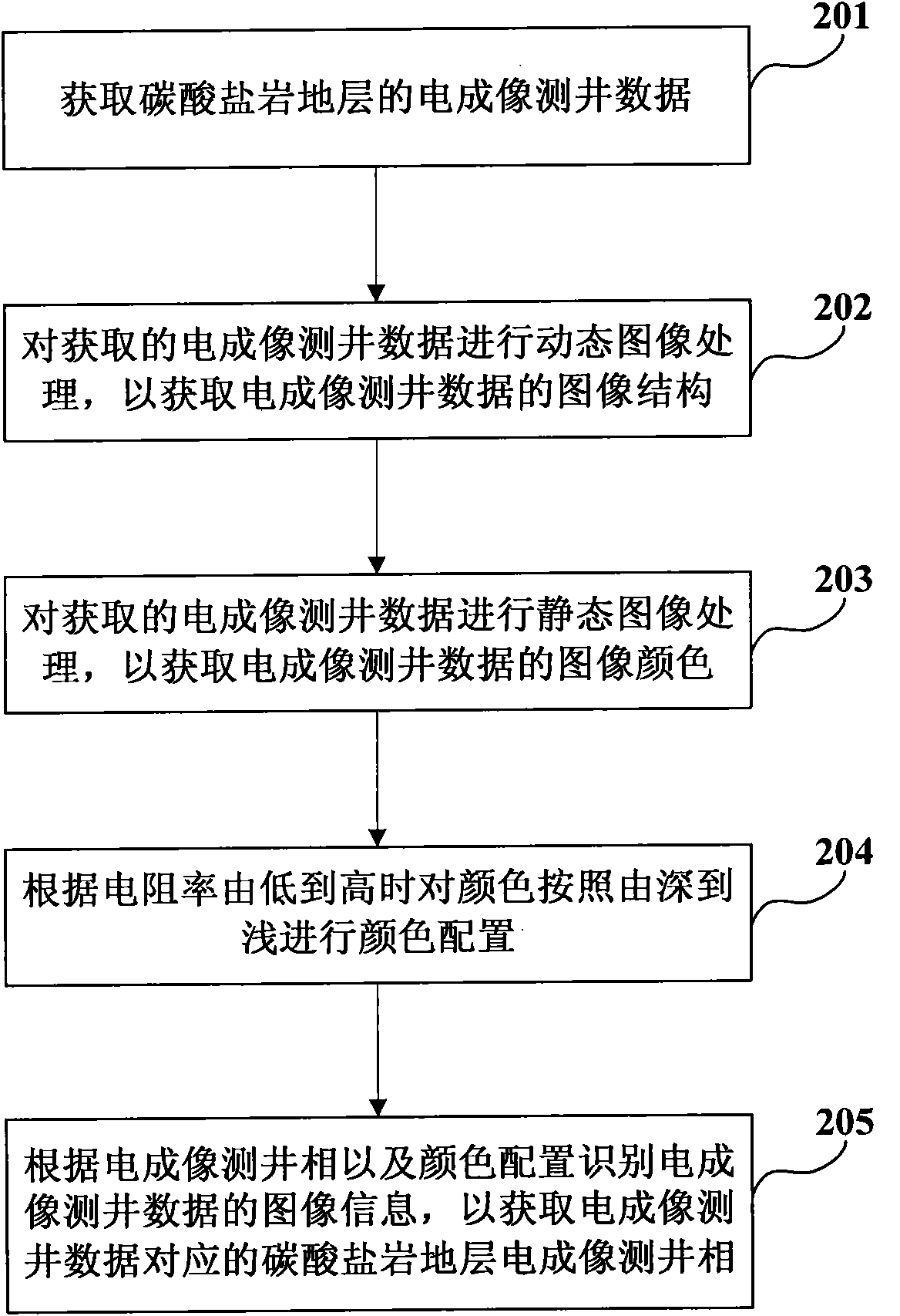

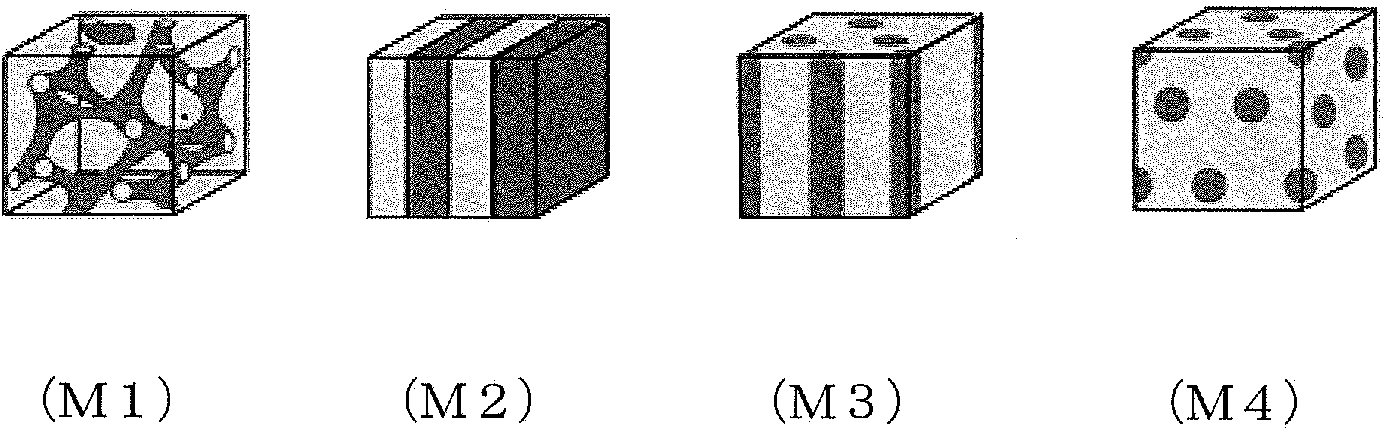

Identification method for electric imaging electrofacies of carbonate formation and device thereof

InactiveCN101899971AStudy and predict distribution patternsBorehole/well accessoriesElectricityLamellar phase

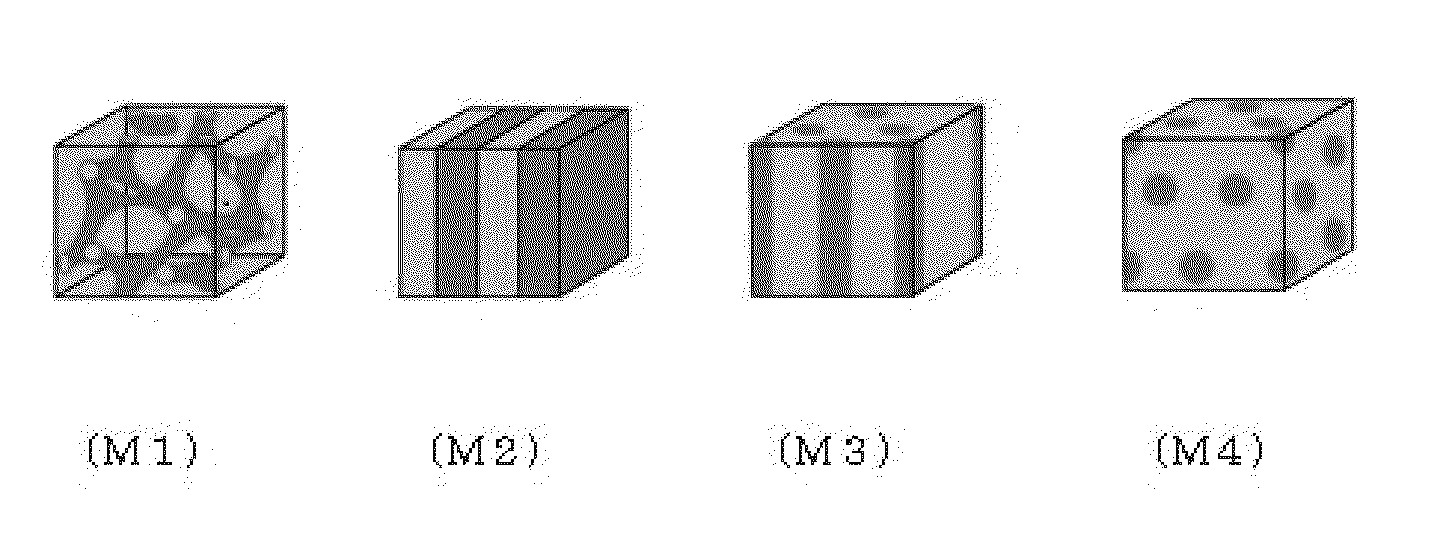

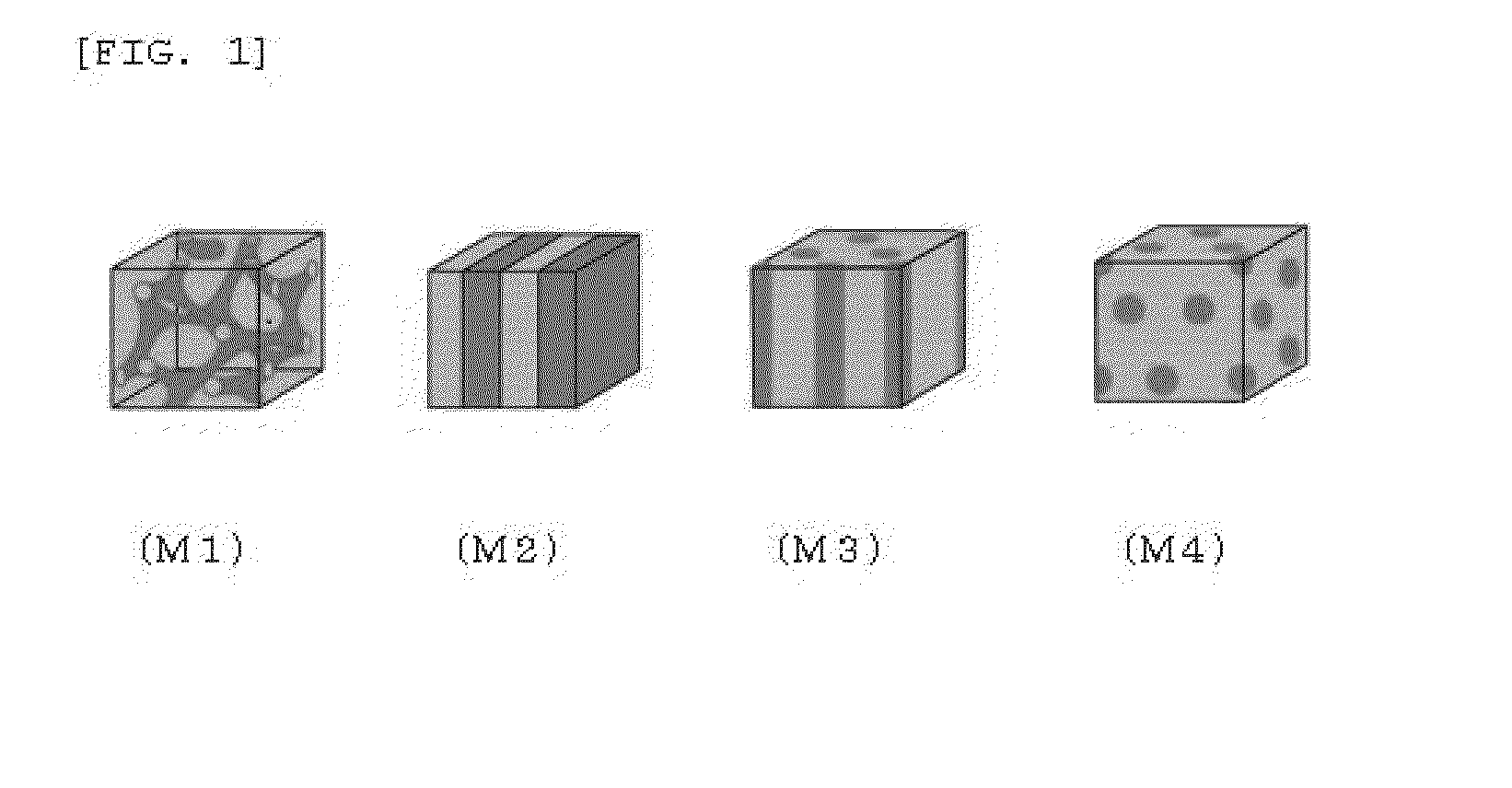

The embodiment of the invention provides an identification method for electric imaging electrofacies of carbonate formation and a device thereof. The method comprises the following steps: acquiring the electric imaging log data of the carbonate formation; processing the electric imaging log data to acquire the image information of the electric imaging log data; according to the preset electric imaging electrofacies, identifying the acquired image information of the acquired electric imaging log data; and acquiring the electric imaging eletrofacies of the carbonate formation corresponding to the electric imaging log data, wherein the electric imaging electrofacies comprises a massive phase, a lamellar phase and a porphyritic phase. The embodiment of the invention can identify the sedimentary facies of the carbonate formation, obtain the electric imaging electrofacies of the carbonate formation and better research and forecast the regularities of distribution of a reservoir bed.

Owner:PETROCHINA CO LTD

Process For Making A Cleaning Composition Employing Direct Incorporation Of Concentrated Surfactants

The proposed process of the present application passes a concentrated surfactant in a lamellar phase though a high-shear device diluting the concentrated surfactant in a lamellar phase to an isotropic phase without encountering the highly viscous middle phase.

Owner:THE PROCTER & GAMBLE COMPANY

Skin Cleansing Compositions and Methods

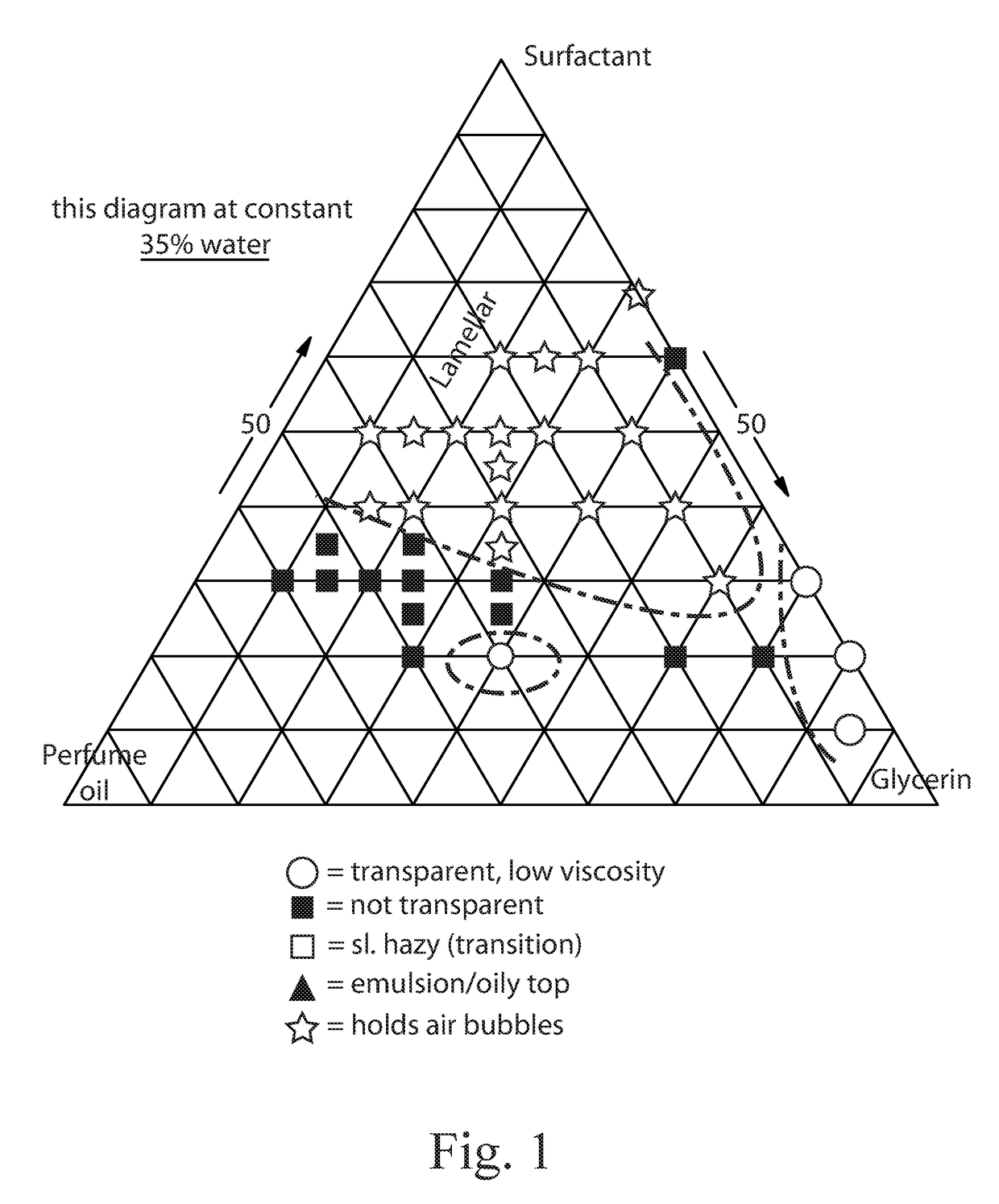

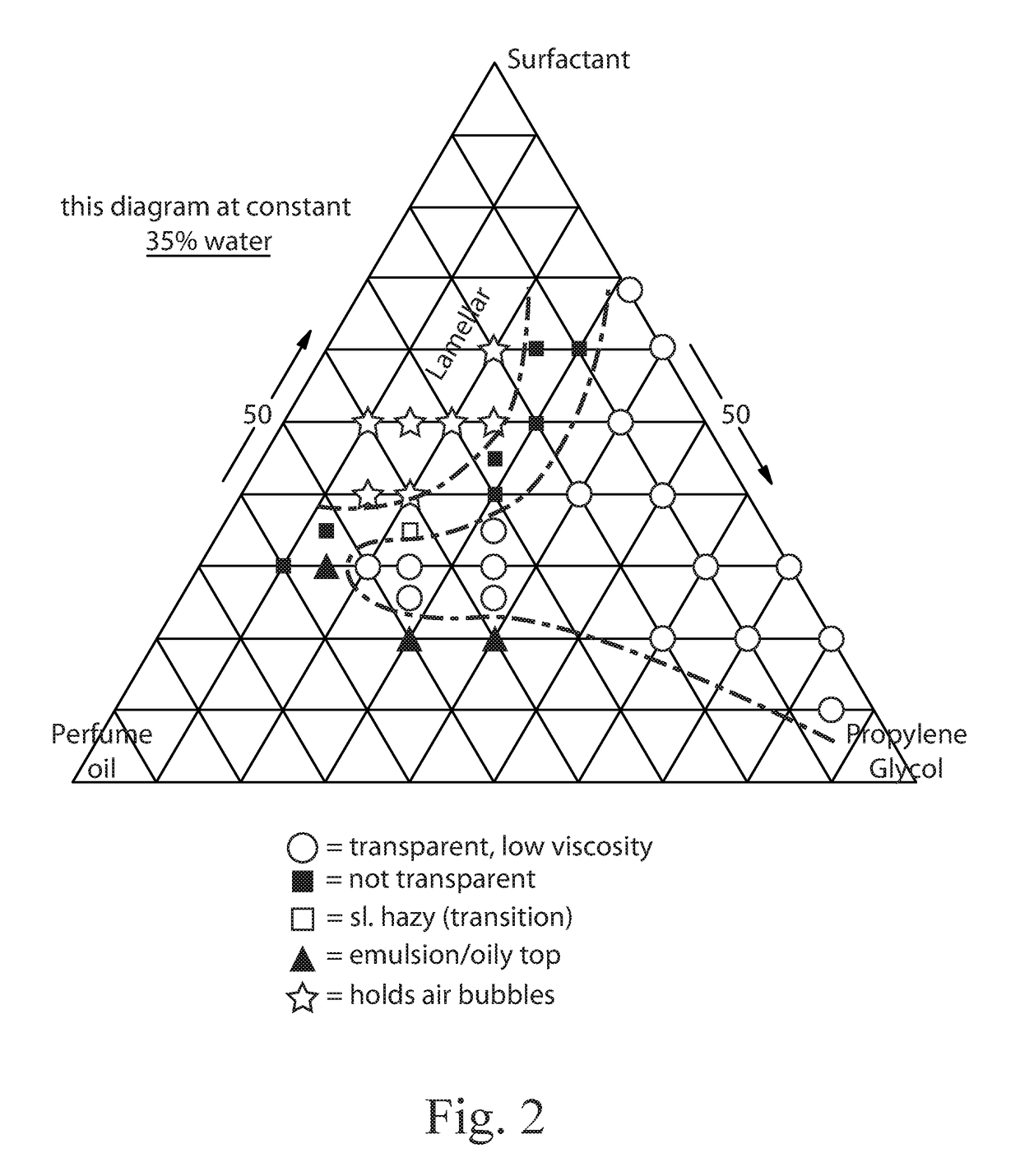

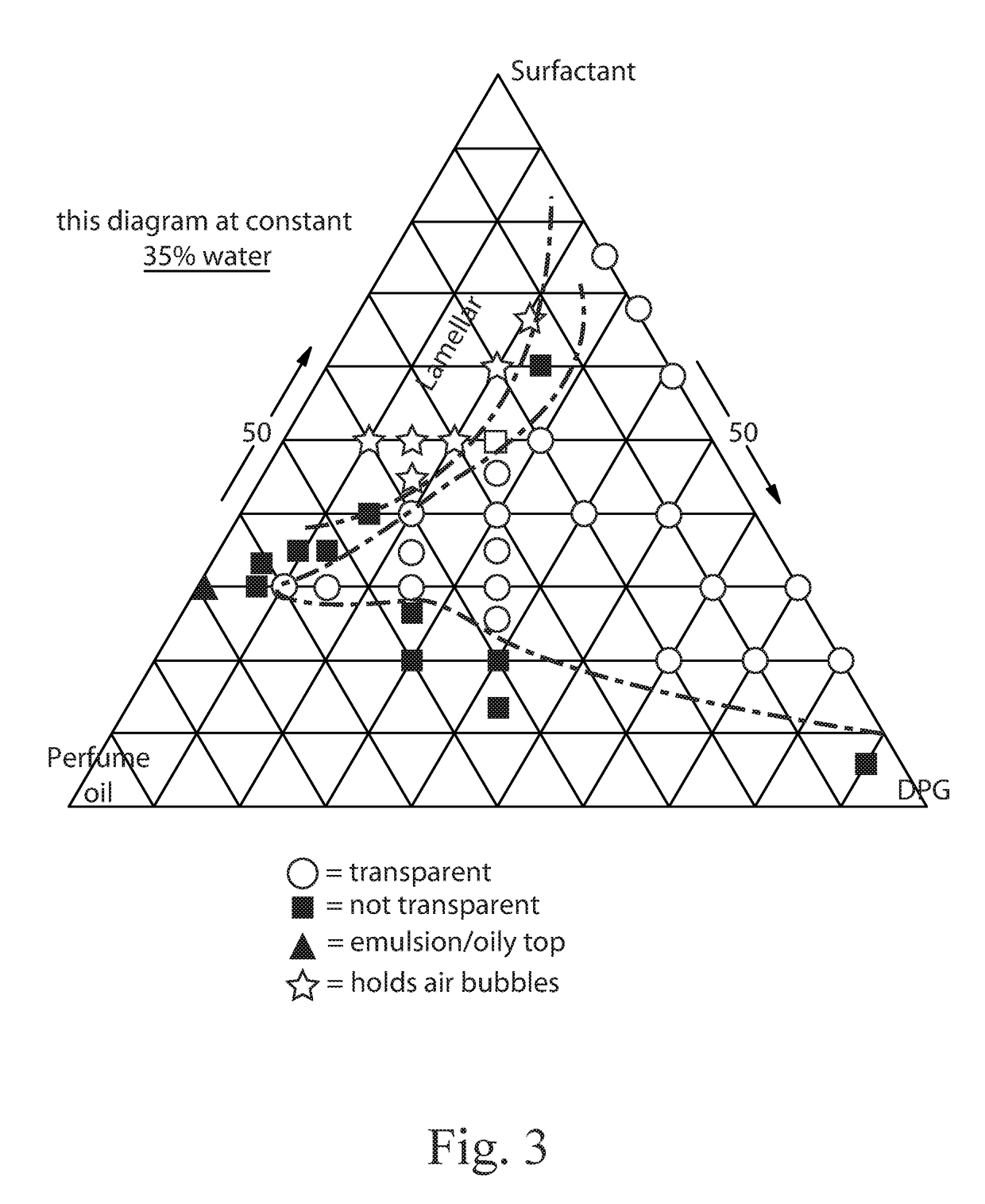

A skin cleansing composition includes surfactant, glycerin, perfume, and water, where at least a portion of the composition is in a lamellar phase.

Owner:THE PROCTER & GAMBLE COMPANY

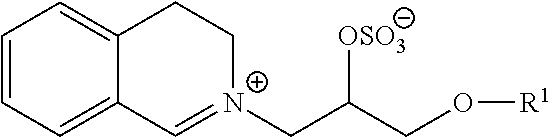

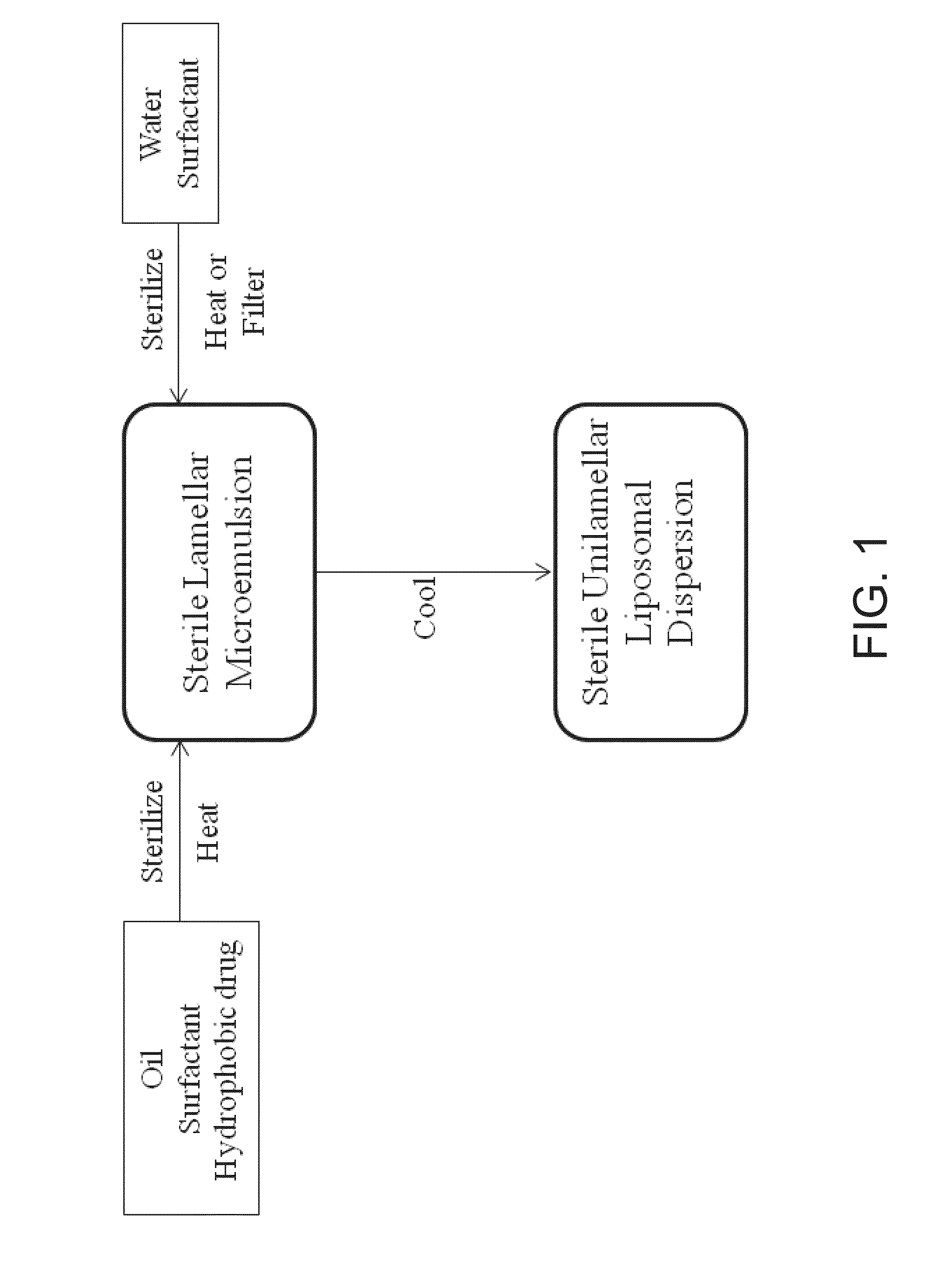

UNILAMELLAR NIOSOMES HAVING HIGH Kow PHARMACOLOGICAL COMPOUNDS SOLVATED THEREIN AND A METHOD FOR THE PREPARATION THEREOF

InactiveUS20160184228A1Maximize bioavailabilityImprove adaptabilitySalicyclic acid active ingredientsBiocideMicroemulsionLipid bilayer

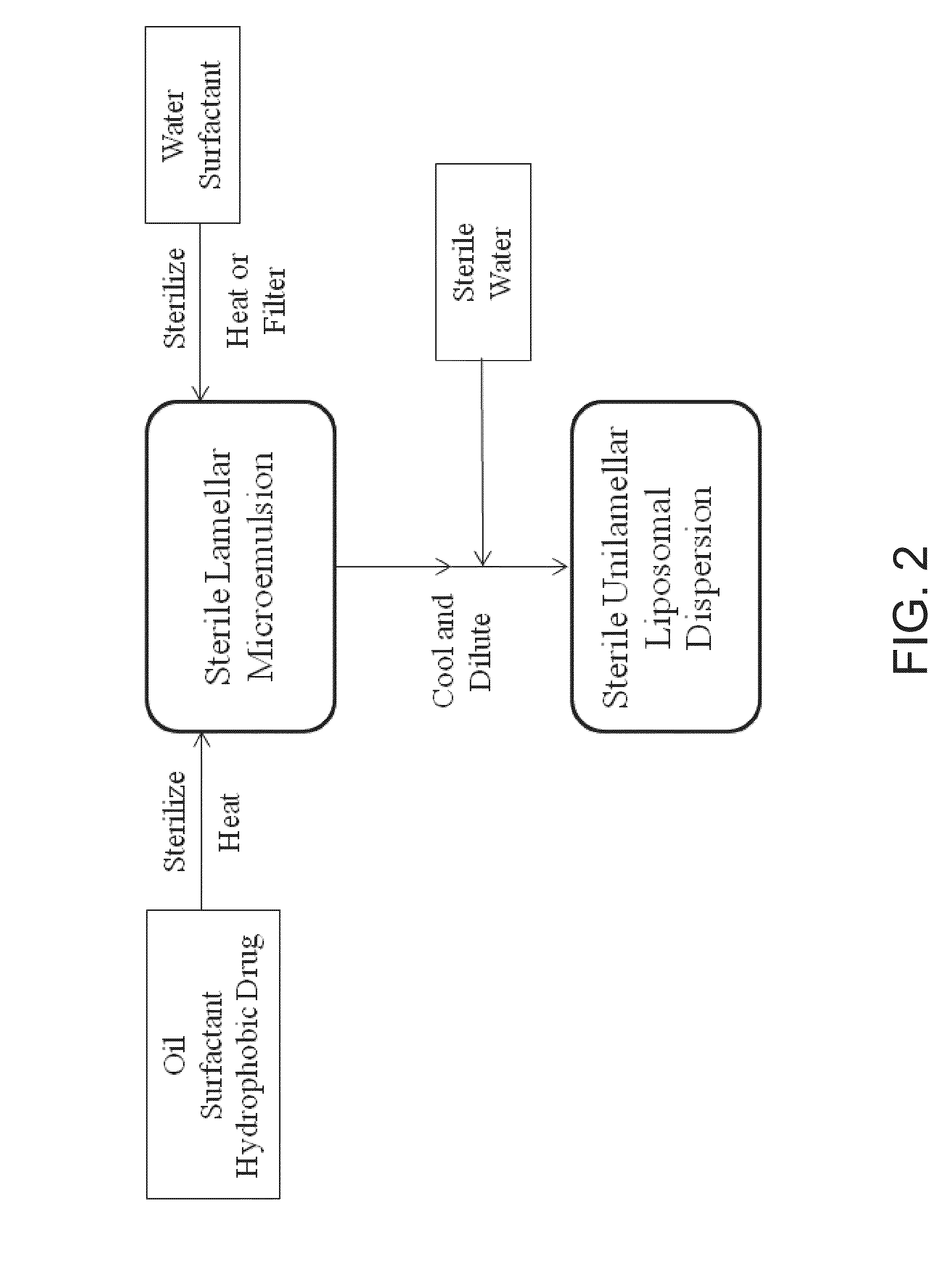

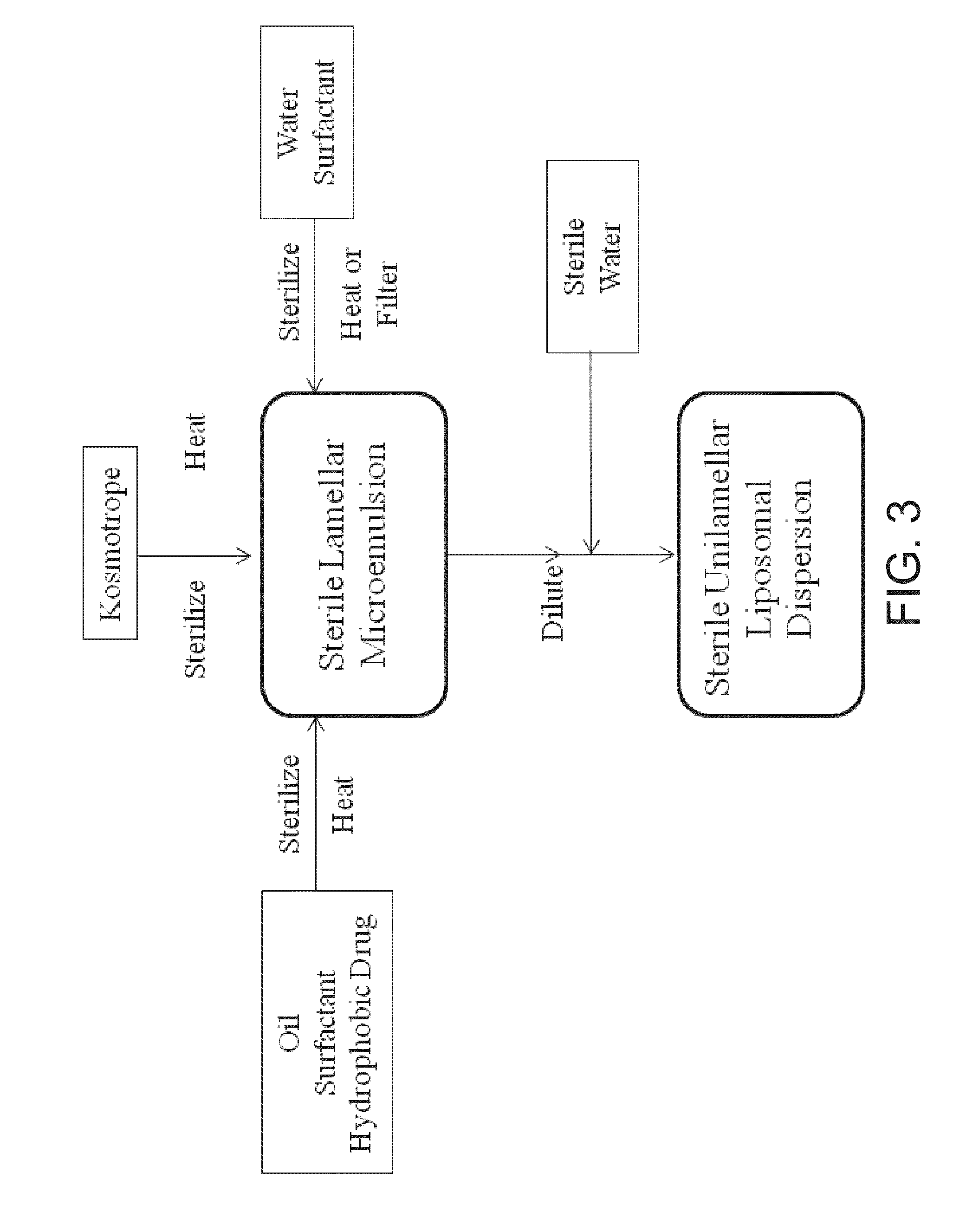

The present invention provides a niosomal composition having including: one or more high Kow pharmacologically active compounds; one or more water immiscible oils; one or more low HLB surfactants; one or more polyethoxylated high HLB surfactants; water, and wherein the niosomal composition includes an external phase and a dispersed phase, the particles of the dispersed phase including an oil swollen lipid bilayer. Methods of preparing niosomal compositions by hydration of lamellar phase microemulsions and methods of using these compositions to treat various disorders in a patient in need thereof are also provided.

Owner:MORRISON ERIC

Magnesium alloy material and production process thereof

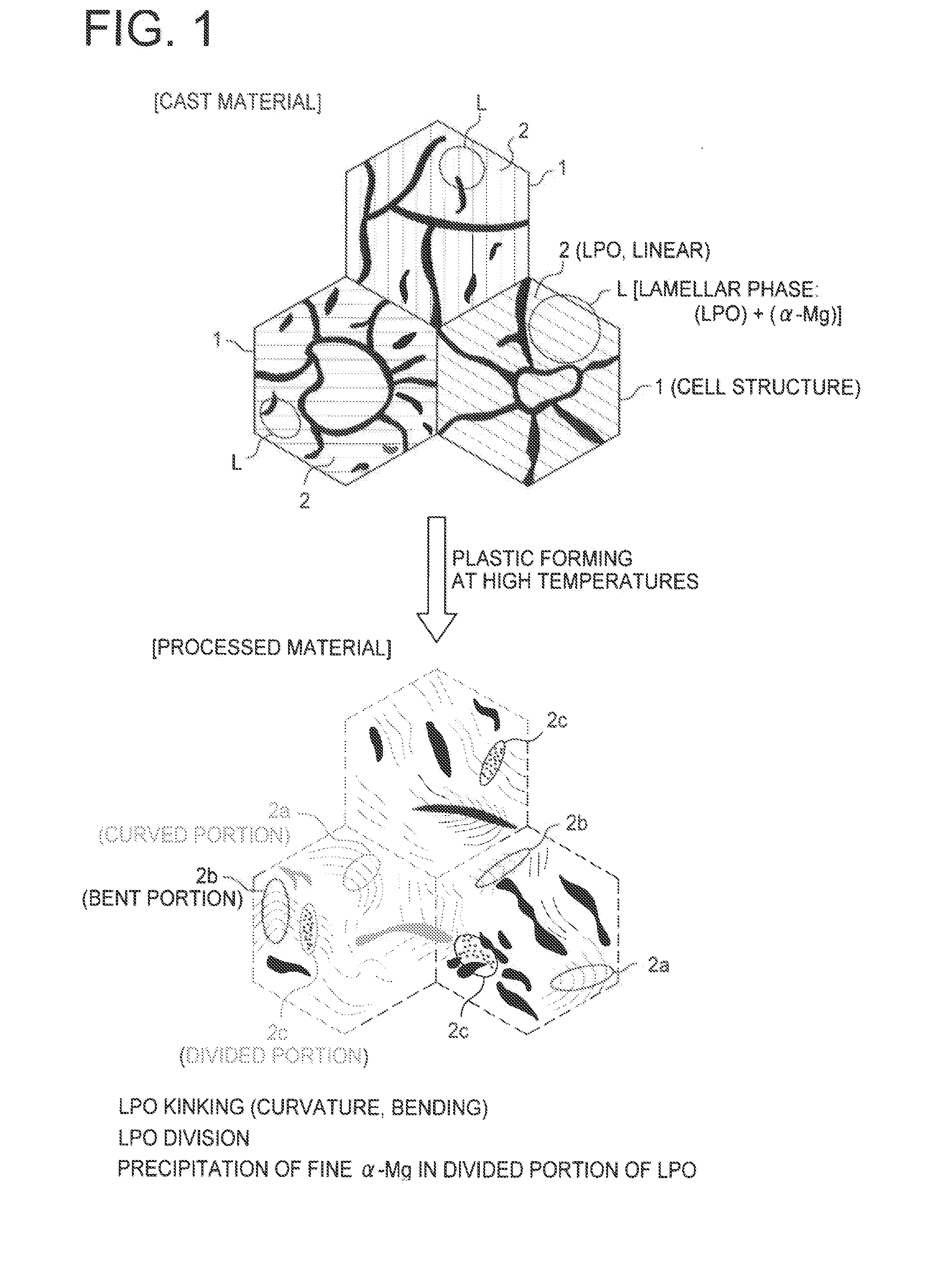

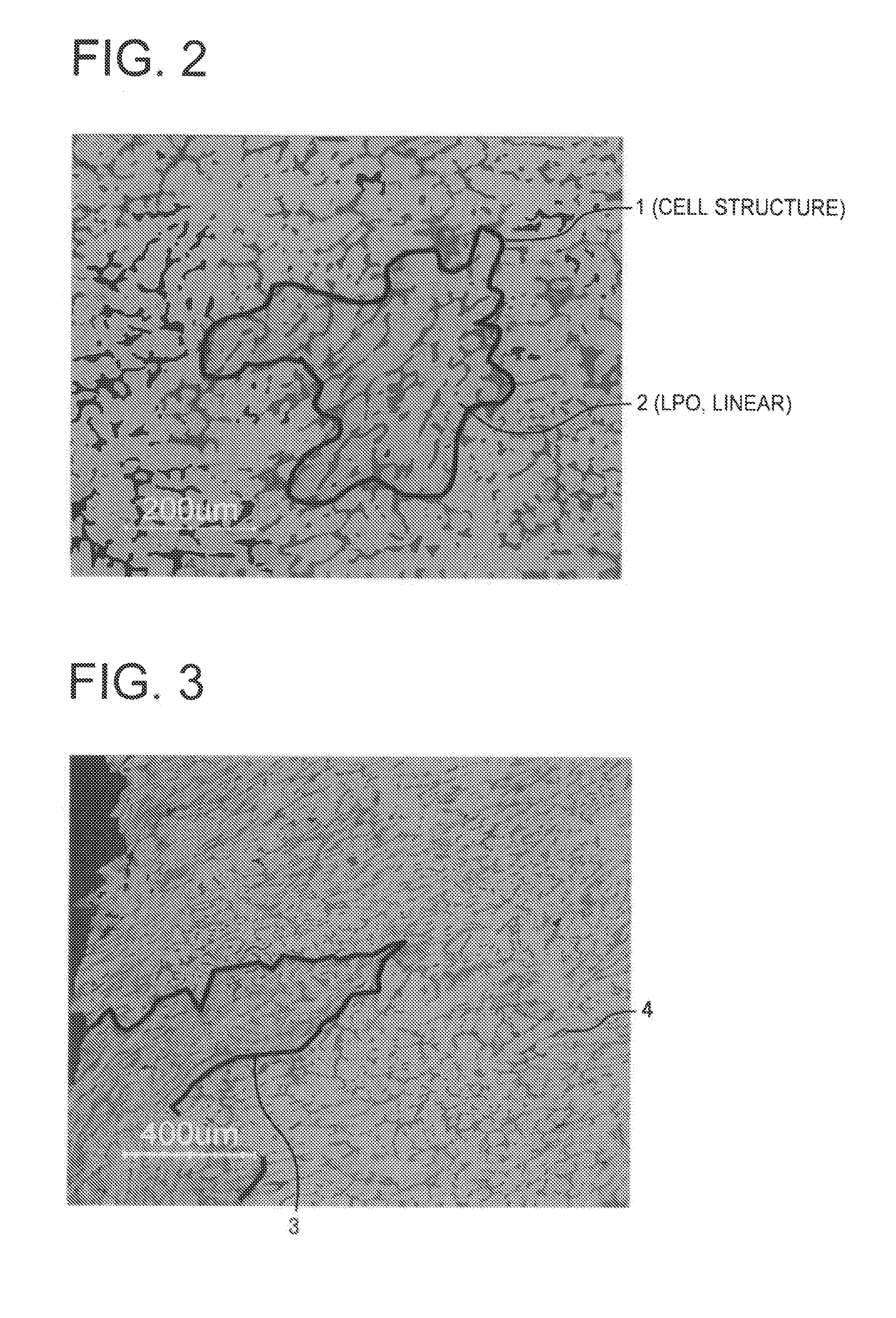

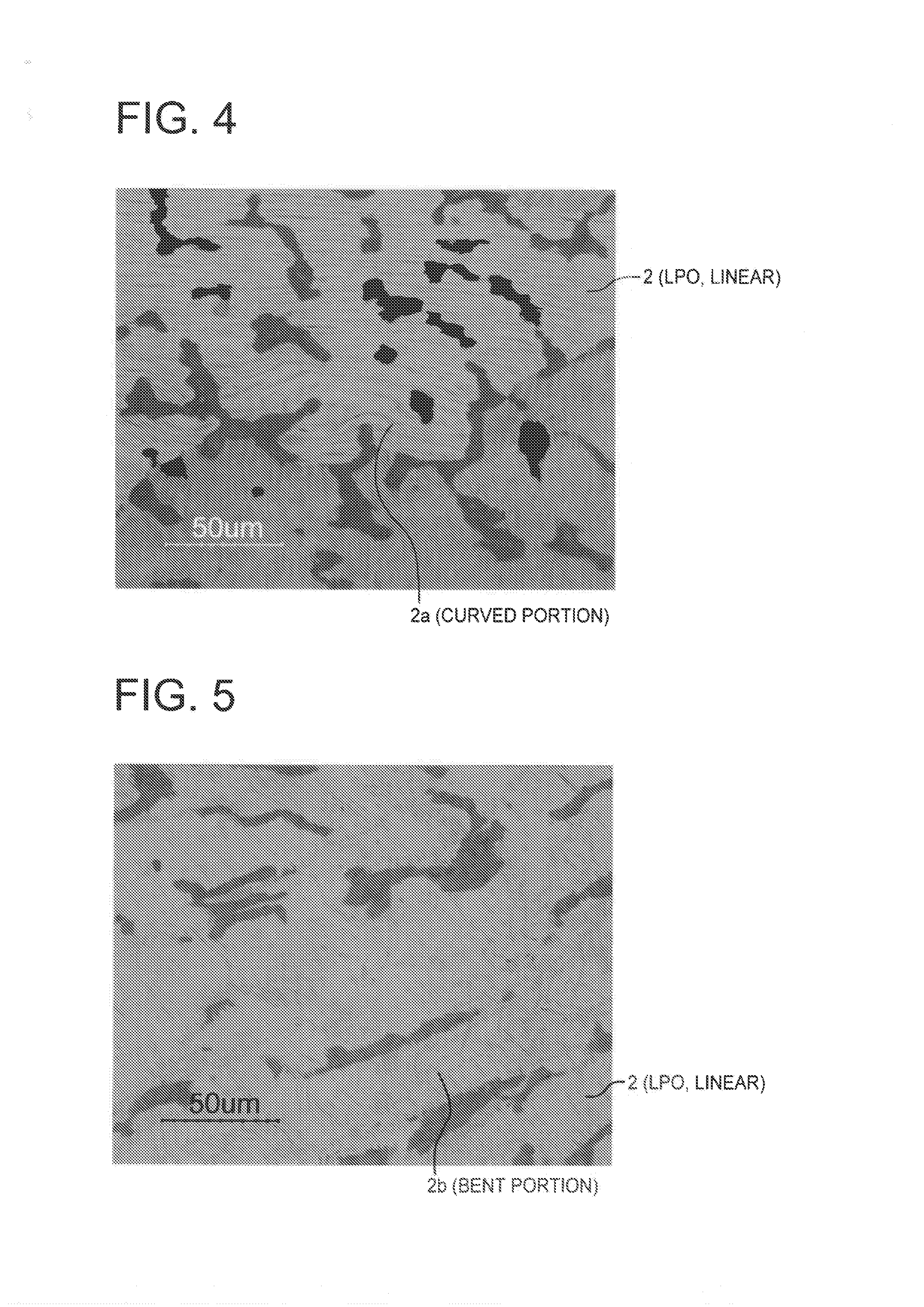

The present invention provides a magnesium alloy material, having superior mechanical properties without using special production equipment or processes, and a production process thereof. The magnesium alloy material of the present invention composed of an Mg—Zn-RE alloy comprises essential components in the form of 0.5 to 3 atomic percent of Zn and 1 to 5 atomic percent of RE, with the remainder comprising Mg and unavoidable impurities. The Mg—Zn-RE alloy has a lamellar phase formed from a long period stacking ordered structure and α-Mg in the alloy structure thereof. The long period stacking ordered structure has at least one of a curved portion and a bent portion and has a divided portion in at least a portion thereof. Finely granulated α-Mg having a mean particle diameter of 2 μm or less is formed in the divided portion.

Owner:KOBE STEEL LTD +2

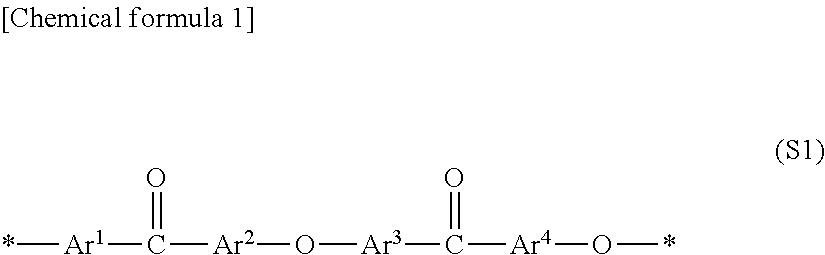

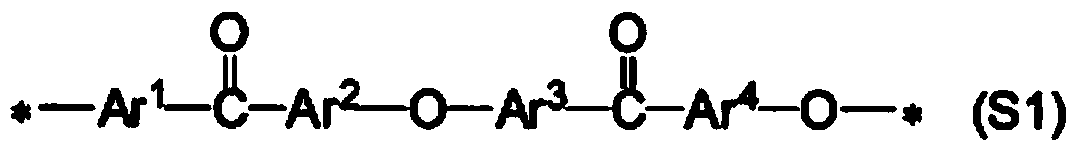

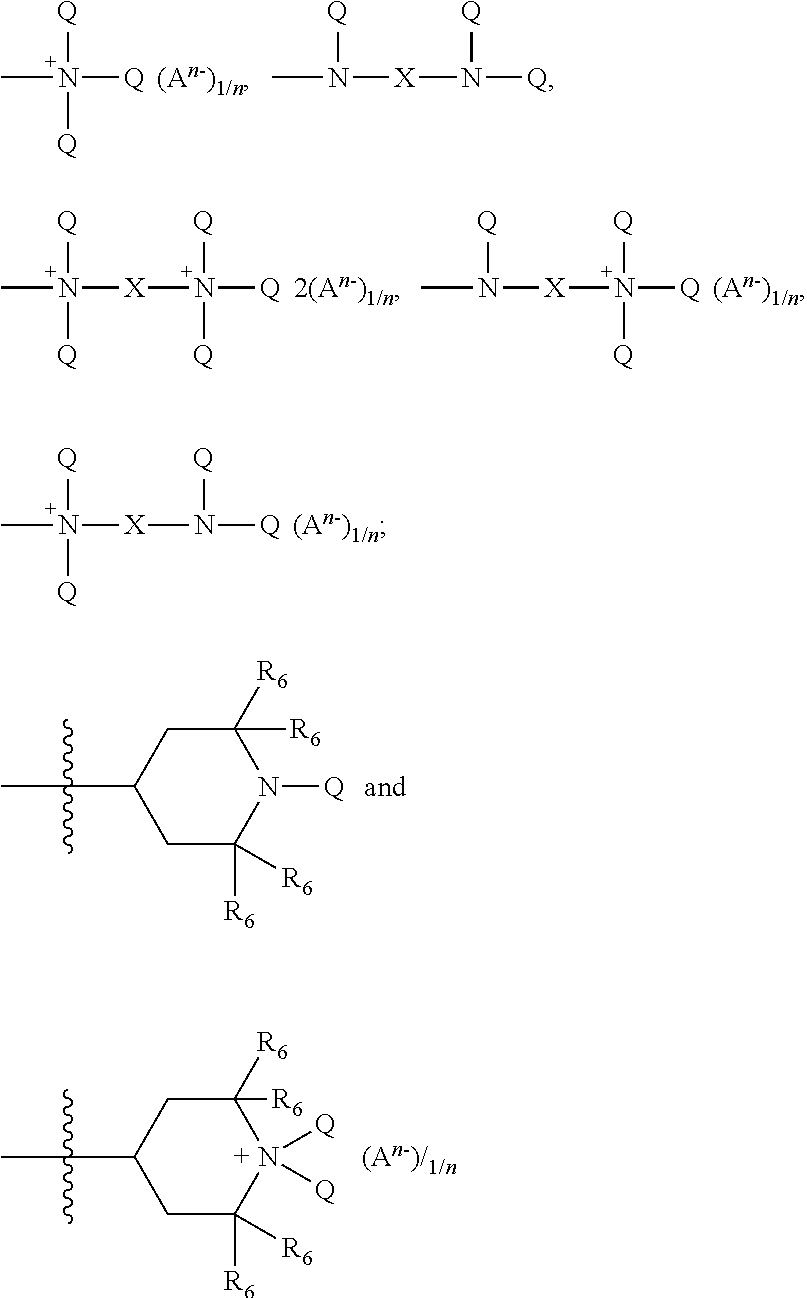

Molded article of polymer electrolyte composition and solid polymer type fuel cell using same

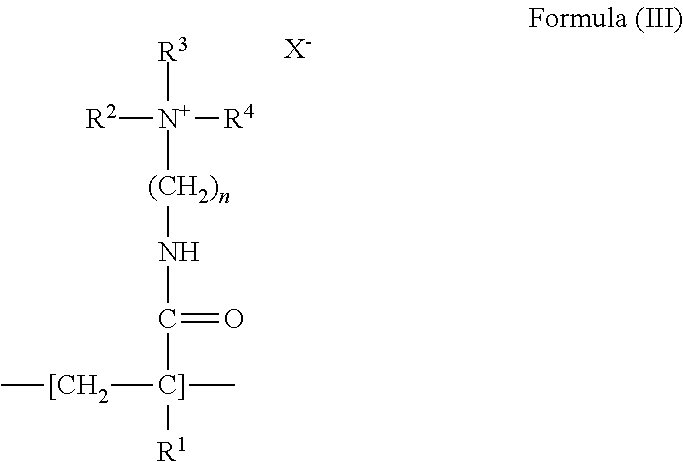

InactiveUS20140335440A1Excellent physical durabilityIncrease productionSolid electrolytesFinal product manufacturePolymer scienceHigh energy

[Summary]To provide a formed article of polymer electrolyte composition which exhibits excellent proton conductivity even under low-humidification conditions and under low-temperature conditions, which is excellent in chemical stability, mechanical strength, fuel shutoff properties, and which can achieve high output, high energy density, and excellent long-term durability when used in a polymer electrolyte fuel cell; and also to provide a polymer electrolyte fuel cell using thereof. The formed article of polymer electrolyte composition includes: a block copolymer having one or more of each of a hydrophilic segment (A1) containing an ionic group and a hydrophobic segment (A2) not containing an ionic group; and an additive, wherein the formed article forms co-continuous or lamellar phase separation structure, and the additive is hydrophilic.

Owner:TORAY IND INC

Structural liquid detergent composition

InactiveCN1330710AOrganic detergent compounding agentsDetergent materialsPhysical formSURFACTANT BLEND

An aqueous detergent composition having a physical form selected from the group consisting of liquids, pourable gels and non-pourable gels, said composition comprising surfactant and water, which composition is structured with a lamellar phase formed of at least some of the surfactant and at least some of the water, the composition being substantially clear at 25 DEG C.

Owner:UNILEVER NV

Hair care composition

InactiveUS20070166258A1Reduce hair damageKeep the styleCosmetic preparationsHair cosmeticsFatty acidFatty alcohol

A hair styling cream comprising: i) an aqueous lamellar phase comprising a) cationic surfactant and b) fatty alcohol having a melting point greater than 35° C. and / or fatty acid having a melting point greater than 40° C.; and ii) 20 wt % or greater of one or more non-volatile liquid emollient(s), the viscosity of any single non-volatile emollient or the viscosity of a blend of non-volatile emollients being less than 1000 mPa·s at 35° C. and 5 s−l.

Owner:CONOPCO INC D B A UNILEVER

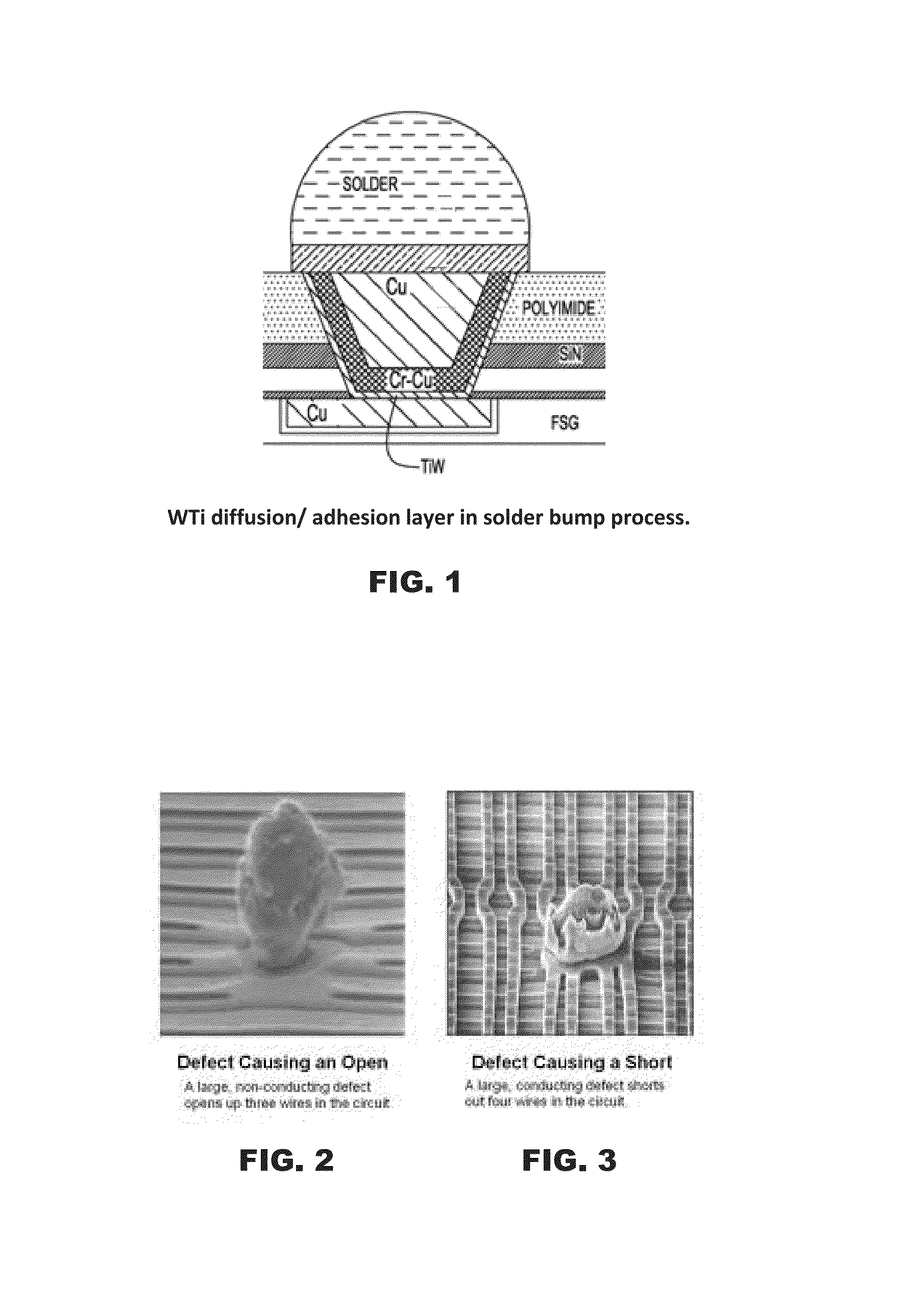

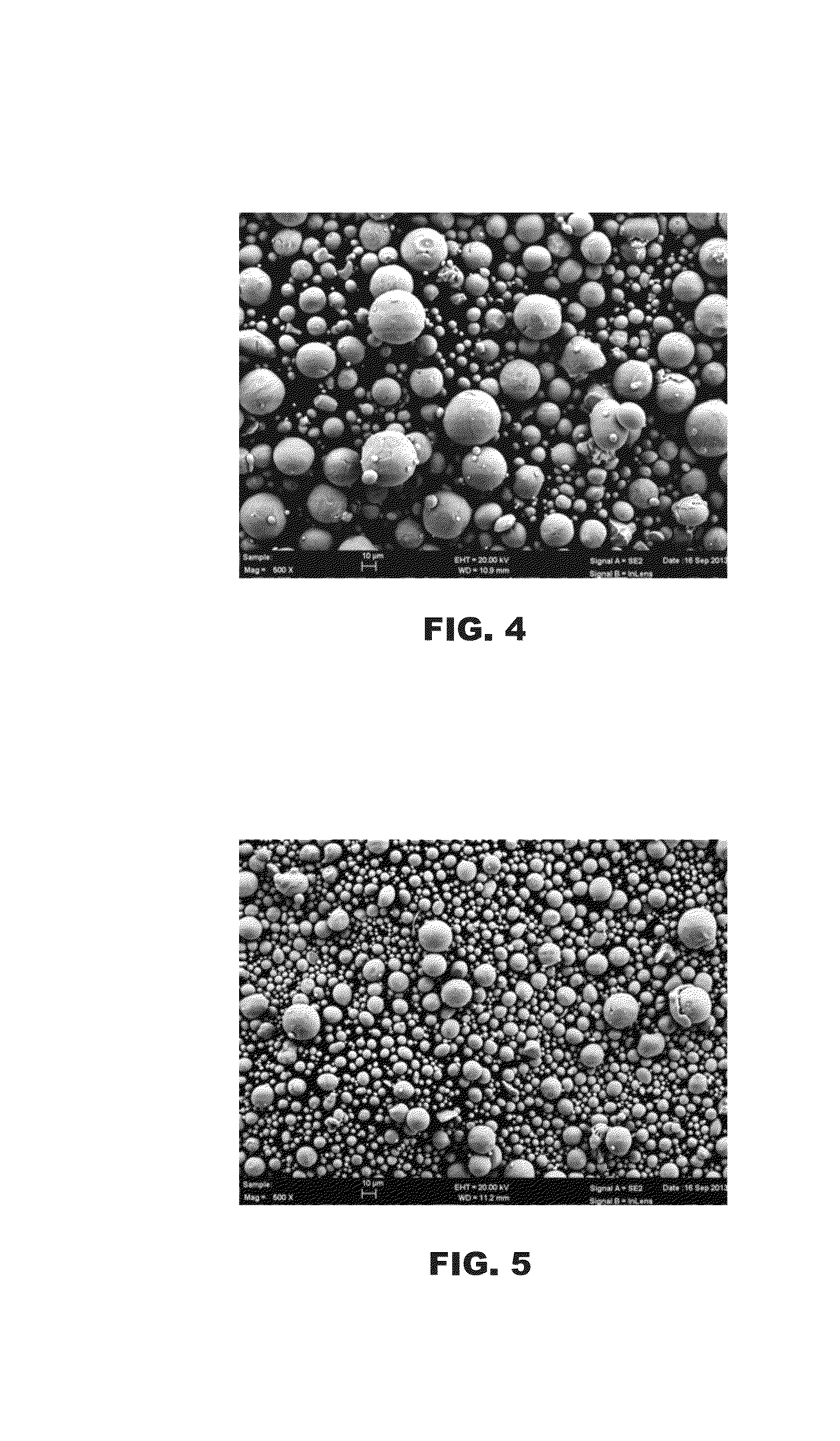

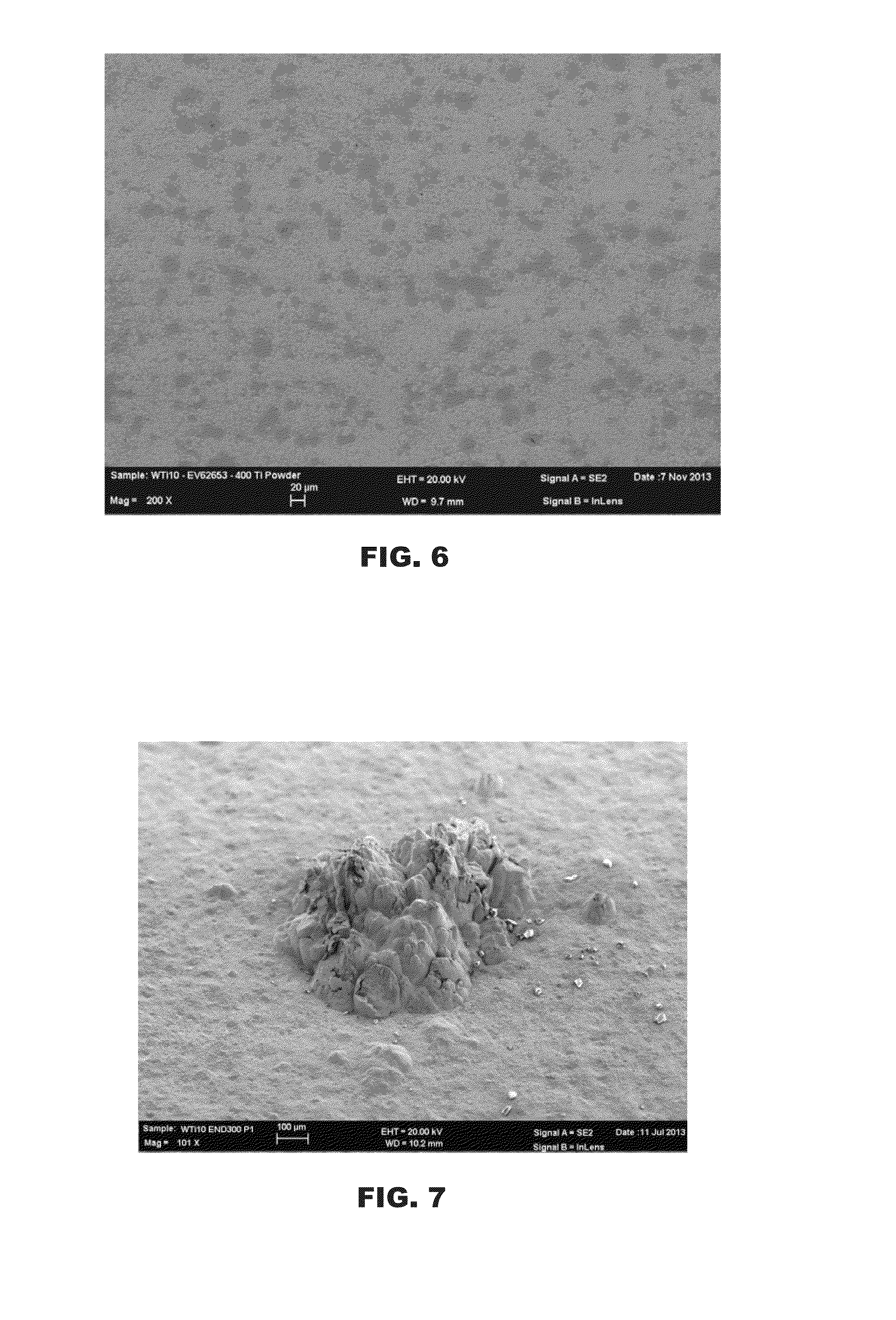

Modified tungsten-titanium sputtering targets

InactiveUS20150162172A1Reducing and eliminating particle generationReduce eliminateCellsElectric discharge tubesSputteringTitanium

A novel WTi target is described as having a Ti particle size similar to that of the W particle size. The target also contains controlled microstructural multi-phases characterized by an absence of a β (titanium-tungsten) alloy lamellar phase structure. The combination of controlled microstructural phases and controlled particle size improves overall sputtering performance whereby the sputtered face reduces formation of nodules which can flake off and deposit onto the resultant film to produce film defects during sputtering.

Owner:PRAXAIR ST TECH INC

Molded article of polymer electrolyte composition and solid polymer type fuel cell using same

ActiveCN103814413AExcellent physical durabilityHigh outputNon-metal conductorsSolid electrolytesPolymer electrolytesPolymer science

Provided are a molded article of a polymer electrolyte composition, which has an excellent proton conductivity even under low humidity and low temperature conditions, yet shows a high chemical stability, a good mechanical strength and a good fuel shutoff ability, and, when used in a solid polymer type fuel cell, can achieve a high output, a high energy density and a long-term durability, and a solid polymer type fuel cell using the same. The molded article of the polymer electrolyte composition, which comprises a block copolymer having one or more ionic group-containing hydrophilic segments (A1) and one or more ionic group-free hydrophobic segments (A2) together with an additive, is characterized in that the molded article forms a co-continuous or lamellar phase separation structure and the additive has a hydrophilic nature.

Owner:TORAY IND INC

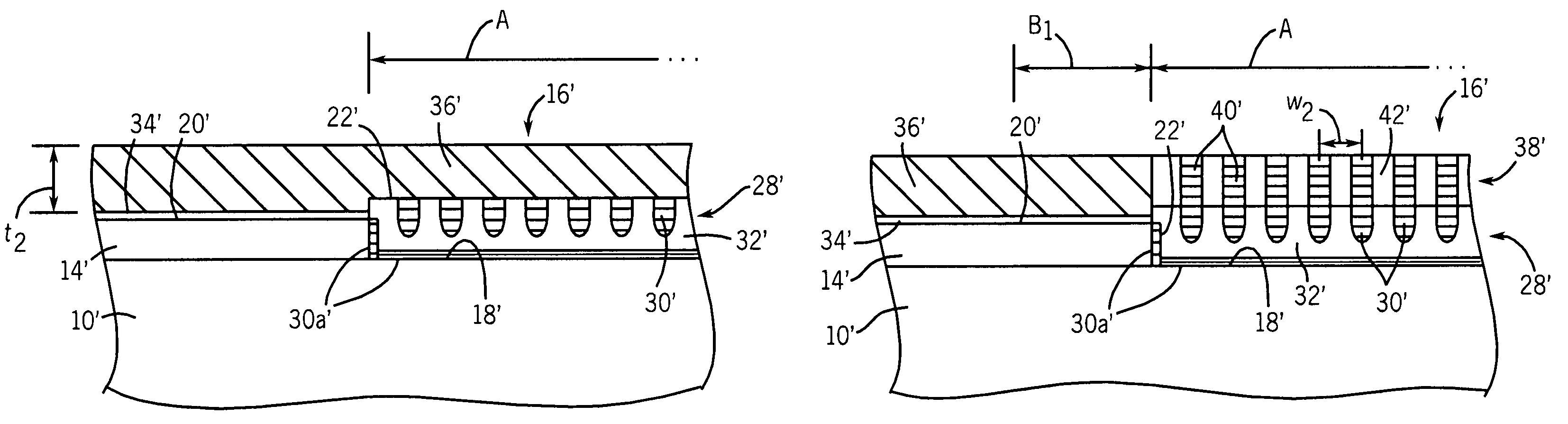

Registered Structure Formation via the Application of Directed Thermal Energy to Diblock Copolymer Films

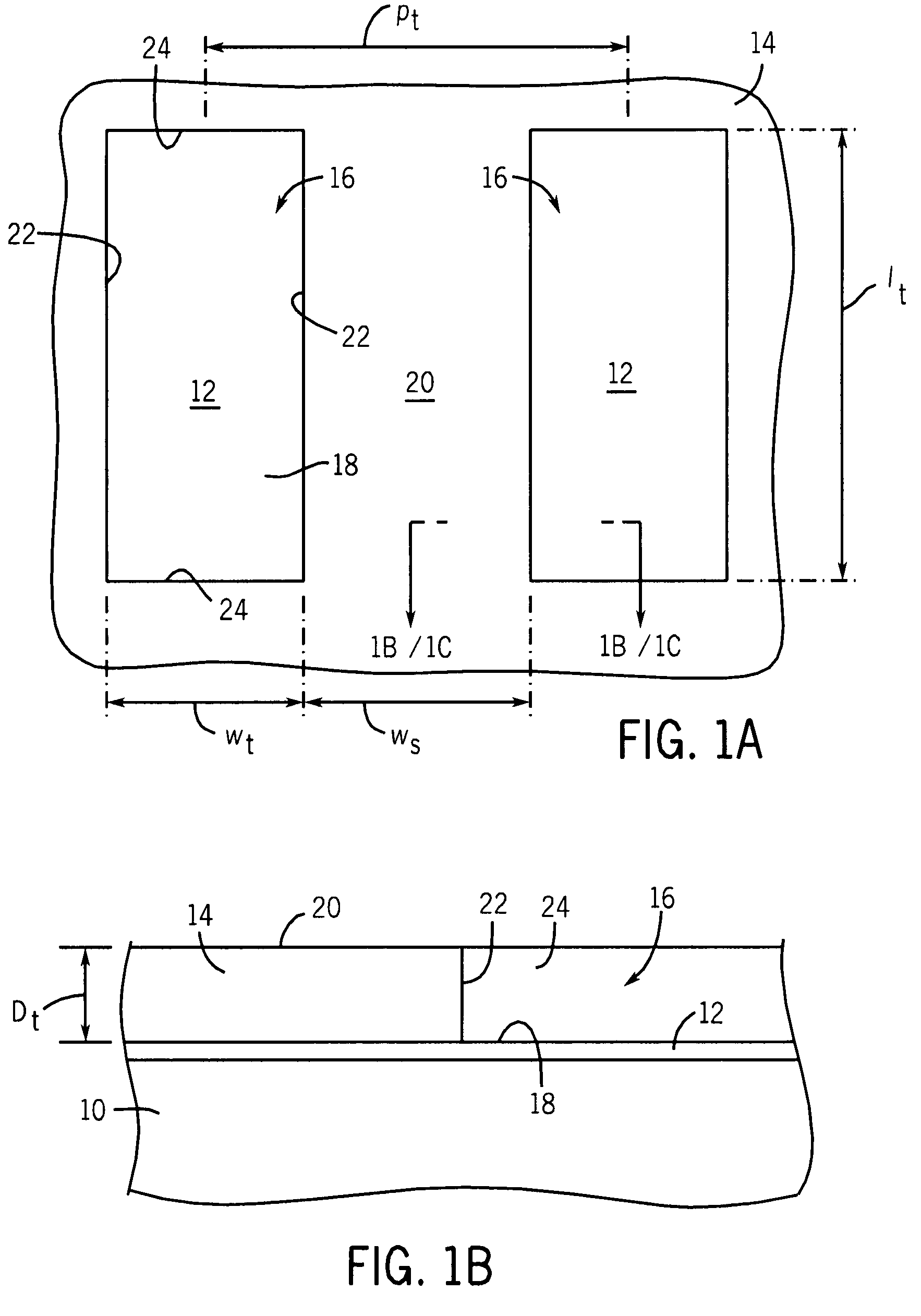

Methods for fabricating sublithographic, nanoscale linear microchannel arrays over surfaces without defined features utilizing self-assembling block copolymers, and films and devices formed from these methods are provided. Embodiments of the methods use a multilayer induced ordering approach to align lamellar films to an underlying base film within trenches, and localized heating to anneal the lamellar-phase block copolymer film overlying the trenches and outwardly over the remaining surface.

Owner:MICRON TECH INC

Medicine lipid composition

ActiveCN101123949AResolve inflammationReduce "stickinessLiposomal deliveryParticulatesLipid formation

The present invention relates to a particulate composition containing; a) 5 to 90% of at least one phosphatidyl choline component b) 5 to 90% of at least one diacyl glycerol component, at least one tocopherol, or mixtures thereof, and c) 1 to 40% of at least one non-ionic stabilising amphiphile, where all parts are by weight relative to the sum of the weights of a+b+c and where the composition contains particles of at least one non-lamellar phase structure or forms particles of at least one non-lamellar phase structure when contacted with an aqueous fluid. The invention additionally relates to pharmaceutical formulations containing such compositions, methods for their formation and methods of treatment comprising their administration.

Owner:CAMURUS AB

Water-in-oil emulsions and methods for their preparation

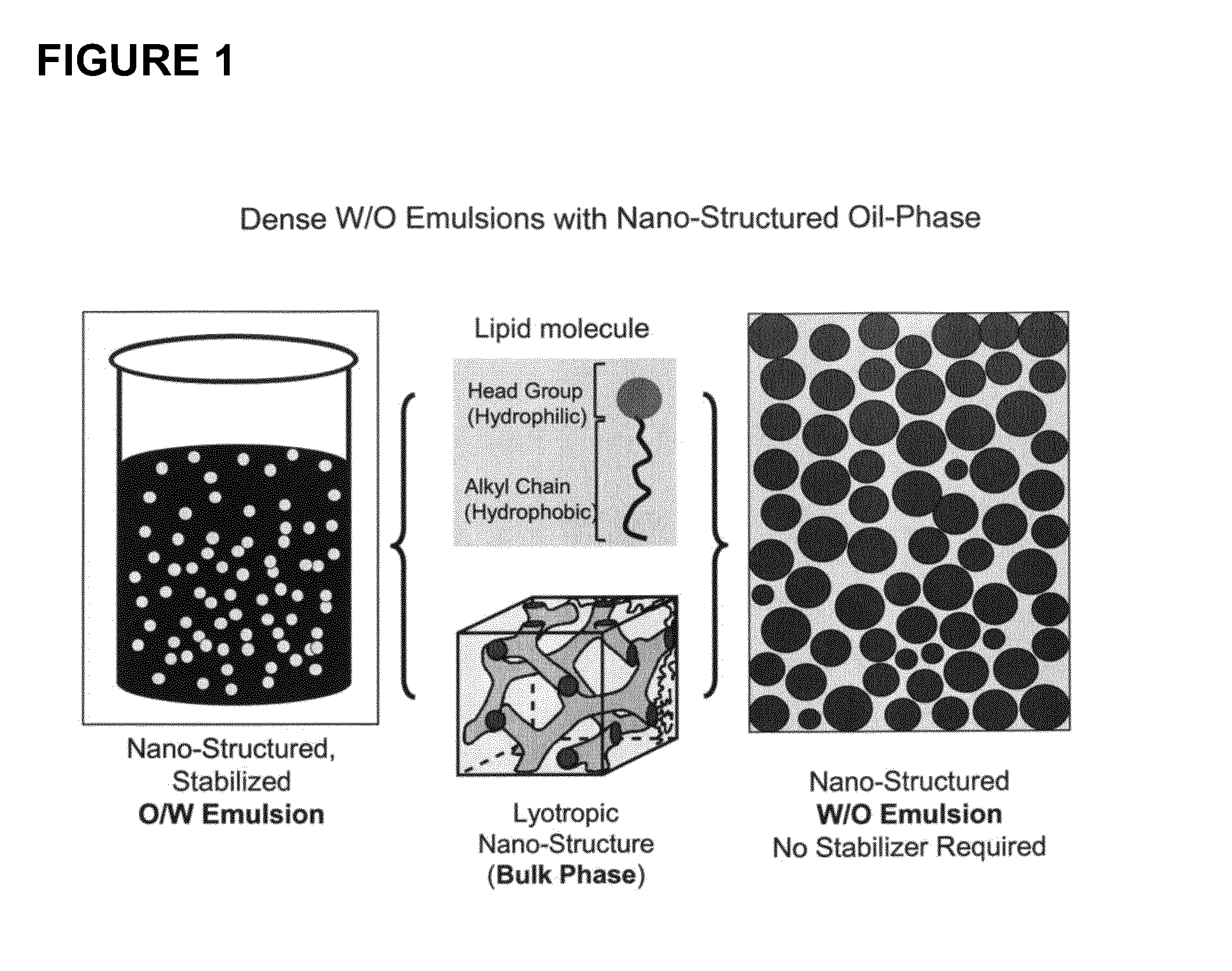

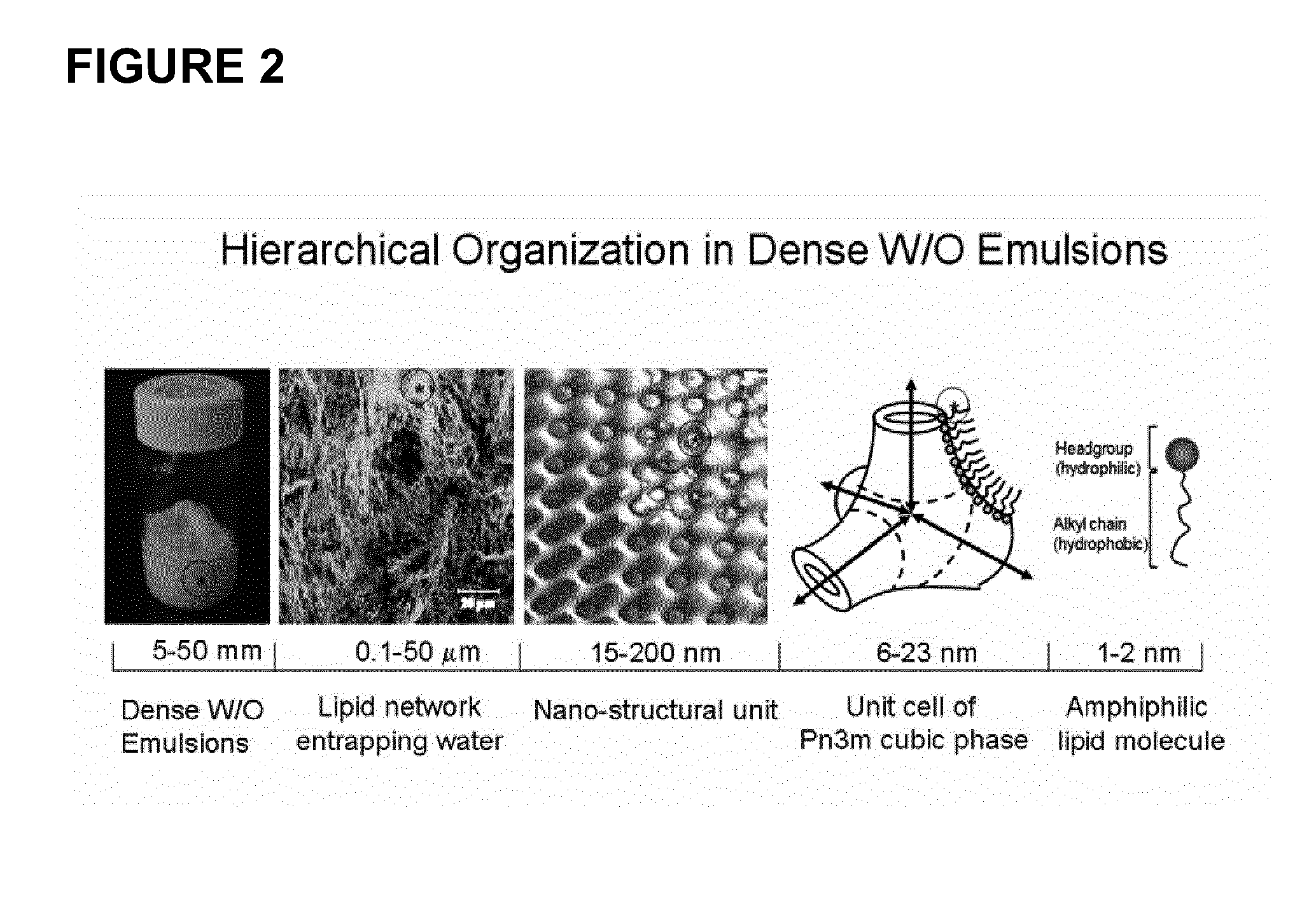

The present invention relates to a water-in-oil emulsion, comprising a continuous hydrophobic phase in which the hydrophilic phase is dispersed, wherein: (i) the emulsion has a total water content in the range of 30% to 95% (w / w); (ii) the emulsion does not comprise an emulsion stabilizer; (iii) the hydrophobic phase has a ratio of low hydrophilic-lipophilic balance amphiphilic molecules to oils in the range of 50% to 96% (w / w); and (iv) the continuous hydrophobic phase is made of lyotropic liquid crystalline nanostructures including 5% to 40% (w / w) water and does not comprise a lamellar phase wherein the low hydrophilic- lipophilic balance amphiphilic molecules have an HLB value in the range between 4 and 11. Furthermore, the present invention relates to a corresponding method for preparing such water-in-oil emulsion, the method comprising: (a) pre-mixing of the two fluid hydrophilic and hydrophobic phases at a rotation speed of at least 4,000 rpm and at a temperature of at least 40° C., thus forming a raw emulsion; (b) positioning the raw emulsion in a shear device; and (c) applying a shear rate of at least 4.500 s−1; and cooling the final emulsion obtained to ambient temperature, thus forming a continuous hydrophobic phase of the emulsion that is made of lyotropic liquid crystalline nanostructures.

Owner:GLATTER OTTO +1

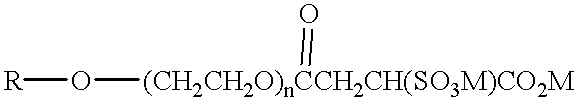

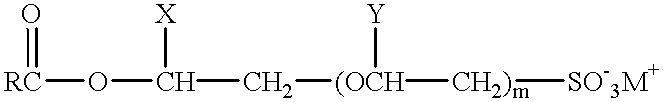

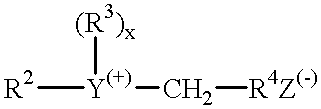

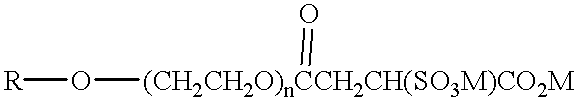

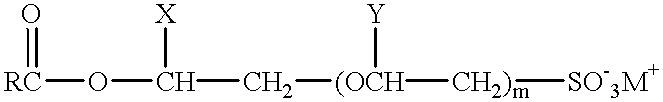

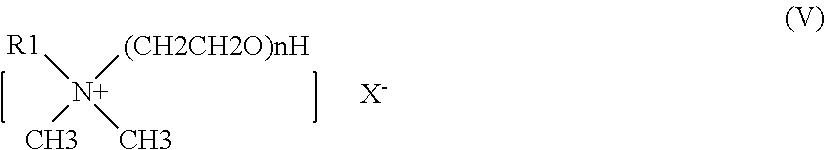

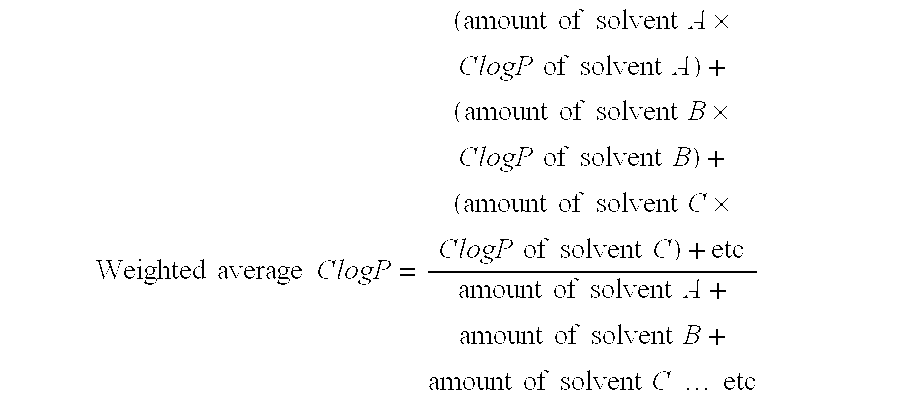

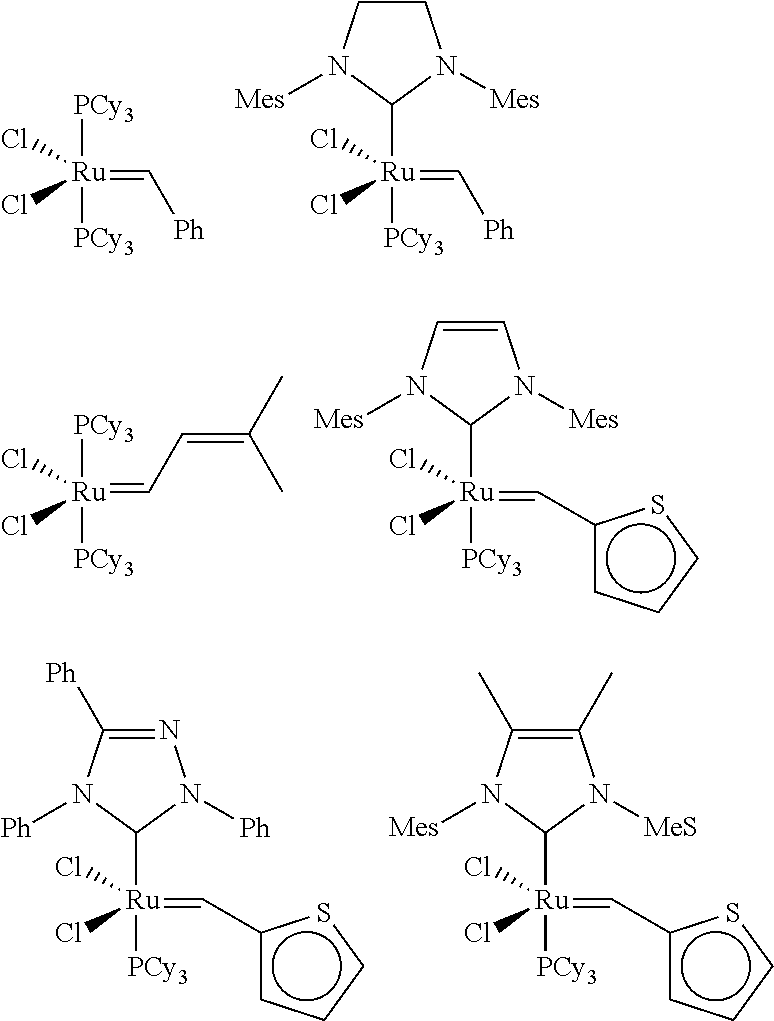

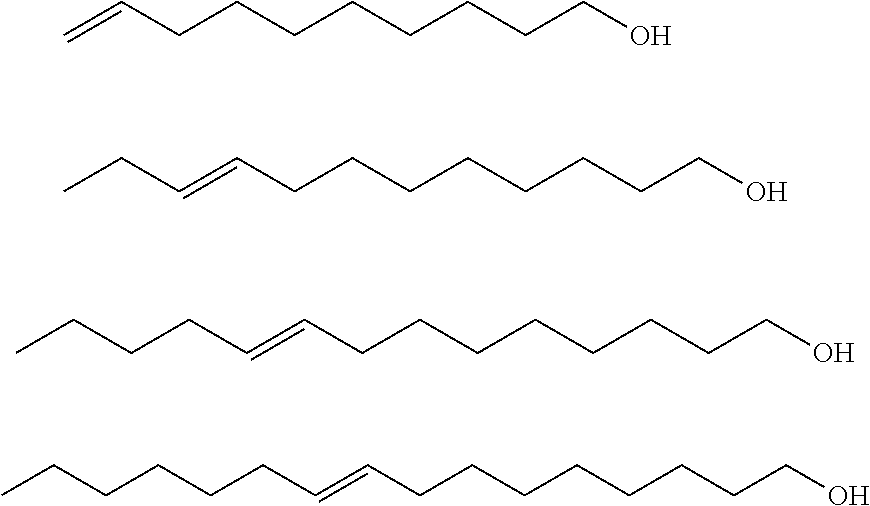

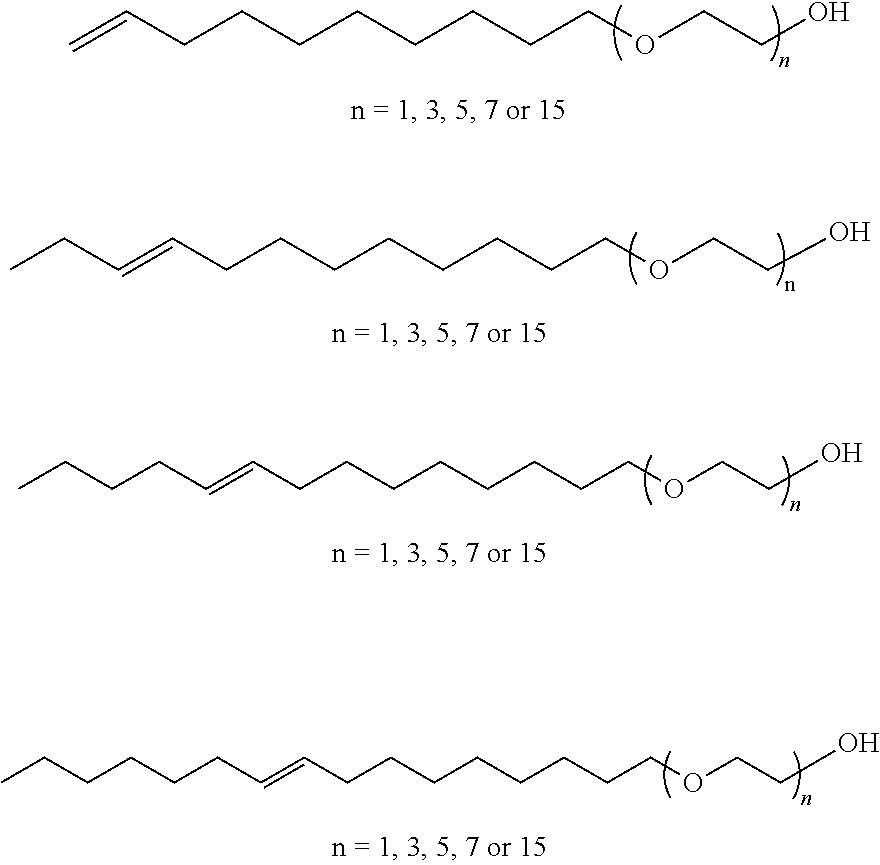

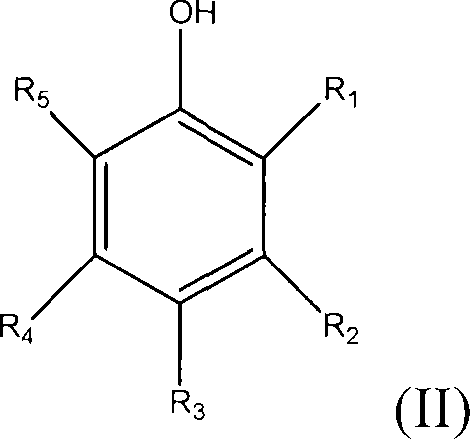

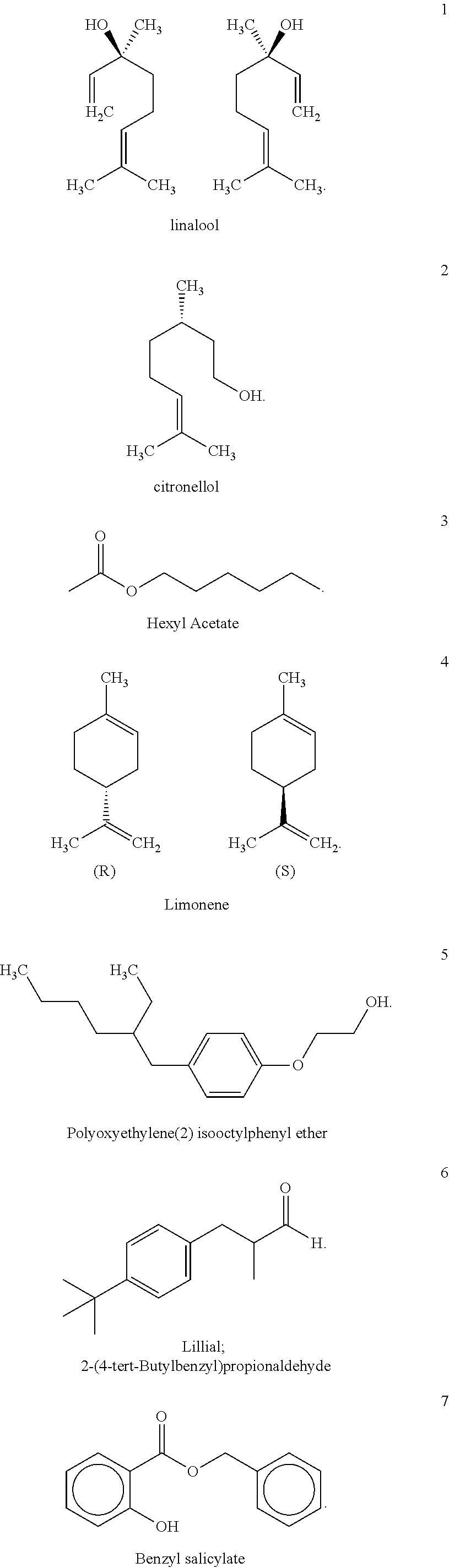

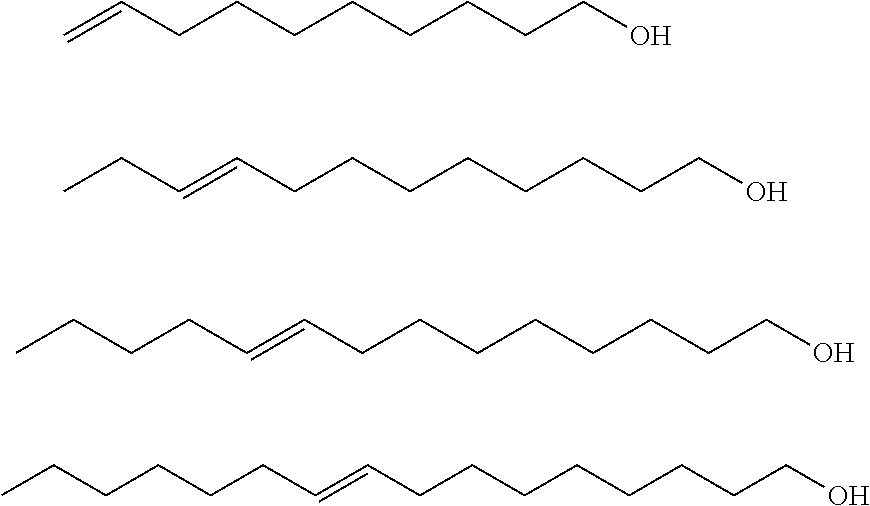

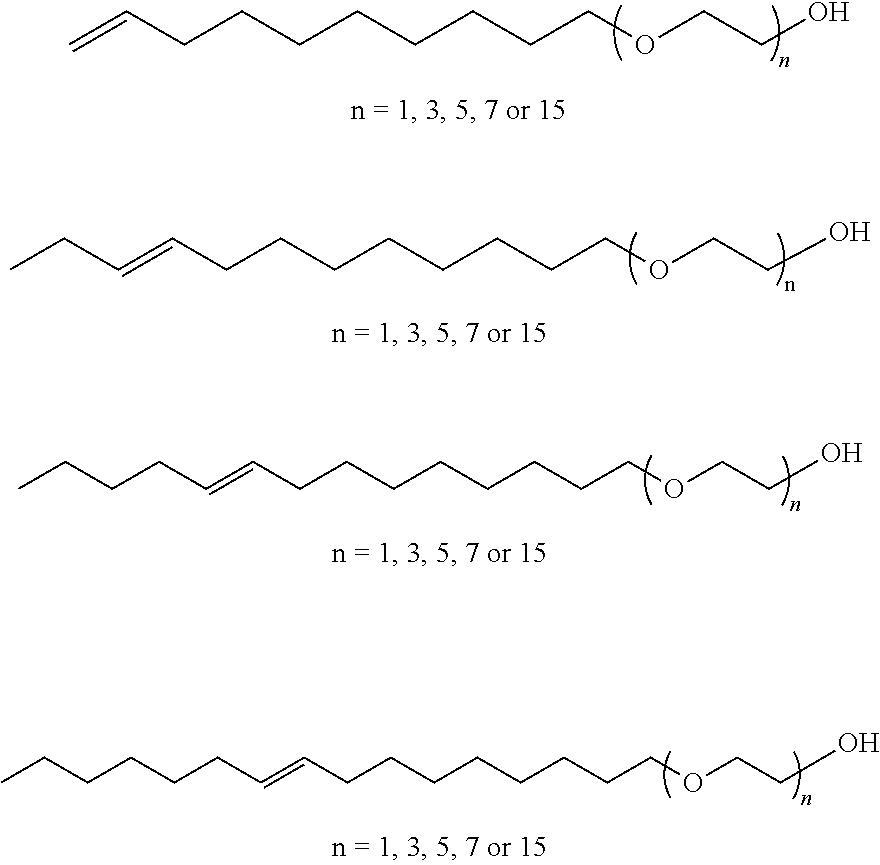

Unsaturated fatty alcohol alkoxylates from natural oil metathesis

ActiveUS20150087724A1Expand formulating latitudeEnhanced overall recoveryBiocideCosmetic preparationsMicroscopic examSolvent

Unsaturated fatty alcohol alkoxylates, processes for making them, and methods of using them are disclosed. In one aspect, a monounsaturated fatty alcohol alkoxylate is made by reducing a metathesis-derived monounsaturated alkyl ester, followed by alkoxylation of the resulting monounsaturated alcohol. Microscopy reveals that the monounsaturated alkoxylates have isotropic and lamellar phases over a wider range of actives levels compared with their saturated analogs. This attribute expands formulating latitude for many end-use applications. The unsaturated fatty alcohol alkoxylates are valuable in, for example, agricultural solvents, nonionic emulsifiers for agricultural compositions, hard surface cleaners, laundry detergents, specialty foams, additives or surfactants for paints or coatings, and surfactant compositions for enhanced oil recovery.

Owner:STEPAN COMPANY

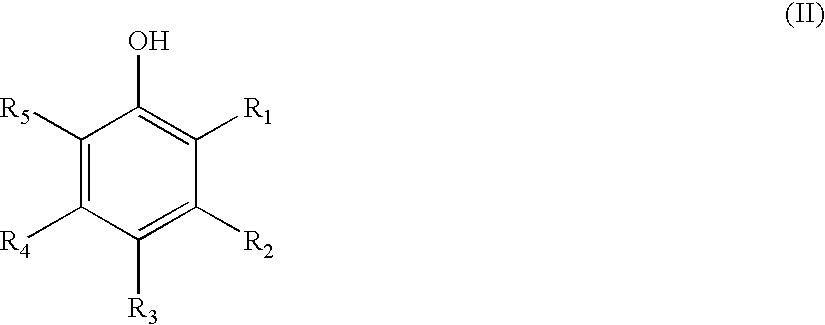

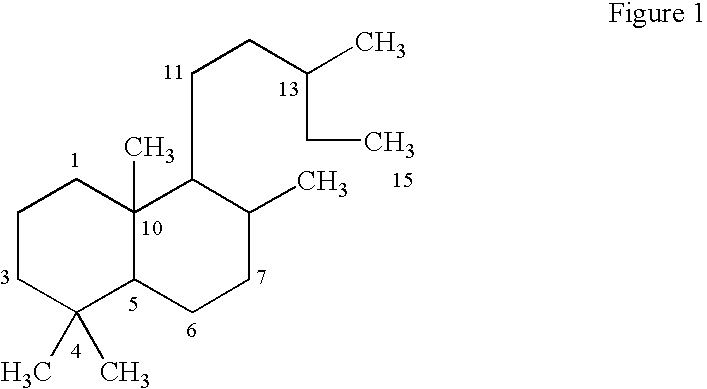

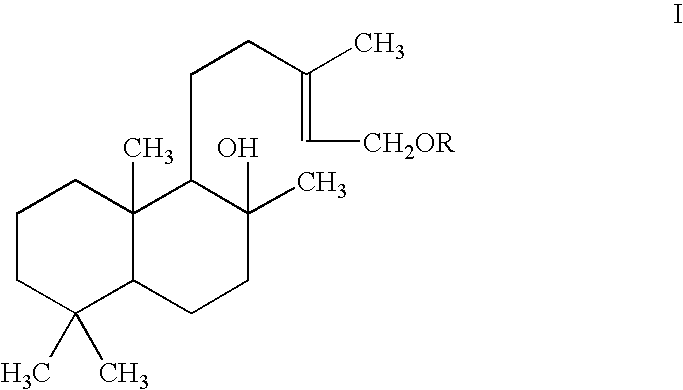

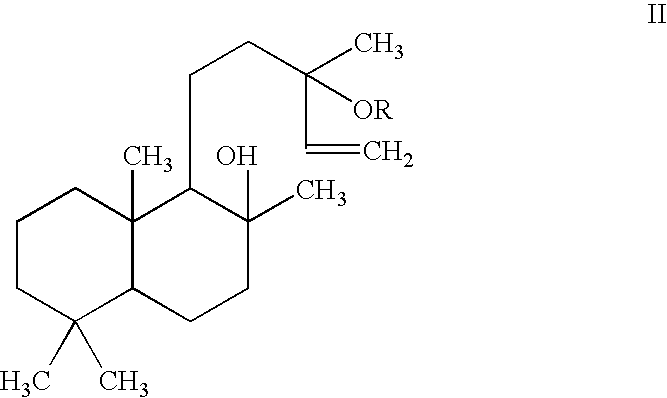

Pharmaceutical formulations comprising labdanes for the treatment of tumors or leukemias

The present invention relates to novel compositions based on hydrated lipidic lamellar phases or liposomal compositions, prepared by combining different lipid molecules, synthetic and / or from natural sources, said compositions comprising at least one of a) labd-13-ene-8α, 15-diol and / or derivatives thereof; b) labd-14-ene-8, 13-diol or derivatives thereof; c) 3β-hydroxy-labd-14-ene-8, 13-epoxy and / or derivatives thereof, d) a plant extract containing the aforementioned labdanes or derivatives thereof. The compositions of the invention exhibit cytotoxicity against cancerous cells and are utilized for the treatment of tumors and leukemias.

Owner:MEDEXIS SA

Hair colouring or bleaching compositions

Owner:THE PROCTER & GAMBLE COMPANY

Concentrated lamellar liquid personal cleansing composition

The invention relates to concentrated liquid cleansing compositions in lamellar phase which possess a lotion-like appearance conveying signals of enhanced moisturization. The use of a specific ratio of synthetic anionic surfactant(s) and co-surfactant(s) to fatty acid(s) in a structured liquid product was found to improve lather production by moderating or eliminating the increase in viscosity upon dilution. In a further embodiment, specific small hydrophobic molecules were found to improve freeze / thaw stability and thereby cause the inventive composition to maintain noticeable moisturization signals.

Owner:CONOPCO INC D B A UNILEVER

Unsaturated fatty alcohol alkoxylates from natural oil metathesis

ActiveUS9708251B2Expand formulating latitudeEnhanced overall recoveryCosmetic preparationsBiocideMicroscopic examSolvent

Unsaturated fatty alcohol alkoxylates, processes for making them, and methods of using them are disclosed. In one aspect, a monounsaturated fatty alcohol alkoxylate is made by reducing a metathesis-derived monounsaturated alkyl ester, followed by alkoxylation of the resulting monounsaturated alcohol. Microscopy reveals that the monounsaturated alkoxylates have isotropic and lamellar phases over a wider range of actives levels compared with their saturated analogs. This attribute expands formulating latitude for many end-use applications. The unsaturated fatty alcohol alkoxylates are valuable in, for example, agricultural solvents, nonionic emulsifiers for agricultural compositions, hard surface cleaners, laundry detergents, specialty foams, additives or surfactants for paints or coatings, and surfactant compositions for enhanced oil recovery.

Owner:STEPAN COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com